Content Menu

● Understanding SMT PCB Assembly

>> Why Choose SMT PCB Assembly?

● Key Factors to Consider When Buying SMT PCB Assembly

>> 1. Design and Complexity

>> 2. Material Selection

>> 3. Volume of Production

>> 4. Quality Assurance and Testing

>> 5. Cost Considerations

● The SMT PCB Assembly Process

● Advantages of SMT PCB Assembly

>> 1. Compactness

>> 2. Cost Efficiency

>> 3. High Reliability

>> 4. Flexibility

>> 5. Scalability

● Challenges in SMT PCB Assembly

● Tips for Choosing the Right SMT PCB Assembly Provider

● Conclusion

● FAQs

>> 1. What is the difference between SMT and through-hole technology?

>> 2. How does production volume affect SMT assembly costs?

>> 3. What are common inspection methods in SMT assembly?

>> 4. Why is material selection important in SMT assembly?

>> 5. How can I get an accurate quote for SMT PCB assembly?

Surface Mount Technology (SMT) PCB assembly is a cornerstone of modern electronics manufacturing. It involves mounting electronic components directly onto the surface of printed circuit boards (PCBs), enabling compact, efficient, and cost-effective designs. Whether you are developing a prototype or scaling up to mass production, buying SMT PCB assembly services requires careful consideration of numerous factors to ensure quality, reliability, and value for money. This comprehensive guide will walk you through the critical aspects to consider before making your purchase.

Understanding SMT PCB Assembly

SMT PCB assembly has revolutionized the electronics industry by enabling the production of smaller, lighter, and more efficient devices. Unlike traditional through-hole technology, which requires drilling holes into the PCB for component leads, SMT mounts components directly onto the surface of the board.

Why Choose SMT PCB Assembly?

- Compact Designs: SMT enables high-density layouts, making it ideal for modern electronics like smartphones and IoT devices.

- Cost Efficiency: Automated processes reduce labor costs and material waste.

- High Reliability: Advanced soldering techniques ensure durable electrical connections.

- Scalability: From prototypes to mass production, SMT supports a wide range of applications.

Key Factors to Consider When Buying SMT PCB Assembly

When purchasing SMT PCB assembly services, several factors must be evaluated to ensure that your project requirements are met effectively.

1. Design and Complexity

The design and complexity of your PCB play a significant role in determining the feasibility and cost of SMT assembly.

- Layer Count: PCBs can range from single-layer to multi-layer designs. Multi-layer boards require advanced manufacturing capabilities.

- Component Density: High-density designs with closely spaced components demand precise placement techniques.

- Special Features: Incorporating fine-pitch components, BGAs (Ball Grid Arrays), or microcontrollers increases design complexity.

- Design for Manufacturability (DFM): Ensure your design is optimized for manufacturing to avoid costly errors during production.

2. Material Selection

Choosing the right materials is crucial for achieving optimal performance and durability.

- PCB Substrate: FR4 is commonly used for standard applications due to its affordability and reliability. For high-frequency or thermal applications, materials like Rogers or polyimide may be required.

- Component Quality: Always source components from reputable suppliers to avoid counterfeit parts that could compromise performance.

- Solder Paste: The type of solder paste used can impact the strength and longevity of solder joints.

3. Volume of Production

Production volume directly influences pricing and manufacturing processes.

- Low Volume/Prototyping: Ideal for testing new designs but may involve higher costs due to manual processes.

- Medium Volume: Suitable for small-scale production runs with moderate automation.

- High Volume/Mass Production: Fully automated processes reduce per-unit costs and ensure consistency across large batches.

4. Quality Assurance and Testing

Quality assurance is critical in ensuring that your assembled PCBs function reliably under real-world conditions.

- Inspection Methods: Automated Optical Inspection (AOI) detects soldering defects, while X-ray inspection identifies hidden issues like voids in BGAs.

- Functional Testing: Verifies that the assembled PCBs meet all electrical and mechanical specifications.

- Certifications: Look for manufacturers who comply with industry standards such as IPC-A-610 (Acceptability of Electronic Assemblies) or ISO 9001 (Quality Management Systems).

5. Cost Considerations

Understanding the cost structure of SMT PCB assembly helps you make informed decisions.

- Component Costs: Ordering components in bulk can significantly reduce expenses.

