Content Menu

● Introduction to Laser SMT Stencils

>> Advantages of Laser-Cut SMT Stencils

● Types of SMT Stencils

>> Framed SMT Stencils

>> Frameless SMT Stencils

● Materials Used for SMT Stencils

>> Stainless Steel

● Stencil Thickness

>> Choosing the Right Thickness

● Design Considerations

>> Aperture Size and Shape

>> Advanced Design Techniques

● Best Practices for Stencil Maintenance

>> Regular Cleaning

>> Inspection and Storage

● Challenges in SMT Stencil Printing

>> Common Issues

>> Overcoming Challenges

● Future Trends in SMT Stencil Technology

>> Nano-coatings and Surface Treatments

>> Additive Manufacturing and Customization

>> Integrated Inspection and Quality Assurance

● Conclusion

● FAQs

>> 1. What is the primary function of a laser SMT stencil?

>> 2. What materials are commonly used for laser SMT stencils?

>> 3. How does the thickness of a laser SMT stencil affect solder paste deposition?

>> 4. What are the advantages of framed SMT stencils?

>> 5. Why is regular cleaning of laser SMT stencils important?

● Citations:

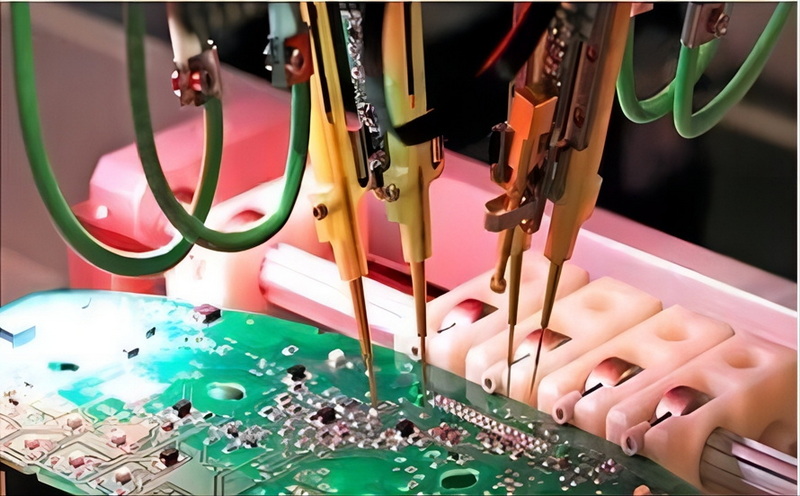

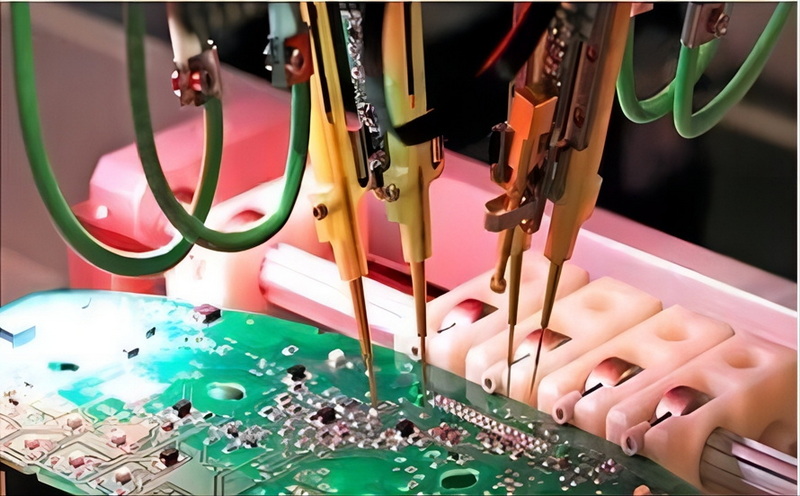

Choosing the right laser SMT (Surface Mount Technology) stencil is crucial for ensuring high-quality solder paste application during the PCB assembly process. Laser SMT stencils are precision tools used to deposit solder paste onto PCB pads accurately, facilitating the placement of SMD components. This article will delve into the key factors to consider when selecting a laser SMT stencil, covering types, materials, thickness, design considerations, and best practices for optimal performance.

Introduction to Laser SMT Stencils

Laser SMT stencils are thin metal sheets, typically made of stainless steel, with apertures laser-cut to match the solder pad locations on a PCB. These stencils are essential for achieving precise solder paste deposition, which is vital for creating reliable solder joints between components and the PCB. The use of laser cutting technology ensures smooth aperture walls, enhancing solder paste release and reducing defects such as insufficient or excessive solder paste on the pads.

