Content Menu

● The Evolution of LED Chip SMD Mounting

>> Advancements in LED Chip SMD Mounting Machines

● Innovations in SMD Packaging Technology

>> Miniaturization of SMD Packages

>> Flip Chip Technology

>> Advanced Thermal Management Solutions

● The Role of Automation in LED Chip SMD Mounting

>> Automated Component Feeding

>> Vision-guided Placement

>> In-line Quality Control

● Challenges and Future Directions

>> Ultra-fine Pitch Mounting

>> Handling Fragile Components

>> Sustainability and Energy Efficiency

>> Integration with Industry 4.0

● Conclusion

● FAQ

>> 1. What is SMD technology in LED manufacturing?

>> 2. How do LED chip SMD mounting machines improve production efficiency?

>> 3. What are the advantages of flip chip technology in LED packaging?

>> 4. How does miniaturization impact LED chip SMD mounting?

>> 5. What role does automation play in LED chip SMD mounting processes?

● Citations:

In recent years, the LED industry has witnessed significant advancements in chip mounting technology, particularly in Surface Mount Device (SMD) applications. These innovations have revolutionized the way LED displays and lighting solutions are manufactured, leading to improved performance, efficiency, and cost-effectiveness. This article explores the latest trends in LED chip SMD mounting technology, with a focus on the machines and processes that are shaping the future of the industry.

The Evolution of LED Chip SMD Mounting

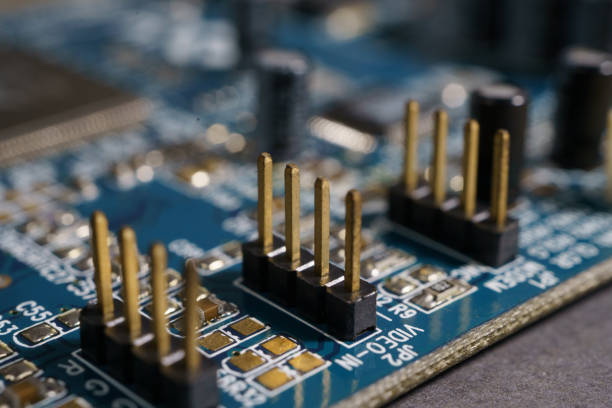

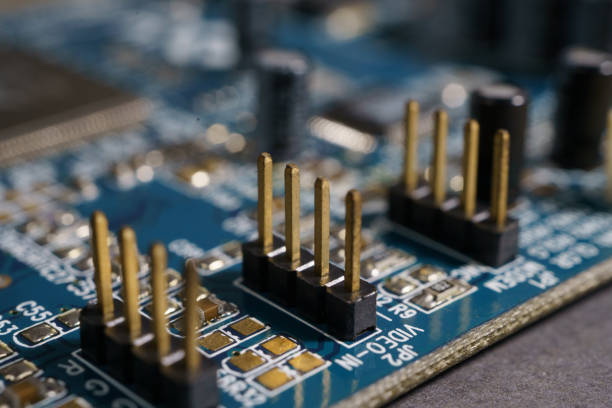

Surface Mount Technology (SMT) has become the standard for LED chip mounting, replacing older through-hole technology. SMD LEDs offer numerous advantages, including smaller size, better heat dissipation, and suitability for automated production[1]. As the demand for high-quality LED displays and lighting solutions continues to grow, manufacturers are constantly seeking ways to improve the SMD mounting process.

Advancements in LED Chip SMD Mounting Machines

LED chip SMD mounting machines have undergone significant improvements to meet the increasing demands of the industry. These machines are crucial in the production of LED displays and lighting products, as they precisely place and solder LED chips onto circuit boards. Some of the latest trends in LED chip SMD mounting machines include:

1. Increased Speed and Precision

Modern LED chip SMD mounting machines are designed to operate at higher speeds while maintaining exceptional accuracy. Advanced vision systems and precise positioning mechanisms allow these machines to place thousands of components per hour with micron-level precision[4]. This increased speed and accuracy contribute to higher production efficiency and improved product quality.

2. Multi-functional Capabilities

Leading LED chip SMD mounting machines now offer multi-functional capabilities, allowing them to handle various component types and sizes. These versatile machines can mount not only LED chips but also other electronic components, such as resistors and capacitors, in a single pass. This flexibility reduces production time and costs by eliminating the need for multiple specialized machines.

3. Intelligent Software Integration

The integration of intelligent software systems has significantly enhanced the performance of LED chip SMD mounting machines. These software solutions provide real-time monitoring, data analysis, and process optimization capabilities. Machine learning algorithms can adapt to changing production requirements and optimize placement parameters for different LED chip types and board designs.

4. Improved Heat Management

As LED chips become smaller and more powerful, effective heat management during the mounting process becomes crucial. Advanced LED chip SMD mounting machines incorporate sophisticated temperature control systems to ensure optimal soldering conditions. These systems help prevent thermal damage to the LED chips and improve the overall reliability of the final product.

5. Enhanced Flexibility for Small-batch Production

With the growing demand for customized LED solutions, LED chip SMD mounting machines are now designed to offer greater flexibility for small-batch production. Quick-change tooling and easily programmable systems allow manufacturers to switch between different product types rapidly, reducing setup times and increasing overall production efficiency.