- Setup Costs: Initial setup fees include stencil creation, programming pick-and-place machines, and testing protocols.

- Labor Costs: Automation minimizes labor expenses in high-volume production but may not be cost-effective for low-volume projects.

- Hidden Costs: Be aware of potential additional costs such as expedited shipping or rework fees.

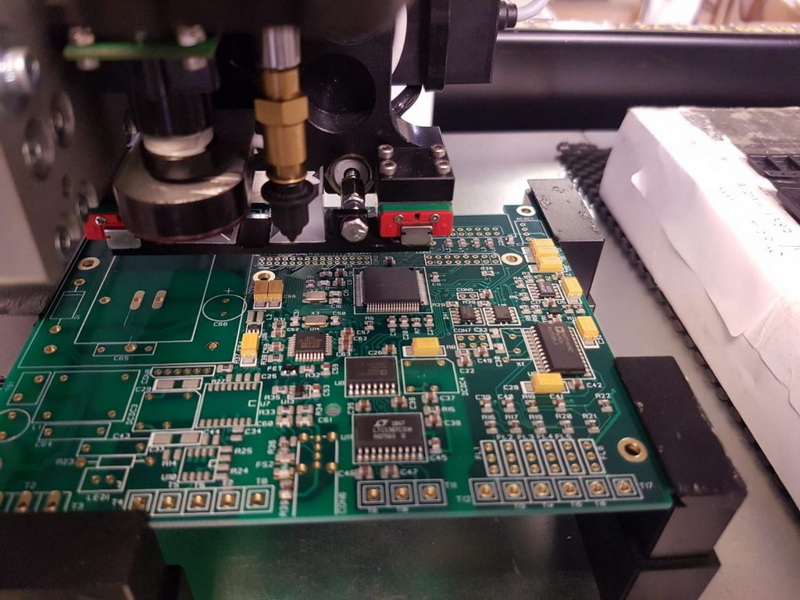

The SMT PCB Assembly Process

To better understand what goes into SMT assembly, let's break down the key steps involved:

1. Preparation:

- Review design files (Gerber files) for manufacturability.

- Inspect PCBs and components for defects before assembly begins.

2. Solder Paste Application:

- A stencil is used to apply solder paste onto specific pads on the PCB surface where components will be placed.

