Content Menu

● Introduction to SMT Part Sizes

● Common SMT Part Sizes

>> 0201

>> 0402

>> 0603

>> 0805

>> 1206

>> Emerging Size: 01005

● Importance of Standardization

● Applications of Standard SMT Part Sizes

>> Detailed Application Insights

>>> Consumer Electronics

>>> Automotive Systems

>>> Telecommunications

>>> Medical Devices

>>> Industrial Automation

>>> Aerospace and Defense

● Challenges with Smaller SMT Part Sizes

>> Additional Challenges

>>> Design Complexity

>>> Testing Difficulties

● Design Considerations for PCB Development

>> Component Density

>> Layout Optimization

>> Thermal Management Solutions

>> Automated Assembly Compatibility

● Future Trends in SMT Part Sizes

>> Ultra-Small Packages (USP)

>> Advanced Packaging Technologies

>> Integration of IoT Components

● Conclusion

● FAQ

>> 1. What is the smallest SMT part size?

>> 2. Why are SMT part sizes standardized?

>> 3. What are the most common SMT part sizes?

>> 4. How do SMT part sizes affect electronic design?

>> 5. What are typical applications for 0603 SMT components?

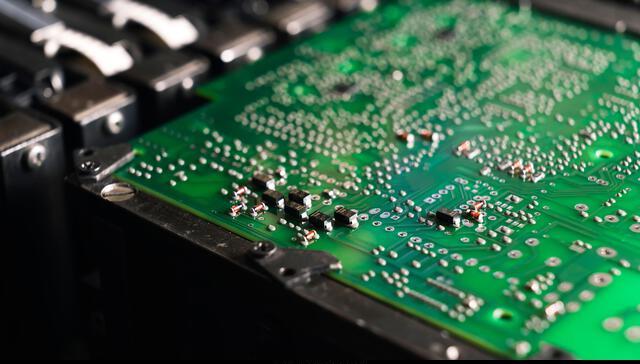

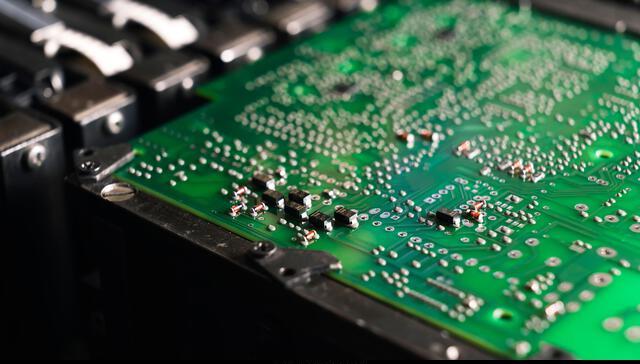

Surface Mount Technology (SMT) has transformed the electronics assembly landscape by enabling the direct mounting of components onto the surface of printed circuit boards (PCBs). This method not only enhances the efficiency of manufacturing processes but also allows for more compact and cost-effective designs. A critical aspect of SMT is the standardization of component sizes, known as SMT part sizes, which ensures compatibility and functionality across various electronic devices.

Introduction to SMT Part Sizes

SMT part sizes refer to the dimensions of components used in surface mount technology. These sizes are essential as they dictate how components fit onto a PCB, impacting the overall design and performance of electronic devices. The standardization of SMT part sizes facilitates mass production, reduces manufacturing costs, and ensures that components from different manufacturers can be interchanged without compatibility issues.

Common SMT Part Sizes

The most common SMT part sizes include:

- 0201

- 0402

- 0603

- 0805

- 1206

- 01005 (emerging trend)

These numbers represent dimensions in inches, where the first two digits indicate length and the last two digits indicate width. For example, a 0603 component measures 0.06 inches in length and 0.03 inches in width.

0201

The 0201 size is one of the smallest available, measuring just 0.02 inches by 0.01 inches. These components are typically used in applications with stringent space limitations, such as mobile devices and RF circuits. The miniaturization trend has led to increased use of this size in high-density PCBs.

0402

The 0402 size is slightly larger, measuring 0.04 inches by 0.02 inches. This size is commonly found in consumer electronics and sensors, where a balance between size and performance is crucial. Its compactness allows for more efficient use of board space without compromising functionality.

0603

The 0603 size is among the most widely used SMT components, measuring 0.06 inches by 0.03 inches. Its versatility makes it suitable for various applications, including power management systems and audio devices. The popularity of this size stems from its balance between ease of handling and performance characteristics.

0805

Measuring 0.08 inches by 0.05 inches, the 0805 size is often utilized in LED drivers and industrial applications. This size provides a good compromise between compactness and power handling capabilities, making it suitable for applications requiring higher power dissipation.

