Content Menu

● Introduction to BGA Rework

>> Types of BGA Rework Equipment

● Common Issues Resolved by BGA Rework Equipment

>> 1. Warped BGAs

>> 2. Residue Cleaning

>> 3. Pad Damage During BGA Removal

>> 4. Incorrect BGA Orientation or Joint Bridging

>> 5. Excessive Solder Joint Voiding

● Choosing the Right BGA Rework Equipment

● Future Trends and Innovations in BGA Rework

>> Integration of AI in BGA Rework

>> Advancements in Heating Technologies

● Benefits of BGA Rework Equipment

● Challenges in BGA Rework

● Future Trends in BGA Rework

>> Integration of Smart Technologies

>> Compact and Automated Solutions

● Emerging Trends in BGA Rework

>> Impact of Industry 4.0

● Conclusion

● FAQs

>> 1. What are the main types of BGA rework equipment?

>> 2. How do you prevent warping during BGA rework?

>> 3. What are the advantages of infrared (IR) BGA rework stations?

>> 4. How important is technician training in BGA rework?

>> 5. What are the benefits of using BGA rework equipment in electronics manufacturing?

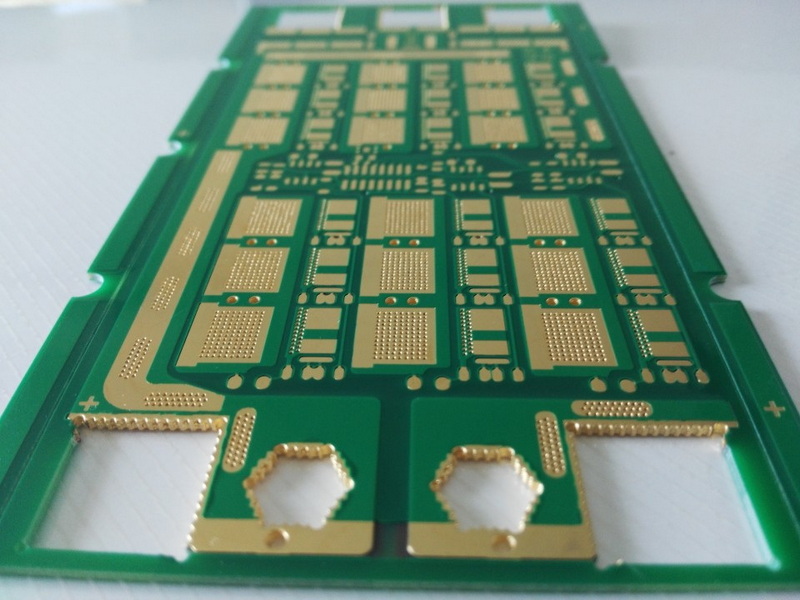

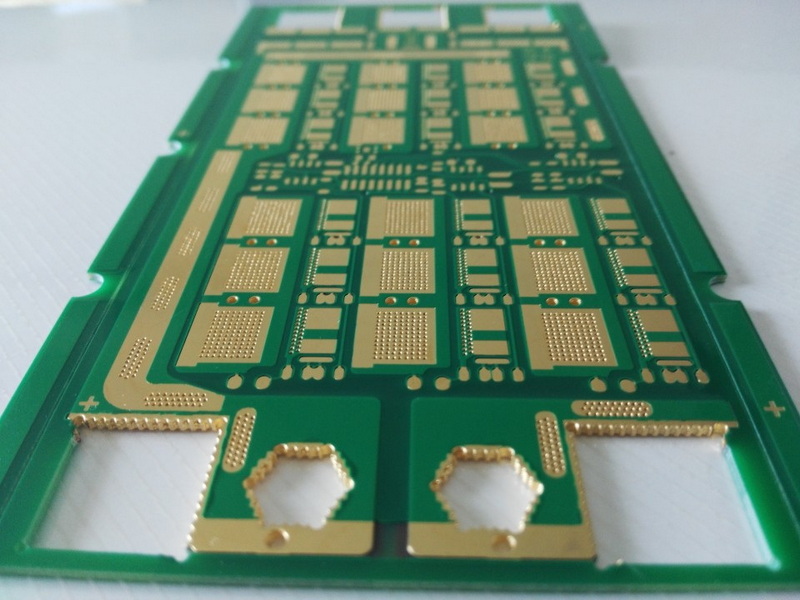

Ball Grid Array (BGA) rework is a critical process in the electronics manufacturing and repair industry, involving the removal and replacement of BGA components on printed circuit boards (PCBs). This process requires specialized equipment and techniques to ensure successful rework without damaging the surrounding components or the PCB itself. BGA rework equipment plays a vital role in addressing various common issues that arise during the manufacturing and repair of electronic devices.

