Content Menu

● Understanding SMT Lines

● Essential Equipment for an SMT Line

>> 1. Solder Paste Printing Machine

>> 2. Pick and Place Machine

>> 3. Reflow Oven

>> 4. Automated Optical Inspection (AOI) System

>> 5. Solder Paste Inspection (SPI) Machine

>> 6. SMT Loader and Unloader

>> 7. Cleaning Equipment

>> 8. Docking Stations

>> 9. Conveyor Systems

>> 10. Software Management Systems

● Additional Equipment Considerations

>> Solder Paste Mixer

>> Glue Dispensing Machines

● Benefits of Implementing an SMT Line

● Challenges in SMT Assembly

● Conclusion

● FAQs

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What role does a pick-and-place machine play in an SMT line?

>> 3. Why is reflow soldering important in SMT assembly?

>> 4. How does automated optical inspection (AOI) improve quality control?

>> 5. What benefits do conveyor systems provide in an SMT line?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the assembly of components directly onto the surface of printed circuit boards (PCBs). The efficiency and precision of SMT have made it the preferred method for producing compact and high-performance electronic devices. To establish a successful SMT line, several pieces of specialized equipment are necessary. This article will explore the essential equipment required for a successful SMT line in PCB assembly, detailing their functions and significance.

Understanding SMT Lines

An SMT line is a complex system that integrates various machines and processes to assemble electronic components onto PCBs. The typical SMT assembly process involves several key steps:

1. Solder Paste Printing

2. Component Placement

3. Reflow Soldering

4. Inspection and Testing

Each step requires specific equipment to ensure high-quality production and efficiency.

Essential Equipment for an SMT Line

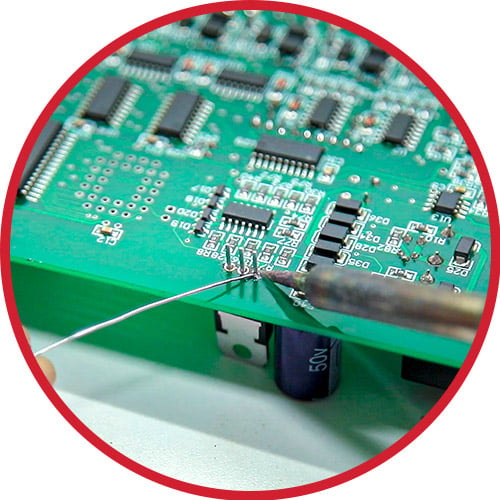

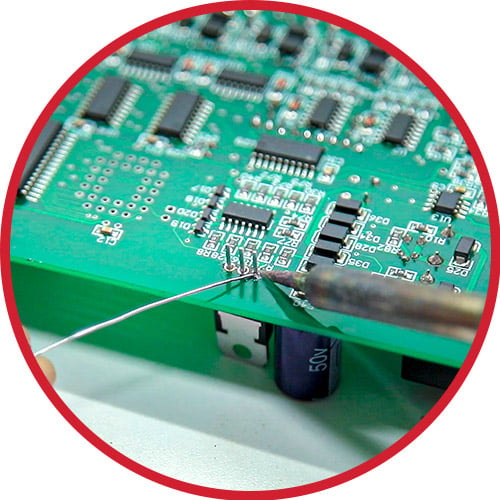

1. Solder Paste Printing Machine

The solder paste printing machine is crucial for applying solder paste to the PCB pads where components will be mounted. It utilizes a stencil to ensure that solder paste is applied accurately and evenly across the board.

- Function: Applies solder paste to designated areas on the PCB, preparing it for component placement.

- Importance: Proper solder paste application is vital for creating reliable electrical connections between components and the PCB.

