Content Menu

● Introduction to SMT Reel Storage Racks

>> Key Features of Durable SMT Reel Storage Racks

● Benefits of Using Durable SMT Reel Storage Racks

>> Improved Efficiency

>> Enhanced Inventory Management

>> Protection of Components

>> Cost-Effectiveness

● Examples of Durable SMT Reel Storage Racks

>> TDI International's SMT Reel Storage Desiccator Cabinets

>> KenWei's SMD Smart Carts

>> Inovaxe's Smart Racks

>> Neo Light Plus by Neotel Technology

● Trends in SMT Reel Storage

>> Hyper-Dense Storage Systems

>> Dynamic Adaptability

>> Goods-to-Person Systems

>> Sustainable Storage Solutions

>> Connected Warehousing

● Future of SMT Reel Storage

● Conclusion

● Frequently Asked Questions

>> 1. What materials are used for durable SMT reel storage racks?

>> 2. How do SMT reel storage racks protect against ESD and moisture?

>> 3. Can SMT reel storage racks accommodate different reel sizes?

>> 4. What level of automation can I expect from SMT reel storage systems?

>> 5. How do SMT reel storage racks improve inventory management?

● Citations:

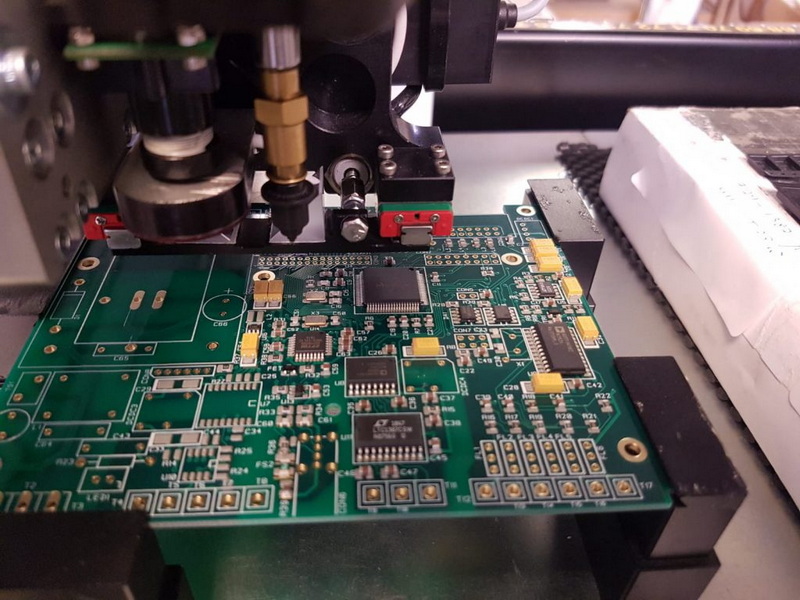

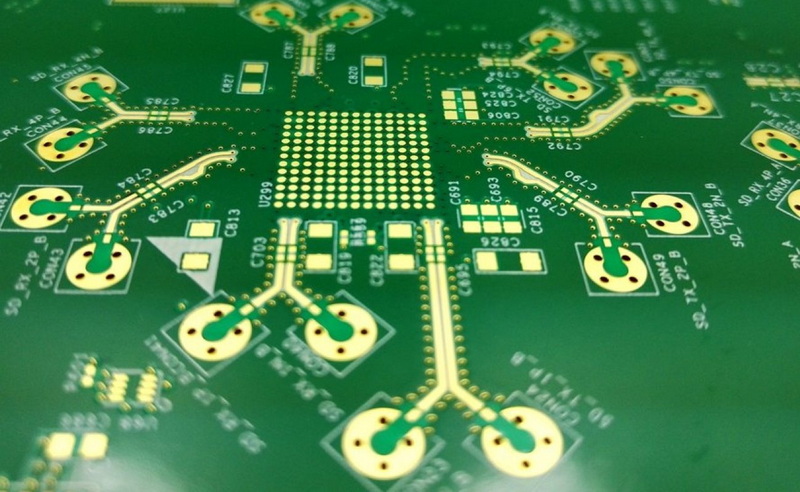

In the fast-paced world of electronics manufacturing, the efficient storage and management of Surface Mount Technology (SMT) reels are crucial for maintaining production efficiency and component integrity. SMT reel storage racks play a vital role in organizing, protecting, and efficiently retrieving components for production processes. This article will delve into the features and benefits of the most durable SMT reel storage racks available today, highlighting their importance in modern electronics manufacturing.

