Content Menu

● Understanding SMT and Its Importance

● Key Responsibilities of an SMT Manufacturing Engineer

● Skills Required for an SMT Manufacturing Engineer

● Educational Background

● Career Path and Opportunities

● Challenges Faced by SMT Manufacturing Engineers

● Conclusion

● Related Questions

>> 1. What qualifications do I need to become an SMT manufacturing engineer?

>> 2. What are the primary tools used by an SMT manufacturing engineer?

>> 3. How does an SMT engineer ensure product quality?

>> 4. What challenges do SMT engineers face in their work?

>> 5. What career advancement opportunities exist for SMT engineers?

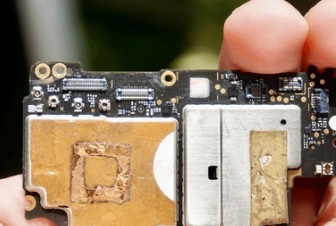

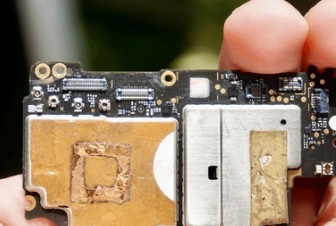

Surface Mount Technology (SMT) manufacturing engineers play a crucial role in the production of electronic devices by overseeing the assembly of printed circuit boards (PCBs). Their responsibilities range from ensuring the effectiveness of SMT processes to troubleshooting and improving manufacturing efficiencies. This article delves into the various aspects of an SMT manufacturing engineer's role, including their responsibilities, required skills, educational background, and the significance of their work in the electronics industry.

Understanding SMT and Its Importance

Surface Mount Technology is a method used to mount electronic components directly onto the surface of PCBs. This technology has revolutionized the electronics industry by allowing for smaller, more efficient designs compared to traditional through-hole mounting techniques. The advantages of SMT include:

- Reduced Size: Components can be placed closer together, allowing for more compact circuit designs.

- Higher Performance: SMT components typically have better electrical performance due to shorter lead lengths.

- Cost Efficiency: The manufacturing process is often less expensive due to reduced material costs and improved automation capabilities.

Given these benefits, SMT has become a standard in PCB manufacturing, making the role of an SMT manufacturing engineer essential for ensuring high-quality production.

Key Responsibilities of an SMT Manufacturing Engineer

An SMT manufacturing engineer is responsible for several critical tasks throughout the PCB assembly process. These include:

- Process Development: Designing and improving SMT assembly processes to enhance efficiency and quality. This involves selecting appropriate materials, equipment, and methods for production.

- Equipment Management: Operating and maintaining SMT machinery such as pick-and-place machines, solder paste printers, and reflow ovens. Engineers must ensure that these machines are calibrated correctly to avoid defects during production.

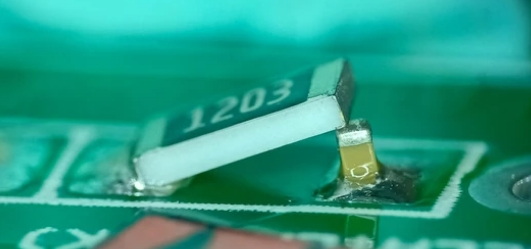

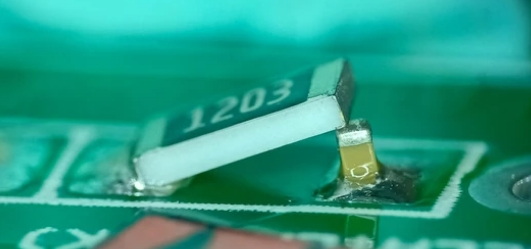

- Quality Control: Implementing quality assurance measures to inspect finished products for defects. This includes using automated optical inspection (AOI) systems and conducting manual inspections to ensure compliance with industry standards.

