Content Menu

● Introduction to SMT Reel Racks

>> Key Features of SMT Reel Racks

● Benefits of Using SMT Reel Racks

>> Improved Efficiency

>> Enhanced Production Quality

>> Better Use of Space

>> Protection of Components

● Intelligent SMT Reel Racks

>> Features of Intelligent Racks

● Choosing the Right SMT Reel Rack

● Innovations in SMT Reel Shelving Technology

>> Automation and AI Integration

>> IoT and Real-Time Tracking

>> Modular and Scalable Designs

>> Sustainability and Eco-Friendliness

● Impact of Industry 4.0 on SMT Reel Storage

● Emerging Trends and Future Developments

>> Integration with MES and ERP Systems

>> Sustainability Initiatives

>> Customization and Flexibility

● Case Studies: Successful Implementations

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT reel racks?

>> 2. How do intelligent SMT reel racks improve production efficiency?

>> 3. What features should I look for in a high-quality SMT reel rack?

>> 4. How do SMT reel racks contribute to better space utilization?

>> 5. Can SMT reel racks be customized for specific manufacturing needs?

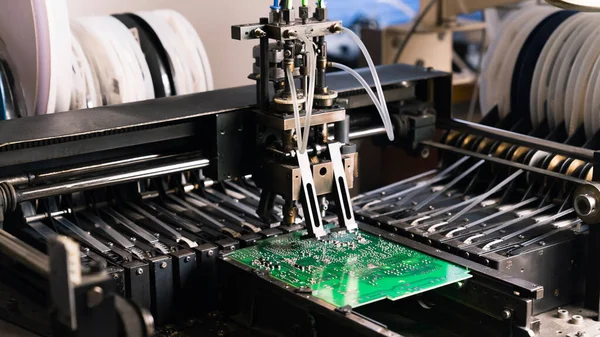

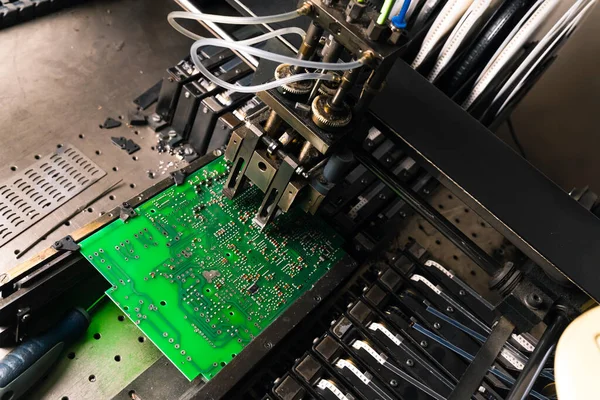

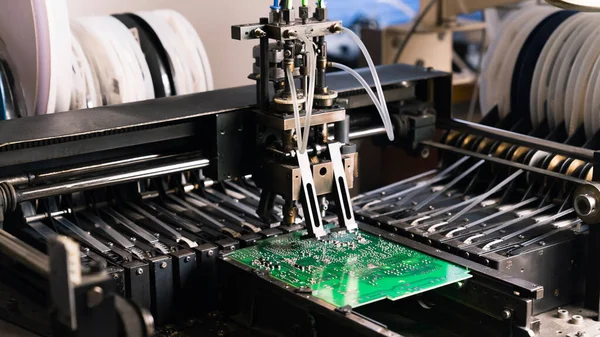

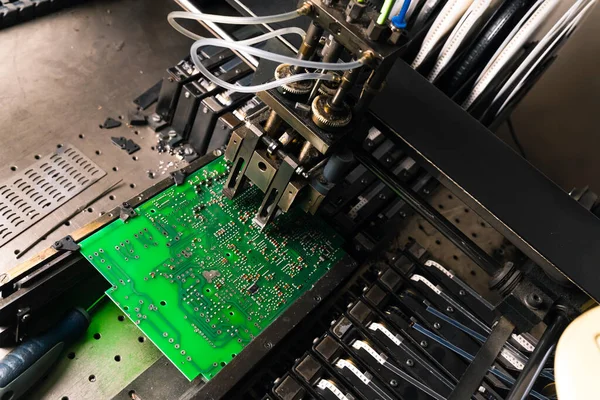

In the realm of electronics manufacturing, particularly in surface mount technology (SMT), the efficient storage and management of components are crucial for maintaining productivity and quality. SMT reel racks play a pivotal role in this process by providing a structured and accessible way to store SMT component reels. These racks are designed to optimize space, improve efficiency, and protect the integrity of electronic components. When selecting a high-quality SMT reel rack, several key features should be considered to ensure that it meets the needs of your manufacturing environment.