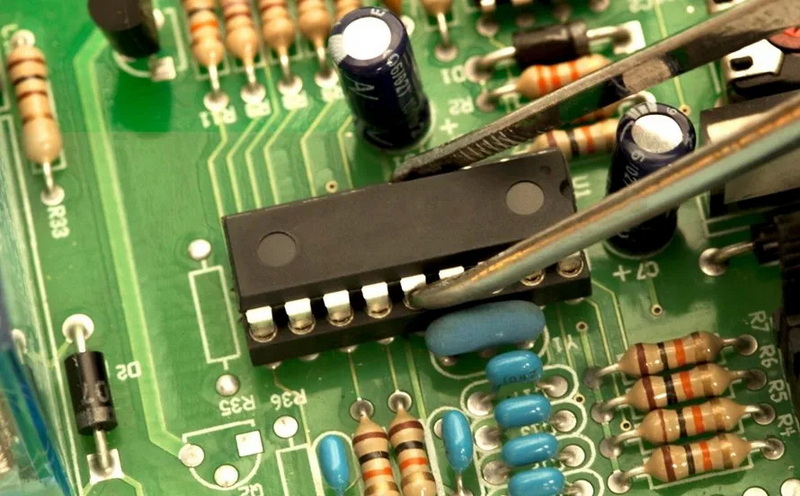

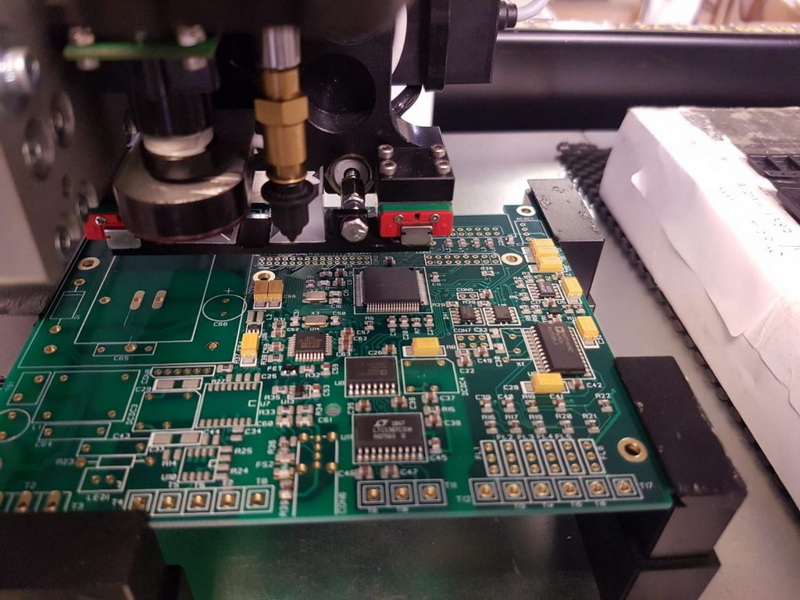

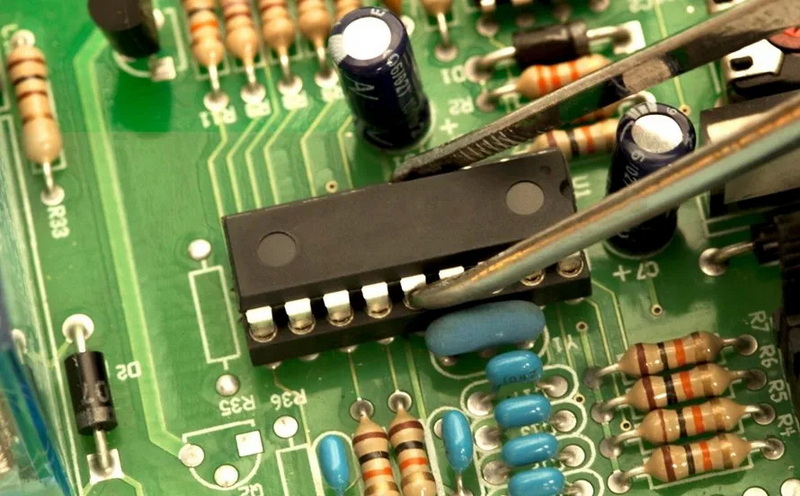

3. Component Placement:

- Automated pick-and-place machines position components with high precision based on design specifications.