Introduction to BGA Rework

BGA components are widely used in electronic devices due to their compact size and high performance. However, their complex structure and the challenges associated with their rework make it essential to use high-quality BGA rework equipment. The process involves several steps, including inspection, desoldering, cleaning, component placement, and soldering, all of which require precise control over temperature and airflow to prevent damage to the components or the PCB.

Types of BGA Rework Equipment

There are several types of BGA rework equipment available, each designed to address specific challenges in the rework process:

- BGA Rework Stations: These are complete systems designed for the removal and installation of BGA components. They offer precise temperature control and hot air delivery mechanisms to ensure successful BGA rework. Rework stations can be categorized into hot air and infrared (IR) types, each with its advantages and disadvantages.

- BGA Preheaters: Used to evenly distribute heat across the circuit board during BGA removal or installation, preventing warping and damage.

- BGA Soldering Stations: Specialized for reflow soldering of BGA components, providing controlled heating and precise solder placement.

Common Issues Resolved by BGA Rework Equipment

1. Warped BGAs

Warped BGAs occur due to thermal stress, leading to uneven connections and potential failure. BGA rework equipment helps mitigate this issue by providing controlled heating, ensuring even temperature distribution across the BGA and PCB. Pre-baking the BGA and PCB can also reduce moisture content, which contributes to warping during reflow.

2. Residue Cleaning

Residues from flux or failed solder joints can be trapped under the BGA, affecting electrical performance and reliability. Effective cleaning methods, such as ultrasonic cleaners or specialized cleaning solutions, are used to remove residues before reballing or placing a new BGA.

3. Pad Damage During BGA Removal

Delicate PCB pads can be damaged during BGA removal, leading to connectivity issues. High-quality rework stations with controlled heating and vacuum lifts help gently remove BGAs without damaging the pads. Well-trained technicians are crucial in minimizing pad damage.

4. Incorrect BGA Orientation or Joint Bridging

Incorrect orientation or joint bridging can lead to additional rework thermal cycles and increased risk of damage. Proper equipment and skilled technicians are essential in preventing these issues.

5. Excessive Solder Joint Voiding

Excessive voiding in solder joints can compromise the integrity of the BGA component. Proper solder paste application and thermal profiling help minimize void formation.

Choosing the Right BGA Rework Equipment

Selecting the appropriate BGA rework equipment is crucial for successful rework operations. Factors to consider include:

- Heating Technology: Hot air or infrared, each with its own advantages and limitations. Hot air stations are versatile but may require more maintenance, while IR stations offer precise heating with less airflow disturbance.

- Temperature Range and Accuracy: Ensuring precise temperature control to prevent damage to components.

- Nozzle Compatibility: Ensuring compatibility with different BGA component sizes.

- Support for Lead-Free Soldering: Essential for working with lead-free solder.

Future Trends and Innovations in BGA Rework

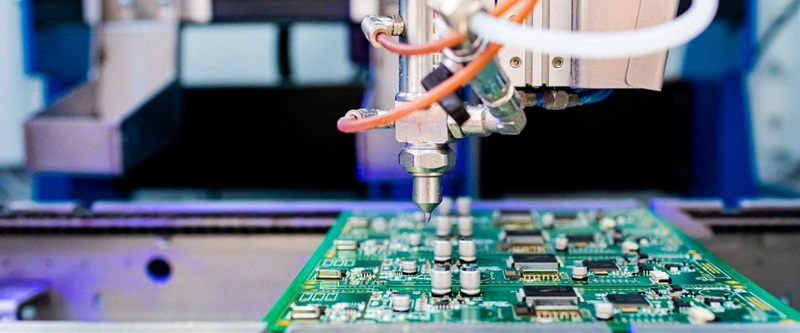

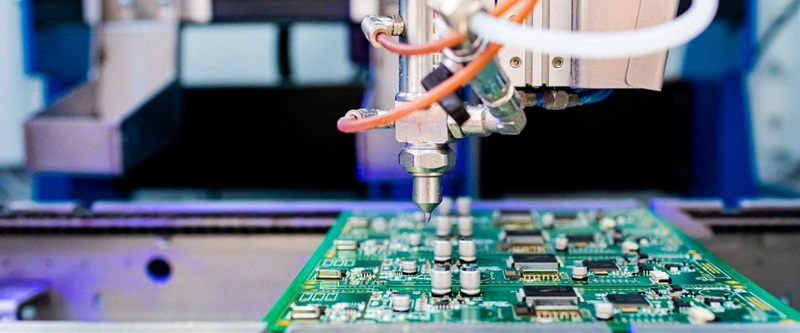

The future of BGA rework equipment looks promising, with advancements in technology and the integration of AI. Manufacturers can expect increased efficiencies, reduced downtime, and improved repair quality. AI algorithms are being used to automate tasks such as alignment and placement of BGA components, reducing human error and increasing productivity.

