Content Menu

● Introduction

● Global Competition

● Supply Chain Disruptions

● Technological Advancements

● Labor Shortages

● Environmental Regulations

● Market Demand Fluctuations

● Intellectual Property Concerns

● Trade Policies and Tariffs

● Quality Control Challenges

● Economic Uncertainty

● Conclusion

● Related Questions

>> 1. What are the key advantages of Surface Mounting Technology in electronics manufacturing?

>> 2. How does Taiwan's SMT sector compare to other countries?

>> 3. What steps are Taiwanese companies taking to address labor shortages?

>> 4. How are environmental regulations affecting the SMT industry in Taiwan?

>> 5. What impact do trade policies have on Taiwan's SMT sector?

Introduction

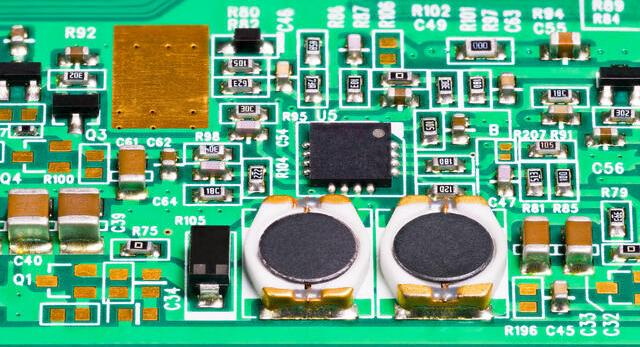

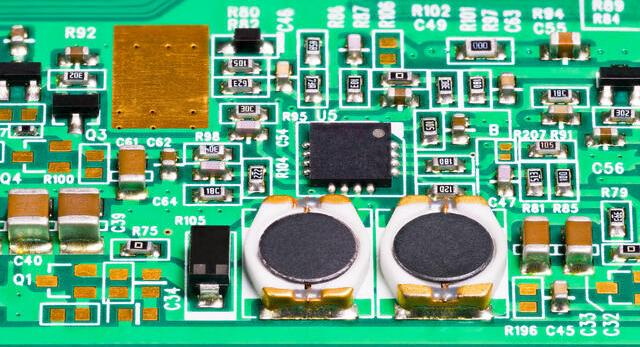

Taiwan has established itself as a global leader in the electronics manufacturing industry, particularly in the field of Surface Mounting Technology (SMT). This technology is crucial for the production of compact and efficient electronic devices, enabling manufacturers to place components directly onto the surface of printed circuit boards (PCBs). However, despite its advancements and innovations, the Taiwan surface mounting technology sector faces several challenges that could impact its future growth and competitiveness. This article explores these challenges in detail, providing insights into the current landscape of SMT in Taiwan.

Global Competition

One of the most significant challenges facing Taiwan's surface mounting technology sector is the intense global competition. Countries like China, South Korea, and Japan have made substantial investments in their electronics manufacturing capabilities, often at lower costs. This competition puts pressure on Taiwanese companies to innovate continuously and reduce production costs while maintaining high-quality standards. The need to stay competitive forces Taiwanese manufacturers to adopt advanced technologies and improve operational efficiencies, which can be a daunting task.

Supply Chain Disruptions

The COVID-19 pandemic highlighted vulnerabilities in global supply chains, and the SMT sector in Taiwan was not immune. Disruptions in the supply of raw materials and components have led to delays in production and increased costs. For instance, shortages of semiconductors have significantly impacted the electronics industry, causing delays in product launches and affecting revenue. Taiwanese companies must develop more resilient supply chains to mitigate these risks, which may involve diversifying suppliers and increasing inventory levels.

Technological Advancements

As technology evolves, so do the demands of the market. The rapid pace of technological advancements in electronics, such as the rise of 5G, Internet of Things (IoT), and artificial intelligence (AI), requires Taiwanese SMT manufacturers to adapt quickly. This adaptation often involves significant investment in research and development (R&D) to create new products and improve existing processes. Companies that fail to keep up with these technological changes risk losing market share to more agile competitors.