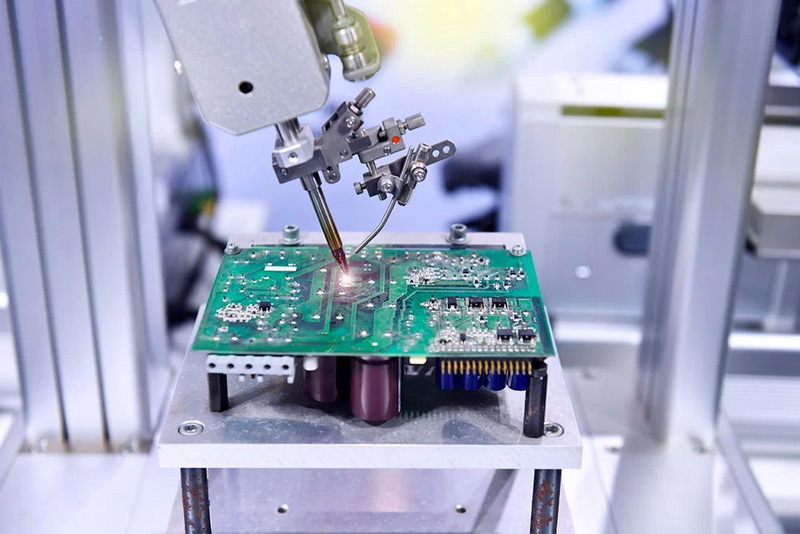

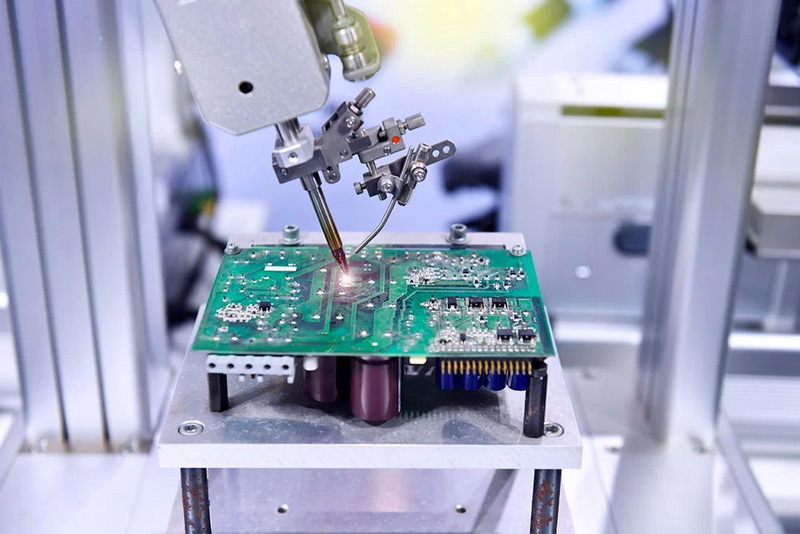

4. Reflow Soldering:

- The assembled PCBs are passed through a reflow oven where heat melts the solder paste, creating secure electrical connections.

5. Inspection and Testing:

- AOI checks for visible defects such as misaligned components or insufficient soldering.

- X-ray inspection identifies hidden issues like voids in solder joints.

- Functional testing ensures that the final product operates as intended.

Advantages of SMT PCB Assembly

SMT offers numerous benefits that make it the preferred choice for modern electronics manufacturing:

1. Compactness

With components mounted directly onto the board's surface, SMT enables smaller PCBs with higher component density—perfect for portable devices.

2. Cost Efficiency

Automation reduces material waste and labor costs while improving production speed.

3. High Reliability

Advanced soldering techniques create robust connections that can withstand environmental stresses like vibration or temperature fluctuations.

4. Flexibility

Components can be mounted on both sides of the PCB, optimizing space utilization and design layouts.

5. Scalability

SMT supports a wide range of production volumes, from prototypes to mass production runs.

Challenges in SMT PCB Assembly

While SMT offers many advantages, it also comes with its own set of challenges:

1. Miniaturization Issues:

- Handling extremely small components requires advanced machinery and expertise.

2. Thermal Management:

- High-density designs may face overheating issues if proper thermal management strategies are not implemented.

3. Solder Joint Reliability:

- Improper reflow profiles can lead to weak solder joints or defects like tombstoning (where one end of a component lifts off the board).

4. Material Compatibility:

- Ensuring compatibility between different materials (e.g., solder paste and substrate) is crucial for long-term reliability.

Tips for Choosing the Right SMT PCB Assembly Provider

Selecting a reliable manufacturer is essential for successful project execution:

1. Evaluate their experience in handling similar projects or industries.

2. Check their certifications (e.g., ISO 9001) to ensure quality standards are met.

3. Request samples or prototypes before committing to large-scale production.

4. Assess their communication skills—clear communication reduces misunderstandings during production.

5. Compare quotes from multiple providers but avoid compromising quality for lower prices.

Conclusion

Buying SMT PCB assembly services is a critical decision that impacts your project's success. By considering factors such as design complexity, material selection, production volume, quality assurance measures, and cost structure, you can make an informed choice that aligns with your goals and budget. Additionally, understanding the assembly process and potential challenges will help you collaborate effectively with your chosen manufacturer, ensuring high-quality results every time.

FAQs

1. What is the difference between SMT and through-hole technology?

SMT mounts components directly on the surface of PCBs without drilling holes, enabling compact designs suitable for modern electronics. Through-hole technology involves inserting component leads into drilled holes, offering better mechanical strength but less compactness.

2. How does production volume affect SMT assembly costs?

Higher production volumes reduce per-unit costs through automation and bulk purchasing efficiencies, while low volumes may incur higher setup fees due to manual processes.

3. What are common inspection methods in SMT assembly?

Automated Optical Inspection (AOI), X-ray inspection, and functional testing are commonly used to detect defects such as misaligned components or voids in solder joints while ensuring overall quality.

4. Why is material selection important in SMT assembly?

The choice of materials affects performance, durability, and cost-effectiveness. For example, high-frequency applications may require specialized substrates like Rogers laminates instead of standard FR4 materials.

5. How can I get an accurate quote for SMT PCB assembly?

Provide detailed documentation such as Gerber files, Bill of Materials (BOM), testing requirements, and any specific certifications needed when requesting quotes from manufacturers.