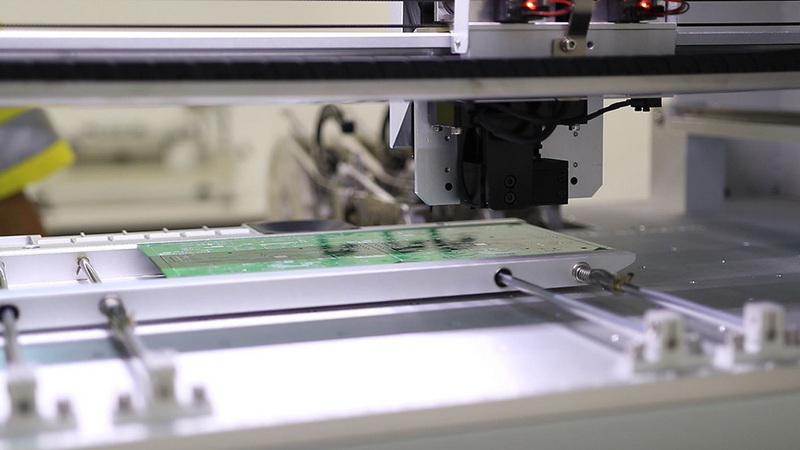

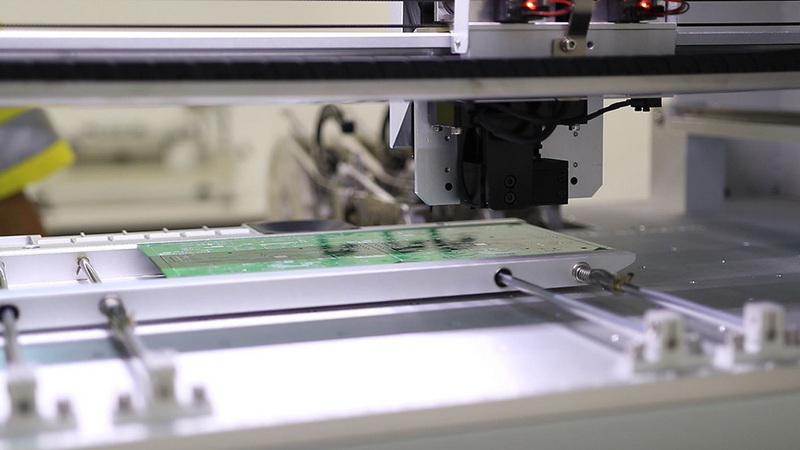

2. Pick and Place Machine

The pick and place machine is arguably the most critical piece of equipment in an SMT line. It accurately places surface-mount devices (SMDs) onto the PCB pads coated with solder paste.

- Function: Picks up components from reels or trays and places them onto the PCB in precise locations.

- Importance: High-speed operation allows for rapid assembly, significantly increasing production efficiency.

3. Reflow Oven

Once components are placed on the PCB, they need to be soldered securely. The reflow oven heats the assembly to melt the solder paste, creating permanent electrical connections.

- Function: Melts solder paste using controlled heating profiles, allowing for proper bonding between components and PCB.

- Importance: Ensures high-quality solder joints that are essential for device reliability.

4. Automated Optical Inspection (AOI) System

After soldering, it is crucial to inspect the assembled PCBs for defects such as misaligned components or insufficient solder joints.

- Function: Uses cameras and software to inspect PCBs automatically for defects.

- Importance: Early detection of defects helps minimize waste and ensures high product quality.

5. Solder Paste Inspection (SPI) Machine

Before proceeding to component placement, it is essential to verify that the solder paste has been applied correctly.

- Function: Measures the thickness, area, and volume of solder paste on each pad.

- Importance: Ensures that there is enough solder paste for proper component attachment while avoiding excess that could lead to defects.

6. SMT Loader and Unloader

These machines automate the loading of bare PCBs onto the assembly line and unloading completed assemblies from it.

- Function: The loader feeds PCBs into the production line, while the unloader removes finished boards.

- Importance: Reduces manual handling, improves efficiency, and minimizes damage risks during transport.

7. Cleaning Equipment

After reflow soldering, excess flux residues may remain on PCBs, which can affect performance and reliability.

- Function: Cleans PCBs using solvents or ultrasonic cleaning methods.

- Importance: Ensures that PCBs are free from contaminants before final inspection or testing.

8. Docking Stations

These stations serve as connection points between different machines in an SMT line, facilitating seamless transitions between processes.

- Function: Provides a stable platform for transferring PCBs between machines.

- Importance: Enhances workflow efficiency by reducing downtime during product transfers.

9. Conveyor Systems

Conveyor systems transport PCBs between different stages of production automatically.

- Function: Moves PCBs through various machines in a predefined sequence.

- Importance: Streamlines operations by minimizing manual interventions and maintaining a continuous flow of materials.

10. Software Management Systems

Advanced software solutions monitor and control SMT lines, providing real-time data on production metrics.

- Function: Tracks machine performance, production rates, and quality metrics.

- Importance: Helps optimize processes by identifying bottlenecks or inefficiencies in real-time.

