Content Menu

● The Rise of AI and Automation in PCB SMT

>> AI-Driven Design Optimization

>> Automated Assembly and Inspection

>> Predictive Maintenance

● Advanced Materials Driving Innovation

>> Flexible and Stretchable PCBs

>> Graphene and Nanomaterials

>> Eco-Friendly Substrates

● The Growth of 3D PCB Printing

>> Additive Manufacturing for Complex Designs

>> On-Demand Production

>> Hybrid 3D-Printed Electronics

● Sustainable and Green PCB Manufacturing Practices

>> Recycling and Waste Reduction

>> Energy-Efficient Manufacturing

>> Eco-Friendly Soldering Techniques

● Advancements in Flexible PCB SMT Assembly

>> Automated Solutions for Flexible PCBs

>> Real-Time Monitoring and Adjustments

>> Thermal Stability and Flexibility

● Miniaturization and High-Density Interconnect (HDI) Technology

>> Micro-BGA and Chip-Scale Packaging

>> Advanced Via Technologies

>> Fine-Pitch Component Placement

● Integration of 5G Technology in PCB Design and Manufacturing

>> High-Frequency PCB Materials

>> Advanced RF PCB Designs

>> Thermal Management Solutions

● Enhanced Quality Control and Testing Procedures

>> Advanced Automated Optical Inspection (AOI)

>> X-ray Inspection for Hidden Solder Joints

>> In-Circuit Testing (ICT) and Functional Testing

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT) in PCB manufacturing?

>> 2. How is AI being used in PCB SMT factories?

>> 3. What are the advantages of flexible PCBs in modern electronics?

>> 4. How are PCB SMT factories addressing environmental concerns?

>> 5. What role does 3D printing play in modern PCB manufacturing?

● Citations:

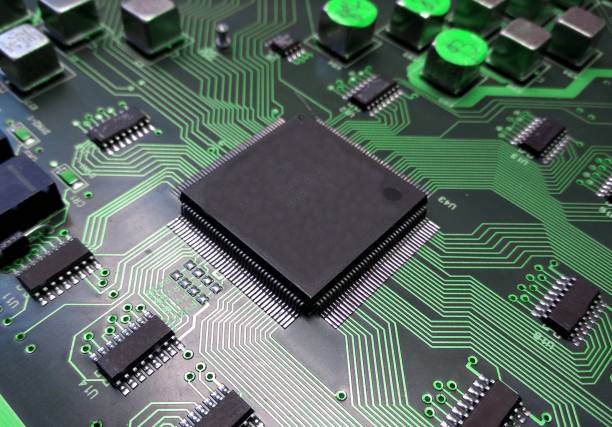

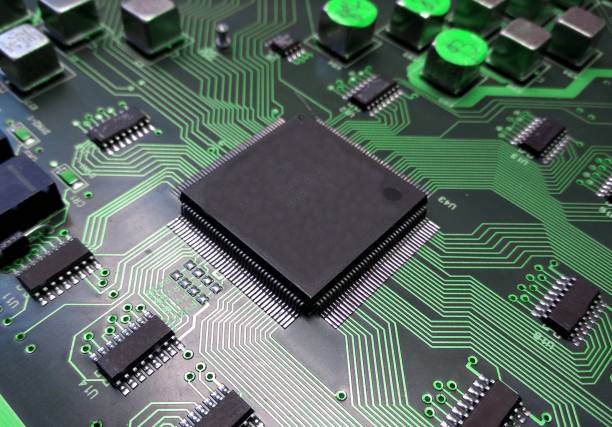

In the ever-evolving landscape of electronics manufacturing, Printed Circuit Board (PCB) Surface Mount Technology (SMT) continues to be at the forefront of innovation. As we delve into 2025, the industry is witnessing remarkable advancements that are reshaping the way we approach PCB assembly and production. This article explores the cutting-edge trends in PCB SMT technology, highlighting how these developments are transforming pcb smt factories and the broader electronics manufacturing sector.

