Content Menu

● Understanding SMT LEDs

● Causes of Green Lines on SMT LEDs

● Identifying the Issue

● Fixing Green Lines on SMT LEDs

● Preventive Measures

● Detailed Troubleshooting Steps

● Conclusion

● FAQ

>> 1. What does a green line on my SMT LED indicate?

>> 2. Can I fix a green line on my SMT LED myself?

>> 3. How do I prevent overheating in my SMT LEDs?

>> 4. Are all SMT LEDs susceptible to green lines?

>> 5. When should I seek professional help for my SMT LED issues?

● Citations:

The appearance of a green line on Surface Mount Technology (SMT) Light Emitting Diodes (LEDs) can be quite alarming, especially in applications where visual performance is critical. This article will delve into the causes behind this issue, potential fixes, and preventive measures to ensure the longevity of your LED displays.

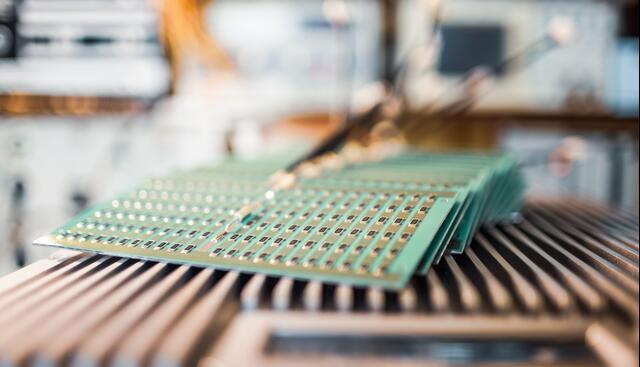

Understanding SMT LEDs

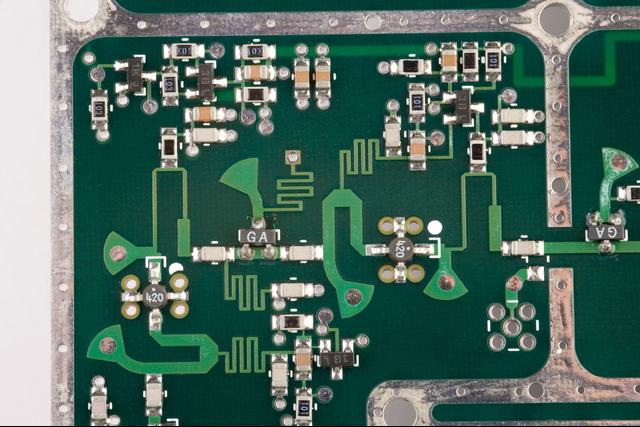

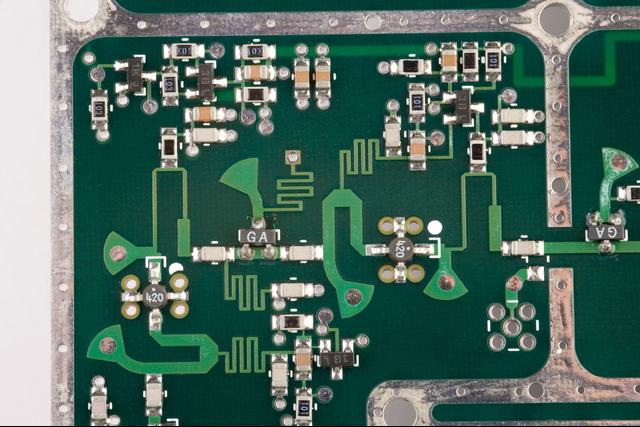

SMT LEDs are widely used in various applications, from consumer electronics to large-scale displays. These compact components are favored for their efficiency and brightness. However, like any electronic component, they can experience failures that manifest in various ways, including the notorious green line.

Causes of Green Lines on SMT LEDs

Understanding the root causes of green lines on SMT LEDs is essential for effective troubleshooting. Here are some common reasons:

- Defective LED Chip: The most straightforward cause is a malfunction within the LED chip itself. Manufacturing defects can lead to inconsistencies in color output.

