Content Menu

● Understanding PCB SMT Connectors

>> What are PCB SMT Connectors?

>> Advantages of PCB SMT Connectors

● Common Applications of PCB SMT Connectors

>> Consumer Electronics

>> Automotive Electronics

>> Industrial Automation

>> Telecommunications

>> Medical Devices

>> Aerospace and Defense

● Challenges and Considerations

>> Thermal Management

>> Mechanical Stress

>> Rework and Repair

>> High-Frequency Performance

● Future Trends in PCB SMT Connectors

>> Miniaturization

>> Higher Data Rates

>> Improved Environmental Resistance

>> Integration with Flexible and Rigid-Flex PCBs

● Conclusion

● FAQ

>> 1. What are the main advantages of using PCB SMT connectors?

>> 2. How do PCB SMT connectors differ from through-hole connectors?

>> 3. What industries commonly use PCB SMT connectors?

>> 4. What are some challenges associated with using PCB SMT connectors?

>> 5. What future trends are expected in PCB SMT connector technology?

● Citations:

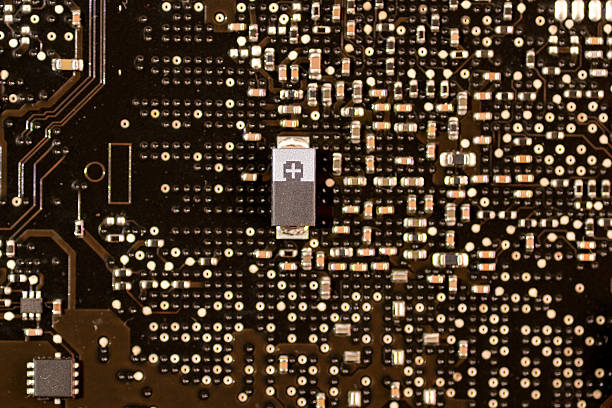

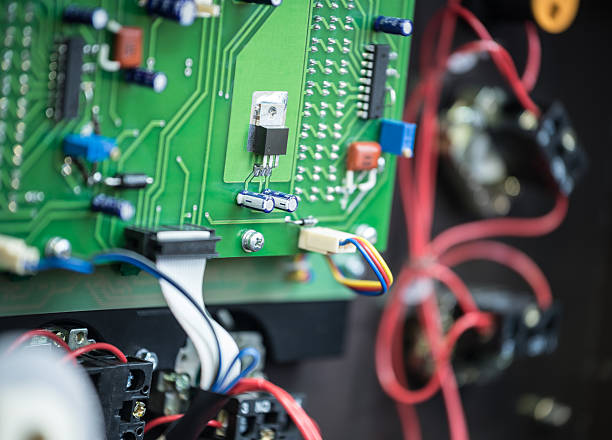

Surface Mount Technology (SMT) connectors have revolutionized the world of Printed Circuit Board (PCB) design and manufacturing. These compact and versatile components have become integral to a wide range of electronic devices and systems across various industries. This article explores the common applications that utilize PCB SMT connectors, their benefits, and the impact they have on modern electronics.

Understanding PCB SMT Connectors

Before delving into the applications, it's essential to understand what PCB SMT connectors are and how they differ from traditional through-hole connectors.

What are PCB SMT Connectors?

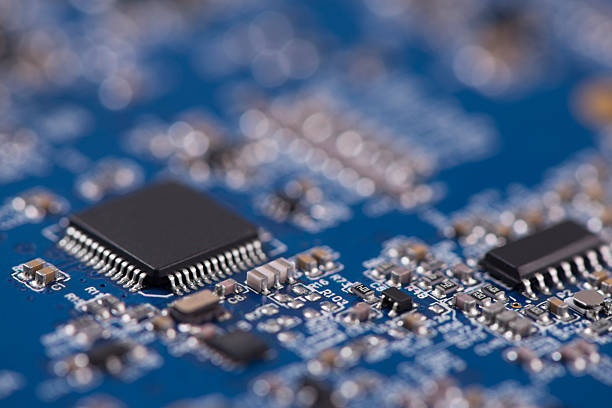

PCB SMT connectors are specialized electronic components designed to be mounted directly onto the surface of a printed circuit board[1]. Unlike through-hole connectors that require holes to be drilled through the PCB, SMT connectors are soldered onto pads on the board's surface. This mounting technique allows for more compact designs and efficient manufacturing processes.