1206

The 1206 size is larger at 0.12 inches by 0.06 inches and is typically employed in high-power applications and automotive electronics where larger components are necessary to accommodate increased power levels.

Emerging Size: 01005

The 01005 package size is an emerging trend in miniaturization, measuring just 0.016 inches by 0.008 inches. These ultra-small components are becoming increasingly common in advanced electronics like smartphones and wearables, pushing the limits of what is possible in component miniaturization.

Importance of Standardization

Standardizing SMT part sizes is vital for several reasons:

- Interchangeability: It allows manufacturers to produce components that can be used interchangeably across different PCB designs.

- Supply Chain Efficiency: Standardization simplifies the supply chain by reducing complexity in sourcing parts from multiple suppliers.

- Quality Control: It helps maintain consistent quality and reliability across various electronic devices.

As technology advances, there is a continuous push towards miniaturization, leading to an increasing demand for smaller SMT part sizes like 01005, which measures just 0.016 inches by 0.008 inches.

Applications of Standard SMT Part Sizes

Standard SMT part sizes are utilized across a wide range of applications:

- Consumer Electronics: Devices such as smartphones, tablets, and laptops rely heavily on compact SMT components to maximize functionality while minimizing size.

- Automotive Systems: Modern vehicles incorporate numerous electronic systems that require reliable and efficient components to ensure safety and performance.

- Telecommunications: In telecommunications, SMT components play a vital role in communication devices and networking equipment.

- Medical Devices: High precision and reliability are paramount in medical devices; thus, SMT components are extensively utilized here.

- Industrial Automation: Robotics and control systems benefit from the small size and high-speed capabilities of SMT components.

- Aerospace and Defense: Critical applications like avionics rely on lightweight yet robust electronics made possible through SMT technology.

Detailed Application Insights

Consumer Electronics

In consumer electronics, the demand for smaller devices with enhanced functionality drives the need for compact SMT parts. For instance, smartphones incorporate various sensors, processors, and communication modules that require efficient use of PCB space. The use of smaller parts like 0201 or 0402 allows manufacturers to integrate more features into slimmer designs without sacrificing performance.

Automotive Systems

The automotive industry has seen a significant shift towards electronic systems that enhance safety, efficiency, and user experience. From advanced driver-assistance systems (ADAS) to infotainment units, automotive electronics rely on reliable SMT parts to function correctly under varying conditions. Larger components like 1206 may be used for power management circuits due to their ability to handle higher currents.

Telecommunications

Telecommunications equipment must support high data rates while maintaining compact designs to fit into limited spaces within network infrastructure setups. Components like 0603 or smaller packages are often used in RF modules that require precise signal integrity while minimizing interference.

Medical Devices

In medical technology, reliability is crucial as these devices often operate under strict regulatory standards to ensure patient safety. The use of standard SMT sizes allows for consistent manufacturing practices while enabling manufacturers to produce compact devices that can easily fit into wearable health monitors or implantable devices.

Industrial Automation

Industrial automation systems often utilize a variety of sensors and controllers that benefit from compact designs provided by SMT technology. Smaller packages allow for dense configurations on PCBs that can withstand harsh environments while ensuring high reliability.

Aerospace and Defense

In aerospace applications, weight reduction is critical; thus, using smaller SMT parts can significantly affect overall system weight without compromising functionality or reliability. Components must also withstand extreme conditions such as temperature fluctuations and vibrations typical in aviation environments.

Challenges with Smaller SMT Part Sizes

While smaller SMT part sizes offer numerous advantages, they also present challenges:

- Manufacturing Precision: As component sizes decrease, the precision required during assembly increases significantly.

- Handling Difficulty: Smaller parts can be more challenging to handle during assembly processes due to their diminutive size.

- Thermal Management: Smaller components may have limited thermal dissipation capabilities, necessitating careful design considerations to avoid overheating.

Additional Challenges

Design Complexity

As designers strive to pack more functionality into smaller spaces using standard SMT part sizes, they face increasing complexity in layout design. This complexity includes ensuring proper electrical routing while maintaining signal integrity across densely populated boards.

Testing Difficulties

Testing smaller components can also be challenging due to their size; specialized equipment may be required to accurately assess their performance without damaging them during testing procedures.

