Content Menu

● Understanding SMD Glue Machines

● Key Features to Look for in an SMD Glue Machine

>> 1. Precision and Accuracy

>> 2. Dispensing Technology

>> 3. Glue Compatibility and Control

>> 4. Programming and User Interface

>> 5. Machine Size and PCB Handling

>> 6. Speed and Throughput

>> 7. Integration and Connectivity

>> 8. Maintenance and Support

● Additional Considerations

>> Glue Types and Application Needs

>> Environmental Control

>> Cost vs. Performance

● Conclusion

● FAQ

>> 1. What types of glue can an SMD glue machine dispense?

>> 2. How accurate are SMD glue machines?

>> 3. Can SMD glue machines integrate with pick-and-place machines?

>> 4. What programming options do SMD glue machines offer?

>> 5. How do SMD glue machines prevent glue clogging?

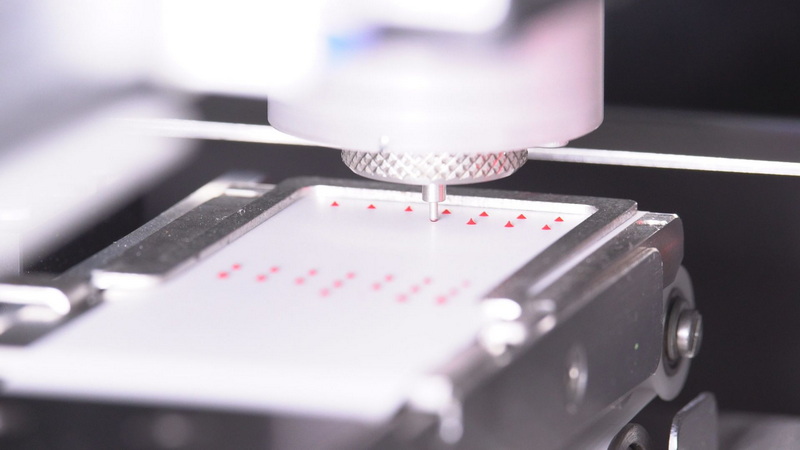

Surface Mount Device (SMD) glue machines are essential equipment in modern electronics manufacturing, particularly in the assembly of printed circuit boards (PCBs). These machines dispense precise amounts of adhesive to secure components before soldering, ensuring product reliability and quality. Choosing the right SMD glue machine can significantly impact production efficiency, accuracy, and cost-effectiveness. This article explores the key features to consider when selecting an SMD glue machine, highlighting the latest technologies and practical considerations.

Understanding SMD Glue Machines

An SMD glue machine is designed to apply adhesives such as epoxy, UV glue, red glue, or conductive glue onto PCBs or other substrates in a precise, controlled manner. This process is critical for fixing components in place during assembly and protecting sensitive parts from environmental damage. The glue also acts as a mechanical support, preventing components from shifting during soldering or handling.

Modern SMD glue machines often integrate with pick-and-place machines or operate as standalone dispensing systems. They support various glue types and dispensing methods, including dot, line, arc, and surface coating, adapting to diverse production needs. The glue application process must be both accurate and repeatable to maintain the high quality standards required in electronics manufacturing.

Key Features to Look for in an SMD Glue Machine

1. Precision and Accuracy

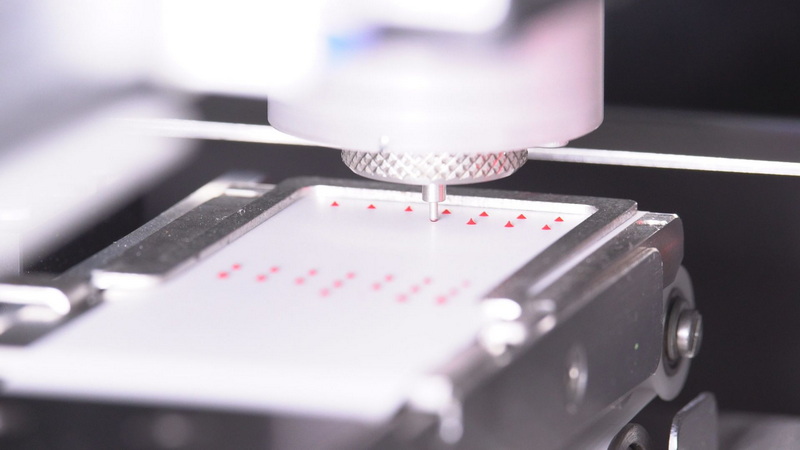

Precision is paramount in glue dispensing to avoid excess or insufficient adhesive, which can cause defects or rework. Look for machines with:

- High repeatability and positioning accuracy: Typically within ±0.02mm to ±0.03mm, ensuring that glue is applied exactly where needed.

- Advanced visual positioning systems: Many modern machines use CCD (Charge-Coupled Device) cameras or mark cameras to detect fiducial marks on PCBs. This allows automatic compensation for any PCB misalignment or warping, ensuring the glue is applied in the correct locations.