Integration of AI in BGA Rework

AI integration in BGA rework equipment enables predictive maintenance by monitoring equipment performance and flagging potential issues before they escalate. This proactive approach ensures uninterrupted operations and increases the overall lifespan of the equipment.

Advancements in Heating Technologies

Recent advancements include the integration of reflow ovens within BGA rework equipment, allowing for a more streamlined process. This integration eliminates the need for separate heating equipment and provides better control over the reflow process, resulting in improved yield rates and reduced production time.

Benefits of BGA Rework Equipment

Investing in BGA rework equipment offers several benefits:

- Cost-Effectiveness: Extends the life of PCBs, reducing the need for new assemblies.

- Efficiency: Allows for precise and rapid rework, increasing productivity.

- Accuracy: Enables technicians to perform delicate tasks without damaging components.

Challenges in BGA Rework

Despite the advancements, BGA rework still presents several challenges:

- Large BGA Packages: Handling very large BGA packages requires upgraded vision systems and bottom heaters to ensure uniform heating.

- Underfilled BGAs: Removing underfilled BGAs can be challenging due to the strong adhesion between the BGA and the PCB.

- Mirrored BGAs: When BGAs are placed back-to-back on a double-sided PCB, rework becomes more complex due to the risk of damaging the underside BGA during heating.

Future Trends in BGA Rework

As technology advances, BGA rework equipment is evolving to meet the demands of more complex and miniaturized electronics. The integration of AI and machine learning algorithms is expected to enhance the precision and speed of rework processes. These advancements will enable real-time monitoring and predictive maintenance, reducing downtime and improving overall efficiency.

Integration of Smart Technologies

The future of BGA rework will see increased use of smart technologies, including automated systems that can analyze data from previous repairs to optimize future operations. This will lead to faster and more accurate placements, reducing the reliance on manual intervention and minimizing errors.

Compact and Automated Solutions

There is a growing demand for compact and automated rework solutions that can handle complex BGA components efficiently. These solutions will be critical in industries requiring high functionality and reliability, such as aerospace and automotive electronics.

Emerging Trends in BGA Rework

Emerging trends in BGA rework include the use of advanced thermal profiling technologies and eco-friendly rework systems. These innovations are driven by the need for greater miniaturization and complexity in electronics, requiring adaptive strategies that prioritize flexibility and efficiency.

Impact of Industry 4.0

The integration of Industry 4.0 technologies, such as machine vision and automation, will significantly enhance the precision and repeatability of rework processes. This will be crucial in meeting the demands of smart manufacturing and ensuring high-quality repairs.

By embracing these trends and innovations, the BGA rework industry is poised to overcome current challenges and drive business growth effectively.

Conclusion

BGA rework equipment is indispensable for resolving common issues encountered during the repair and maintenance of electronic devices. By providing precise control over temperature and airflow, these machines help prevent damage to components and PCBs, ensuring reliable and efficient rework operations. As technology advances, the demand for sophisticated BGA rework equipment continues to grow, emphasizing the importance of investing in high-quality machines and training skilled technicians.

FAQs

1. What are the main types of BGA rework equipment?

- The main types of BGA rework equipment include BGA rework stations, BGA preheaters, and BGA soldering stations. Each type serves specific functions in the rework process, such as removal, installation, and soldering of BGA components.

2. How do you prevent warping during BGA rework?

- Warping can be prevented by using controlled heating systems in BGA rework stations and preheaters. Additionally, pre-baking the BGA and PCB helps reduce moisture content, which can contribute to warping.

3. What are the advantages of infrared (IR) BGA rework stations?

- IR BGA rework stations offer silent operation and easier maintenance compared to hot air stations. They also provide precise heating, which can be beneficial for sensitive components.

4. How important is technician training in BGA rework?

- Technician training is crucial in BGA rework. Skilled technicians can recognize potential issues early, handle equipment effectively, and minimize the risk of component or PCB damage.

5. What are the benefits of using BGA rework equipment in electronics manufacturing?

- BGA rework equipment provides cost-effectiveness by extending PCB life, increases efficiency through precise and rapid rework, and ensures accuracy in delicate operations, thereby enhancing overall productivity and reliability.