Content Menu

● Understanding the Role of SMT Stencil Printers

● Key Features to Evaluate in a Used SMT Stencil Printer

>> 1. Precision and Alignment System

>> 2. Squeegee Pressure Control

>> 3. Stencil Handling and Replacement Mechanism

>> 4. PCB Handling and Throughput

>> 5. Solder Paste Management

>> 6. User Interface and Automation Level

>> 7. Maintenance and Support

● Additional Considerations When Buying a Used SMT Stencil Printer

● Conclusion

● FAQ

>> 1. What is the primary function of an SMT stencil printer?

>> 2. How important is the squeegee pressure control in a stencil printer?

>> 3. Can a used SMT stencil printer be integrated into an automated production line?

>> 4. What maintenance should I expect with a used SMT stencil printer?

>> 5. How do I verify the print quality of a used SMT stencil printer before purchase?

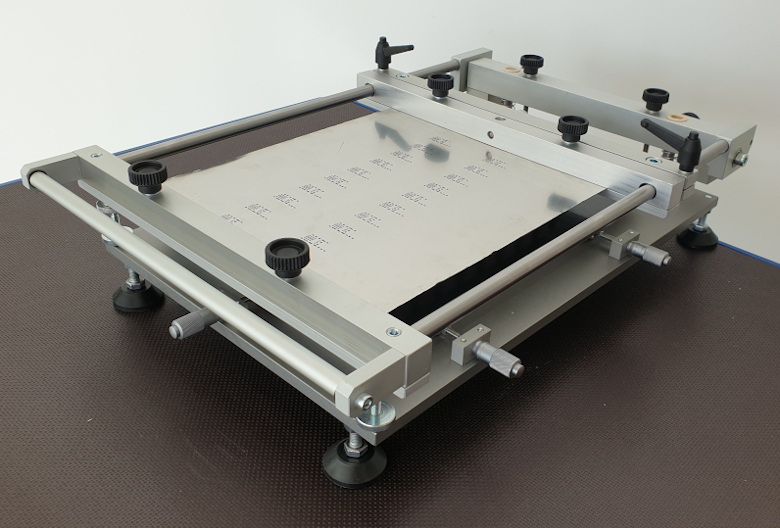

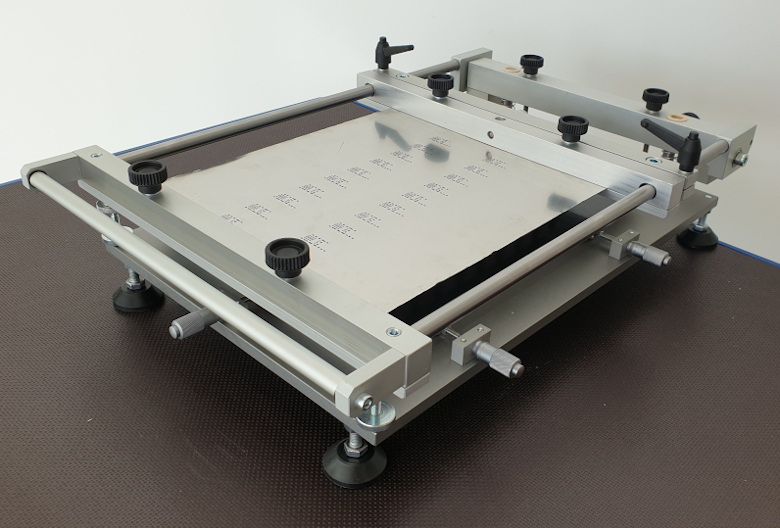

Surface Mount Technology (SMT) stencil printers play a critical role in the electronics manufacturing process, particularly in the precise application of solder paste onto printed circuit boards (PCBs). For manufacturers looking to optimize production efficiency and quality without the high cost of new equipment, purchasing a used SMT stencil printer can be an excellent option. However, selecting the right used machine requires a thorough understanding of the key features that impact performance, reliability, and suitability for specific production needs.

This comprehensive article explores the most important features to consider when evaluating a used SMT stencil printer, helping you make an informed decision that balances cost savings with production quality and efficiency.