- Stable dispensing control: This ensures consistent glue volume and shape, reducing waste and improving product quality. Machines with stable pressure and timing controls avoid glue stringing or splattering.

The precision of glue application is especially important for small components or densely packed PCBs where even minor misplacement can cause shorts or assembly failures.

2. Dispensing Technology

The dispensing method affects speed, glue compatibility, and application quality. Common technologies include:

- Jet dispensing valves: These provide high-speed dispensing with stable paste quantities, suitable for solder paste, glue, and similar media. Jet valves work by rapidly opening and closing a valve to release precise glue droplets without contact.

- Contactless high-speed injection dispensing heads: These heads allow continuous, efficient glue application with minimal waste. They are ideal for high-volume production lines.

- Rotatable dispensing heads: These allow flexible dispensing directions and complex patterns, enhancing versatility. The ability to rotate the dispensing needle or head helps apply glue in hard-to-reach areas or on irregularly shaped PCBs.

Some machines also offer multiple dispensing heads working simultaneously to increase throughput.

3. Glue Compatibility and Control

An ideal SMD glue machine should handle a wide range of adhesives, including UV glue, AB glue, epoxy, red glue, conductive adhesives, and solder paste. Features to consider include:

- Constant temperature control: Maintaining the dispensing head at a stable temperature prevents glue from thickening or curing prematurely inside the nozzle, which can cause clogging and inconsistent dispensing.

- Precise control of glue volume: This is achieved by adjusting dispensing time, pressure, and needle diameter. Machines that allow fine-tuning of these parameters enable manufacturers to optimize glue usage and ensure consistent bonding strength.

- Automatic anti-curing functions: Some machines incorporate UV light or heating elements to prevent glue from curing inside the dispensing needle, reducing downtime and maintenance.

Glue compatibility is critical because different adhesives have varying viscosities, curing times, and sensitivities to temperature and humidity. Machines that can adapt to these differences provide greater flexibility in production.

4. Programming and User Interface

Ease of programming and operation enhances productivity and reduces operator errors. Look for:

- User-friendly interfaces: Touchscreen displays with intuitive menus and graphical programming options simplify operation.

- Support for importing design files: The ability to import CAD files such as NC, AI, DXF, JPG, and BMP formats allows for quick setup and reduces manual programming errors.

- Teaching functions: These allow the machine to record bonding lines automatically by moving the dispensing head manually or using a joystick, making it easier to program complex glue patterns.

- Large memory capacity: Storing multiple dispensing programs enables quick switching between different product setups, which is essential for manufacturers handling multiple PCB designs.

Some advanced machines also offer remote monitoring and control capabilities, enabling operators to manage production from a distance.

5. Machine Size and PCB Handling

Depending on your production scale and PCB sizes, consider:

- Maximum PCB size supported: Machines vary in the size of PCBs they can handle, with common maximum sizes like 350mm × 260mm or larger for industrial applications.

- Track length and movement range: The X, Y, and Z axes movement ranges determine the machine's ability to handle different PCB dimensions and component heights.

- Compact footprint: For space-limited production lines, compact or benchtop models are available, which still offer high precision but occupy less floor space.

- PCB clamping and positioning: Reliable clamping mechanisms prevent PCB movement during glue dispensing, ensuring accuracy.

Choosing a machine that matches your PCB size requirements avoids unnecessary costs and ensures efficient production.

6. Speed and Throughput

High throughput is critical for mass production. Features that influence speed include:

- High-speed linear motor drives: These provide fast and accurate axis movement, reducing cycle times without sacrificing precision.