Advantages of PCB SMT Connectors

SMT connectors offer several advantages over their through-hole counterparts:

1. Space-saving: SMT connectors require less board space, allowing for higher component density[1].

2. Improved performance: The shorter leads of SMT connectors result in reduced parasitic capacitance and inductance, leading to better electrical performance, especially at high frequencies[1].

3. Cost-effective: SMT assembly processes are generally more automated and faster, reducing manufacturing costs[4].

4. Reliability: SMT connectors often provide better resistance to vibration and mechanical stress due to their lower profile and surface-mounted nature[1].

Common Applications of PCB SMT Connectors

PCB SMT connectors find applications in a vast array of electronic devices and systems. Let's explore some of the most common areas where these connectors play a crucial role.

Consumer Electronics

The consumer electronics industry is perhaps the most visible user of PCB SMT connectors. These connectors are found in virtually every modern electronic device we use daily.

Smartphones and Tablets: In the compact designs of smartphones and tablets, SMT connectors are essential for connecting various components such as cameras, speakers, and display modules to the main PCB[1]. The small form factor of SMT connectors allows manufacturers to create increasingly thinner and lighter devices without compromising functionality.

Laptops and Computers: PCB SMT connectors are used extensively in laptops and desktop computers for connecting internal components like hard drives, SSDs, and memory modules[7]. They also facilitate connections for USB ports, audio jacks, and other external interfaces.

Wearable Devices: Smartwatches, fitness trackers, and other wearable technologies rely heavily on SMT connectors due to their space-saving properties[1]. These connectors enable the integration of various sensors, displays, and communication modules in compact, wearable form factors.

Automotive Electronics

The automotive industry has seen a significant increase in electronic content in vehicles, and PCB SMT connectors play a crucial role in this evolution.

Engine Control Units (ECUs): Modern vehicles contain numerous ECUs that control various aspects of the car's performance. SMT connectors are used to connect sensors and actuators to these ECUs, ensuring reliable communication and control[1].

Infotainment Systems: Car infotainment systems, which include navigation, audio, and connectivity features, utilize SMT connectors to interface with various modules and the vehicle's main electrical system[4].

Advanced Driver Assistance Systems (ADAS): ADAS features like lane departure warnings, adaptive cruise control, and parking assistance rely on SMT connectors to link cameras, radar sensors, and control modules[1].

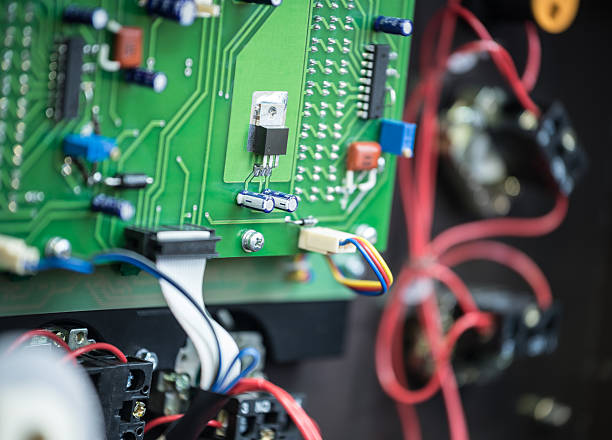

Industrial Automation

In the realm of industrial automation, PCB SMT connectors are crucial for creating compact and reliable control systems.

Programmable Logic Controllers (PLCs): PLCs, which are the backbone of many industrial control systems, use SMT connectors to interface with various input and output modules[4]. The compact nature of these connectors allows for high-density I/O configurations in a small footprint.

Human-Machine Interfaces (HMIs): Industrial HMIs, which provide operators with system status and control interfaces, utilize SMT connectors for internal connections and external communication ports[1].

Sensors and Actuators: In industrial settings, SMT connectors are used to connect a wide array of sensors and actuators to control systems, enabling precise monitoring and control of manufacturing processes[4].

