Content Menu

● Understanding Solder Paste Printing

● Key Features to Consider

>> 1. Build Quality and Stability

>> 2. Alignment Mechanism

>> 3. Squeegee Design

>> 4. Stencil Compatibility

>> 5. Ease of Use

>> 6. Maintenance and Cleaning

>> 7. Print Speed and Efficiency

>> 8. Size and Footprint

● Types of Manual Solder Paste Printers

● Setting Up Your Manual Solder Paste Printer

● Common Challenges in Manual Solder Paste Printing

● Best Practices for Successful Manual Solder Paste Printing

>> 1. Use High-Quality Materials

>> 2. Optimize Your Environment

>> 3. Regular Calibration

>> 4. Conduct Test Prints

>> 5. Document Your Process

● Conclusion

● FAQ

>> 1. What is a manual solder paste printer?

>> 2. How does a manual solder paste printer work?

>> 3. What are common issues faced when using a manual solder paste printer?

>> 4. How do I maintain my manual solder paste printer?

>> 5. Can I use different types of stencils with my manual printer?

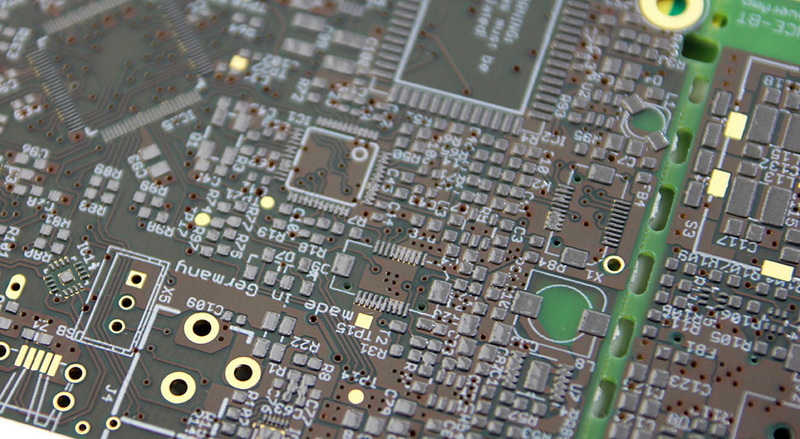

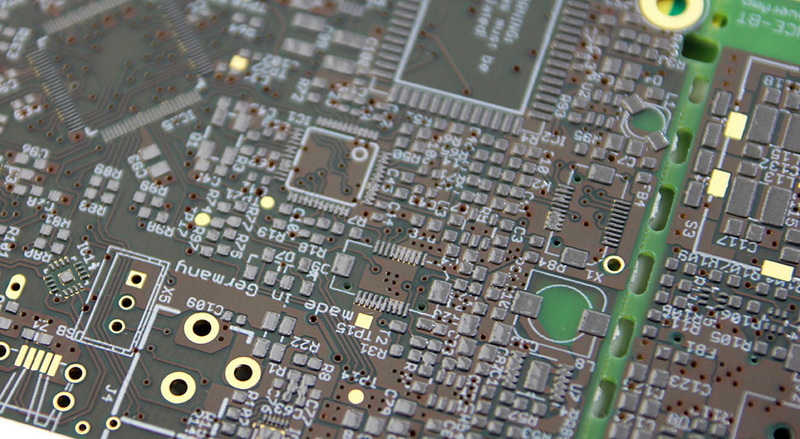

When it comes to assembling printed circuit boards (PCBs) using surface mount technology (SMT), the choice of a solder paste printer is crucial. A manual solder paste printer is often the go-to option for small-scale operations, hobbyists, or those just starting in electronics assembly. This article will delve into the essential features to consider when selecting a manual solder paste printer, ensuring that you make an informed decision that meets your specific needs.

Understanding Solder Paste Printing

Solder paste printing is a vital step in the SMT assembly process. It involves applying solder paste onto specific pads on the PCB using a stencil. The quality of this application directly affects the reliability and performance of the final product. A manual solder paste printer allows for precision and control, making it ideal for small runs or prototypes.

Key Features to Consider

When selecting a manual solder paste printer, several features should be prioritized:

1. Build Quality and Stability

The stability of the printer is paramount. A sturdy construction minimizes vibrations during operation, ensuring consistent and accurate paste application. Look for printers made from high-quality materials that can withstand repeated use without losing alignment or precision. Some models come with adjustable feet or leveling systems to accommodate uneven work surfaces, further enhancing stability.