The Rise of AI and Automation in PCB SMT

Artificial Intelligence (AI) and automation are revolutionizing PCB SMT processes, bringing unprecedented levels of efficiency and precision to pcb smt factories. In 2025, we're seeing a significant push towards AI-powered systems that optimize various aspects of PCB production[1].

AI-Driven Design Optimization

One of the most notable advancements is the integration of AI into PCB design software. These intelligent systems can now suggest optimal layouts, significantly reducing design flaws and enhancing overall performance. By leveraging machine learning algorithms, designers can create more efficient and reliable PCBs in less time[1].

Automated Assembly and Inspection

PCB smt factories are increasingly adopting AI-powered robotics to streamline the manufacturing process. These advanced systems ensure precise component placement and utilize Automated Optical Inspection (AOI) for rapid defect detection. The result is a dramatic improvement in production speed and accuracy, leading to higher-quality PCBs and reduced waste[1].

Predictive Maintenance

Machine learning algorithms are now being employed to analyze manufacturing equipment performance in real-time. This predictive maintenance approach allows pcb smt factories to anticipate and prevent equipment failures before they occur, significantly reducing downtime and improving overall productivity[1].

Advanced Materials Driving Innovation

The demand for high-performance and flexible PCBs has led to the adoption of new, innovative materials in pcb smt factories. These advanced materials are enabling the creation of more versatile and durable electronic products.

Flexible and Stretchable PCBs

In 2025, we're seeing a surge in the use of flexible and stretchable PCBs, particularly in wearables, medical devices, and IoT applications. These advanced PCBs allow for new product designs and enhanced durability, opening up exciting possibilities for electronics manufacturers[1].

Graphene and Nanomaterials

The incorporation of graphene and other nanomaterials into PCB production is gaining traction. These materials offer improved conductivity and heat resistance, making them ideal for next-generation electronics that require high performance in compact designs[1].

Eco-Friendly Substrates

As environmental concerns continue to shape industry practices, pcb smt factories are increasingly turning to lead-free and eco-friendly substrates. This shift is driven by both regulatory requirements and a growing demand for more sustainable electronics manufacturing processes[1].

The Growth of 3D PCB Printing

3D printing technology is making significant inroads in PCB production, offering new possibilities for rapid prototyping and customization.

Additive Manufacturing for Complex Designs

In 2025, pcb smt factories are leveraging 3D printing to create multi-layer PCBs with integrated components. This additive manufacturing approach allows for the production of more complex designs while reducing overall size and improving performance[1].

On-Demand Production

The ability to 3D print PCBs on-demand is revolutionizing small-batch production. This capability enables faster product iterations and more cost-effective manufacturing for specialized or low-volume products[1].

Hybrid 3D-Printed Electronics

PCB smt factories are now combining traditional manufacturing techniques with 3D printing to create hybrid electronics. This innovative approach offers improved efficiency and functionality, particularly for unique or customized electronic components[1].

Sustainable and Green PCB Manufacturing Practices

Sustainability has become a key focus in the electronics industry, and PCB manufacturing is no exception. PCB smt factories are adopting greener practices to reduce their environmental impact and meet growing consumer demand for eco-friendly products.

Recycling and Waste Reduction

Advanced recycling techniques are being implemented to recover precious metals and reuse PCB components, significantly reducing electronic waste. This not only benefits the environment but also helps pcb smt factories reduce costs associated with raw materials[1].

Energy-Efficient Manufacturing

PCB smt factories are increasingly turning to renewable energy sources and optimizing their processes to reduce power consumption. These efforts not only lower the carbon footprint of PCB production but also contribute to long-term cost savings[1].

Eco-Friendly Soldering Techniques

The adoption of lead-free solder and alternative bonding methods is becoming more widespread in pcb smt factories. These eco-friendly soldering techniques help reduce the environmental impact of PCB production while meeting stringent regulatory requirements[1].