Introduction to SMT Reel Racks

SMT reel racks are specialized storage solutions designed for the reels used in surface mount technology. These reels contain electronic components such as resistors, capacitors, and ICs, which are mounted directly onto the surface of a printed circuit board (PCB). The reels are typically made of plastic or cardboard and are wound with a tape that holds the components in place, ensuring they remain organized and protected during storage and transportation.

Key Features of SMT Reel Racks

1. Adjustable Shelving: This feature allows for customization of the storage layout to accommodate different sizes and types of reels. Adjustable shelving ensures that each reel is securely held in place, making it easier to locate and access the exact component needed.

2. Space Efficiency: High-quality SMT reel racks are designed to maximize vertical space, minimizing the footprint in the production area. This is particularly beneficial in environments where floor space is limited. For instance, advanced smart storage systems can store up to 720 reels in just 0.45 square meters, significantly reducing the space required for component storage.

3. ESD Protection: Electrostatic discharge (ESD) protection is essential for preventing damage to sensitive electronic components. ESD-safe materials and coatings help safeguard components from static electricity.

4. Climate Control: Some advanced SMT reel storage solutions include climate control features to maintain stable temperature and humidity conditions. This is crucial for preventing moisture-related damage to components.

5. Labelling and Identification: Clear labelling and identification systems help in quickly locating specific reels, reducing search times and improving overall efficiency.

6. Security Features: Locks, alarms, or other security measures can be integrated to prevent unauthorized access or tampering with stored components.

Benefits of Using SMT Reel Racks

Improved Efficiency

SMT reel racks streamline the component management process by organizing reels in a way that facilitates quick access and minimizes search times. This efficiency is further enhanced by features like pick-to-light systems, which use visual cues to guide operators in locating and picking specific reels. Advanced smart storage systems can reduce kitting time and offer fast reel storage and retrieval times, as low as 5 seconds for storage and 3 seconds for retrieval.

Enhanced Production Quality

By ensuring components are stored correctly and easily accessible, SMT reel racks contribute to higher production quality. They help prevent errors such as misplacing components or using the wrong reel, which can lead to costly rework or scrapping.

Better Use of Space

Vertical storage solutions allow for a high capacity of reels to be stored within a small footprint, making them ideal for facilities with limited space.

Protection of Components

SMT reel racks protect components from dust, moisture, and other contaminants, ensuring they remain in optimal condition for use in production.

Intelligent SMT Reel Racks

Modern manufacturing environments are increasingly adopting intelligent SMT reel racks that integrate technologies like RFID and barcode scanning. These systems provide real-time tracking of component inventory, location, and usage, significantly reducing manual errors and improving production efficiency.

Features of Intelligent Racks

1. Precise Material Management: Intelligent racks use RFID or barcode technology to track and manage materials accurately, reducing issues like material loss or misplacement.

2. Reduced Manual Intervention: By automating inventory tracking and management, these racks minimize the need for manual labor, thereby reducing operational costs and improving efficiency.

3. Improved Production Quality: Real-time monitoring and feedback systems help prevent material-related issues that could affect product quality.

4. Integration with Production Systems: Intelligent racks can seamlessly integrate with automated production lines, enhancing the overall efficiency of the manufacturing process.

5. Predictive Maintenance: The integration of IoT devices allows for predictive maintenance, where potential issues are identified before they disrupt production, thereby enhancing operational reliability.

Choosing the Right SMT Reel Rack

When selecting an SMT reel rack, consider the following factors:

- Durability: The rack should be made from high-quality materials to withstand the demands of a manufacturing environment.

- Adjustability: Ensure the rack can accommodate various reel sizes and types.

- ESD Protection: If handling sensitive components, ESD protection is crucial.

- Space Efficiency: Opt for racks that maximize vertical space to save floor area.

- Integration Capabilities: Consider racks that can integrate with existing inventory management systems or production lines.

Innovations in SMT Reel Shelving Technology

Recent innovations in SMT reel shelving technology include the integration of automation and AI, IoT for real-time tracking, modular and scalable designs, and a focus on sustainability. These advancements aim to enhance operational efficiency, reduce environmental impact, and improve component protection.