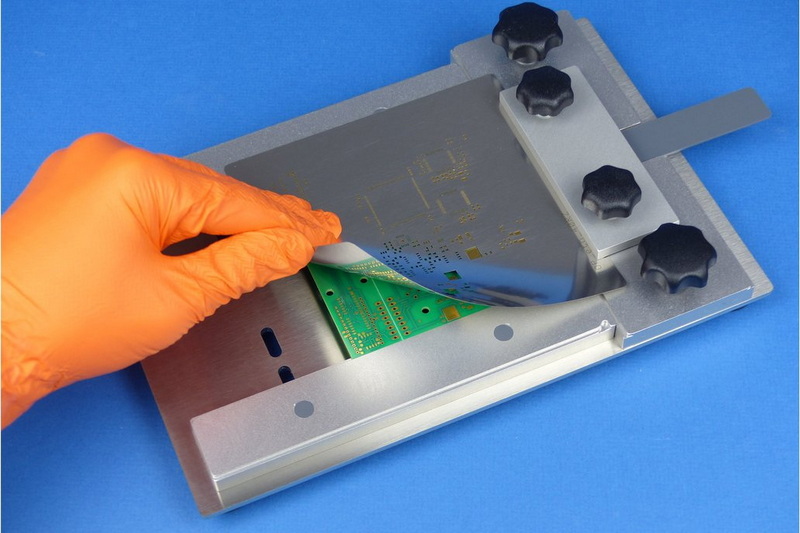

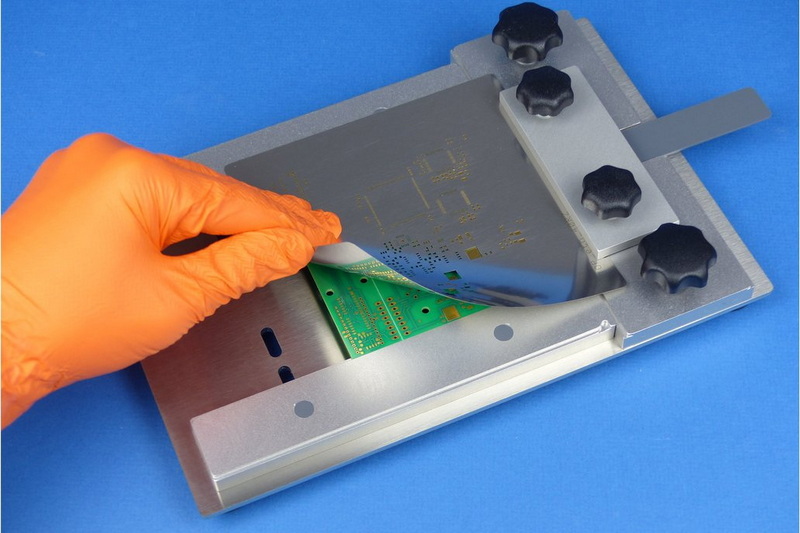

2. Alignment Mechanism

Accurate alignment between the stencil and PCB is critical for effective solder paste application. Many manual printers come with built-in alignment guides or fixtures to help position the PCB correctly. This feature reduces the risk of misalignment, which can lead to poor solder joints. Advanced models may offer optical alignment systems that allow for fine-tuning adjustments, ensuring perfect placement every time.

3. Squeegee Design

The squeegee is responsible for spreading solder paste across the stencil openings. A good squeegee design allows for adjustable pressure and angle, which can significantly impact the amount of paste applied. Some printers offer dual squeegees for improved consistency and coverage, allowing users to apply solder paste in both directions for more efficient printing.

4. Stencil Compatibility

Ensure that the printer supports various stencil types and sizes. Stencils can be framed or frameless, and having a printer that accommodates both options increases versatility in your projects. Additionally, consider whether the printer can handle different thicknesses of stencils, as this can affect the amount of solder paste deposited on the PCB.

5. Ease of Use

A user-friendly interface is essential, especially for beginners. Look for printers with intuitive controls that simplify the setup process, including easy adjustments for height and alignment. Some models even come with digital displays that provide real-time feedback during printing, helping users monitor their progress.

