Content Menu

● Introduction

● Overview of SMD LED Chip Machines

>> Key Features of SMD LED Chip Machines

● Applications of SMD LED Chip Machines

>> Residential and Commercial Lighting

>> Automotive Lighting

>> Display Technology

>> Horticulture Lighting

>> Outdoor and Architectural Lighting

● Benefits of Using SMD LED Chip Machines

● Challenges and Future Developments

>> Emerging Trends in LED Technology

● Impact on Global Markets

>> Role in Energy Efficiency and Sustainability

● Technological Advancements in SMD Displays

>> Future Applications of SMD LEDs

● Conclusion

● Frequently Asked Questions

>> 1. What does SMD stand for in LED lights?

>> 2. What are the advantages of using SMD LEDs over traditional LEDs?

>> 3. What are the common applications of SMD LEDs?

>> 4. How do SMD LED chip machines improve production efficiency?

>> 5. What are the future developments expected in SMD LED technology?

● Citations:

Introduction

SMD (Surface Mount Device) LED chips have revolutionized the lighting industry with their compact size, high efficiency, and versatility. These chips are widely used in various applications, from residential lighting to large-scale displays. The production of SMD LEDs involves sophisticated machinery, known as SMD LED chip machines, which are crucial for manufacturing high-quality LEDs. This article will explore the most popular applications of SMD LED chip machines and delve into the benefits and features of these machines.

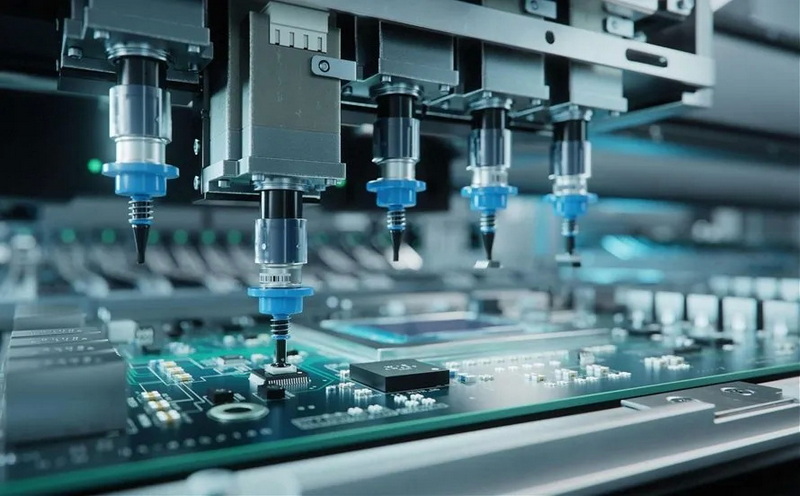

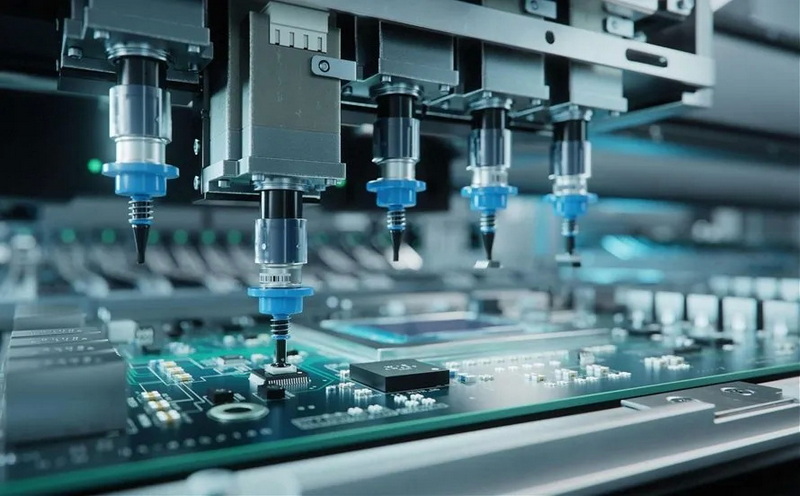

Overview of SMD LED Chip Machines

SMD LED chip machines are designed to handle the precise assembly and testing of SMD LEDs. These machines utilize advanced surface mount technology (SMT) to place LED chips onto printed circuit boards (PCBs) efficiently. The process involves several stages, including component placement, soldering, and inspection, ensuring that the LEDs are accurately positioned and securely attached to the PCB.

