Content Menu

● Understanding SMT Nozzles

>> Types of SMT Nozzles

● Key Features to Look for in an SMT Nozzle Manufacturer

>> 1. Quality of Materials

>> 2. Variety of Nozzle Designs

>> 3. Precision Engineering

>> 4. Compatibility with Equipment

>> 5. Performance Metrics

>> 6. Customer Support and Service

>> 7. Cost-effectiveness

>> 8. Innovation and Technology

● Additional Considerations When Choosing an SMT Nozzle Manufacturer

>> 1. Reputation in the Industry

>> 2. Location and Logistics

>> 3. Sustainability Practices

● Conclusion

● FAQs

>> 1. What materials are commonly used for SMT nozzles?

>> 2. How do I determine if an SMT nozzle is compatible with my machine?

>> 3. What are some signs that an SMT nozzle needs replacement?

>> 4. Can I customize nozzles for specific components?

>> 5. How often should I perform maintenance on my SMT nozzles?

● Citations:

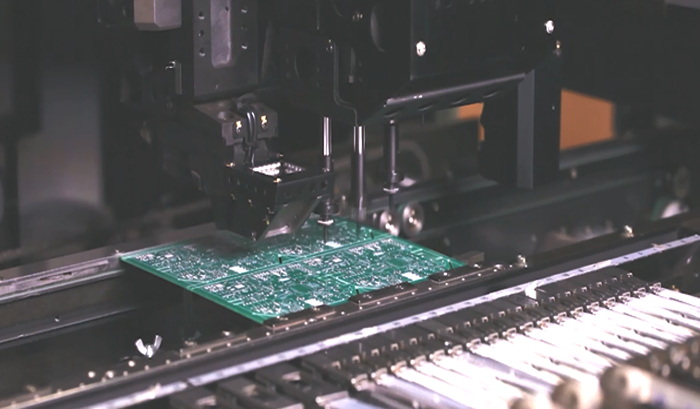

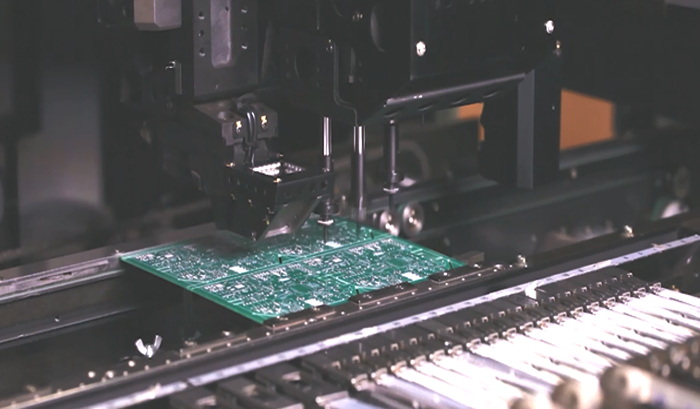

In the world of electronics manufacturing, particularly in Surface Mount Technology (SMT), the choice of nozzle is critical. The nozzle is the component responsible for picking up and placing electronic components onto printed circuit boards (PCBs). Selecting a reliable SMT nozzle manufacturer can significantly impact production efficiency, accuracy, and overall quality. This article explores the top features to consider when choosing an SMT nozzle manufacturer, ensuring that your production line operates at peak performance.

Understanding SMT Nozzles

SMT nozzles come in various shapes and materials, each designed for specific types of components. Their primary function is to create a vacuum that allows them to pick up components from feeders and place them accurately onto PCBs. The effectiveness of this process relies heavily on the quality and design of the nozzles used.

Types of SMT Nozzles

There are several types of SMT nozzles available in the market, each suited for different applications:

- Standard Nozzles: These are commonly used for standard components like resistors and capacitors. They come in various sizes to accommodate different component dimensions.

- Flat Nozzles: Designed for flat components such as ICs (Integrated Circuits) or connectors, these nozzles provide a larger surface area for better grip.

- Vacuum Nozzles: These nozzles utilize a vacuum mechanism to pick up components securely. They are essential for handling delicate or small parts that require precise placement.

- Custom Nozzles: Tailored to specific needs, custom nozzles are designed based on unique component shapes or sizes. They are often necessary for specialized applications in industries like automotive or medical devices.

Understanding the types of nozzles available helps manufacturers select the right one for their specific production needs.

Key Features to Look for in an SMT Nozzle Manufacturer

When evaluating potential SMT nozzle manufacturers, consider the following features:

1. Quality of Materials

The materials used in manufacturing nozzles directly affect their durability and performance. High-quality materials reduce wear and tear, ensuring longevity and consistent performance. Common materials include:

- Ceramic: Known for its durability and resistance to wear, ceramic nozzles maintain their shape and performance over time.