- Poor Connections: A weak or broken connection between the LED and its circuit board can result in incomplete signals reaching the LED, leading to color issues.

- Overheating: Excessive heat can damage the LED chip or surrounding components, causing abnormal behavior including color distortions.

- Electrical Noise: Fluctuations in power supply or interference from nearby electronic devices can disrupt the normal operation of LEDs, resulting in unexpected color outputs.

- Driver Issues: The driver circuitry that controls the LED's brightness and color may malfunction, leading to improper signals being sent to the LED.

Identifying the Issue

Before attempting to fix the problem, it's crucial to diagnose it correctly. Here are steps to identify whether the issue is due to a faulty LED or another component:

1. Visual Inspection: Check for any visible damage on the LED or surrounding components.

2. Connection Check: Ensure that all connections are secure and free from corrosion or damage.

3. Test with a Multimeter: Measure voltage and continuity across connections to ensure proper functionality.

4. Swap Components: If possible, replace the suspected faulty LED with a known good one to see if the problem persists.

Fixing Green Lines on SMT LEDs

Once you have identified the cause of the green line issue, you can proceed with appropriate fixes:

- Replace Defective LEDs: If a specific LED is found to be defective, replacing it is often the best solution.

- Reflow Solder Joints: If poor connections are suspected, reflowing solder joints can restore connectivity. This involves heating up the solder to allow it to flow and create a better connection.

- Upgrade Drivers: If driver issues are identified, consider upgrading or replacing them with higher quality components that can handle your application's requirements better.

- Improve Cooling Solutions: If overheating is an issue, enhance heat dissipation by adding heatsinks or improving airflow around the LEDs.

- Check Power Supply Stability: Ensure that your power supply is stable and free from noise. Using capacitors for filtering can help smooth out fluctuations.

Preventive Measures

To avoid future occurrences of green lines on SMT LEDs, consider implementing these preventive measures:

- Quality Components: Always source high-quality LEDs and drivers from reputable manufacturers to minimize defects.

- Proper Installation Techniques: Ensure that installation methods do not subject components to undue stress or heat during soldering.

- Thermal Management: Design your circuits with adequate thermal management in mind to prevent overheating.

- Regular Maintenance Checks: Implement regular checks on your LED systems to identify potential issues before they escalate into more significant problems.

Detailed Troubleshooting Steps

To further assist in diagnosing and fixing green lines on SMT LEDs, here are some detailed troubleshooting steps:

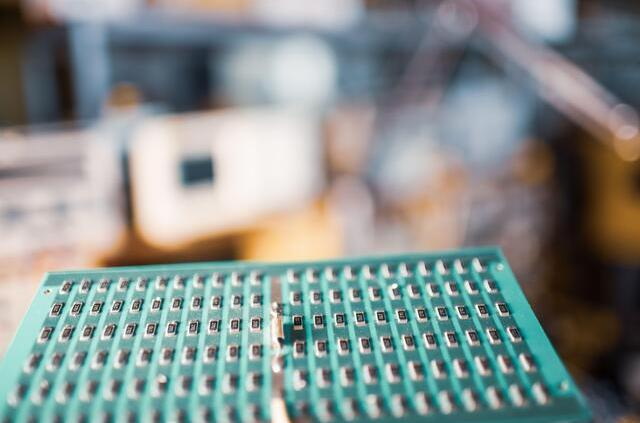

1. Inspect for Physical Damage: Look for any signs of physical damage on both the PCB and the LED itself. This includes checking for cracks or burnt areas around solder joints.

2. Check Solder Quality: Poor solder joints can lead to intermittent connections. Use a magnifying glass to inspect solder joints closely for cold solder joints or bridges that may cause shorts.

3. Use Thermal Imaging Tools: If available, thermal imaging cameras can help identify overheating components which may be contributing to color distortion issues.