Key Features of SMD LED Chip Machines

1. High Precision: These machines offer precise placement of LED chips, ensuring minimal errors and high-quality output.

2. Efficiency: They can handle large volumes of production, making them ideal for mass production environments.

3. Flexibility: SMD LED chip machines can be adapted for various types of LED chips, including different sizes and configurations.

Applications of SMD LED Chip Machines

SMD LED chip machines are used in a wide range of applications due to their versatility and efficiency. Some of the most popular applications include:

Residential and Commercial Lighting

SMD LEDs are widely used in residential and commercial lighting due to their energy efficiency and long lifespan. They are commonly found in recessed lighting, track lighting, and downlights. SMD LED chip machines play a crucial role in producing these LEDs, ensuring consistent quality and performance. In commercial settings, SMD LEDs are often used in high-bay lighting for warehouses and retail spaces, providing bright and reliable illumination.

Automotive Lighting

In the automotive sector, SMD LEDs are used in headlights and taillights, providing bright and focused illumination. The reliability and durability of SMD LEDs make them ideal for automotive applications, where they are exposed to various environmental conditions. Additionally, SMD LEDs are used in interior lighting, such as dashboard lights and ambient lighting, enhancing the overall driving experience.

Display Technology

SMD LEDs are used as backlighting for LCD displays in devices such as televisions, smartphones, and tablets. Their ability to provide uniform illumination enhances the display quality and visibility of these devices. In high-end displays, SMD LEDs are often arranged in a matrix to achieve higher contrast ratios and better color accuracy.

Horticulture Lighting

In horticulture, SMD LEDs are used to create custom light spectra tailored to different stages of plant growth. Their energy efficiency and ability to produce specific wavelengths make them ideal for indoor farming and greenhouses. By adjusting the spectrum, growers can optimize plant growth, increase yields, and reduce energy consumption.

Outdoor and Architectural Lighting

SMD LEDs are used in outdoor lighting applications, including street lighting and landscape lighting. Their durability and resistance to weather conditions make them suitable for outdoor environments. In architectural lighting, SMD LEDs are used to highlight building features and create visually appealing effects, enhancing the aesthetic appeal of structures.

Benefits of Using SMD LED Chip Machines

1. Increased Efficiency: These machines automate the production process, reducing manual labor and increasing output.

2. Improved Quality: By ensuring precise placement and soldering, SMD LED chip machines help maintain high-quality standards.

3. Cost Savings: The efficiency and precision of these machines reduce waste and minimize the need for rework, leading to cost savings.

Challenges and Future Developments

Despite the advantages of SMD LED chip machines, there are challenges related to maintaining high precision and adapting to new technologies. Future developments are likely to focus on enhancing machine precision and integrating new LED technologies, such as COB (Chip On Board) LEDs, into production lines. Additionally, advancements in automation and AI could further optimize production processes, improving efficiency and reducing costs.

Emerging Trends in LED Technology

1. Miniaturization: The trend towards smaller LED chips continues, enabling more compact lighting solutions and higher density displays.

2. Color Tuning: Advances in LED technology allow for precise color tuning, enabling applications like smart lighting that can adjust color temperature based on time of day or environment.

3. Sustainability: There is a growing focus on sustainable LED production, with efforts to reduce the use of hazardous materials in manufacturing, improve recyclability, and enhance energy efficiency further[2].

Impact on Global Markets

The use of SMD LED chip machines has a significant impact on global markets. As demand for energy-efficient lighting solutions increases, the production capacity of SMD LEDs must also rise. This has led to investments in new manufacturing facilities and the development of more advanced machinery. Furthermore, the versatility of SMD LEDs has opened up new markets, such as horticulture and automotive lighting, which were previously less prominent.

Role in Energy Efficiency and Sustainability

SMD LEDs play a crucial role in energy efficiency and sustainability. They convert a high percentage of their energy into light, reducing waste heat and energy consumption compared to traditional lighting methods[4]. This efficiency not only saves energy but also reduces greenhouse gas emissions, contributing to global sustainability efforts.