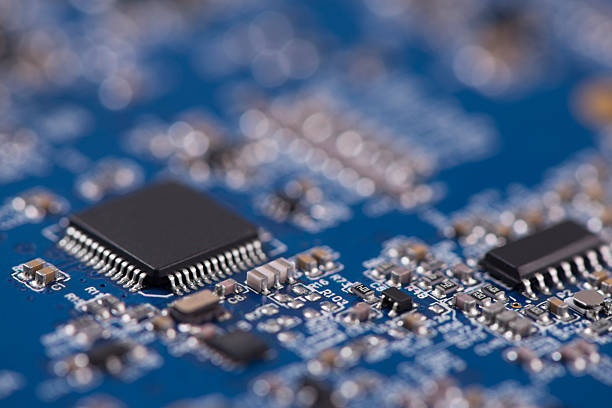

Telecommunications

The telecommunications industry relies heavily on PCB SMT connectors for creating efficient and high-performance communication equipment.

Network Routers and Switches: These devices use SMT connectors extensively for connecting various internal components and external ports[1]. The high-frequency performance of SMT connectors is particularly beneficial in networking equipment that handles high-speed data transmission.

Mobile Base Stations: In cellular network infrastructure, SMT connectors are used in base station equipment for connecting RF modules, power amplifiers, and other critical components[4].

Fiber Optic Equipment: SMT connectors play a role in fiber optic communication equipment, connecting optical transceivers and other components to the main PCB[1].

Medical Devices

The medical industry has embraced PCB SMT connectors for creating compact and reliable medical devices.

Portable Medical Devices: Devices like blood glucose meters, portable ECG monitors, and wearable health trackers use SMT connectors to achieve compact designs while maintaining functionality[1].

Imaging Equipment: Medical imaging devices such as ultrasound machines and portable X-ray equipment utilize SMT connectors for internal connections and interfaces with probes and sensors[4].

Patient Monitoring Systems: Hospital patient monitoring systems rely on SMT connectors for connecting various sensors and displays, ensuring reliable data transmission in critical care environments[1].

Aerospace and Defense

The aerospace and defense sectors utilize PCB SMT connectors in various applications where reliability and performance are paramount.

Avionics Systems: Aircraft avionics systems, including navigation, communication, and flight control systems, use SMT connectors to ensure reliable connections in compact spaces[1].

Satellite Systems: Satellites and space-based systems employ SMT connectors for their compact size and reliability in harsh environments[4].

Military Communication Equipment: Portable military communication devices and radar systems benefit from the compact and robust nature of SMT connectors[1].

Challenges and Considerations

While PCB SMT connectors offer numerous advantages, there are some challenges and considerations to keep in mind when using them in various applications.

Thermal Management

In high-power applications, thermal management can be a challenge with SMT connectors. The compact nature of these connectors can lead to heat buildup, potentially affecting performance and reliability[4]. Designers must consider thermal dissipation strategies when using SMT connectors in high-current or high-power applications.

Mechanical Stress

Although SMT connectors are generally resistant to vibration, they can be susceptible to mechanical stress in certain applications. In automotive or industrial environments where significant vibration or shock is present, additional measures may be needed to ensure the long-term reliability of SMT connections[1].

Rework and Repair

Reworking or repairing SMT connectors can be more challenging compared to through-hole connectors. Special equipment and techniques are often required to remove and replace SMT connectors without damaging the PCB or surrounding components[4].

High-Frequency Performance

While SMT connectors generally offer better high-frequency performance than through-hole connectors, careful design considerations are necessary for applications operating at very high frequencies. Factors such as impedance matching and signal integrity become critical in these scenarios[1].

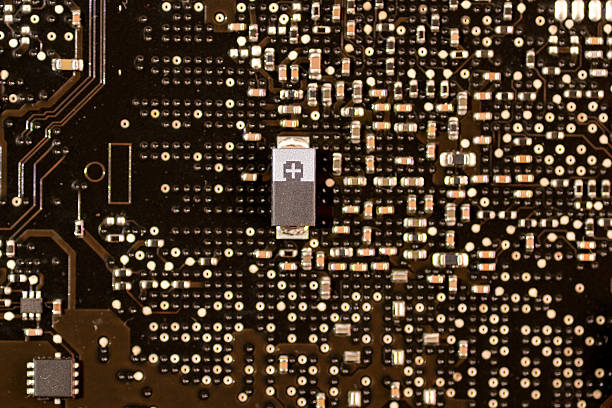

Future Trends in PCB SMT Connectors

As technology continues to evolve, so do PCB SMT connectors. Several trends are shaping the future of these essential components:

Miniaturization

The ongoing trend towards smaller and more compact electronic devices is driving the development of even smaller SMT connectors. Manufacturers are pushing the boundaries of connector design to create ultra-miniature connectors that maintain reliability and performance[1].

