Content Menu

● Understanding Surface Mount Technology

● The Importance of SMT Training

● Latest Trends in SMT Training

>> 1. Increased Focus on Automation

>> 2. Emphasis on Quality Control

>> 3. Integration of Virtual and Augmented Reality

>> 4. Sustainability and Environmental Considerations

>> 5. Customized Training Solutions

● The Role of Certification in SMT Training

>> Popular Certification Programs

● Conclusion

● Related Questions

>> 1. What are the key benefits of Surface Mount Technology training?

>> 2. How does automation impact Surface Mount Technology training?

>> 3. What role does certification play in SMT training?

>> 4. How can virtual reality be used in SMT training?

>> 5. Why is sustainability important in Surface Mount Technology training?

Surface Mount Technology (SMT) has become a cornerstone of modern electronics manufacturing, enabling the production of compact, high-performance devices. As the industry evolves, so too does the training required to keep pace with these advancements. This article explores the latest trends in Surface Mount Technology training, highlighting the skills and knowledge that professionals need to thrive in this dynamic field.

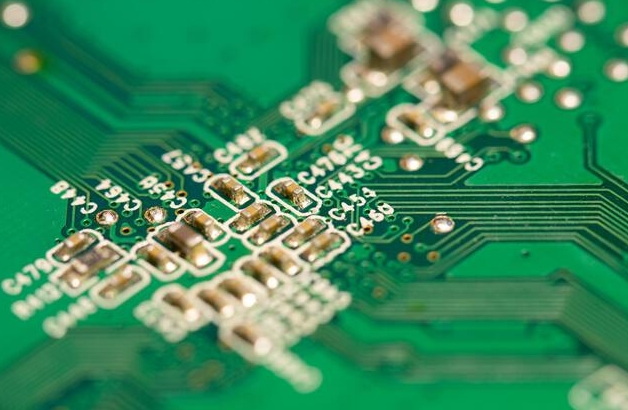

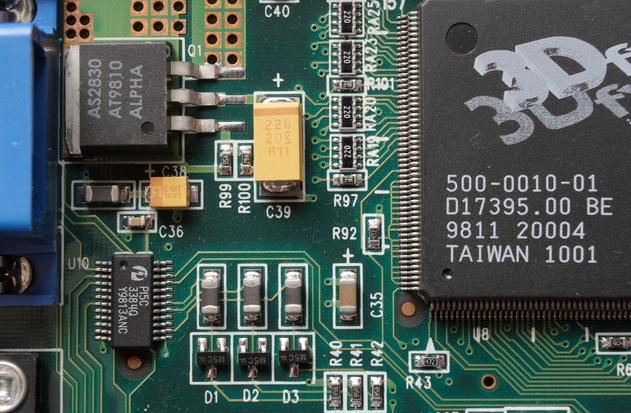

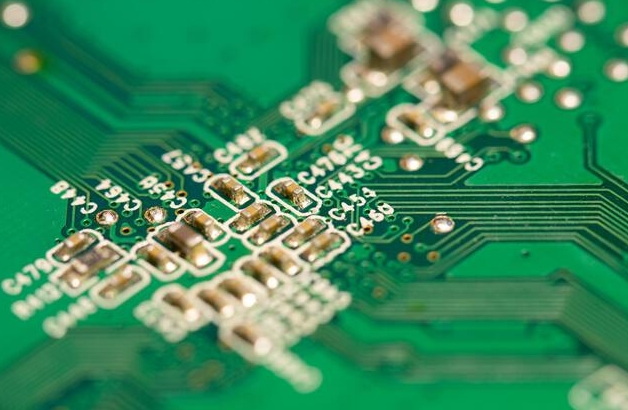

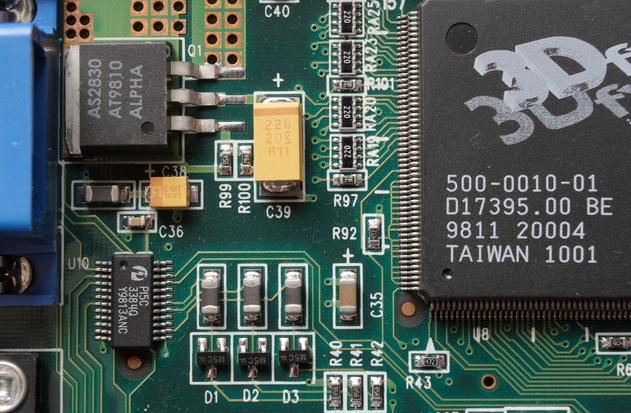

Understanding Surface Mount Technology

Surface Mount Technology refers to a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for smaller components and more efficient use of space. This technology has revolutionized the electronics industry, leading to the development of smaller, lighter, and more reliable devices.

