Content Menu

● Introduction to SMT and Dull Joints

>> Causes of Dull Joints in SMT

● Troubleshooting and Solutions

>> Cleaning and Preparation

>> Reflow Process Optimization

>> Design Considerations

● Advanced Techniques for Preventing Dull Joints

>> Automated Inspection Systems

>> Statistical Process Control (SPC)

>> Material Selection

>> Training and Quality Control

● Impact of Dull Joints on Product Reliability

>> Reliability Testing

>> Cost Implications

● Advanced Reliability Testing Techniques

>> X-Ray Inspection

>> Acoustic Microscopy

>> Environmental Stress Screening (ESS)

● Future Trends in SMT PCB Assembly

>> Miniaturization

>> Smart Manufacturing

>> Sustainable Materials

● Conclusion

● FAQ

>> 1. What is the primary cause of dull joints in SMT PCB assemblies?

>> 2. How does contamination affect solder joints in SMT?

>> 3. What role does the reflow profile play in preventing dull joints?

>> 4. How does PCB design influence the formation of dull joints?

>> 5. What are the consequences of having dull joints in SMT PCB assemblies?

Surface Mount Technology (SMT) is a widely used method for assembling electronic components onto Printed Circuit Boards (PCBs). Despite its efficiency and high component density, SMT can sometimes result in defects, one of which is the formation of dull joints. Dull joints, often associated with cold solder joints, can compromise the reliability and performance of the PCB. Understanding the causes and addressing these issues are crucial for ensuring the quality of SMT PCB assemblies.

Introduction to SMT and Dull Joints

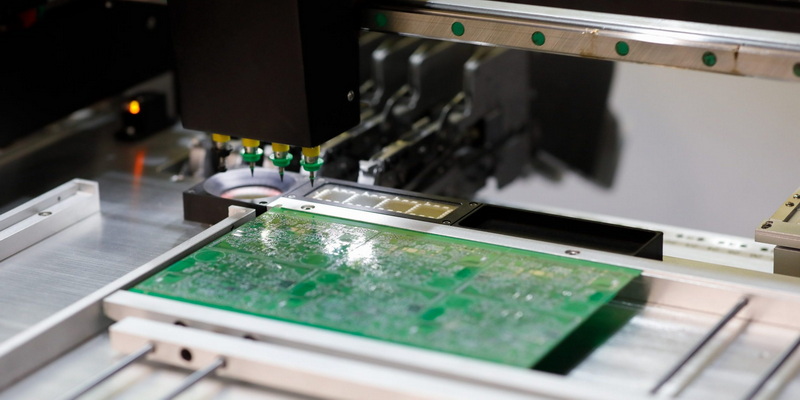

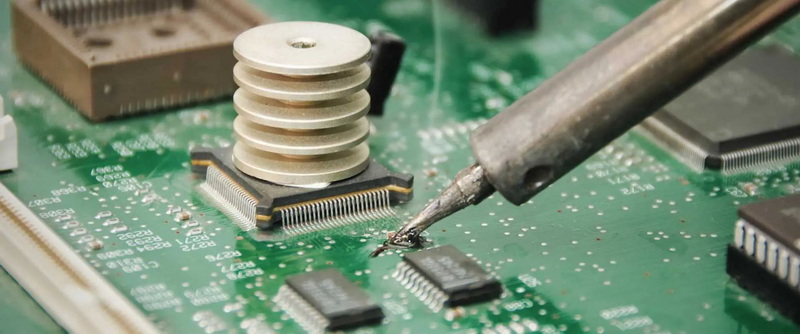

SMT involves mounting components directly onto the surface of a PCB, offering advantages such as higher circuit speeds and better high-frequency performance compared to through-hole technology. However, the process is not immune to defects. Dull joints, characterized by a non-reflective, rough appearance, indicate poor solder wetting and can lead to electrical failures.

Causes of Dull Joints in SMT

Several factors contribute to the formation of dull joints in SMT PCB assemblies:

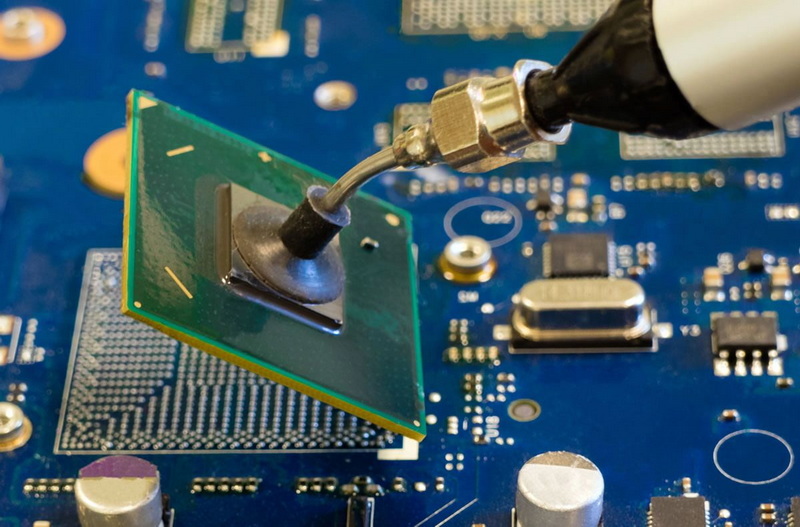

1. Insufficient Heat: Inadequate heat during the reflow process can prevent the solder from melting properly, resulting in a dull, porous joint. This is particularly common when using lead-free solder, which has a higher melting point than traditional solder.