Higher Data Rates

With the increasing demand for high-speed data transmission, particularly in applications like 5G networks and high-performance computing, SMT connector designs are evolving to support higher data rates while maintaining signal integrity[4].

Improved Environmental Resistance

As electronic devices are used in increasingly diverse environments, SMT connectors are being developed with enhanced resistance to moisture, temperature extremes, and other environmental factors[1].

Integration with Flexible and Rigid-Flex PCBs

The growing adoption of flexible and rigid-flex PCBs is driving the development of SMT connectors specifically designed for these applications, offering new possibilities for creating compact and flexible electronic devices[4].

Conclusion

PCB SMT connectors have become indispensable components in modern electronic design and manufacturing. Their widespread adoption across various industries, from consumer electronics to aerospace and defense, is a testament to their versatility and effectiveness. As technology continues to advance, SMT connectors will undoubtedly evolve to meet the changing needs of electronic devices, enabling even more compact, efficient, and high-performance systems.

The applications discussed in this article represent just a fraction of the areas where PCB SMT connectors play a crucial role. As engineers and designers continue to push the boundaries of what's possible in electronic design, these compact and reliable connectors will remain at the forefront of innovation, enabling the creation of increasingly sophisticated and compact electronic devices that shape our modern world.

FAQ

1. What are the main advantages of using PCB SMT connectors?

PCB SMT connectors offer several advantages:

- Space-saving: They require less board space, allowing for higher component density.

- Improved performance: Shorter leads result in better electrical performance, especially at high frequencies.

- Cost-effective: SMT assembly processes are generally more automated and faster, reducing manufacturing costs.

- Reliability: They often provide better resistance to vibration and mechanical stress due to their lower profile[1][4].

2. How do PCB SMT connectors differ from through-hole connectors?

The main differences between PCB SMT connectors and through-hole connectors are:

- Mounting method: SMT connectors are soldered directly onto the PCB surface, while through-hole connectors require holes in the PCB.

- Size: SMT connectors are generally smaller and have a lower profile.

- Assembly process: SMT connectors can be placed and soldered using automated pick-and-place machines and reflow soldering, while through-hole connectors often require manual insertion and wave soldering[1][2].

3. What industries commonly use PCB SMT connectors?

PCB SMT connectors are widely used across various industries, including:

- Consumer electronics (smartphones, laptops, wearables)

- Automotive electronics

- Industrial automation

- Telecommunications

- Medical devices

- Aerospace and defense[1][4][7]

4. What are some challenges associated with using PCB SMT connectors?

Some challenges of using PCB SMT connectors include:

- Thermal management: Heat dissipation can be challenging in high-power applications.

- Mechanical stress: They may require additional protection in high-vibration environments.

- Rework and repair: Replacing SMT connectors can be more difficult than through-hole connectors.

- High-frequency design considerations: Careful design is needed for optimal performance at very high frequencies[1][4].

5. What future trends are expected in PCB SMT connector technology?

Future trends in PCB SMT connector technology include:

- Miniaturization: Development of even smaller connectors for more compact devices.

- Higher data rates: Designs supporting faster data transmission for applications like 5G and high-performance computing.

- Improved environmental resistance: Enhanced protection against moisture, temperature extremes, and other environmental factors.

- Integration with flexible PCBs: Connectors designed specifically for use with flexible and rigid-flex PCBs[1][4].

Citations:

[1] https://promaxpogopin.com/professional/smt-connectors-in-pcb-everything-you-need-to-know/

[2] https://www.wevolver.com/article/types-of-pcb-connectors-an-in-depth-guide

[3] https://patents.google.com/patent/CN112040669B/zh

[4] https://www.attend.com.tw/en/news.php?act=view&id=139

[5] https://versae.com/smt-assembly-faq/

[6] https://suddendocs.samtec.com/processing/edge-mount-processing-ch.pdf

[7] https://www.pcbasic.com/blog/smt_connectorsper.html

[8] https://lugsdirect.com/FAQ_SMT_SMD_High_CurrentPCB_Terminal_LugsSolderCreep.htm