Introduction to SMT Reel Storage Racks

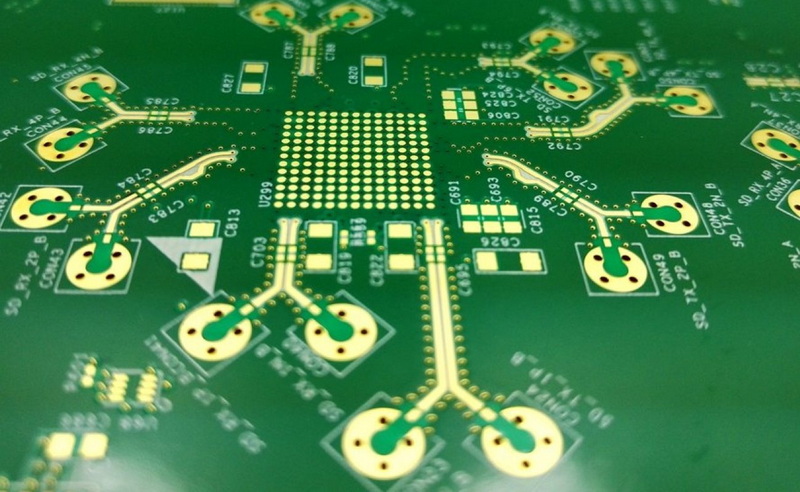

SMT reel storage racks are specialized systems designed to store and manage the reels of electronic components used in surface mount technology manufacturing. These systems are essential for protecting sensitive components from environmental factors such as humidity and electrostatic discharge (ESD), while also optimizing storage space and improving inventory management.

Key Features of Durable SMT Reel Storage Racks

1. Material and Construction: Durable SMT reel storage racks are often made from high-quality materials such as industrial aluminum alloys or static dissipative acrylic. These materials ensure that the racks are not only robust but also provide ESD protection, which is critical for preventing damage to sensitive electronic components.

2. Modular Design: Modular designs allow for easy expansion and customization, making them highly adaptable to changing storage needs. This feature is particularly beneficial for manufacturers who need to accommodate different reel sizes and types.

3. Climate Control and ESD Protection: Advanced systems often include climate control features to maintain stable temperature and humidity conditions, ensuring that components remain in optimal condition. Additionally, built-in ESD protection measures safeguard components against static electricity.

4. Automation and Inventory Management: Many modern SMT reel storage racks integrate with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This integration enhances stock management and reduces errors.

5. Space Optimization: Vertical storage solutions, such as carousels and lift modules, maximize vertical space, significantly reducing the footprint required for component storage. This is particularly advantageous in facilities with limited floor space.

Benefits of Using Durable SMT Reel Storage Racks

Improved Efficiency

- Quick Access and Retrieval: Automated systems can retrieve reels in seconds, significantly reducing kitting time and increasing production efficiency.

- Reduced Errors: Guided retrieval systems minimize the risk of component mix-ups or losses, ensuring smoother operations.

Enhanced Inventory Management

- Real-Time Tracking: Advanced systems provide accurate and timely stock data, enabling informed decisions and efficient resource management.

- Component Traceability: Detailed records of component usage and location facilitate quality control and audits.

Protection of Components

- ESD and Moisture Protection: Built-in protective measures ensure that sensitive components are safeguarded against environmental hazards.

- Secure Storage: Features like locks and alarms prevent unauthorized access, protecting valuable components.

Cost-Effectiveness

- Space Savings: Vertical storage solutions save floor space, allowing for more efficient use of facility resources.

- Long-Term Durability: High-quality materials and construction reduce maintenance costs and extend the lifespan of the storage racks.

Examples of Durable SMT Reel Storage Racks

TDI International's SMT Reel Storage Desiccator Cabinets

TDI International offers high-density SMT reel storage desiccator cabinets designed for clean and dry nitrogen environments. These cabinets feature slide drawer trays for easy access, upright reel storage for efficient space use, and a continuous nitrogen gas source for optimal humidity control. The use of 1/4" static dissipative acrylic ensures ESD safety and prevents the buildup of static charges.

KenWei's SMD Smart Carts

KenWei provides intelligent SMT reel storage solutions with modular designs, allowing for rapid assembly and disassembly. These systems integrate with inventory management software, offering real-time tracking and lighting guidance for efficient material retrieval. The use of industrial aluminum alloys ensures durability while maintaining a lightweight structure.

Inovaxe's Smart Racks

Inovaxe's Smart Racks are highly configurable and cost-effective, offering high-density storage options. The SR series can store up to 560 reels in about 3 square feet, while the SREX series stores up to 880 reels in only 2.5 square feet. These racks are ideal for maximizing storage capacity in limited spaces.

Neo Light Plus by Neotel Technology

Neo Light PLUS is an innovative storage solution designed specifically for SMT reels. This advanced system combines the convenience of Pick to Light technology with the added benefit of location sensors for material detection. It significantly improves over traditional SMT reel storage solutions and provides numerous benefits for electronics manufacturers. The system can store up to 1400 reels per rack, significantly increasing storage capacity and enhancing inventory management.

