Content Menu

● Introduction

● Understanding Surface Mount Devices (SMD)

>> What Are SMDs?

>> Types of SMD Components

● The Advantages of SMD Technology

>> Space Efficiency

>> Improved Electrical Performance

>> Automated Assembly

>> Cost Efficiency

>> Design Flexibility

● The Manufacturing Process of SMDs

>> PCB Design

>> Application of Solder Paste

>> Component Placement

>> Reflow Soldering

>> Quality Control

● Challenges Associated with SMD Technology

>> Higher Complexity

>> Repair and Rework Difficulties

>> Sensitivity to Handling

● Conclusion

● FAQ

>> 1. What is the difference between SMT and SMD?

>> 2. What types of components can be classified as SMD?

>> 3. Why are SMDs preferred over traditional through-hole components?

>> 4. What challenges do manufacturers face when using SMD technology?

>> 5. How does automated assembly benefit the production of SMDs?

Introduction

In the realm of electronics manufacturing, the acronym SMD stands for Surface Mount Device. This term refers to electronic components that are designed to be mounted directly onto the surface of a printed circuit board (PCB). The introduction of SMD technology has significantly transformed the way electronic devices are produced, enabling manufacturers to create smaller, lighter, and more efficient products.

Understanding Surface Mount Devices (SMD)

What Are SMDs?

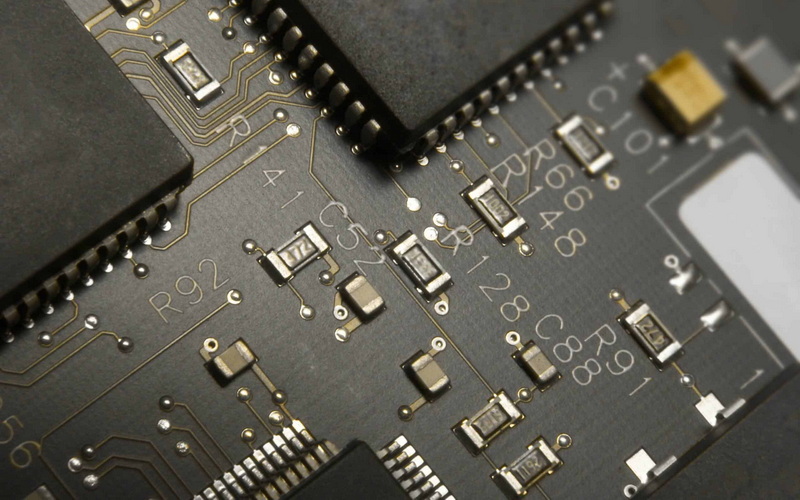

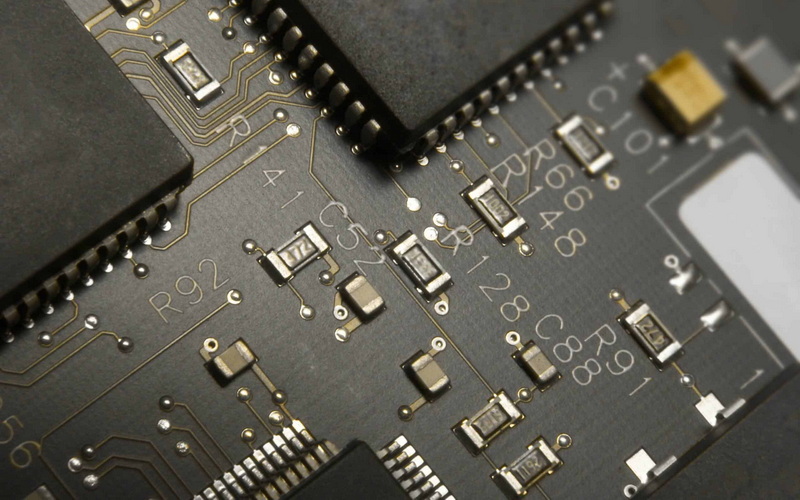

Surface Mount Devices (SMDs) are compact electronic components that eliminate the need for traditional through-hole mounting methods. In through-hole technology, components are inserted into holes drilled into the PCB and soldered from the underside. In contrast, SMDs are soldered directly onto the surface of the PCB, which allows for a more efficient use of space and facilitates higher component density.

Types of SMD Components

SMDs encompass a wide range of electronic components, including:

- Active Components: These require an external power source to operate and include transistors, integrated circuits (ICs), and sensors.

- Passive Components: These do not require power to function actively and include resistors, capacitors, inductors, and diodes.

The versatility of SMDs allows them to be used in various applications, from consumer electronics to industrial machinery.

The Advantages of SMD Technology

The adoption of SMD technology has brought numerous benefits to electronics manufacturing:

Space Efficiency

SMDs are typically smaller than their through-hole counterparts. This compact size allows manufacturers to design smaller devices with higher functionality. As a result, products like smartphones and tablets can incorporate more features without increasing their physical dimensions.

Improved Electrical Performance

Because SMDs have shorter lead lengths compared to traditional components, they offer better electrical performance. This is particularly important in high-frequency applications where signal integrity is crucial. Shorter connections reduce parasitic inductance and capacitance, leading to enhanced circuit performance.