Advantages of Laser-Cut SMT Stencils

1. Improved Solder Paste Deposition: Laser-cut stencils have smooth aperture walls, allowing for better solder paste release and more consistent deposits.

2. Enhanced Aperture Accuracy: Laser cutting enables the creation of highly accurate apertures, even for fine-pitch components, ensuring proper solder joint formation.

3. Faster Stencil Production: Laser cutting is a fast and efficient process, reducing lead times and enabling quicker turnaround for electronics manufacturers.

4. Increased Durability: Laser-cut stencils are made from high-quality stainless steel, providing excellent durability and resistance to wear and tear.

Types of SMT Stencils

There are primarily two types of SMT stencils: framed and frameless (also known as foil stencils).

Framed SMT Stencils

- Description: Framed stencils are permanently fixed within a rigid frame, making them ideal for high-volume production. The stencil foil is tightly stretched within the frame, ensuring high-accuracy printing and consistent performance over extended periods.

- Advantages: Framed stencils offer excellent stability and repeatability, making them suitable for automated production lines.

- Disadvantages: They are more expensive due to the additional frame support and require more storage space.

Frameless SMT Stencils

- Description: Frameless stencils, or foils, are low-cost laser-cut stencils not glued to a frame. They are significantly less expensive than framed stencils and provide cost-effective storage while delivering superior quality and performance.

- Advantages: Suitable for low-volume stencil printing, prototyping, and manual alignment.

- Disadvantages: Manual alignment can be less consistent than machine-based methods.

Materials Used for SMT Stencils

SMT stencils are typically made from materials like stainless steel, nickel, brass, and polymer composites. Stainless steel is the most commonly used material due to its durability, heat resistance, and corrosion resistance.

Stainless Steel

- Advantages: Offers excellent dimensional stability, high strength, and resistance to corrosion and oxidation.

- Common Grades: 304, 316, and 321 stainless steel are commonly used for laser-cut SMT stencils.

Stencil Thickness

The thickness of a laser SMT stencil is critical for determining the amount of solder paste deposited onto the PCB pads. Common thicknesses include 100 μm (4 mil), 125 μm (5 mil), 150 μm (6 mil), and 200 μm (8 mil).

Choosing the Right Thickness

- Fine-Pitch Components: Thinner stencils (e.g., 100 μm) are used for fine-pitch components and smaller apertures.

- Larger Components: Thicker stencils (e.g., 200 μm) are used for larger components requiring higher solder paste volumes.

Design Considerations

Proper stencil design is crucial for achieving high-quality solder paste prints and minimizing defects.

Aperture Size and Shape

- Matching PCB Pads: Apertures should match the size and shape of PCB pads while accounting for the solder paste's properties and desired solder joint profile. Common aperture shapes include rectangles, circles, and home plates. Designers must adhere to minimum aperture width and pitch guidelines to ensure proper paste release and prevent bridging.

- Aspect Ratio and Area Ratio: These ratios are critical for ensuring optimal solder paste release. The aspect ratio (aperture width divided by stencil thickness) should be sufficient to prevent clogging, while the area ratio (aperture area to wall area) affects paste release efficiency.

Advanced Design Techniques

- Nano-Coatings and Surface Treatments: Advanced nano-coatings improve solder paste release and reduce adhesion, enhancing print quality and fine-pitch component printing. They also require less frequent cleaning, prolonging stencil life[4].

- 3D Printing and Customization: Additive manufacturing enables custom-designed SMT stencils with intricate geometries and tailored aperture designs. This flexibility accommodates unique PCB layouts and component configurations[4].

Best Practices for Stencil Maintenance

Regular maintenance and cleaning are essential for ensuring consistent print quality and extending the stencil's lifespan.

Regular Cleaning

- Methods: Manual wiping with solvents, ultrasonic cleaning, or automated stencil cleaning systems.

- Frequency: Cleaning frequency may vary based on production volume and specific requirements.

Inspection and Storage

- Inspection: Regularly inspect stencils for damage or aperture clogging using magnification tools.

- Storage: Store stencils in a clean, dry environment with protective covers to prevent damage.

Challenges in SMT Stencil Printing

Despite advancements in technology, several challenges persist in the SMT stencil printing process.

Common Issues

1. Insufficient Solder Paste Deposition: This can lead to weak solder joints. Solutions include increasing stencil thickness, enlarging aperture size, or adjusting print parameters[3].