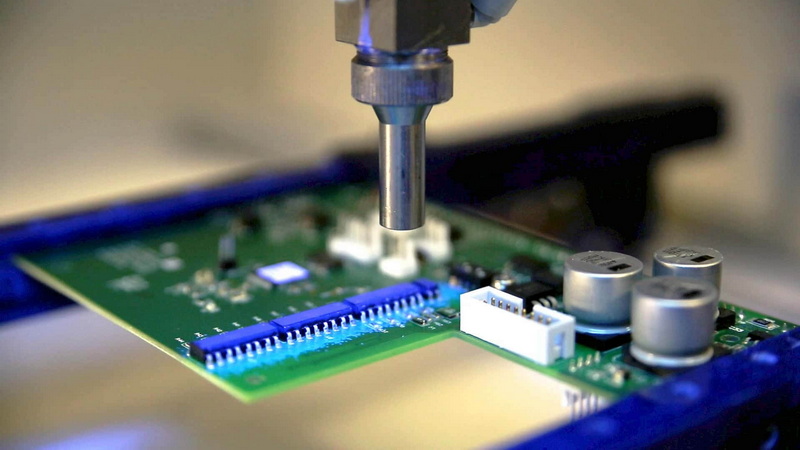

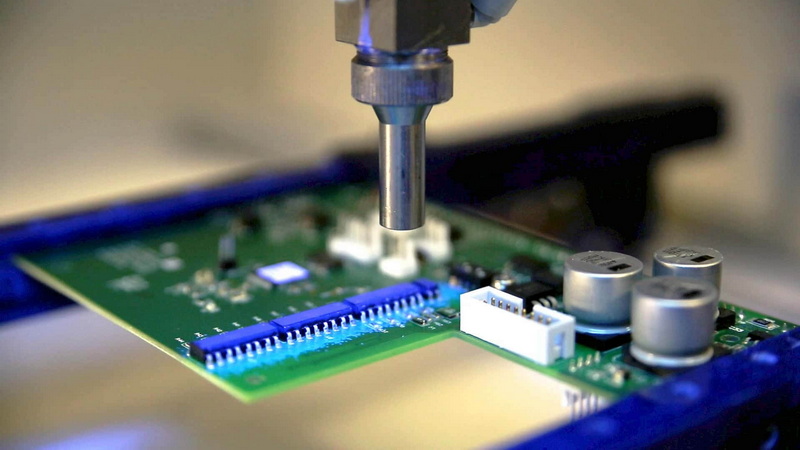

- Simultaneous pick-and-place and glue dispensing: Some integrated machines can perform glue dispensing and component placement concurrently, significantly improving production efficiency.

- Efficient glue dispensing controllers: These ensure stable output without leakage or stringing, allowing faster dispensing without compromising quality.

Balancing speed with accuracy is crucial; a machine that is fast but imprecise will lead to costly defects.

7. Integration and Connectivity

Modern SMD glue machines often need to integrate with other production line equipment or factory automation systems:

- Universal signal connections: These facilitate easy online integration with pick-and-place machines, inspection systems, or conveyor lines.

- Compatibility with software and hardware standards: This enables synchronized operation and data exchange, supporting Industry 4.0 initiatives.

- Data logging and traceability: Some machines record dispensing parameters and production data, aiding quality control and process optimization.

Integration capabilities help streamline production workflows and reduce manual intervention.

8. Maintenance and Support

Consider machines with features that simplify maintenance and reduce downtime:

- Easy-to-clean dispensing heads: Quick disassembly and cleaning reduce machine downtime.

- Accessible parts: Components that are easy to replace or service improve maintenance efficiency.

- Reliable anti-clogging mechanisms: Automatic cleaning cycles or nozzle purging prevent glue buildup.

- Technical support and spare parts availability: Choose manufacturers with good after-sales service and readily available spare parts to minimize production interruptions.

Regular maintenance is essential to keep the machine operating at peak performance and extend its lifespan.

Additional Considerations

Glue Types and Application Needs

Different adhesives require specific dispensing parameters and machine capabilities. For example, red glue used in SMT assembly demands precise control of dispensing pressure and temperature to ensure proper curing and adhesion. Conductive adhesives require careful handling to maintain electrical properties. Understanding the properties of the glue you intend to use will help you select a machine with suitable features.

Environmental Control

Some adhesives are sensitive to temperature and humidity, which can affect viscosity and curing times. Machines with temperature-controlled dispensing heads or enclosed work areas help maintain consistent glue quality. Additionally, cleanroom-compatible machines may be necessary for sensitive electronics manufacturing environments.

Cost vs. Performance

While high-end SMD glue machines offer greater precision and automation, they come at a higher cost. Small-scale manufacturers or those with simpler applications might opt for more affordable machines with fewer features. It is important to balance your budget with the required performance to avoid overspending or compromising quality.

Conclusion

Selecting the right SMD glue machine involves evaluating multiple factors, including precision, dispensing technology, glue compatibility, programming ease, machine size, speed, integration capabilities, and maintenance. Machines equipped with advanced visual positioning, stable dispensing control, and user-friendly interfaces provide the best value by enhancing product quality and production efficiency. Understanding your specific production requirements and adhesive types will guide you to the optimal choice, ensuring reliable and cost-effective SMT assembly.

Investing in a high-quality SMD glue machine not only improves product reliability but also reduces waste, lowers production costs, and increases throughput. As electronics manufacturing continues to evolve, having a versatile and precise glue dispensing system is more important than ever.

FAQ

1. What types of glue can an SMD glue machine dispense?

An SMD glue machine can dispense various adhesives such as UV glue, AB glue, epoxy, red glue, conductive glue, solder paste, and thermal paste. Compatibility depends on the machine's dispensing technology and temperature control features.

2. How accurate are SMD glue machines?

High-precision SMD glue machines typically achieve repeatability and positioning accuracy within ±0.02mm to ±0.03mm, ensuring consistent glue application and minimizing defects.

3. Can SMD glue machines integrate with pick-and-place machines?

Yes, some SMD glue machines are integrated with pick-and-place machines, allowing simultaneous component placement and glue dispensing, which improves throughput and reduces cycle times.

4. What programming options do SMD glue machines offer?

Modern machines offer graphical programming, online visual editing, and support for importing CAD files like NC, AI, DXF, JPG, and BMP. They also feature teaching functions for automatic path recording.

5. How do SMD glue machines prevent glue clogging?

Machines use constant temperature control of dispensing heads, automatic anti-curing functions, and special dispensing controllers to maintain glue liquidity and prevent needle blockage, ensuring stable operation.