- Tungsten Steel: Offers strength and durability but may discolor with use.

- Diamond Steel: Extremely durable but comes at a higher cost.

- Plastic: Generally cheaper but less durable; suitable for short-term use or specific applications.

Choosing a manufacturer that uses advanced materials can enhance the reliability of your SMT processes.

2. Variety of Nozzle Designs

Different applications require different nozzle designs. A reputable SMT nozzle manufacturer should offer a wide range of designs to accommodate various component shapes and sizes. This includes:

- Standard Nozzles: For common shapes like rectangular or cylindrical components.

- Custom Nozzles: Tailored designs for unique or irregularly shaped components.

- Specialized Nozzles: Such as those designed for high-speed applications or specific industries like automotive or medical devices.

A diverse product line indicates a manufacturer's capability to meet various production needs.

3. Precision Engineering

Precision is paramount in SMT processes. High-quality nozzles must be engineered to exact specifications to ensure they pick up and place components accurately. Look for manufacturers that utilize advanced engineering techniques, such as:

- Computer Numerical Control (CNC) Machining: Ensures high precision in manufacturing.

- Quality Control Processes: Regular testing and inspection protocols to maintain product standards.

Manufacturers that prioritize precision engineering will help minimize defects and improve overall production efficiency.

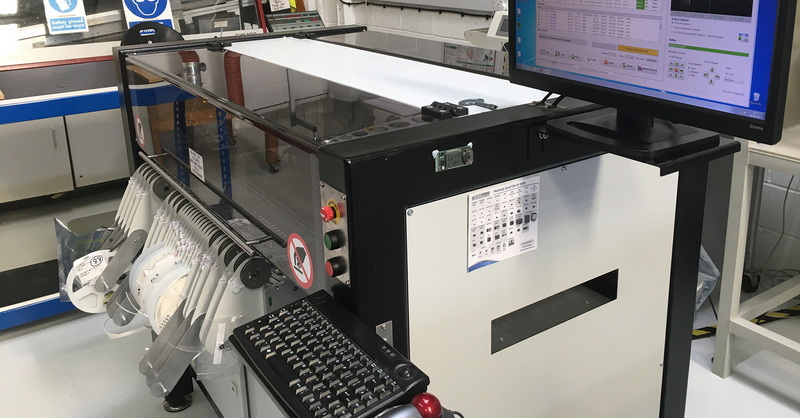

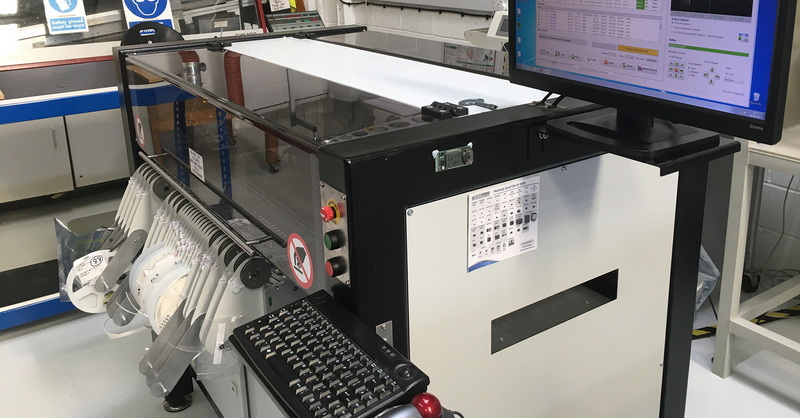

4. Compatibility with Equipment

The nozzles must be compatible with various pick-and-place machines. A good manufacturer should provide nozzles that fit multiple brands and models of equipment, allowing for flexibility in production lines. This compatibility reduces downtime during changes or upgrades to machinery.

Additionally, some manufacturers offer adapters or modifications that can enhance compatibility with older machines, ensuring that businesses can maximize their existing investments without needing significant upgrades.

5. Performance Metrics

A reliable manufacturer should provide performance metrics for their nozzles, including:

- Pick-and-Place Speed: How quickly components can be picked up and placed.

- Vacuum Retention: The ability of the nozzle to hold components securely during transport.

- Failure Rates: Data on how often nozzles fail or require maintenance.

Understanding these metrics helps assess whether a manufacturer's products will meet your production requirements effectively.

6. Customer Support and Service

Post-purchase support is crucial when selecting an SMT nozzle manufacturer. Look for companies that offer:

- Technical Support: Assistance with installation, maintenance, and troubleshooting.

- Training Programs: Resources to help your team understand how to use the nozzles effectively.

- Warranty Policies: Guarantees on products that provide peace of mind regarding quality and reliability.