- Troubleshooting: Identifying and resolving issues that arise during the manufacturing process. This may involve analyzing defects, adjusting process parameters, or collaborating with design engineers to improve product designs.

- Documentation: Keeping detailed records of production processes, including materials used, machine settings, and inspection results. This documentation is essential for traceability and continuous improvement efforts.

Skills Required for an SMT Manufacturing Engineer

To excel in their roles, SMT manufacturing engineers must possess a blend of technical and soft skills:

- Technical Proficiency: A strong understanding of electronics, materials science, and mechanical engineering principles is essential. Familiarity with IPC standards (such as IPC-A-610) is also crucial.

- Analytical Skills: The ability to analyze complex problems and develop effective solutions is vital in this role. Engineers must be adept at using statistical process control techniques to monitor production quality.

- Communication Skills: Effective communication is necessary for collaborating with team members across various departments, including design engineering, quality assurance, and production management.

- Attention to Detail: Precision is critical in electronics manufacturing; thus, engineers must be meticulous in their work to prevent defects.

Educational Background

Most SMT manufacturing engineers hold a bachelor's degree in engineering disciplines such as electrical engineering, mechanical engineering, or industrial engineering. Relevant coursework typically includes:

- Physics

- Materials Science

- Manufacturing Processes

- Electronics Design

In addition to formal education, practical experience through internships or co-op programs can significantly enhance an engineer's skill set and employability.

Career Path and Opportunities

The demand for skilled SMT manufacturing engineers continues to grow as technology advances. Engineers can pursue various career paths within the electronics industry, including:

- Process Engineering: Focusing on optimizing manufacturing processes for efficiency and quality.

- Quality Assurance Engineering: Ensuring that products meet rigorous quality standards before they reach consumers.

- Project Management: Overseeing projects related to new product development or process improvements within a manufacturing facility.

As engineers gain experience, they may also move into leadership roles such as department managers or technical directors.

Challenges Faced by SMT Manufacturing Engineers

Despite the rewarding nature of their work, SMT manufacturing engineers face several challenges:

- Rapid Technological Changes: Keeping up with advancements in technology requires continuous learning and adaptation. Engineers must stay informed about new materials, equipment, and processes that could impact production.

- Quality Assurance: Maintaining high-quality standards while meeting production deadlines can be challenging. Engineers must balance speed with accuracy to minimize defects.

- Cost Management: As companies strive to reduce costs while improving product quality, engineers must find ways to optimize processes without sacrificing performance.

Conclusion

In summary, SMT manufacturing engineers are integral to the success of modern electronics production. Their expertise in optimizing assembly processes ensures that products are manufactured efficiently while meeting stringent quality standards. As technology continues to evolve, the role of these engineers will remain critical in driving innovation within the industry. With a solid educational foundation and a commitment to continuous improvement, aspiring engineers can look forward to a rewarding career in this dynamic field.

Related Questions

1. What qualifications do I need to become an SMT manufacturing engineer?

To become an SMT manufacturing engineer, you typically need a bachelor's degree in engineering (electrical or mechanical preferred) along with relevant experience in electronics manufacturing or internships related to PCB assembly processes.

2. What are the primary tools used by an SMT manufacturing engineer?

SMT manufacturing engineers use various tools including pick-and-place machines, solder paste printers, reflow ovens, automated optical inspection systems (AOI), and software for programming machine operations.

3. How does an SMT engineer ensure product quality?

An SMT engineer ensures product quality through rigorous inspection processes that include automated optical inspection (AOI), manual checks during production stages, and adherence to IPC standards for workmanship.

4. What challenges do SMT engineers face in their work?

SMT engineers face challenges such as keeping up with rapid technological changes, maintaining high-quality standards under tight deadlines, managing costs effectively while optimizing production processes.

5. What career advancement opportunities exist for SMT engineers?

SMT engineers can advance into roles such as process engineering specialists, quality assurance managers, project managers in new product development or even executive positions overseeing entire production facilities.