Understanding the Role of SMT Stencil Printers

An SMT stencil printer is designed to accurately apply solder paste onto the pads of a PCB through a stencil, which has apertures corresponding to the component footprints. This process ensures the right amount of solder paste is deposited in the correct locations, which is essential for reliable solder joints and overall product quality.

The printer typically aligns the stencil with the PCB, spreads the solder paste evenly using a squeegee, and then removes the stencil, leaving behind a precise solder paste pattern. This step is foundational to the SMT assembly line and directly affects the yield and reliability of the final electronic product.

The quality of solder paste printing directly influences downstream processes such as component placement and reflow soldering. Poor solder paste application can result in defects like solder bridging, insufficient solder joints, or tombstoning of components, all of which increase rework costs and reduce product reliability. Therefore, the stencil printer's performance is critical to achieving high production yields.

Key Features to Evaluate in a Used SMT Stencil Printer

When considering a used SMT stencil printer, focus on the following critical features that influence printing accuracy, throughput, ease of use, and maintenance.

1. Precision and Alignment System

The core function of an SMT stencil printer is to align the stencil accurately with the PCB pads. High precision in alignment reduces defects such as solder bridging or insufficient solder.

- Vision Alignment: Modern printers use vision systems to detect fiducial marks on the PCB and stencil for precise alignment. Check if the used printer has an advanced vision alignment system or if it relies on manual or mechanical alignment, which may be less accurate. Vision systems can include cameras and software algorithms that automatically adjust the stencil position relative to the PCB, minimizing human error.

- Repeatability: The printer should consistently reproduce the same alignment accuracy across multiple boards to ensure uniform solder paste application. This repeatability is essential for high-volume production where consistency is key.

- Registration Tolerance: Consider the printer's registration tolerance, which defines how closely the stencil aligns with the PCB pads. Tighter tolerances are necessary for fine-pitch components and high-density boards.

2. Squeegee Pressure Control

Uniform solder paste deposition depends heavily on the squeegee pressure applied during printing.

- Pressure Feedback System: Look for printers equipped with load cell sensors or feedback mechanisms that maintain constant squeegee pressure. This reduces variation between forward and backward strokes and ensures consistent paste volume. A stable pressure system prevents over- or under-deposition of solder paste, which can cause assembly defects.

- Adjustability: The ability to fine-tune squeegee pressure is important for different PCB designs and solder paste types. Some solder pastes require softer or harder pressure to achieve optimal printing results.

- Squeegee Type: Check if the printer supports different squeegee materials and shapes, such as metal or polyurethane blades, which affect paste transfer efficiency and stencil wear.

3. Stencil Handling and Replacement Mechanism

Efficient stencil handling improves productivity and reduces downtime.

- Easy Stencil Mounting: Features such as quick-release stencil holders or automatic positioning systems simplify stencil replacement and reduce human error. This is especially valuable in production environments where stencil changes are frequent due to different PCB designs.

- Stencil Size Compatibility: Check if the printer supports multiple stencil sizes, which adds flexibility for different PCB formats. Some printers accommodate a wide range of stencil dimensions, enabling versatile production capabilities.

- Cleaning System: Some printers include automatic stencil cleaning mechanisms to remove excess solder paste during production, maintaining stencil aperture clarity and print quality. Automated cleaning reduces manual labor and helps maintain consistent print quality over long production runs.

- Stencil Tensioning: Proper stencil tensioning ensures flatness and prevents stencil deformation during printing, which can affect solder paste deposition accuracy.

4. PCB Handling and Throughput

The printer should accommodate the PCB sizes and volumes typical for your production.

- Conveyor System: Automatic feeders and conveyors enable continuous production and reduce manual handling. This is crucial for high-volume manufacturing where minimizing downtime and operator intervention improves efficiency.

- Cycle Time: Evaluate the printer's printing speed and how quickly it can process PCBs, including features like simultaneous operations (e.g., cleaning while printing) that reduce overall cycle time. Faster cycle times increase throughput and lower production costs.

- PCB Size Range: Ensure the printer can handle the minimum and maximum PCB dimensions you require. Some printers are optimized for small boards, while others can handle large or odd-shaped PCBs.

- Board Support and Clamping: Reliable board support and clamping mechanisms prevent PCB movement during printing, ensuring consistent paste application.

5. Solder Paste Management

Proper solder paste supply and monitoring are essential to avoid defects.