The Importance of SMT Training

As SMT continues to advance, the need for specialized training becomes increasingly critical. Professionals in the electronics manufacturing sector must stay updated on the latest techniques, tools, and best practices to ensure high-quality production. Training programs focused on SMT cover a range of topics, including:

- Soldering Techniques: Understanding the various soldering methods used in SMT, including reflow soldering and wave soldering.

- Component Placement: Learning how to accurately place components on PCBs to ensure optimal performance.

- Inspection and Testing: Familiarizing oneself with automated optical inspection (AOI) and other testing methods to ensure quality control.

Latest Trends in SMT Training

1. Increased Focus on Automation

With the rise of Industry 4.0, automation is becoming a significant trend in SMT training. Training programs are increasingly incorporating lessons on automated assembly processes, robotics, and machine learning. This shift helps professionals understand how to work alongside advanced machinery and optimize production efficiency.

2. Emphasis on Quality Control

Quality control is paramount in electronics manufacturing. Recent trends in SMT training emphasize the importance of quality assurance practices. Training now includes modules on statistical process control (SPC), failure mode and effects analysis (FMEA), and other methodologies that help ensure product reliability and compliance with industry standards.

3. Integration of Virtual and Augmented Reality

Virtual and augmented reality (VR/AR) technologies are being integrated into SMT training programs. These immersive technologies allow trainees to practice skills in a simulated environment, providing hands-on experience without the risks associated with real-world assembly. This trend enhances learning outcomes and prepares professionals for the complexities of modern SMT processes.

4. Sustainability and Environmental Considerations

As the electronics industry faces increasing scrutiny regarding its environmental impact, SMT training is adapting to include sustainability practices. Training programs now cover topics such as waste reduction, energy-efficient manufacturing processes, and the use of eco-friendly materials. This focus on sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers.

5. Customized Training Solutions

Recognizing that different organizations have unique needs, many training providers are offering customized SMT training solutions. These tailored programs allow companies to address specific challenges and skill gaps within their workforce. Customization can include on-site training, specialized workshops, and the development of proprietary training materials.

The Role of Certification in SMT Training

Certification plays a crucial role in validating the skills and knowledge acquired through SMT training. Various organizations offer certification programs that demonstrate a professional's competency in SMT practices. These certifications can enhance career prospects and provide a competitive edge in the job market.

Popular Certification Programs

- IPC-A-610: Acceptability of Electronic Assemblies

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

- IPC-7711/7721: Rework, Modification, and Repair of Electronic Assemblies

Conclusion

The landscape of Surface Mount Technology training is rapidly evolving, driven by advancements in automation, quality control, and sustainability. As the demand for skilled professionals in the electronics manufacturing sector continues to grow, staying abreast of these trends is essential. By investing in comprehensive SMT training, individuals and organizations can ensure they remain competitive in a fast-paced industry.

Related Questions

1. What are the key benefits of Surface Mount Technology training?

Surface Mount Technology training enhances skills in soldering, component placement, and quality control, leading to improved job performance and career advancement.

2. How does automation impact Surface Mount Technology training?

Automation introduces new technologies and processes that require specialized training, focusing on how to operate and optimize automated assembly systems.

3. What role does certification play in SMT training?

Certification validates the skills acquired through training, enhancing career prospects and demonstrating competency to employers.

4. How can virtual reality be used in SMT training?

Virtual reality provides a safe, immersive environment for trainees to practice SMT skills, improving learning outcomes and confidence.

5. Why is sustainability important in Surface Mount Technology training?

Sustainability practices in SMT training address environmental concerns and regulatory requirements, promoting responsible manufacturing processes.