Content Menu

● Introduction to Surface Mount Technology (SMT)

● Component Miniaturization

● Design Complexity

● Equipment and Technology Requirements

● Quality Control and Testing

● Supply Chain Management

● Environmental Considerations

● Emerging Technologies and Trends

● Conclusion

● Related Questions and Answers

>> 1. What are the main advantages of using SMT in PCB design?

>> 2. How can engineers ensure proper soldering in SMT?

>> 3. What inspection methods are commonly used in SMT?

>> 4. How does component obsolescence affect SMT design?

>> 5. What role does thermal management play in SMT?

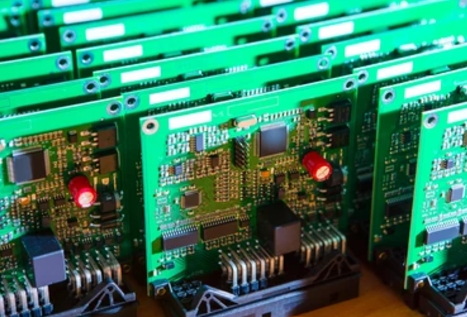

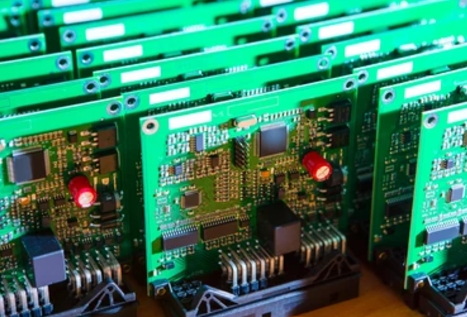

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for the production of smaller, more efficient, and more complex devices. However, implementing SMT in PCB (Printed Circuit Board) design comes with its own set of challenges. This article explores these challenges in detail, providing insights into how engineers can navigate them effectively.

Introduction to Surface Mount Technology (SMT)

Surface Mount Technology is a method used to mount electronic components directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes in the PCB, SMT allows for a more compact design, which is essential in today's miniaturized electronic devices. The benefits of SMT include reduced size and weight, improved performance, and lower manufacturing costs. However, the transition to SMT is not without its difficulties.

Component Miniaturization

One of the most significant challenges engineers face when implementing SMT is the trend toward miniaturization. As electronic devices become smaller, the components used in SMT also shrink. This miniaturization leads to several issues:

- Precision Placement: Smaller components require more precise placement on the PCB. Any misalignment can lead to poor solder joints, which can affect the performance and reliability of the device. Engineers must utilize advanced placement machines that can handle the precision required for these tiny components.

- Soldering Challenges: The smaller the component, the more challenging it is to solder. Engineers must ensure that the solder paste is applied correctly and that the reflow process is optimized to avoid defects such as solder bridges or tombstoning. Tombstoning occurs when one end of a component lifts off the PCB during soldering, leading to a poor connection.

- Design for Manufacturability (DFM): Engineers must consider DFM principles to ensure that the design can be manufactured reliably. This includes ensuring that components are not too close together, which can complicate soldering and inspection processes.

Design Complexity

The complexity of PCB design increases significantly with SMT. Engineers must consider various factors, including:

- Layer Count: SMT often requires multi-layer PCBs to accommodate the increased number of components. This complexity can lead to challenges in routing and signal integrity. Each additional layer can introduce issues such as increased capacitance and inductance, which can affect the performance of high-speed circuits.

- Thermal Management: With more components packed into a smaller area, managing heat becomes critical. Engineers must design for adequate thermal dissipation to prevent overheating, which can damage components and affect performance. This may involve using thermal vias, heat sinks, or even active cooling solutions in some cases.

- Signal Integrity: As the density of components increases, maintaining signal integrity becomes more challenging. Engineers must carefully route traces to minimize interference and ensure that high-speed signals are transmitted without degradation.

Equipment and Technology Requirements

Implementing SMT requires specialized equipment and technology, which can be a barrier for some manufacturers:

- High Initial Investment: The cost of SMT equipment, such as pick-and-place machines and reflow ovens, can be significant. Smaller manufacturers may struggle to justify this investment. Additionally, maintaining and upgrading this equipment can add to ongoing costs.

- Skilled Workforce: SMT processes require skilled operators who understand the intricacies of the technology. Training staff can be time-consuming and costly. Companies may need to invest in ongoing training programs to keep their workforce updated on the latest SMT techniques and technologies.

- Software Tools: Engineers also need access to advanced design and simulation software to create and test their PCB designs. These tools can be expensive and require training to use effectively.