Advancements in Flexible PCB SMT Assembly

The demand for flexible PCBs continues to grow, driven by the increasing popularity of wearable technology and IoT devices. PCB smt factories are adapting their assembly techniques to meet this demand, focusing on efficiency and precision.

Automated Solutions for Flexible PCBs

PCB smt factories are implementing advanced automated solutions, such as robotic arms and computer vision systems, to streamline the process of placing components onto flexible PCBs. These systems not only speed up assembly but also enhance accuracy, reducing errors and the need for costly rework[2].

Real-Time Monitoring and Adjustments

The integration of advanced software for design verification and testing allows for real-time monitoring and adjustments during production. This capability enables pcb smt factories to address potential issues promptly, ensuring higher quality output and reduced waste[2].

Thermal Stability and Flexibility

PCB smt factories are increasingly using materials with higher thermal stability and flexibility in their SMT processes. These advanced materials minimize physical stress on components during assembly, leading to longer product lifespans and improved reliability[2].

Miniaturization and High-Density Interconnect (HDI) Technology

As electronic devices continue to shrink in size while increasing in functionality, pcb smt factories are focusing on miniaturization and HDI technology to meet these demands.

Micro-BGA and Chip-Scale Packaging

The adoption of micro-BGA (Ball Grid Array) and chip-scale packaging is enabling pcb smt factories to create smaller, more densely packed PCBs. These technologies allow for the integration of more components in a smaller area, supporting the trend towards compact and portable electronic devices[4].

Advanced Via Technologies

PCB smt factories are implementing advanced via technologies, such as laser-drilled microvias and buried/blind vias, to create more complex interconnections in multi-layer PCBs. These techniques allow for higher component density and improved signal integrity in compact designs[4].

Fine-Pitch Component Placement

The ability to place components with extremely fine pitch (the distance between component leads) is becoming crucial in pcb smt factories. Advanced SMT equipment capable of handling components with pitches as small as 0.3mm or less is now commonplace, enabling the production of highly miniaturized electronic devices[4].

Integration of 5G Technology in PCB Design and Manufacturing

With the global rollout of 5G networks, pcb smt factories are adapting their processes to meet the unique requirements of 5G-enabled devices.

High-Frequency PCB Materials

PCB smt factories are increasingly using specialized high-frequency PCB materials designed to minimize signal loss and maintain signal integrity at the high frequencies used in 5G communications. Materials such as low-loss laminates and high-speed digital materials are becoming standard in 5G PCB production[7].

Advanced RF PCB Designs

The design and manufacturing of RF (Radio Frequency) PCBs are becoming more sophisticated to support the complex antenna systems and transmission lines required for 5G devices. PCB smt factories are investing in advanced design tools and manufacturing equipment to produce these specialized PCBs with high precision[7].

Thermal Management Solutions

The high-speed data transfer in 5G devices generates more heat, requiring advanced thermal management solutions. PCB smt factories are incorporating innovative cooling techniques, such as embedded heat sinks and thermal vias, to ensure optimal performance and longevity of 5G-enabled PCBs[7].

Enhanced Quality Control and Testing Procedures

As PCBs become more complex and miniaturized, quality control and testing procedures in pcb smt factories are evolving to ensure the highest standards of reliability and performance.

Advanced Automated Optical Inspection (AOI)

PCB smt factories are implementing more sophisticated AOI systems that use high-resolution cameras and AI-powered image processing to detect even the smallest defects in PCB assemblies. These systems can identify issues such as misaligned components, solder bridging, and missing parts with unprecedented accuracy[5].

X-ray Inspection for Hidden Solder Joints

For complex multi-layer PCBs and components with hidden solder joints (such as BGAs), pcb smt factories are increasingly using X-ray inspection systems. These advanced machines can detect defects that are not visible to the naked eye or traditional optical inspection methods, ensuring the integrity of all connections[5].