4. Test Individual Components: Isolate sections of your circuit by disconnecting segments and testing individual components one at a time. This method helps pinpoint which part of your circuit is causing issues.

5. Examine Circuit Design: Review your circuit design for any potential flaws that could lead to signal integrity problems. Ensure that trace widths are adequate for current loads and that there are no excessive lengths causing delays in signals.

6. Software Calibration: In some cases, software settings might need adjustment if your LED system includes programmable features. Check if there's an option for recalibrating colors through software interfaces provided by manufacturers.

7. Environmental Factors Assessment: Consider environmental factors such as humidity and temperature which could affect performance over time. Ensure that your setup is within recommended operating conditions.

Conclusion

The presence of a green line on SMT LEDs can stem from various causes ranging from manufacturing defects to connection issues. By understanding these causes and implementing effective troubleshooting and repair strategies, you can significantly reduce downtime and improve the performance of your LED displays. Regular maintenance and quality control during installation will also help mitigate future issues.

FAQ

1. What does a green line on my SMT LED indicate?

A green line typically indicates a malfunction within the LED chip or issues with connections or drivers affecting signal integrity.

2. Can I fix a green line on my SMT LED myself?

Yes, if you have basic electronics skills, you can troubleshoot and potentially fix minor issues such as poor connections or defective LEDs by replacing them.

3. How do I prevent overheating in my SMT LEDs?

Implement proper thermal management strategies such as using heatsinks and ensuring adequate airflow around your LEDs.

4. Are all SMT LEDs susceptible to green lines?

While many SMT LEDs can experience this issue, it is more common in lower-quality components or those subjected to extreme conditions.

5. When should I seek professional help for my SMT LED issues?

If you are unable to diagnose or fix the problem after basic troubleshooting steps, it may be best to consult with a professional technician who specializes in electronic repairs.

Citations:

[1] https://www.youtube.com/watch?v=X75Afgg-Lvw

[2] https://diy.stackexchange.com/questions/259790/the-green-line-of-the-led-bulb

[3] https://jhdpcb.com/blog/efficient-smt-assembly/

[4] https://www.reddit.com/r/mobilerepair/comments/1gq70pq/solution_for_samsung_green_line_issue/

[5] http://www.neufeld.newton.ks.us/electronics/?p=150

[6] https://www.gmleds.com/info/7-common-problems-and-solutions-of-smd-led-chi-63204474.html

[7] https://electronics.stackexchange.com/questions/141438/smd-led-polarity-marking-is-the-cathode-marking-standardized

[8] https://www.reddit.com/r/AskElectronics/comments/bhnjqd/all_green_leds_on_this_rgb_light_stopped_working/

[9] https://www.therpf.com/forums/threads/help-troubleshooting-a-surface-mount-led.332256/

[10] https://www.carlcare.com/ng/tips-detail/fix-green-line-android-phone/

[11] https://www.pcbonline.com/blog/smd-polarity-led-capacitor-diode-inductor-ic.html

[12] https://www.hobbytalk.com/threads/working-with-smd-leds-tips-and-tricks.475058/

[13] https://electronics.stackexchange.com/questions/640156/do-smd-leds-need-less-current-than-tht-leds

[14] https://www.novastar.tech/novastar-innovation/understanding-the-differences-between-dip-smd-and-cob-in-led-screen-installation/

[15] https://www.avsforum.com/threads/green-line-on-right-edge-of-image-how-do-i-fix-this.369848/

[16] https://www.eevblog.com/forum/projects/smd-led-size-for-beginners/

[17] https://greencreative.com/lighting-academy/led-101/about-led/

[18] https://www.ledestar.com/illuminate-quality-unraveling-common-quality-issues-in-smd-led/

[19] https://www.reddit.com/r/soldering/comments/pdewmd/soldering_smd_leds_with_really_small_pads/

[20] https://forums.adafruit.com/viewtopic.php?t=64122