Automation and AI Integration

The integration of automation and AI into SMT reel storage solutions has revolutionized the way manufacturers manage inventory and streamline production processes. Automated systems, such as robotic storage and retrieval systems, achieve a level of precision and speed previously unattainable. AI algorithms analyze usage patterns and predict demand, allowing for intelligent restocking of reels and minimizing downtime.

IoT and Real-Time Tracking

The use of IoT devices enables real-time tracking of reel inventory, providing continuous monitoring and alerts when stock levels fall below a predefined threshold. This proactive approach ensures that production lines remain uninterrupted, as manufacturers can replenish stock before it runs out.

Modular and Scalable Designs

Modular designs allow for easy expansion or reconfiguration as storage needs change, providing a cost-effective solution for growing businesses. This flexibility is crucial in adapting to changing production demands and minimizing environmental impact.

Sustainability and Eco-Friendliness

Manufacturers are increasingly adopting eco-friendly practices, leading to a shift towards systems that optimize space and reduce waste. Intelligent SMT reel storage solutions designed with modularity in mind allow for scalable operations, accommodating varying production demands while minimizing environmental impact.

Impact of Industry 4.0 on SMT Reel Storage

The rise of Industry 4.0 is significantly influencing the SMT reel storage landscape. The integration of IoT devices into storage systems facilitates seamless communication between machines and inventory management software. This connectivity enables predictive maintenance and provides valuable insights into usage patterns and inventory turnover, empowering manufacturers to make informed decisions.

Emerging Trends and Future Developments

The future of SMT reel rack technology is poised for significant advancements, driven by the increasing demand for automation, sustainability, and customization in electronics manufacturing. As Industry 4.0 continues to shape the manufacturing landscape, SMT reel racks will likely integrate more sophisticated IoT and AI technologies to enhance operational efficiency and predictive maintenance.

Integration with MES and ERP Systems

The integration of SMT reel racks with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems will become more prevalent. This integration enables real-time data exchange, allowing for more informed decision-making and optimized production processes.

Sustainability Initiatives

Manufacturers are increasingly focusing on sustainability, and SMT reel racks will need to align with these goals by optimizing space, reducing waste, and promoting eco-friendly practices. Modular designs that allow for easy reconfiguration and expansion will be crucial in supporting scalable operations while minimizing environmental impact.

Customization and Flexibility

As consumer preferences evolve towards personalized products, manufacturers will require flexible storage solutions that can accommodate diverse component types and sizes. Intelligent SMT reel racks that offer dynamic storage configurations will be essential for adapting to changing production needs without significant downtime.

Case Studies: Successful Implementations

Several companies have successfully implemented intelligent SMT reel storage systems, achieving significant improvements in operational efficiency and production quality. For instance, a leading electronics manufacturer reported a 30% reduction in idle time and a substantial decrease in manual errors after integrating an automated SMT reel storage system into their production line.

In another case, a mid-sized electronics firm adopted a modular SMT reel storage solution that allowed them to easily expand their storage capacity as production demands increased. This flexibility enabled them to maintain high efficiency levels while minimizing the need for additional floor space.

Conclusion

SMT reel racks are indispensable tools in the electronics manufacturing industry, offering numerous benefits such as improved efficiency, enhanced production quality, and better use of space. When choosing a high-quality SMT reel rack, it is essential to consider features like adjustability, ESD protection, and integration capabilities. As technology advances, intelligent SMT reel racks are becoming increasingly popular due to their ability to automate inventory management and improve production efficiency.

Frequently Asked Questions

1. What are the primary benefits of using SMT reel racks?

- The primary benefits include improved efficiency, enhanced production quality, better use of space, and protection of components from damage.

2. How do intelligent SMT reel racks improve production efficiency?

- Intelligent racks use technologies like RFID and barcode scanning to automate inventory tracking, reduce manual errors, and integrate with production systems, thereby improving efficiency and reducing costs.

3. What features should I look for in a high-quality SMT reel rack?

- Key features include adjustable shelving, ESD protection, climate control, labelling and identification systems, and security features.

4. How do SMT reel racks contribute to better space utilization?

- By storing reels vertically, SMT reel racks maximize available space, allowing for a high capacity of components to be stored within a small footprint.

5. Can SMT reel racks be customized for specific manufacturing needs?

- Yes, many SMT reel racks offer adjustable shelving and customizable layouts to accommodate different reel sizes and types, making them adaptable to specific manufacturing requirements.