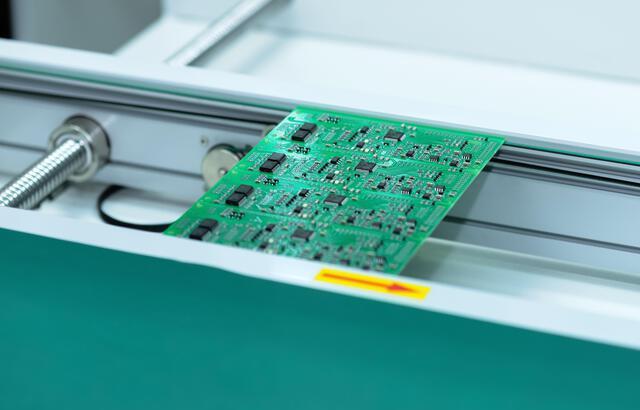

Design Considerations for PCB Development

When designing PCBs with SMT parts, several considerations must be taken into account:

Component Density

Higher component density allows for more functionality within a smaller footprint but may complicate manufacturing processes due to increased potential for errors during assembly or soldering.

Layout Optimization

Proper layout optimization ensures that signal integrity is maintained while minimizing electromagnetic interference (EMI). Designers must carefully consider trace widths and spacing between components based on their respective power requirements.

Thermal Management Solutions

Implementing thermal management solutions is crucial for ensuring that smaller components do not overheat during operation. Techniques such as thermal vias or heat sinks may be necessary depending on component specifications.

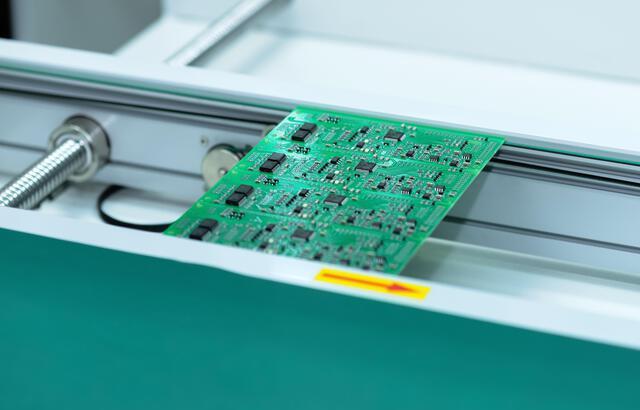

Automated Assembly Compatibility

Designs should consider compatibility with automated assembly equipment to streamline production processes; this includes ensuring proper pad dimensions for pick-and-place machines as well as solder paste application methods.

Future Trends in SMT Part Sizes

As technology continues to evolve, we can expect further trends toward miniaturization:

Ultra-Small Packages (USP)

The emergence of ultra-small packages such as the 01005 will likely continue as consumer demand for smaller devices grows alongside advancements in manufacturing techniques that enable production at these scales.

Advanced Packaging Technologies

Manufacturers are investing in new technologies like flip chip packaging and wafer-level packaging to create smaller components that maintain performance levels while reducing overall footprint significantly compared with traditional packages.

Integration of IoT Components

With the rise of IoT devices requiring efficient communication capabilities within tight spaces comes an increased need for compact yet powerful SMT parts capable of meeting diverse application requirements across various sectors including smart home technologies or wearables designed specifically for health monitoring purposes among others.

Conclusion

In summary, SMT part sizes play a crucial role in modern electronics assembly by facilitating efficient design and production processes. The standardization of these sizes ensures compatibility across various manufacturers and applications while contributing significantly towards evolving electronic devices into more compact yet efficient designs capable of meeting ever-growing demands from consumers worldwide seeking innovative solutions tailored specifically towards improving their daily lives through technology integration seamlessly woven into everyday objects surrounding them today!

As technology continues advancing rapidly within this field—pushing boundaries further than ever before—it's likely we'll see even greater innovations emerge regarding component sizing alongside enhanced capabilities arising from new materials being developed aimed at optimizing performance characteristics further still!

FAQ

1. What is the smallest SMT part size?

The smallest standard SMT part size is 0201, measuring 0.02 inches by 0.01 inches, commonly used in applications with very limited space.

2. Why are SMT part sizes standardized?

SMT part sizes are standardized to ensure compatibility across different manufacturers' products while facilitating easier assembly processes that reduce overall manufacturing costs significantly over time!

3. What are the most common SMT part sizes?

The most common SMT part sizes include 0201, 0402, 0603, 0805, and 1206, each suited perfectly towards meeting diverse application needs ranging from consumer electronics through automotive systems alike!

4. How do SMT part sizes affect electronic design?

SMT part sizes influence electronic design directly by determining how individual components fit onto PCBs—affecting overall device functionality/performance based upon available space constraints imposed upon designers!

5. What are typical applications for 0603 SMT components?

0603 SMT components are versatile enough being utilized frequently within power management systems/audio devices/consumer electronics/general-purpose applications alike!