Content Menu

● Understanding Mobile PCB SMT Process

● Key Challenges in Mobile PCB SMT Assembly

>> Miniaturization and Component Density

>> Signal Integrity and Electromagnetic Interference

>> Solder Paste Application and Reflow

>> Component Placement Accuracy

>> Quality Control and Inspection

● Emerging Solutions and Technologies

>> Advanced Materials and Designs

>> Improved Manufacturing Processes

>> Advanced Inspection and Testing

● Future Trends in Mobile PCB SMT Assembly

● Conclusion

● FAQ

>> 1. What is the most critical step in the mobile PCB SMT process?

>> 2. How does miniaturization affect mobile PCB SMT assembly?

>> 3. What role does automation play in mobile PCB SMT assembly?

>> 4. How are quality control challenges addressed in mobile PCB SMT assembly?

>> 5. What are the emerging trends in materials for mobile PCB SMT assembly?

● Citations:

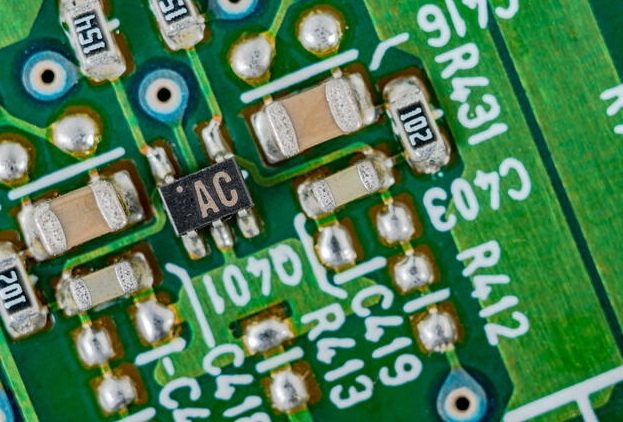

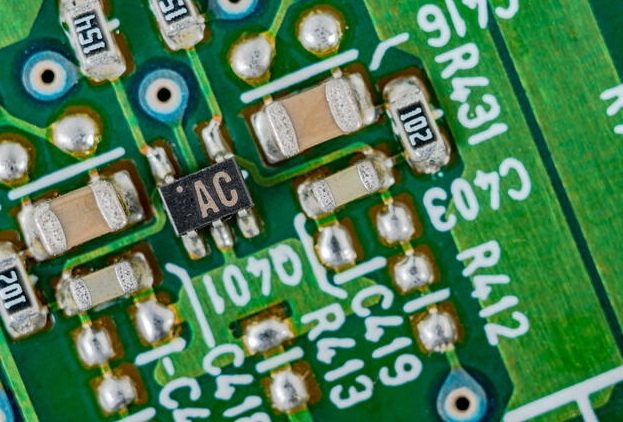

In the rapidly evolving world of mobile technology, the assembly of Printed Circuit Boards (PCBs) using Surface Mount Technology (SMT) is a critical process that faces numerous challenges. As mobile devices become increasingly compact and sophisticated, the demands on PCB assembly have grown exponentially. This article explores the common challenges encountered in mobile PCB SMT assembly and provides insights into potential solutions.

Understanding Mobile PCB SMT Process

Before delving into the challenges, it's essential to understand the basic steps involved in the mobile PCB SMT process. The process typically includes the following stages:

1. PCB Design and Preparation

2. Solder Paste Application

3. Component Placement

4. Reflow Soldering

5. Inspection and Quality Control

Each of these stages plays a crucial role in the overall quality and functionality of the final mobile device. However, as we'll explore, each stage also presents its own set of challenges that manufacturers must overcome.

Key Challenges in Mobile PCB SMT Assembly

Miniaturization and Component Density

One of the most significant challenges in mobile PCB SMT assembly is the ongoing trend towards miniaturization. As mobile devices become smaller and thinner, the PCBs inside them must follow suit. This reduction in size leads to increased component density, which presents several difficulties:

- Precise Component Placement: With components becoming smaller and packed more closely together, the margin for error in placement is drastically reduced. Even minor inaccuracies can lead to short circuits or connectivity issues[4].

- Solder Joint Reliability: Smaller components mean smaller solder joints, which can be more prone to failure under stress or thermal cycling[4].

- Heat Management: Increased component density can lead to heat buildup, potentially affecting the performance and lifespan of the device[9].