In-Circuit Testing (ICT) and Functional Testing

PCB smt factories are enhancing their testing capabilities with advanced ICT systems and functional testing equipment. These tests ensure that each PCB not only meets physical specifications but also functions correctly under various operating conditions, reducing the likelihood of field failures[5].

Conclusion

The landscape of PCB SMT technology is evolving rapidly, driven by advancements in AI, automation, materials science, and manufacturing techniques. PCB smt factories are at the forefront of these changes, adapting their processes and investing in new technologies to meet the growing demands of the electronics industry.

From the integration of AI in design and production to the adoption of sustainable manufacturing practices, the trends we're seeing in 2025 are shaping the future of electronics manufacturing. The push towards miniaturization, the rise of flexible PCBs, and the integration of 5G technology are opening up new possibilities for innovative electronic devices.

As we look to the future, it's clear that pcb smt factories will continue to play a crucial role in driving technological progress. By embracing these latest trends and continuously innovating, the PCB SMT industry is ensuring that it can meet the ever-increasing demands for smaller, faster, and more efficient electronic devices.

The ongoing evolution of PCB SMT technology promises to bring exciting developments in the years to come, further revolutionizing the world of electronics and enabling the next generation of technological advancements.

FAQ

1. What is Surface Mount Technology (SMT) in PCB manufacturing?

Surface Mount Technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). This technology has largely replaced the older through-hole technology, where component leads were inserted through holes in the PCB. SMT allows for more compact designs, faster assembly, and improved performance of electronic devices.

2. How is AI being used in PCB SMT factories?

AI is being integrated into various aspects of PCB production in SMT factories. It's used in design optimization, where AI algorithms suggest optimal PCB layouts. In the manufacturing process, AI-powered robots ensure precise component placement and defect detection. AI is also employed in predictive maintenance, analyzing equipment performance to prevent failures before they occur, thus reducing downtime and improving overall productivity.

3. What are the advantages of flexible PCBs in modern electronics?

Flexible PCBs offer several advantages in modern electronics. They allow for more compact and lightweight designs, making them ideal for wearable technology and IoT devices. Flexible PCBs can conform to unique shapes, enabling innovative product designs. They also offer better resistance to vibration and mechanical stress, improving durability. Additionally, flexible PCBs can be bent or folded, allowing for dynamic applications and saving space in cramped electronic assemblies.

4. How are PCB SMT factories addressing environmental concerns?

PCB SMT factories are addressing environmental concerns through various initiatives. Many are adopting lead-free and eco-friendly substrates to reduce toxic waste. Recycling programs are being implemented to recover precious metals and reuse PCB components, minimizing electronic waste. Factories are also focusing on energy-efficient manufacturing processes, including the use of renewable energy sources. Additionally, some factories are exploring biodegradable materials for PCB production to further reduce environmental impact.

5. What role does 3D printing play in modern PCB manufacturing?

3D printing is playing an increasingly important role in PCB manufacturing. It allows for rapid prototyping of PCB designs, enabling faster product development cycles. 3D printing technology can create complex multi-layer PCBs with integrated components, reducing size and improving performance. It also enables on-demand production of small batches, making it cost-effective for specialized or low-volume products. Some factories are exploring hybrid approaches, combining traditional manufacturing techniques with 3D printing for improved efficiency and functionality.

Citations:

[1] https://www.active-pcb.com/pcb-manufacturing-in-2025/

[2] https://www.andwinpcb.com/advancements-in-flex-pcb-smt-assembly-techniques-and-benefits/

[3] https://patents.google.com/patent/CN104244605B/zh

[4] https://rootsems.com/future-of-electronics-manufacturing-emerging-trends-in-2025/

[5] https://greatpcb.com/smt-pcb-the-core-technology-of-electronics-manufacturing/

[6] https://patents.google.com/patent/CN108012450A/zh

[7] https://www.kinghelm.net/industry-news/2025-The-Future-of-PCB-PCBA-Trends.html

[8] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/