Strong customer support indicates a manufacturer's commitment to their clients' success. Manufacturers who invest in customer relationships often provide additional resources such as online tutorials, troubleshooting guides, and dedicated support teams that can assist with urgent issues as they arise.

7. Cost-effectiveness

While quality is essential, cost also plays a significant role in decision-making. Evaluate the price-to-performance ratio of the nozzles offered by different manufacturers. Consider:

- Bulk Purchase Discounts: Many manufacturers offer discounts for large orders, which can significantly reduce costs.

- Long-term Value: Investing in higher-quality nozzles may reduce overall costs by minimizing defects and downtime over time.

Balancing quality with cost ensures you get the best value for your investment. It's also advisable to consider total cost ownership rather than just initial purchase price; this includes maintenance costs, replacement frequency, and potential downtime caused by inferior products.

8. Innovation and Technology

The electronics manufacturing industry is rapidly evolving, with new technologies emerging regularly. A forward-thinking manufacturer will invest in research and development to innovate their products continually. Features to look for include:

- Smart Nozzle Technologies: Advanced nozzles that can adapt based on component type or size can significantly enhance operational efficiency by reducing setup times between different product runs.

- Automated Cleaning Systems: Innovations that simplify maintenance tasks can improve efficiency significantly by reducing manual labor requirements and minimizing downtime associated with cleaning processes.

Staying ahead with innovative products can provide a competitive edge in production capabilities. Manufacturers who embrace cutting-edge technology often lead the market by offering solutions that enhance productivity while reducing waste and improving accuracy.

Additional Considerations When Choosing an SMT Nozzle Manufacturer

Beyond the primary features discussed above, there are other considerations that can influence your decision-making process:

1. Reputation in the Industry

Researching a manufacturer's reputation within the electronics manufacturing community can provide valuable insights into their reliability and product quality. Look for reviews from other businesses, case studies showcasing successful implementations, and any industry awards or recognitions received by the manufacturer.

2. Location and Logistics

The location of a manufacturer can impact shipping times and costs. Choosing a local manufacturer may reduce lead times significantly compared to sourcing from overseas suppliers. Additionally, consider logistics capabilities such as inventory management systems that allow you to track orders efficiently.

3. Sustainability Practices

As environmental concerns continue to grow globally, many companies are prioritizing sustainability in their supply chains. Investigate whether potential manufacturers adhere to eco-friendly practices such as using recyclable materials or implementing energy-efficient manufacturing processes. This commitment not only benefits the environment but also enhances your brand image when aligned with corporate social responsibility goals.

Conclusion

Selecting the right SMT nozzle manufacturer is critical for achieving optimal performance in electronics manufacturing. By focusing on quality materials, diverse designs, precision engineering, compatibility, performance metrics, customer support, cost-effectiveness, innovation, industry reputation, logistics considerations, and sustainability practices, businesses can ensure they choose a partner that enhances their production capabilities while aligning with their operational goals. Investing time in evaluating these features will lead to better outcomes in terms of efficiency, accuracy, and product quality on the assembly line.

FAQs

1. What materials are commonly used for SMT nozzles?

Common materials include ceramic, tungsten steel, diamond steel, and plastic. Each material has its advantages regarding durability and application suitability.

2. How do I determine if an SMT nozzle is compatible with my machine?

Check the manufacturer's specifications regarding compatibility with various brands and models of pick-and-place machines before making a purchase.

3. What are some signs that an SMT nozzle needs replacement?

Signs include visible wear or damage, decreased vacuum retention capability, or increased defect rates in component placement during production.

4. Can I customize nozzles for specific components?

Yes, many manufacturers offer custom nozzle designs tailored to unique component shapes or sizes needed for specific applications.

5. How often should I perform maintenance on my SMT nozzles?

Regular maintenance should be conducted based on usage frequency but generally recommended after every production shift or as specified by the manufacturer guidelines.

Citations:

[1] https://www.raypcb.com/smt-machine/

[2] https://www.rhsmt.com/news/china-smt-nozzle-manufacturer/

[3] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[4] https://smtnova.com/hanwha-smt-nozzles/

[5] https://www.gssmt-parts.com/what-are-the-key-factors-to-consider-when-choosing-an-smt-pick-and-place-nozzle-supplier.html

[6] http://www.bstkor.com/eng/product/bnc8000.html

[7] https://www.flason-smt.com/new/Analysis-of-smt-nozzle-Material.html

[8] https://www.neodensmt.com/other-products/smt-suction-nozzle.html

[9] https://www.tronstol.com/selection-and-function-of-pick-and-place-nozzle.html

[10] https://ap.connect.panasonic.com/ph/en/smart-factory-smt-tht-fatp-and-beyond