Trends in SMT Reel Storage

Hyper-Dense Storage Systems

The trend towards hyper-dense storage systems is gaining momentum, with solutions like high-density mobile shelving and ActivRAC systems becoming more popular. These systems allow for double or triple storage capacity without expanding warehouse footprints, making them ideal for facilities with limited space.

Dynamic Adaptability

Dynamic storage solutions, such as modular shelving and mezzanines, are increasingly favored for their adaptability to fluctuating SKU volumes and inventory types. This flexibility enhances overall warehouse efficiency and responsiveness to changing production demands.

Goods-to-Person Systems

Goods-to-person workflows, powered by Vertical Lift Modules (VLMs) and Automated Storage and Retrieval Systems (ASRS), are transforming inventory movement. These technologies eliminate hours wasted retrieving items manually and improve order-picking accuracy, leading to faster and more efficient production processes.

Sustainable Storage Solutions

Eco-conscious businesses are seeking energy-efficient and recyclable shelving options. As sustainability becomes a priority, expect an increase in storage systems with minimal environmental impact.

Connected Warehousing

The integration of IoT sensors and AI is becoming the norm, providing real-time visibility into inventory levels, shelf conditions, and storage utilization. This enables more intelligent decision-making and optimized warehouse operations.

Future of SMT Reel Storage

As technology continues to evolve, SMT reel storage systems are expected to become even more sophisticated. The integration of advanced automation, AI, and IoT technologies will further enhance efficiency, reduce errors, and improve inventory management. Additionally, there will be a greater emphasis on sustainable and eco-friendly storage solutions to align with global environmental goals.

Conclusion

In conclusion, durable SMT reel storage racks are indispensable in modern electronics manufacturing for their ability to protect components, optimize storage space, and enhance operational efficiency. By selecting the right storage system, manufacturers can significantly improve their production processes, reduce costs, and ensure the integrity of sensitive electronic components.

Frequently Asked Questions

1. What materials are used for durable SMT reel storage racks?

Durable SMT reel storage racks are often made from high-quality materials such as industrial aluminum alloys or static dissipative acrylic. These materials provide both structural integrity and ESD protection.

2. How do SMT reel storage racks protect against ESD and moisture?

Advanced SMT reel storage racks include features such as climate control to maintain stable humidity levels and ESD protection measures like grounding mechanisms and static dissipative materials to safeguard components.

3. Can SMT reel storage racks accommodate different reel sizes?

Yes, many modern SMT reel storage systems are designed to accommodate various reel sizes. Modular designs allow for customization to fit specific storage needs, including reels of different diameters and widths.

4. What level of automation can I expect from SMT reel storage systems?

The level of automation varies from basic guided light systems for manual picking to fully automated storage and retrieval systems using robotic mechanisms. The choice depends on specific operational needs and budget.

5. How do SMT reel storage racks improve inventory management?

SMT reel storage racks improve inventory management by integrating with inventory management software, providing real-time tracking of component quantities, locations, and usage history. This enhances stock accuracy and facilitates informed decision-making.

Citations:

[1] https://industrial4less.com/collections/reel-shelving-units

[2] https://global.neotel.tech/products/neo-light-series/neo-light-plus/

[3] https://inovaxe.com/smt-reel-storage/

[4] https://inovaxe.com/inovaxe-to-launch-new-smart-racks-alongside-pick-and-place-machines-at-smtai/

[5] https://www.scanditron.com/equipment/stower-ii-komponenttorn/

[6] https://blog.mcmurraystern.com/en/2025-storage-and-shelving-trends-for-warehouses

[7] https://www.allsmt.com/automated-warehouse-systems-smt-production

[8] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[9] https://www.allsmt.com/SMT-Feederstorage

[10] https://www.globalsmt.net/trade-show-news/accu-assembly-to-debut-accucart-smart-rack-for-feeders-at-apex-2025/

[11] https://www.youtube.com/watch?v=FqXA2UmkJRY

[12] https://www.thebusinessresearchcompany.com/report/surface-mount-technology-smt-equipment-global-market-report

[13] https://smttoday.com/2024/08/13/explore-the-latest-innovations-in-smt-material-handling-from-inovaxe-at-smta-guadalajara/

[14] https://resources.sw.siemens.com/zh-TW/white-paper-smart-solutions-for-smt-reel-storage/

[15] https://inovaxe.com/optimize-storage-efficiency-with-inovaxe-at-smtai-2024/

[16] https://smttoday.com/2025/02/20/inovaxe-to-unveil-smart-storage-technologies-at-apex/

[17] https://inovaxe.com

[18] https://www.wicz.com/story/52271912/2025-2033-Heavy-Duty-Storage-Rack-Market-Research-Report-Analysis

[19] https://smt.asmpt.com/en/products/storage-solutions/material-tower/

[20] https://smta.org/news/686700/Accu-Assembly-to-Exhibit-Innovative-Component-Storage-Solutions-at-SMTA-Space-Coast-Expo.htm