Technological Advancements in SMD Displays

In recent years, SMD display technology has seen significant advancements. For instance, higher pixel densities have improved image quality, making SMD screens ideal for outdoor advertising and event displays[1]. Additionally, improved energy efficiency and weather-resistant designs have expanded their use in various applications[1].

Future Applications of SMD LEDs

As technology evolves, SMD LEDs are expected to play a key role in emerging applications such as smart lighting systems integrated with IoT technology, flexible displays for wearable devices, and advanced automotive lighting systems[2]. Their versatility and efficiency make them suitable for a wide range of innovative uses.

Conclusion

SMD LED chip machines are essential for the production of high-quality SMD LEDs, which are used in a wide range of applications. Their efficiency, precision, and flexibility make them indispensable in modern lighting manufacturing. As technology continues to evolve, these machines will play a crucial role in adapting to new LED technologies and meeting the increasing demand for efficient and reliable lighting solutions.

Frequently Asked Questions

1. What does SMD stand for in LED lights?

- SMD stands for Surface Mount Device. It refers to a type of LED that is mounted directly onto a printed circuit board (PCB) without leads, offering a compact and efficient design.

2. What are the advantages of using SMD LEDs over traditional LEDs?

- SMD LEDs offer several advantages, including higher efficiency, longer lifespan, and lower power consumption compared to traditional LEDs. They also provide a wider beam angle and can be clustered together for brighter light output.

3. What are the common applications of SMD LEDs?

- SMD LEDs are commonly used in residential and commercial lighting, automotive lighting, display technology, horticulture, and outdoor lighting applications.

4. How do SMD LED chip machines improve production efficiency?

- SMD LED chip machines automate the assembly and testing process, reducing manual labor and increasing production volume. They ensure precise placement and soldering, minimizing errors and rework.

5. What are the future developments expected in SMD LED technology?

- Future developments are expected to focus on enhancing machine precision, integrating new LED technologies like COB LEDs, and adapting to emerging applications such as advanced horticulture and high-resolution displays.

Citations:

[1] https://ledsino.com/blog/evolution-of-smd-screens/

[2] https://www.megasigninc.com/blog/what-are-smd-leds

[3] https://www.allaboutcircuits.com/industry-articles/smd-led-considerations-for-lighting-and-indicator-applications/

[4] https://www.paclights.com/explore/the-impact-of-surface-mount-led-on-energy-savings-and-sustainability/

[5] https://tech-led.com/evolution-led-applications/

[6] https://www.vision-systems.com/home/article/55136636/how-have-lighting-solutions-evolved-to-keep-pace-with-advances-in-machine-vision-camera-technology

[7] https://www.doitvision.com/led-displays-4/

[8] https://www.linkedin.com/pulse/benefits-high-efficiency-smd-leds-led-lighting-fixtures-winny-liu-elfrc

[9] https://www.zgsm-china.com/blog/something-you-should-know-about-leds.html

[10] https://www.bivar.com/resources/leds-technology-and-applications/

[11] https://www.minimicroled.com/mip-technology-a-new-era-for-led-packaging/

[12] https://www.hpwinner.com/shaping-the-future-of-lighting-the-aesthetics-and-functionality-of-module-led-smd.html

[13] https://www.queendomlamp.com/revolutionizing-lighting-the-advancements-and-applications-of-small-smd-leds/

[14] https://www.hpwinner.com/efficiency-redefined-how-module-led-smd-is-revolutionizing-energy-consumption.html

[15] https://www.thal-technologies.com/led-smb-smd/

[16] https://www.linkedin.com/pulse/latest-technology-advancements-flexible-led-strips-neon-%E8%81%AAcici-%E6%9B%B9-uuwjc

[17] https://www.queendomlamp.com/revolutionizing-lighting-technology-the-future-of-smd-led-innovations/

[18] https://www.dp-light.com/news/smd-led-packaging-technology-the-future-of-led-lighting-282788.html

[19] https://www.hpwinner.com/green-lighting-revolution-the-ecofriendly-impact-of-module-led-smd.html

[20] https://www.getiangroup.com/resources/comparison-of-smd-led-types-and-application-tips.html