6. Maintenance and Cleaning

Manual solder paste printers require regular cleaning to maintain performance. Consider models that allow easy access to components for cleaning purposes. Features like automated stencil wiping can also enhance efficiency by reducing downtime between prints. Additionally, some printers come with removable parts that make cleaning straightforward and hassle-free.

7. Print Speed and Efficiency

While speed may not be as critical in low-volume applications, it's still worth considering how quickly a printer can complete a print cycle. Efficient printers reduce downtime and improve overall productivity. Look for models that allow you to adjust print speed based on your specific needs without compromising quality.

8. Size and Footprint

Depending on your workspace, the size of the manual solder paste printer may be a significant factor. Ensure that the printer fits comfortably in your designated area without compromising accessibility. Compact models are available for those with limited space but still offer robust features suitable for effective printing.

Types of Manual Solder Paste Printers

There are various types of manual solder paste printers available on the market:

- Simple Manual Printers: These are basic models that require manual alignment and operation but are cost-effective for small projects.

- Advanced Manual Printers: These models may include features like adjustable squeegee pressure and better alignment systems, suitable for more complex PCB designs.

- Hybrid Models: Some printers combine manual operation with semi-automated features, providing flexibility while maintaining control over the printing process.

Setting Up Your Manual Solder Paste Printer

Proper setup is essential to achieve optimal results when using a manual solder paste printer:

1. Preparation: Ensure all components are clean and free from dust or debris.

2. Stencil Alignment: Place the stencil over the PCB and align it carefully using any built-in guides.

3. Solder Paste Application: Use the squeegee to apply solder paste evenly across the stencil openings.

4. Inspection: After printing, inspect the PCB for any defects such as insufficient or excessive solder paste application.

5. Cleaning: Regularly clean both the stencil and squeegee to prevent contamination and ensure consistent results.

Common Challenges in Manual Solder Paste Printing

While manual solder paste printing can be rewarding, it comes with its challenges:

- Alignment Issues: Misalignment between the stencil and PCB can lead to poor solder joints.

- Inconsistent Paste Application: Variations in squeegee pressure or speed can result in uneven paste distribution.

- Cleaning Difficulties: Stencils can become clogged if not cleaned properly, affecting print quality.

Best Practices for Successful Manual Solder Paste Printing

To maximize your success with manual solder paste printing, consider implementing these best practices:

1. Use High-Quality Materials

Investing in high-quality solder paste and stencils will yield better results than cheaper alternatives. Quality materials ensure better adhesion during reflow and reduce defects in your final assembly.

2. Optimize Your Environment

Maintain a clean workspace free from dust and contaminants that could affect print quality. Additionally, controlling temperature and humidity levels can help maintain optimal conditions for both solder paste viscosity and performance.

3. Regular Calibration

Periodically calibrate your manual solder paste printer to ensure consistent performance over time. This includes checking alignment mechanisms and adjusting squeegee pressure as needed.

4. Conduct Test Prints

Before starting a production run, conduct test prints on scrap PCBs to fine-tune settings such as squeegee pressure and speed. This practice helps identify potential issues before they affect your final assemblies.

5. Document Your Process

Keep records of settings used during successful prints so you can replicate them in future projects easily. Documentation helps streamline processes when working on similar designs later on.

Conclusion

Choosing the right manual solder paste printer involves careful consideration of various features such as build quality, alignment mechanisms, squeegee design, compatibility with stencils, ease of use, maintenance requirements, print speed, size, and type of printer suitable for your needs. By understanding these aspects, you can select a printer that enhances your PCB assembly process while ensuring high-quality results.

With proper setup and maintenance practices, a manual solder paste printer can serve as an invaluable tool in your electronics assembly toolkit.

FAQ

1. What is a manual solder paste printer?

A manual solder paste printer is a device used to apply solder paste onto PCBs using stencils manually, allowing for precise control over the printing process.

2. How does a manual solder paste printer work?

It works by aligning a stencil over a PCB and using a squeegee to spread solder paste through openings in the stencil onto specific pads on the board.

3. What are common issues faced when using a manual solder paste printer?

Common issues include misalignment between stencil and PCB, inconsistent application of solder paste, and difficulties in cleaning stencils after use.

4. How do I maintain my manual solder paste printer?

Regular cleaning of stencils and squeegees is crucial; ensure all components are free from debris before use to maintain print quality.

5. Can I use different types of stencils with my manual printer?

Yes, many manual solder paste printers are designed to accommodate various types of stencils (framed or frameless), enhancing versatility in your projects.