Content Menu

● Understanding Surface Mount Technology

● The Importance of Skills in SMT Jobs

>> 1. Technical Proficiency

>> 2. Attention to Detail

>> 3. Problem-Solving Skills

>> 4. Knowledge of Quality Control Processes

>> 5. Communication Skills

>> 6. Adaptability and Continuous Learning

>> 7. Teamwork and Collaboration

>> 8. Time Management

>> 9. Familiarity with Automation and Robotics

>> 10. Safety Awareness

● Preparing for a Career in Surface Mount Technology

● Conclusion

● Related Questions

>> 1. What qualifications are needed for surface mount technology jobs?

>> 2. How can I improve my skills for a career in SMT?

>> 3. What are the common job titles in surface mount technology?

>> 4. What is the average salary for surface mount technology jobs?

>> 5. What industries employ surface mount technology professionals?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient devices. As the demand for electronic products continues to grow, so does the need for skilled professionals in SMT. This article explores the top skills required for surface mount technology jobs, providing insights into what employers look for and how aspiring candidates can prepare themselves for a successful career in this field.

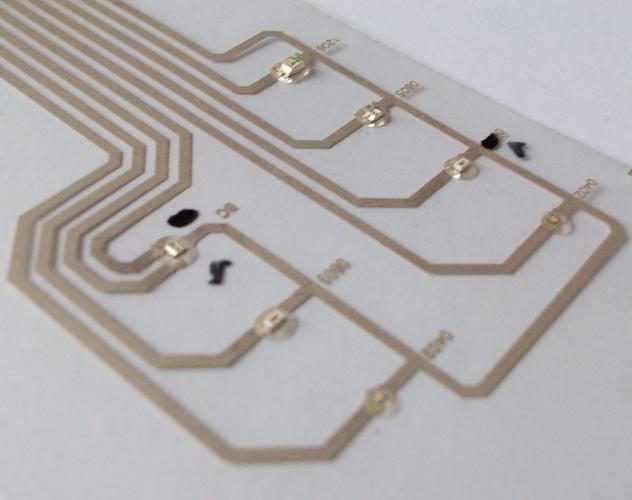

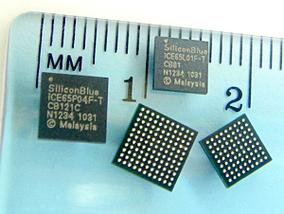

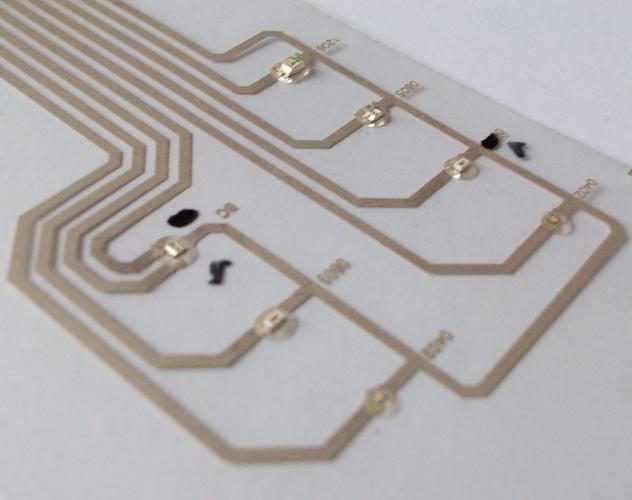

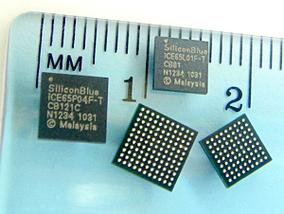

Understanding Surface Mount Technology

Before diving into the skills needed for surface mount technology jobs, it's essential to understand what SMT is. Surface Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technique allows for higher component density and improved performance compared to traditional through-hole mounting methods. As a result, SMT is widely used in various applications, from consumer electronics to automotive systems.

The Importance of Skills in SMT Jobs

In the competitive landscape of surface mount technology jobs, possessing the right skills can significantly enhance a candidate's employability. Employers seek individuals who not only have technical knowledge but also demonstrate problem-solving abilities, attention to detail, and a commitment to quality. Here are the top skills needed for success in SMT roles:

1. Technical Proficiency

Technical proficiency is the cornerstone of any surface mount technology job. Candidates should have a solid understanding of electronic components, circuit design, and PCB layout. Familiarity with industry-standard software tools, such as CAD (Computer-Aided Design) programs, is also crucial. Proficiency in using soldering equipment and understanding the principles of soldering techniques are essential for assembling and repairing SMT components.