2. Excessive Solder Paste Deposition: Causes bridging or solder balling. Solutions involve reducing stencil thickness, decreasing aperture size, or optimizing print settings[3].

3. Bridging or Solder Balling: Often due to improper solder paste volume or aperture design. Solutions include reducing solder paste volume, increasing aperture wall tapering, or optimizing print parameters[3].

Overcoming Challenges

- High-Quality Stencils: Utilize stencils specifically designed for your PCB layout to ensure accurate solder paste application[7].

- Automated Inspection Systems: Implement SPI (Solder Paste Inspection) systems to detect defects early in the process[7].

- Advanced Materials and Technologies: Leverage advancements in nano-coatings and additive manufacturing to enhance stencil performance and customization[4].

Future Trends in SMT Stencil Technology

The evolution of SMT stencil technology continues to drive innovation:

Nano-coatings and Surface Treatments

Advanced nano-coatings improve solder paste release and reduce adhesion, enhancing print quality and fine-pitch component printing. They also require less frequent cleaning, prolonging stencil life[4].

Additive Manufacturing and Customization

3D printing enables custom-designed SMT stencils with intricate geometries and tailored aperture designs. This flexibility accommodates unique PCB layouts and component configurations[4].

Integrated Inspection and Quality Assurance

Emerging technologies integrate automated inspection systems into the stencil printing process, enabling real-time monitoring of solder paste deposition quality. Automated systems detect defects like insufficient solder paste volume or misalignment, ensuring adherence to manufacturing specifications[4].

Conclusion

Choosing the right laser SMT stencil involves considering several factors, including the type of stencil, material, thickness, and design specifications. By understanding these elements and implementing best practices for maintenance, manufacturers can optimize their PCB assembly processes, ensuring high-quality solder joints and reliable electronic devices.

FAQs

1. What is the primary function of a laser SMT stencil?

- A laser SMT stencil is used to apply solder paste onto PCB pads accurately, facilitating the placement of SMD components.

2. What materials are commonly used for laser SMT stencils?

- The most common material is stainless steel, due to its durability and heat resistance. Other materials include nickel, brass, and polymer composites.

3. How does the thickness of a laser SMT stencil affect solder paste deposition?

- The thickness determines the amount of solder paste deposited. Thinner stencils are used for fine-pitch components, while thicker stencils are used for larger components requiring more solder paste.

4. What are the advantages of framed SMT stencils?

- Framed stencils offer excellent stability and repeatability, making them ideal for high-volume automated production lines.

5. Why is regular cleaning of laser SMT stencils important?

- Regular cleaning prevents aperture clogging and ensures consistent print quality, extending the stencil's lifespan.

Citations:

[1] https://pcbpit.com/smt-stencil-a-comprehensive-guide/

[2] https://stencillaser.lpkf.com/en/applications/smd-stencil

[3] https://rigidflexpcb.org/comprehensive-guide-to-smt-stencils/

[4] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly

[5] https://blueringstencils.com/wp-content/uploads/2017/10/123386-361848.smt-printing-challenges.pdf

[6] https://rigidflexpcb.org/smt-stencil-and-laser-stencil/

[7] https://www.bigmateph.com/what-are-the-common-challenges-of-smt-and-how-to-overcome-it/

[8] https://www.marketreportanalytics.com/reports/smt-stencils-27937

[9] https://www.stentech.com/company/cvd-treatment-for-smt-stencils

[10] https://www.twistedtraces.com/blog/understanding-smt-stencils-the-backbone-of-electronics-manufacturing

[11] https://iconnect007.com/article/115048/overcoming-the-challenges-of-miniaturization-with-new-stencil-technologiessolder-paste-release-pt-2/115051/smt

[12] https://www.wiseguyreports.com/reports/laser-cut-smt-stencil-market

[13] https://smtnet.com/library/files/upload/Best-Stencil-SMT.pdf

[14] https://www.lpkfusa.com/products-technologies/pcb-production-lasers/about-stencil-manufacturing

[15] https://fctsolder.com/wp-content/uploads/2017/08/123386-361848.smt-printing-challenges.pdf

[16] https://www.latechlaser.com/news/future-trends-in-smt-stencil-laser-cutting-tec-78495992.html

[17] https://www.ipc.org/system/files/technical_resource/E38&S12-02%20-%20Chrys%20Shea.pdf

[18] https://www.pcbgogo.com/knowledge-center/Laser_Stencil.html

[19] https://www.circuitinsight.com/programs/52394.html

[20] https://www.linkedin.com/pulse/smt-stencils-market-innovations-addressing-key-challenges-kzrcc/