To address these challenges, manufacturers are investing in more precise pick-and-place machines and developing advanced thermal management strategies. Additionally, designers are focusing on optimizing component layouts to balance density with thermal considerations.

Signal Integrity and Electromagnetic Interference

As mobile devices operate at higher frequencies and process more data, maintaining signal integrity becomes increasingly challenging. The compact nature of mobile PCBs exacerbates this issue:

- Signal Path Optimization: Designers must carefully plan signal paths to minimize interference and maintain signal quality[4].

- EMI Shielding: With components packed closely together, electromagnetic interference (EMI) becomes a significant concern, potentially affecting device performance[9].

- Power Integrity: Ensuring stable power delivery across the board becomes more complex as component density increases.

To combat these issues, designers are employing advanced simulation tools to optimize signal paths and implementing sophisticated EMI shielding techniques. The use of embedded components and advanced PCB materials is also becoming more common to improve signal integrity.

Solder Paste Application and Reflow

The solder paste application and reflow processes are critical in SMT assembly, but they present unique challenges in mobile PCB production:

- Stencil Design: Creating stencils that accurately apply solder paste to increasingly small pads requires precision engineering[5].

- Solder Paste Volume Control: Applying the correct amount of solder paste is crucial. Too little can lead to weak joints, while too much can cause bridging between components[7].

- Reflow Profile Management: Achieving the optimal reflow profile becomes more challenging with the mix of component sizes and types found on mobile PCBs[10].

Manufacturers are addressing these challenges by using advanced stencil designs, implementing solder paste inspection (SPI) systems, and developing more sophisticated reflow ovens with precise temperature control.

Component Placement Accuracy

The accuracy of component placement is paramount in mobile PCB SMT assembly:

- Fine-Pitch Components: Many mobile devices use fine-pitch and ultra-fine-pitch components, which require extremely accurate placement[4].

- Component Variety: Mobile PCBs often feature a wide variety of component types and sizes, challenging pick-and-place machines to handle this diversity efficiently.

- Placement Speed vs. Accuracy: Balancing the need for high-speed production with the requirement for precise placement is an ongoing challenge.

To meet these challenges, manufacturers are investing in advanced pick-and-place machines with improved vision systems and placement algorithms. Some are also exploring the use of AI and machine learning to optimize component placement strategies.

Quality Control and Inspection

Ensuring the quality of assembled mobile PCBs is crucial but presents several challenges:

- Automated Optical Inspection (AOI): While AOI systems are essential, they must be continually updated to detect defects on increasingly complex and dense boards[8].

- X-ray Inspection: For components with hidden solder joints, such as BGAs, X-ray inspection is necessary but can be time-consuming and requires specialized equipment[8].

- Functional Testing: Developing comprehensive functional tests for complex mobile PCBs can be challenging and time-consuming.

To address these issues, manufacturers are implementing advanced AOI systems with AI capabilities, investing in high-resolution X-ray inspection equipment, and developing more sophisticated functional testing protocols.

Emerging Solutions and Technologies

As the mobile PCB SMT industry faces these challenges, several innovative solutions and technologies are emerging:

Advanced Materials and Designs

- Flexible and Rigid-Flex PCBs: These allow for more compact designs and can help address some of the space constraints in mobile devices.

- Embedded Components: By embedding passive components within the PCB layers, designers can save space and improve signal integrity.

- High-Density Interconnect (HDI) Technology: HDI allows for more compact designs with improved signal performance.

Improved Manufacturing Processes

- 3D Printing: Some manufacturers are exploring the use of 3D printing for certain PCB components or even entire boards.

- Laser Direct Imaging (LDI): This technology allows for more precise creation of PCB patterns, especially for fine-pitch components.

- Plasma Cleaning: Using plasma to clean PCBs before assembly can improve solder joint quality and reliability.

Advanced Inspection and Testing

- AI-Powered Inspection: Machine learning algorithms are being developed to improve the accuracy and speed of PCB inspection.

- In-Circuit Testing (ICT) Advancements: New ICT technologies are being developed to test increasingly complex and dense mobile PCBs more efficiently.

- Boundary Scan Testing: This technique is becoming more important for testing densely packed mobile PCBs with limited physical access points.