- Paste Supply System: Some printers have automated solder paste supply or refill alerts to maintain consistent paste availability. This helps avoid interruptions due to paste depletion.

- Paste Volume Monitoring: Systems that measure solder paste volume on the stencil help prevent printing defects caused by insufficient or excessive paste. This feature can alert operators to potential problems before they affect production quality.

- Paste Temperature Control: Maintaining solder paste at the correct temperature can improve printability and reduce defects. Some advanced printers offer paste temperature management.

6. User Interface and Automation Level

The ease of operation affects training time and error rates.

- Automation: Fully automatic printers reduce operator intervention, improving consistency and throughput, while semi-automatic or manual printers may require more skill. Automation features can include automatic stencil loading, vision alignment, paste printing, and cleaning cycles.

- User Interface: Intuitive controls and clear feedback on printer status help operators manage the process efficiently. Touchscreen interfaces with graphical displays and step-by-step guidance can reduce operator errors.

- Integration Capability: Compatibility with Manufacturing Execution Systems (MES) or Industry 4.0 standards can be beneficial for advanced production environments. This allows real-time monitoring, data logging, and quality control integration.

7. Maintenance and Support

Used equipment may require servicing, so consider:

- Availability of Spare Parts: Check if parts for the specific printer model are still available. Older or discontinued models may have limited support, increasing maintenance costs.

- Machine Condition: Inspect the mechanical components, vision system, and electronics for wear or damage. Look for signs of excessive use, corrosion, or poorly maintained parts.

- Service History: A well-maintained printer with documented service records is preferable. This can indicate how well the machine was cared for and predict future reliability.

- Training and Documentation: Access to operator manuals, training resources, and technical support can ease the transition to using a used SMT stencil printer.

Additional Considerations When Buying a Used SMT Stencil Printer

- Compatibility with Your PCB Designs: Confirm the printer supports the stencil aperture sizes and PCB thicknesses you use. Some printers may have limitations that restrict their use with certain board types.

- Print Quality Samples: Request print samples or test runs to evaluate the solder paste deposition quality. This practical demonstration can reveal issues not apparent from specifications alone.

- Manufacturer Reputation: Some brands have better reliability and support networks. Investing in a used printer from a reputable manufacturer can reduce risks.

- Budget vs. Features: Balance cost savings with the need for critical features to avoid compromising production quality. Sometimes paying slightly more for a better machine can save money in the long run.

- Upgrade Options: Some used printers may be upgradeable with newer vision systems, software, or automation features, extending their useful life and capabilities.

- Environmental Considerations: Evaluate the printer's energy consumption and footprint, especially if production space or power availability is limited.

Conclusion

Selecting the right used SMT stencil printer involves carefully assessing features that impact precision, consistency, throughput, and ease of operation. Key aspects such as the alignment system, squeegee pressure control, stencil handling, PCB throughput, solder paste management, and overall machine condition should guide your decision. By prioritizing these features, manufacturers can acquire a cost-effective SMT stencil printer that delivers reliable solder paste printing and supports high-quality PCB assembly.

Purchasing a used SMT stencil printer offers significant cost advantages but requires due diligence to ensure the machine meets your production demands. Thorough evaluation, including inspection, testing, and understanding the printer's capabilities, will help you select a machine that improves your manufacturing process without compromising quality or efficiency.

FAQ

1. What is the primary function of an SMT stencil printer?

An SMT stencil printer applies solder paste onto PCB pads through a precisely aligned stencil, ensuring accurate solder paste deposition for surface mount components.

2. How important is the squeegee pressure control in a stencil printer?

Squeegee pressure control is crucial as it ensures uniform solder paste application, reducing defects caused by inconsistent paste volume or distribution.

3. Can a used SMT stencil printer be integrated into an automated production line?

Yes, many used printers, especially those with vision alignment and conveyor systems, can be integrated into automated SMT lines, though compatibility should be verified.

4. What maintenance should I expect with a used SMT stencil printer?

Maintenance includes regular cleaning, inspection of mechanical parts, calibration of alignment systems, and replacement of worn components like squeegees and stencil holders.

5. How do I verify the print quality of a used SMT stencil printer before purchase?

Request test prints or samples to inspect solder paste deposition accuracy, uniformity, and alignment. Also, review the printer's service history and condition.