2. Contamination: Dirty or contaminated surfaces can hinder the solder's ability to form a strong bond, leading to dull joints. This includes impurities on the components, PCB pads, or solder paste.

3. Incorrect Solder Paste: Using solder paste with an inappropriate metal-to-flux ratio can lead to defects. The flux may not effectively remove oxides, resulting in poor solder wetting.

4. Reflow Profile Issues: An incorrect reflow profile, including slow preheat rates or inadequate soak times, can cause solder paste to slump or not melt properly, contributing to dull joints.

5. Component and PCB Design: Poor design, such as insufficient thermal relief on pads connected to ground planes, can dissipate heat away from the joint, preventing proper soldering.

Troubleshooting and Solutions

To mitigate dull joints in SMT PCB assemblies, several strategies can be employed:

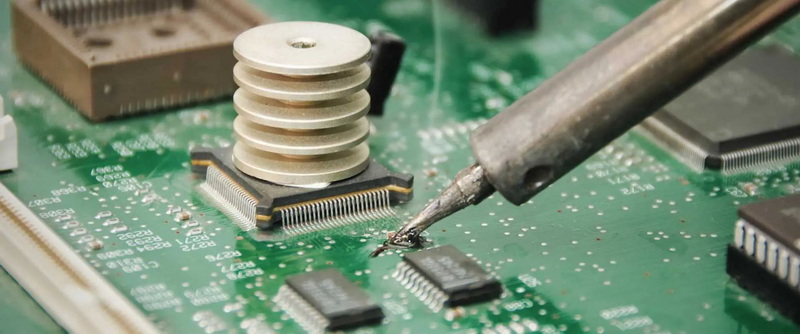

Cleaning and Preparation

- Surface Cleaning: Ensure that both the components and PCB pads are thoroughly cleaned before soldering to remove any contaminants.

- Solder Paste Quality: Use high-quality solder paste with the correct metal-to-flux ratio suitable for the specific application.

Reflow Process Optimization

- Reflow Profile Adjustment: Implement a well-controlled reflow profile with adequate preheat, soak, and reflow temperatures to ensure complete solder melting.

- Environmental Control: Maintain a stable environment during assembly to prevent moisture contamination and ensure consistent solder paste behavior.

Design Considerations

- Thermal Relief: Incorporate thermal relief in PCB designs to prevent heat dissipation, especially for pads connected to large copper areas.

- Component Placement: Ensure accurate component placement to avoid solder paste displacement during reflow.

Advanced Techniques for Preventing Dull Joints

In addition to basic troubleshooting, advanced techniques can further enhance the quality of SMT PCB assemblies:

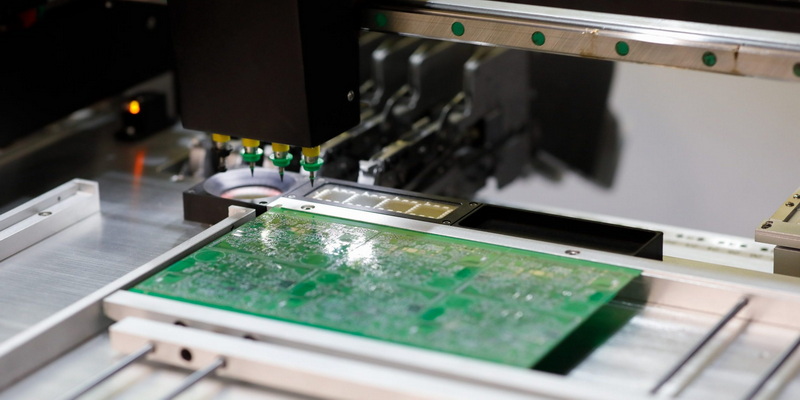

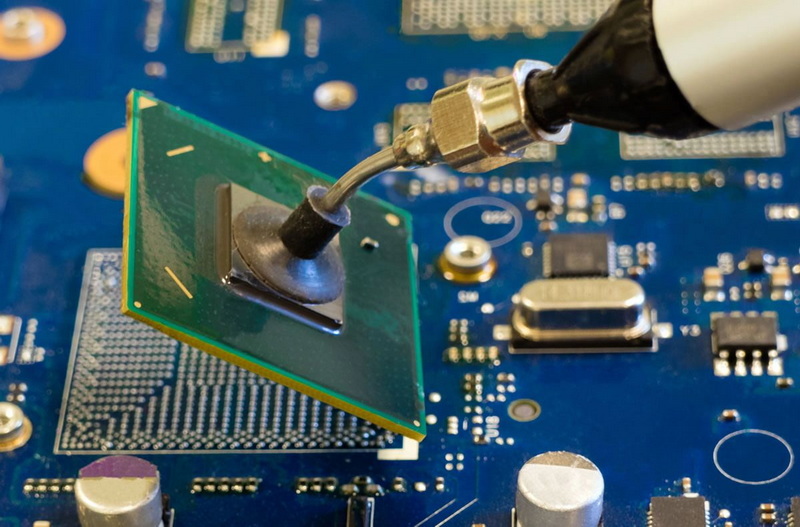

Automated Inspection Systems

- Optical Inspection: Utilize automated optical inspection (AOI) systems to detect defects early in the production process. AOI can identify issues such as solder paste misalignment or insufficient solder coverage.

Statistical Process Control (SPC)

- Process Monitoring: Implement SPC to monitor key parameters during production, such as reflow oven temperature and solder paste application. This helps maintain consistency and identify potential issues before they lead to defects.

Material Selection

- Lead-Free Solders: While lead-free solders are environmentally friendly, they require higher temperatures and more precise reflow profiles. Selecting the right solder alloy and ensuring compatibility with components is crucial.

Training and Quality Control

- Operator Training: Ensure that production staff are well-trained in handling components, applying solder paste, and operating reflow equipment.

- Quality Control Procedures: Establish rigorous quality control procedures to inspect PCBs at various stages of production, catching defects early and preventing them from reaching final assembly.

Impact of Dull Joints on Product Reliability

Dull joints can have significant implications for the reliability and lifespan of electronic devices. These defects can lead to intermittent connections, increased resistance, and eventual circuit failures. In critical applications, such as aerospace or medical devices, the consequences of such failures can be severe.

Reliability Testing

Conducting thorough reliability testing, including thermal cycling and vibration tests, can help identify potential issues with solder joints before products are released to the market. This proactive approach ensures that devices can withstand environmental stresses and maintain performance over time.

Cost Implications

The cost of addressing dull joints can be substantial, particularly if defects are discovered late in the production cycle. Implementing preventive measures and maintaining high-quality assembly processes can significantly reduce costs associated with rework and warranty claims.

Advanced Reliability Testing Techniques

To further ensure the reliability of SMT PCB assemblies, advanced testing techniques can be employed:

X-Ray Inspection

- Internal Defects: Use X-ray inspection to detect internal defects that may not be visible through optical inspection, such as solder voids or bridging.

Acoustic Microscopy

- Material Integrity: Apply acoustic microscopy to assess the material integrity of solder joints, identifying potential weaknesses or defects.

Environmental Stress Screening (ESS)

- Stress Testing: Perform ESS to subject PCBs to controlled environmental stresses, such as temperature and humidity variations, to identify potential failures before they occur in the field.

Future Trends in SMT PCB Assembly

As technology advances, new trends and innovations are emerging in SMT PCB assembly:

Miniaturization

- Component Size Reduction: The trend towards smaller components requires more precise assembly techniques and higher-quality solder joints to maintain reliability.

Smart Manufacturing

- Automation and AI: The integration of automation and artificial intelligence (AI) in SMT production can enhance process control, predict potential defects, and optimize assembly conditions.

Sustainable Materials

- Eco-Friendly Solder: The development of eco-friendly solder materials that are both reliable and environmentally sustainable is becoming increasingly important.

Conclusion

Dull joints in SMT PCB assemblies are a significant concern that can impact the reliability and performance of electronic devices. By understanding the causes, such as insufficient heat, contamination, incorrect solder paste, reflow profile issues, and design flaws, manufacturers can implement effective solutions to prevent these defects. Proper cleaning, solder paste selection, optimized reflow profiles, and thoughtful design considerations are key to achieving high-quality, reliable solder joints.

FAQ

1. What is the primary cause of dull joints in SMT PCB assemblies?

Dull joints are often caused by insufficient heat during the reflow process, leading to incomplete solder melting and poor wetting. This can be exacerbated by factors like contamination and incorrect solder paste composition.

2. How does contamination affect solder joints in SMT?

Contamination on the components or PCB pads can prevent the solder from forming a strong bond, resulting in dull, unreliable joints. Cleaning these surfaces before soldering is crucial for achieving high-quality joints.

3. What role does the reflow profile play in preventing dull joints?

A well-controlled reflow profile ensures that the solder paste melts completely and wets the surfaces properly. Incorrect profiles can lead to solder paste slumping or incomplete melting, contributing to dull joints.

4. How does PCB design influence the formation of dull joints?

Poor PCB design, such as insufficient thermal relief on pads connected to ground planes, can dissipate heat away from the joint, preventing proper soldering. This can lead to dull, ineffective joints.

5. What are the consequences of having dull joints in SMT PCB assemblies?

Dull joints can compromise the electrical conductivity and mechanical strength of the soldered connections, leading to circuit failures and reduced product reliability. These defects can manifest over time, causing serious consequences in critical applications.