Future Trends in Mobile PCB SMT Assembly

Looking ahead, several trends are likely to shape the future of mobile PCB SMT assembly:

1. 5G and Beyond: As mobile devices move towards 5G and eventually 6G technologies, PCB designs will need to accommodate higher frequencies and more complex RF components.

2. Internet of Things (IoT) Integration: Mobile devices are increasingly becoming hubs for IoT ecosystems, requiring PCBs to support a wider range of connectivity options and sensors.

3. Artificial Intelligence and Machine Learning: AI will play a larger role not only in PCB design but also in the manufacturing and quality control processes.

4. Sustainability: There will be a growing focus on sustainable manufacturing practices and materials in mobile PCB production.

5. Modular Designs: To improve repairability and upgradability, some mobile device manufacturers may move towards more modular PCB designs.

Conclusion

The mobile PCB SMT assembly process faces numerous challenges as devices continue to evolve and become more complex. From miniaturization and component density issues to signal integrity and quality control concerns, manufacturers must constantly innovate to overcome these obstacles. By leveraging advanced technologies, materials, and processes, the industry is finding ways to meet these challenges head-on.

As we look to the future, the mobile PCB SMT process will undoubtedly continue to evolve, driven by the relentless pace of innovation in the mobile technology sector. Manufacturers and designers who can adapt to these changes and embrace new technologies will be best positioned to succeed in this dynamic and competitive field.

FAQ

1. What is the most critical step in the mobile PCB SMT process?

The most critical step in the mobile PCB SMT process is often considered to be the solder paste application and reflow soldering. This step is crucial because it establishes the electrical and mechanical connections between components and the PCB. Proper solder paste application ensures that components are securely attached and that electrical connections are reliable. Any errors in this step can lead to defects such as solder bridges, insufficient solder, or component misalignment, which can cause device failure.

2. How does miniaturization affect mobile PCB SMT assembly?

Miniaturization significantly impacts mobile PCB SMT assembly by increasing the complexity of the manufacturing process. As components become smaller and more densely packed, it requires more precise equipment for placement and soldering. It also makes inspection more challenging and increases the risk of defects such as solder bridges or component misalignment. Additionally, miniaturization can lead to thermal management issues and signal integrity challenges, requiring more sophisticated design and manufacturing techniques.

3. What role does automation play in mobile PCB SMT assembly?

Automation plays a crucial role in mobile PCB SMT assembly by improving accuracy, speed, and consistency in the manufacturing process. Automated systems are used for solder paste application, component placement, reflow soldering, and inspection. These systems can handle the placement of extremely small components with high precision, which would be impossible with manual assembly. Automation also helps in maintaining quality standards across large production runs and can adapt to different PCB designs more quickly than manual processes.

4. How are quality control challenges addressed in mobile PCB SMT assembly?

Quality control challenges in mobile PCB SMT assembly are addressed through a combination of advanced inspection technologies and rigorous testing procedures. Automated Optical Inspection (AOI) systems are used to detect visual defects, while X-ray inspection is employed for checking hidden solder joints. In-Circuit Testing (ICT) and functional testing are performed to ensure electrical performance. Additionally, many manufacturers are implementing AI-powered inspection systems that can learn to detect defects more accurately over time. Statistical process control methods are also used to monitor and improve the overall quality of the assembly process.

5. What are the emerging trends in materials for mobile PCB SMT assembly?

Emerging trends in materials for mobile PCB SMT assembly include the use of flexible and rigid-flex PCBs, which allow for more compact and versatile designs. High-frequency materials are becoming more common to support 5G and other advanced wireless technologies. There's also a growing interest in environmentally friendly and halogen-free materials to meet sustainability goals. Additionally, thermal management materials are evolving to handle the increased heat generated by densely packed components. Some manufacturers are also exploring the use of embedded passive components within PCB layers to save space and improve performance.

Citations:

[1] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[2] https://www.wevolver.com/article/smt-process

[3] https://www.medicaldesignbriefs.com/component/content/article/46458-surface-mount-technology-for-pcb-assembly-use-case-and-smt-in-healthcare-systems

[4] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[5] https://jhdpcb.com/pcb-assembly/smt-assembly/

[6] https://en.wikipedia.org/wiki/Surface_mount

[7] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[8] https://www.pgftech.com/smt-assembly-process/

[9] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[10] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[11] https://www.fs-pcba.com/smt-process-flow/