Content Menu

● Introduction to SMT Conveyors

>> Types of SMT Conveyors

● Common Issues in PCB Handling

● Benefits of Using SMT Conveyors

● Role of SMT Conveyors in Preventing Common Issues

● Integration of SMT Conveyors with Other Equipment

● Future Developments in SMT Conveyors

>> Smart Technologies in SMT Conveyors

● Case Studies: Successful Implementation of SMT Conveyors

● Best Practices for Implementing SMT Conveyors

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT conveyors in PCB handling?

>> 2. How do SMT conveyors prevent PCB damage during handling?

>> 3. What types of SMT conveyors are available for different applications?

>> 4. How do SMT conveyors enhance safety in the production environment?

>> 5. Can SMT conveyors be integrated with advanced technologies like AI and IoT?

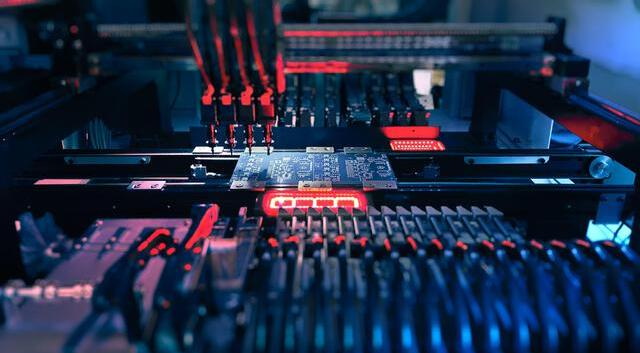

In the realm of Surface Mount Technology (SMT), conveyors play a pivotal role in ensuring the efficient and precise handling of Printed Circuit Boards (PCBs). These conveyors are designed to transport PCBs through various stages of the assembly process, from loading and inspection to soldering and packaging. By utilizing SMT conveyors, manufacturers can significantly reduce common issues associated with manual handling, such as misalignment, damage, and production bottlenecks. This article will delve into the common problems that SMT conveyors can help avoid in PCB handling and explore the benefits of integrating these systems into SMT production lines.

Introduction to SMT Conveyors

SMT conveyors are automated systems used in the electronics industry to move PCBs and components along preset paths. They are crucial for maintaining efficiency, accuracy, and safety in the assembly process. The use of conveyors in SMT lines helps to streamline production by ensuring that PCBs are consistently positioned and aligned correctly for each stage of assembly. This precision is essential for achieving high-quality products and minimizing defects.

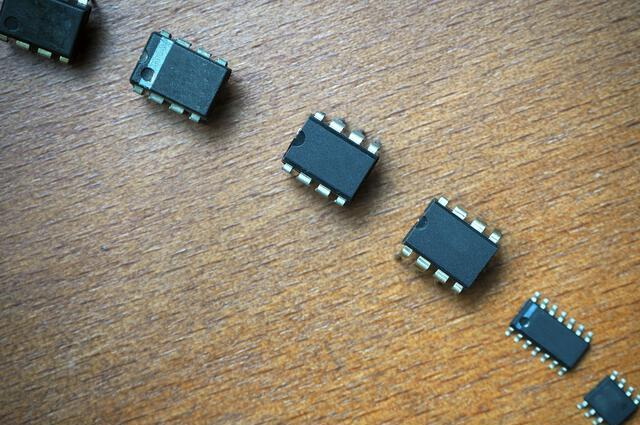

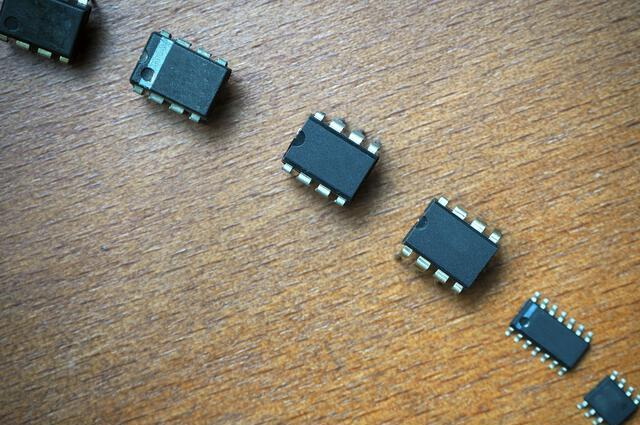

Types of SMT Conveyors

There are several types of SMT conveyors, each designed to meet specific needs within the production line:

- PCB Belt Conveyors: These are popular for transferring components due to their accuracy, reliability, and cost-effectiveness. They consist of rotating belts driven by motors, making them adaptable for use with multiple production machines.

- Inspection Conveyors: Equipped with lighting and magnification features, these conveyors allow for close examination of PCBs during assembly, enhancing quality control.

- Slat Chain Conveyors: Ideal for delicate or oddly-shaped PCBs, these conveyors use interlocking slats to provide stability and precision.

- Link Conveyors: Used in environments requiring precision and synchronization, these conveyors consist of interlocking links that provide a stable platform for PCB transport.

- Buffer Conveyors: These are used to temporarily store PCBs between assembly stages, preventing bottlenecks and ensuring smoother operations.

- Turn Conveyors: Designed to change the direction of PCB flow, allowing for smooth transitions between different assembly stations.

Common Issues in PCB Handling

Without the use of SMT conveyors, PCB handling can be plagued by several issues:

1. Misalignment and Incorrect Orientation: Manual handling increases the risk of misaligning PCBs, which can lead to defective products due to incorrect component placement.

2. Damage to PCBs: Manual movement can cause mechanical stress or accidental drops, leading to PCB damage or warpage.

3. Production Bottlenecks: Manual handling can slow down production, leading to bottlenecks and reduced throughput.

4. Safety Risks: Manual handling poses safety risks, such as accidents from falling PCBs or collisions.

Benefits of Using SMT Conveyors

SMT conveyors help mitigate these issues by providing several key benefits:

- Increased Efficiency: Conveyors automate the movement of PCBs, reducing manual intervention and increasing production speed.

- Improved Accuracy: By maintaining precise alignment and orientation, conveyors ensure accurate component placement, reducing defects.

- Enhanced Safety: Automated systems minimize the risk of accidents associated with manual handling.

- Reduced Downtime: Conveyors help maintain a continuous flow of PCBs, reducing bottlenecks and downtime.

Role of SMT Conveyors in Preventing Common Issues

SMT conveyors are instrumental in preventing common issues in PCB handling by ensuring that PCBs are moved efficiently and accurately through the production line. Here are some ways conveyors help avoid these issues:

- Preventing Misalignment: Conveyors maintain precise alignment of PCBs, ensuring that components are placed correctly.

- Reducing Damage: Automated movement minimizes mechanical stress and accidental drops, protecting PCBs from damage.

- Minimizing Bottlenecks: Continuous flow of PCBs prevents production bottlenecks, maintaining high throughput rates.

- Enhancing Safety: By reducing manual handling, conveyors lower the risk of accidents and injuries.

Integration of SMT Conveyors with Other Equipment

SMT conveyors are often integrated with other equipment in the production line to enhance efficiency and quality:

- Pick and Place Machines: Conveyors ensure that PCBs are accurately positioned for component placement.

- Reflow Ovens: Conveyors transport PCBs to and from reflow ovens, maintaining precise temperature control.

- Inspection Machines: Conveyors facilitate smooth movement of PCBs through inspection stages, ensuring quality control.