Additional Equipment Considerations

While the above equipment forms the core of an SMT line, several additional tools can enhance functionality and efficiency:

Solder Paste Mixer

A solder paste mixer ensures that solder powder is mixed evenly with flux before application on PCBs. This consistency is crucial for achieving optimal printing results during solder paste application.

- Function: Mixes solder powder with flux to create a uniform paste.

- Importance: A well-mixed paste leads to better adhesion during reflow soldering and reduces defects in finished products.

Glue Dispensing Machines

In some applications where additional bonding is required, glue dispensing machines can apply adhesive materials alongside solder paste to secure components effectively.

- Function: Dispenses precise amounts of adhesive onto designated areas of the PCB.

- Importance: Enhances component stability, especially for larger parts or those subject to mechanical stress.

Benefits of Implementing an SMT Line

Implementing an SMT line offers numerous advantages over traditional through-hole technology:

- *Increased Production Speed:* Automated processes significantly reduce assembly time compared to manual methods.

- *Higher Component Density:* SMT allows more components to be placed on both sides of a PCB, leading to smaller device footprints.

- *Improved Reliability:* The precision of automated placement reduces errors associated with manual assembly.

- *Cost Efficiency:* Reduced labor costs and material waste contribute to lower overall production costs.

Challenges in SMT Assembly

Despite its advantages, there are challenges associated with setting up and maintaining an SMT line:

- *Initial Investment:* The cost of purchasing advanced machinery can be significant.

- *Complexity:* Operating an SMT line requires skilled personnel who understand both machine operation and electronics.

- *Maintenance Needs:* Regular maintenance is necessary to keep equipment running smoothly and avoid production delays.

Conclusion

Establishing a successful SMT line requires careful selection and integration of various specialized equipment tailored to each stage of the assembly process. From solder paste printing to automated inspection systems, each piece of machinery plays a vital role in ensuring high-quality production while maximizing efficiency. As technology advances, continuous improvements in SMT equipment will further enhance productivity and product reliability in electronics manufacturing.

In summary, investing in a well-equipped SMT line not only streamlines operations but also positions manufacturers competitively within the rapidly evolving electronics market.

FAQs

1. What is Surface Mount Technology (SMT)?

SMT is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs compared to traditional through-hole technology.

2. What role does a pick-and-place machine play in an SMT line?

The pick-and-place machine accurately places surface-mount devices (SMDs) onto PCB pads coated with solder paste, significantly speeding up the assembly process while ensuring precise placement.

3. Why is reflow soldering important in SMT assembly?

Reflow soldering melts the solder paste applied to PCB pads, creating permanent electrical connections between components and the board, which are crucial for device functionality.

4. How does automated optical inspection (AOI) improve quality control?

AOI uses cameras to automatically inspect assembled PCBs for defects such as misalignment or insufficient solder joints, allowing for early detection of issues before products reach consumers.

5. What benefits do conveyor systems provide in an SMT line?

Conveyor systems automate the transport of PCBs between different stages of production, enhancing workflow efficiency by minimizing manual handling and ensuring a continuous flow of materials throughout the assembly process.

Citations:

[1] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[2] https://pcbpit.com/what-is-an-smt-line/

[3] https://www.sonicmfg.com/what-are-the-advantages-of-surface-mount-technology-in-pcba/

[4] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[5] https://rushpcb.com/smt-components/

[6] https://www.pcbgogo.com/Article/Why_SMT_Technology_Benefit_PCB_Assembly_.html

[7] https://www.raypcb.com/pcb-assembly-equipment/

[8] https://minearc.com/what-is-an-smt-line/

[9] https://geospacemfg.com/blog/smt-assembly-technology/

[10] https://www.wevolver.com/article/smt-process

[11] https://www.itechsmt.com/blogs/news/smt-equipment-list-for-your-new-smt-manufacturing

[12] https://blog.matric.com/what-is-smt-assembly

[13] https://www.flason-smt.com/new/Must-Know-SMT-PCB-Assembly-Line-Equipment.html

[14] https://jhdpcb.com/blog/smt-manufacturing-technology/

[15] https://v2smt.com/smt-equipment-selecction-guidelines/

[16] https://www.linkedin.com/pulse/essential-equipment-complete-smt-production-line-sthlpcba-54nrc

[17] https://novaenginc.com/understanding-the-role-of-surface-mount-technology-in-circuit-board-assembly/

[18] https://core-emt.com/smt-full-line-up