2. Attention to Detail

In SMT jobs, precision is paramount. A small error in component placement or soldering can lead to significant issues in the final product. Therefore, candidates must possess a keen eye for detail. This skill ensures that all components are correctly placed and soldered, minimizing the risk of defects and enhancing the overall quality of the product.

3. Problem-Solving Skills

The ability to troubleshoot and resolve issues is vital in surface mount technology jobs. Candidates should be adept at identifying problems during the manufacturing process and implementing effective solutions. This may involve analyzing circuit designs, testing components, and making adjustments to improve performance. Strong problem-solving skills contribute to increased efficiency and reduced downtime in production.

4. Knowledge of Quality Control Processes

Quality control is a critical aspect of SMT jobs. Professionals in this field must understand various quality assurance techniques and standards, such as IPC-A-610, which outlines the acceptability of electronic assemblies. Familiarity with inspection methods, testing procedures, and documentation practices is essential for ensuring that products meet industry standards and customer expectations.

5. Communication Skills

Effective communication is crucial in any workplace, and SMT jobs are no exception. Candidates must be able to collaborate with team members, engineers, and management to ensure smooth operations. Clear communication helps in conveying technical information, discussing project requirements, and addressing any concerns that may arise during the manufacturing process.

6. Adaptability and Continuous Learning

The electronics industry is constantly evolving, with new technologies and methodologies emerging regularly. Candidates for surface mount technology jobs should be adaptable and willing to learn. Staying updated on industry trends, attending training sessions, and pursuing relevant certifications can enhance a professional's skill set and career prospects.

7. Teamwork and Collaboration

Most SMT jobs require working as part of a team. Candidates should be able to collaborate effectively with colleagues from various departments, including engineering, quality assurance, and production. Strong teamwork skills foster a positive work environment and contribute to the successful completion of projects.

8. Time Management

In a fast-paced manufacturing environment, time management is essential. Candidates must be able to prioritize tasks, meet deadlines, and manage their time efficiently. Effective time management ensures that production schedules are adhered to and that projects are completed on time.

9. Familiarity with Automation and Robotics

As automation becomes increasingly prevalent in electronics manufacturing, familiarity with automated systems and robotics is becoming a valuable skill in surface mount technology jobs. Understanding how to operate and troubleshoot automated assembly equipment can give candidates a competitive edge in the job market.

10. Safety Awareness

Safety is a top priority in any manufacturing environment. Candidates should be knowledgeable about safety protocols and practices related to SMT jobs. This includes understanding the proper handling of chemicals, using personal protective equipment (PPE), and following safety guidelines to prevent accidents and injuries.

Preparing for a Career in Surface Mount Technology

To succeed in surface mount technology jobs, aspiring professionals should take proactive steps to develop the necessary skills. Here are some recommendations:

- Education and Training: Pursuing a degree or certification in electronics, electrical engineering, or a related field can provide a solid foundation. Many technical schools and community colleges offer programs specifically focused on SMT and PCB assembly.

- Hands-On Experience: Gaining practical experience through internships, apprenticeships, or entry-level positions can enhance technical skills and provide valuable insights into the industry.

- Networking: Building a professional network can open doors to job opportunities and mentorship. Attending industry conferences, joining professional organizations, and connecting with professionals on platforms like LinkedIn can be beneficial.

- Continuous Learning: Staying updated on industry advancements and pursuing additional certifications can help professionals remain competitive in the job market.

Conclusion

In conclusion, surface mount technology jobs offer exciting career opportunities for individuals with the right skills and knowledge. Technical proficiency, attention to detail, problem-solving abilities, and effective communication are just a few of the essential skills needed for success in this field. By investing in education, gaining hands-on experience, and staying adaptable, aspiring professionals can position themselves for a rewarding career in surface mount technology.

Related Questions

1. What qualifications are needed for surface mount technology jobs?

Candidates typically need a degree or certification in electronics or a related field, along with hands-on experience in SMT processes.

2. How can I improve my skills for a career in SMT?

Consider pursuing relevant education, gaining practical experience through internships, and staying updated on industry trends.

3. What are the common job titles in surface mount technology?

Common job titles include SMT Technician, PCB Assembly Operator, Electronics Assembler, and Quality Control Inspector.

4. What is the average salary for surface mount technology jobs?

Salaries can vary widely based on experience and location, but entry-level positions typically start around $30,000 to $40,000 annually, while experienced professionals can earn upwards of $70,000.

5. What industries employ surface mount technology professionals?

SMT professionals are employed in various industries, including consumer electronics, automotive, telecommunications, and medical devices.