Labor Shortages

The SMT sector in Taiwan is also facing labor shortages, particularly in skilled positions. As the industry becomes more technologically advanced, the demand for skilled workers who can operate complex machinery and manage sophisticated production processes increases. However, the younger workforce is often less interested in manufacturing jobs, leading to a skills gap. Taiwanese companies must invest in training and development programs to attract and retain talent, ensuring they have the necessary skills to drive innovation and efficiency.

Environmental Regulations

With increasing global awareness of environmental issues, the electronics manufacturing industry is under pressure to adopt more sustainable practices. Taiwan's surface mounting technology sector must comply with stringent environmental regulations, which can increase operational costs. Companies are required to implement eco-friendly practices, such as reducing waste and energy consumption, which may require significant investment in new technologies and processes. Balancing profitability with sustainability is a critical challenge for Taiwanese SMT manufacturers.

Market Demand Fluctuations

The demand for electronic products can be highly volatile, influenced by factors such as consumer preferences, economic conditions, and technological trends. Taiwanese SMT manufacturers must be agile and responsive to these fluctuations to avoid overproduction or stock shortages. This requires sophisticated demand forecasting and inventory management systems, which can be challenging to implement effectively.

Intellectual Property Concerns

Intellectual property (IP) protection is a significant concern for Taiwanese companies in the SMT sector. As technology becomes more advanced, the risk of IP theft increases, particularly from competitors in countries with less stringent IP laws. Taiwanese manufacturers must invest in robust IP protection strategies to safeguard their innovations and maintain a competitive edge in the market.

Trade Policies and Tariffs

Trade policies and tariffs can significantly impact the SMT sector in Taiwan. Changes in trade agreements or the imposition of tariffs can affect the cost of raw materials and components, as well as the competitiveness of Taiwanese products in international markets. Companies must stay informed about global trade dynamics and be prepared to adapt their strategies accordingly.

Quality Control Challenges

Maintaining high-quality standards is crucial in the SMT sector, where even minor defects can lead to significant product failures. Taiwanese manufacturers face challenges in implementing effective quality control measures, especially as production volumes increase. Companies must invest in advanced quality assurance technologies and processes to ensure that their products meet the stringent requirements of the global market.

Economic Uncertainty

Finally, economic uncertainty, both domestically and globally, poses a challenge for the Taiwan surface mounting technology sector. Factors such as inflation, currency fluctuations, and geopolitical tensions can impact consumer spending and investment in electronics. Taiwanese companies must develop strategies to navigate these uncertainties, ensuring they remain resilient in the face of economic challenges.

Conclusion

The Taiwan surface mounting technology sector is at a crossroads, facing numerous challenges that could impact its future growth and competitiveness. From global competition and supply chain disruptions to labor shortages and environmental regulations, Taiwanese manufacturers must navigate a complex landscape to maintain their leadership position in the electronics industry. By investing in innovation, workforce development, and sustainable practices, Taiwan can continue to thrive in the ever-evolving world of surface mounting technology.

Related Questions

1. What are the key advantages of Surface Mounting Technology in electronics manufacturing?

Surface Mounting Technology (SMT) offers several advantages, including reduced size and weight of electronic devices, improved performance, and lower production costs. SMT allows for higher component density on PCBs, leading to more compact designs.

2. How does Taiwan's SMT sector compare to other countries?

Taiwan's SMT sector is known for its high-quality standards and advanced manufacturing capabilities. However, it faces stiff competition from countries like China and South Korea, which often have lower production costs.

3. What steps are Taiwanese companies taking to address labor shortages?

Taiwanese companies are investing in training and development programs to attract and retain skilled workers. They are also exploring automation and advanced manufacturing technologies to reduce reliance on manual labor.

4. How are environmental regulations affecting the SMT industry in Taiwan?

Environmental regulations are pushing Taiwanese SMT manufacturers to adopt more sustainable practices, which can increase operational costs. Companies are required to implement eco-friendly processes to comply with these regulations.

5. What impact do trade policies have on Taiwan's SMT sector?

Trade policies and tariffs can significantly affect the cost of raw materials and the competitiveness of Taiwanese products in international markets. Companies must stay informed about global trade dynamics to adapt their strategies effectively.