Quality Control and Testing

Ensuring the quality of SMT assemblies is crucial, as defects can lead to product failures. Engineers face several challenges in this area:

- Inspection Techniques: Traditional inspection methods may not be sufficient for SMT assemblies. Engineers must implement advanced inspection techniques, such as Automated Optical Inspection (AOI) and X-ray inspection, to detect defects. AOI systems can quickly identify issues such as misaligned components or insufficient solder, while X-ray inspection is essential for checking hidden solder joints.

- Process Control: Maintaining consistent quality throughout the SMT process requires rigorous process control. Engineers must monitor various parameters, including solder paste application, reflow temperatures, and component placement accuracy. Implementing Statistical Process Control (SPC) can help identify trends and variations in the manufacturing process, allowing for timely interventions.

- Reliability Testing: In addition to inspection, reliability testing is essential to ensure that SMT assemblies can withstand the rigors of their intended environments. This may include thermal cycling tests, vibration tests, and humidity tests to simulate real-world conditions.

Supply Chain Management

The supply chain for SMT components can be complex and challenging to manage:

- Component Availability: As the demand for smaller components increases, the availability of specific parts can become an issue. Engineers must work closely with suppliers to ensure they can source the necessary components in a timely manner. This may involve establishing long-term relationships with multiple suppliers to mitigate risks associated with single-source dependencies.

- Obsolescence: Rapid advancements in technology can lead to component obsolescence. Engineers must stay informed about industry trends and be prepared to adapt their designs accordingly. This may involve redesigning PCBs to accommodate newer components or finding suitable replacements for obsolete parts.

- Inventory Management: Managing inventory levels for SMT components can be challenging, especially for smaller manufacturers. Engineers must balance the need to maintain sufficient stock to meet production demands while avoiding excess inventory that can tie up capital.

Environmental Considerations

As environmental regulations become more stringent, engineers must also consider the environmental impact of their SMT processes:

- Lead-Free Solder: The transition to lead-free solder has been a significant challenge for many manufacturers. While lead-free solder is more environmentally friendly, it often requires higher processing temperatures and can lead to different soldering characteristics, which can affect the reliability of joints.

- Waste Management: SMT processes can generate significant waste, including defective components and excess solder paste. Engineers must implement waste management strategies to minimize environmental impact and comply with regulations.

- Sustainable Practices: Many companies are now focusing on sustainability in their manufacturing processes. Engineers can explore options such as using recyclable materials, reducing energy consumption, and implementing closed-loop systems to minimize waste.

Emerging Technologies and Trends

The field of SMT is continually evolving, with new technologies and trends emerging that can impact PCB design:

- Flexible and Rigid-Flex PCBs: The rise of flexible and rigid-flex PCBs presents new challenges and opportunities for SMT. Engineers must adapt their designs to accommodate the unique characteristics of these materials, which can affect component placement and soldering processes.

- Internet of Things (IoT): The growing demand for IoT devices is driving innovation in SMT. Engineers must design PCBs that can support a wide range of sensors and communication technologies while maintaining compact sizes.

- Artificial Intelligence (AI) in Manufacturing: AI is beginning to play a role in SMT processes, from optimizing component placement to predicting equipment failures. Engineers can leverage AI tools to enhance efficiency and reduce downtime in manufacturing.

Conclusion

Implementing Surface Mount Technology in PCB design presents several challenges that engineers must navigate to ensure successful outcomes. From component miniaturization and design complexity to equipment requirements and quality control, each aspect requires careful consideration and planning. By understanding these challenges and developing strategies to address them, engineers can leverage the benefits of SMT to create innovative and reliable electronic devices.

Related Questions and Answers

1. What are the main advantages of using SMT in PCB design?

The main advantages of SMT include reduced size and weight of devices, improved performance due to shorter electrical paths, and lower manufacturing costs due to higher assembly speeds and reduced material usage.

2. How can engineers ensure proper soldering in SMT?

Engineers can ensure proper soldering by optimizing the solder paste application, using the correct reflow profile, and implementing rigorous inspection techniques to detect defects early in the process.

3. What inspection methods are commonly used in SMT?

Common inspection methods in SMT include Automated Optical Inspection (AOI), X-ray inspection for hidden solder joints, and manual inspection for critical components.

4. How does component obsolescence affect SMT design?

Component obsolescence can lead to design challenges as engineers may need to find alternative components or redesign PCBs to accommodate new parts, which can increase costs and time to market.

5. What role does thermal management play in SMT?

Thermal management is crucial in SMT as densely packed components generate heat. Effective thermal design ensures that devices operate within safe temperature limits, preventing failures and extending product life.