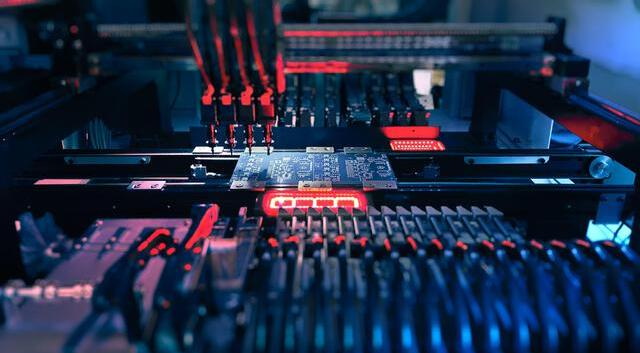

Future Developments in SMT Conveyors

As technology advances, SMT conveyors are becoming more sophisticated, incorporating smart technologies like Artificial Intelligence (AI) and the Internet of Things (IoT). These advancements enable real-time monitoring, predictive maintenance, and adaptive processing, further enhancing machine efficiency and minimizing downtime.

Smart Technologies in SMT Conveyors

The integration of AI and IoT in SMT conveyors offers several benefits:

- Real-time Monitoring: Allows for immediate detection of issues, enabling prompt intervention and reducing production downtime.

- Predictive Maintenance: Enables maintenance to be scheduled based on actual usage and performance data, preventing unexpected breakdowns.

- Adaptive Processing: Conveyors can adjust their speed and operation based on production needs, optimizing efficiency and throughput.

Case Studies: Successful Implementation of SMT Conveyors

Several companies have successfully implemented SMT conveyors to improve their PCB assembly processes:

- Increased Throughput: A leading electronics manufacturer reported a 30% increase in production throughput after integrating SMT conveyors into their assembly line.

- Reduced Defects: Another company saw a significant reduction in defects due to improved alignment and positioning of PCBs facilitated by SMT conveyors.

- Enhanced Safety: By automating PCB handling, a major electronics firm reduced workplace accidents by over 50%.

Best Practices for Implementing SMT Conveyors

To maximize the benefits of SMT conveyors, manufacturers should follow best practices during implementation:

- Assess Production Needs: Evaluate the specific requirements of your production line to select the most appropriate conveyor type.

- Integrate with Existing Systems: Ensure seamless integration with other equipment to maintain workflow efficiency.

- Train Personnel: Provide comprehensive training to operators to ensure they can effectively manage and maintain the conveyor systems.

Conclusion

In conclusion, SMT conveyors are essential for avoiding common issues in PCB handling, such as misalignment, damage, and production bottlenecks. By providing a seamless and efficient flow of PCBs through the assembly process, conveyors improve accuracy, safety, and productivity. As technology continues to evolve, the integration of SMT conveyors with advanced systems will remain crucial for achieving operational excellence in the electronics manufacturing industry.

Frequently Asked Questions

1. What are the primary benefits of using SMT conveyors in PCB handling?

- The primary benefits include increased efficiency, improved accuracy, enhanced safety, and reduced downtime. SMT conveyors automate the movement of PCBs, ensuring precise alignment and minimizing manual intervention.

2. How do SMT conveyors prevent PCB damage during handling?

- SMT conveyors prevent PCB damage by minimizing mechanical stress and accidental drops associated with manual handling. They ensure a smooth and controlled movement of PCBs through the production line.

3. What types of SMT conveyors are available for different applications?

- There are several types of SMT conveyors, including PCB belt conveyors, inspection conveyors, slat chain conveyors, link conveyors, buffer conveyors, and turn conveyors. Each type is designed to meet specific needs within the production line.

4. How do SMT conveyors enhance safety in the production environment?

- SMT conveyors enhance safety by reducing the need for manual handling, which minimizes the risk of accidents such as falling PCBs or collisions. Automated systems provide a safer working environment.

5. Can SMT conveyors be integrated with advanced technologies like AI and IoT?

- Yes, modern SMT conveyors can be integrated with advanced technologies like AI and IoT. This integration enables real-time monitoring, predictive maintenance, and adaptive processing, further optimizing production efficiency and minimizing downtime.