Automated Assembly

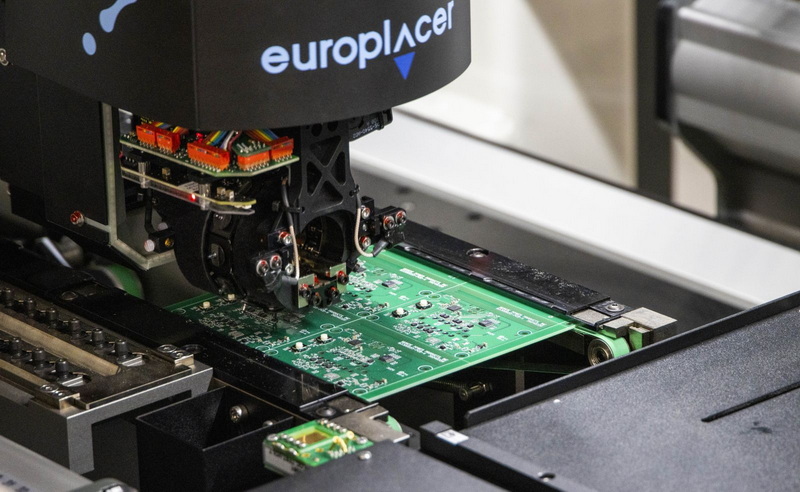

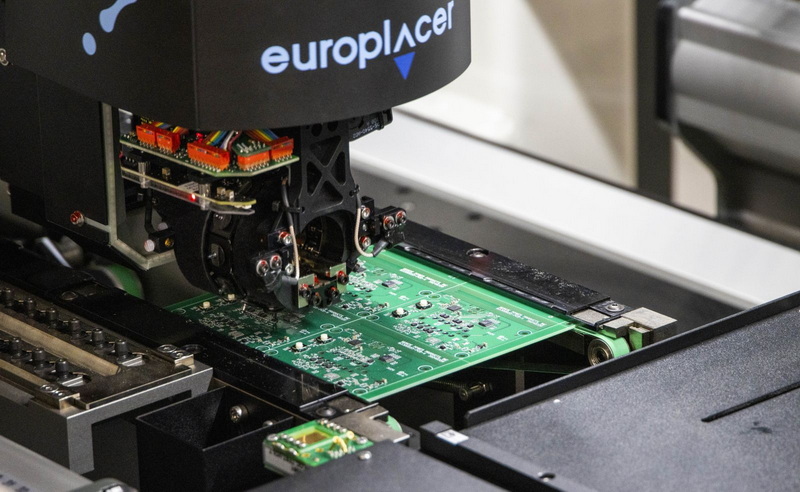

The compatibility of SMDs with automated assembly processes significantly increases production speed and accuracy. Automated placement machines can quickly position and solder thousands of SMDs per hour, drastically reducing manufacturing time and minimizing human error.

Cost Efficiency

While the initial investment in SMD equipment may be higher than traditional methods, mass production leads to lower unit costs. The efficiency gained through automation also contributes to overall cost savings in labor and materials.

Design Flexibility

SMD technology allows for greater freedom in PCB design. Designers can arrange components more densely on the board, enabling innovative layouts that were not feasible with through-hole technology.

The Manufacturing Process of SMDs

The process of manufacturing devices using SMD technology involves several key steps:

PCB Design

Efficient PCB design is crucial for optimizing the arrangement of SMD components. Designers must consider both electrical properties and physical layout to ensure optimal performance.

Application of Solder Paste

Solder paste is applied to the PCB pads where the SMDs will be placed. This paste consists of tiny metal particles mixed with flux and is essential for creating reliable solder joints.

Component Placement

Automated placement machines use precise vision systems to detect component positions on the PCB and place them accurately on the solder paste.

Reflow Soldering

After placement, the PCBs are heated in a reflow oven where the solder paste melts and forms solid connections between the SMDs and the PCB pads.

Quality Control

Following assembly, PCBs undergo rigorous quality control checks to ensure that all components are correctly placed and soldered. Automated optical inspection systems help identify any defects or misalignments.

Challenges Associated with SMD Technology

Despite its advantages, there are challenges associated with using SMD technology:

Higher Complexity

The manufacturing process for SMDs is more complex than traditional methods. Specialized equipment and techniques are required, which may necessitate additional training for personnel.

Repair and Rework Difficulties

Repairing or replacing individual SMDs can be challenging due to their small size and delicate nature. This requires specialized tools and expertise.

Sensitivity to Handling

SMDs are more susceptible to damage from mishandling or electrostatic discharge (ESD). Proper handling procedures must be followed to avoid damaging these components during assembly or repair.

Conclusion

In conclusion, Surface Mount Devices (SMDs) have revolutionized electronics manufacturing by enabling smaller, lighter, and more efficient designs. Their ability to be mounted directly onto PCBs without drilling holes has led to significant advancements in circuit design and production efficiency. As technology continues to evolve, understanding the role of SMDs remains crucial for anyone involved in electronics design or manufacturing.

With their numerous advantages—such as space efficiency, improved electrical performance, automated assembly capabilities, cost-effectiveness, and design flexibility—SMDs have become a standard in modern electronics production.

FAQ

1. What is the difference between SMT and SMD?

SMT stands for Surface Mount Technology, which refers to the method used for mounting electronic components on PCBs. In contrast, SMD refers specifically to the actual electronic components that are mounted using this technology.

2. What types of components can be classified as SMD?

Common types of SMD components include resistors, capacitors, diodes, transistors, integrated circuits (ICs), and sensors. Both active and passive components can be designed as surface mount devices.

3. Why are SMDs preferred over traditional through-hole components?

SMDs are preferred because they allow for more compact designs with higher component density on PCBs. They also facilitate automated assembly processes that improve production speed and reduce costs.

4. What challenges do manufacturers face when using SMD technology?

Manufacturers may face challenges such as higher complexity in manufacturing processes, difficulties in repairing or replacing individual components due to their small size, and sensitivity issues related to handling or ESD.

5. How does automated assembly benefit the production of SMDs?

Automated assembly benefits SMD production by increasing speed and accuracy during placement and soldering processes. It allows manufacturers to produce large quantities of PCBs efficiently while minimizing human error.