Innovations in SMD Packaging Technology

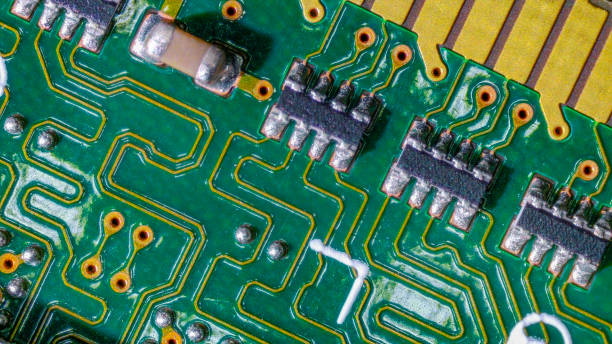

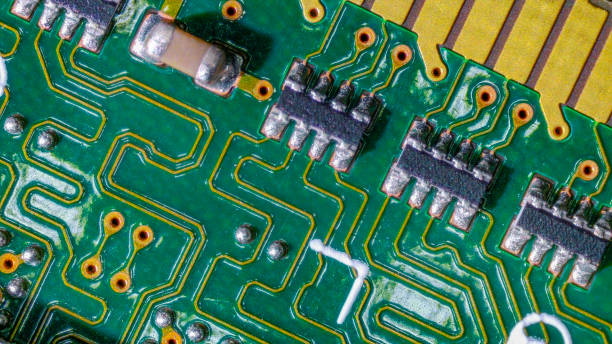

Alongside advancements in mounting machines, SMD packaging technology has also seen significant innovations. These developments aim to improve the performance, reliability, and cost-effectiveness of LED products. Some notable trends include:

Miniaturization of SMD Packages

The trend towards miniaturization continues to drive innovation in SMD packaging. Smaller LED packages allow for higher pixel density in displays and more compact lighting solutions. Chip Scale Package (CSP) technology has emerged as a popular solution, eliminating the need for traditional packaging substrates and reducing the overall size of the LED component[9].

Flip Chip Technology

Flip chip packaging has gained traction in the LED industry due to its superior electrical and thermal performance. In this approach, the LED chip is inverted and directly bonded to the package substrate, eliminating the need for wire bonding. This results in improved heat dissipation and allows for higher current densities, making it particularly suitable for high-power LED applications[9].

Advanced Thermal Management Solutions

As LED chips become more powerful, effective thermal management becomes increasingly critical. New packaging structures incorporate advanced thermal management materials, such as ceramic substrates and metal-core printed circuit boards (MCPCBs). These materials help dissipate heat more efficiently, improving the overall performance and lifespan of LED products[9].

The Role of Automation in LED Chip SMD Mounting

Automation plays a crucial role in modern LED chip SMD mounting processes. The integration of robotics and advanced control systems has led to significant improvements in production efficiency and product quality. Some key aspects of automation in LED chip SMD mounting include:

Automated Component Feeding

LED chip SMD mounting machines now feature sophisticated component feeding systems that can handle a wide range of component types and sizes. These systems use vibration feeders, tape-and-reel feeders, and tray feeders to ensure a continuous supply of components to the placement head. Automated feeding systems reduce human error and increase overall production speed.

Vision-guided Placement

Advanced vision systems are integral to modern LED chip SMD mounting machines. These systems use high-resolution cameras and image processing algorithms to accurately identify and align components before placement. Vision-guided placement ensures precise positioning of LED chips, even for ultra-fine pitch applications.

In-line Quality Control

Automated inspection systems are now commonly integrated into LED chip SMD mounting lines. These systems use advanced imaging techniques to detect defects such as misalignment, solder bridging, or missing components. Real-time quality control helps identify and address issues quickly, reducing waste and improving overall product quality.

Challenges and Future Directions

While LED chip SMD mounting technology has made significant strides, several challenges remain. Addressing these challenges will shape the future direction of the industry:

Ultra-fine Pitch Mounting

As display resolutions continue to increase, the demand for ultra-fine pitch LED displays grows. Mounting LED chips with pitches below 0.5mm presents significant challenges in terms of precision and reliability. Future LED chip SMD mounting machines will need to achieve even higher levels of accuracy to meet these demands.

Handling Fragile Components

As LED chips become smaller and more delicate, handling them without damage becomes increasingly challenging. Future mounting technologies may need to incorporate advanced gripping mechanisms and force-sensing capabilities to handle these fragile components safely.

Sustainability and Energy Efficiency

The LED industry is under pressure to improve its sustainability practices. Future LED chip SMD mounting machines will likely focus on reducing energy consumption and minimizing waste. This may involve the development of more energy-efficient placement mechanisms and the use of eco-friendly materials in the mounting process.

Integration with Industry 4.0

The concept of Industry 4.0, which involves the integration of smart manufacturing technologies, is set to play a significant role in the future of LED chip SMD mounting. This may include the implementation of Internet of Things (IoT) sensors for real-time monitoring, predictive maintenance systems, and seamless integration with enterprise resource planning (ERP) systems.

Conclusion

The LED chip SMD mounting technology landscape is rapidly evolving, driven by the demand for higher performance, increased efficiency, and cost-effectiveness. Advanced LED chip SMD mounting machines, coupled with innovations in packaging technology and automation, are paving the way for the next generation of LED displays and lighting solutions. As the industry continues to address challenges such as ultra-fine pitch mounting and sustainability, we can expect to see even more exciting developments in the field of LED chip SMD mounting technology.

FAQ

1. What is SMD technology in LED manufacturing?

SMD (Surface Mount Device) technology in LED manufacturing refers to the method of directly mounting LED chips onto a printed circuit board (PCB) using automated placement machines. This technology allows for smaller, more efficient LED products compared to traditional through-hole mounting methods[1].

2. How do LED chip SMD mounting machines improve production efficiency?

LED chip SMD mounting machines improve production efficiency through high-speed placement capabilities, multi-functional design, and intelligent software integration. These machines can place thousands of components per hour with micron-level precision, handle various component types, and optimize processes in real-time[4].

3. What are the advantages of flip chip technology in LED packaging?

Flip chip technology in LED packaging offers several advantages, including improved thermal management, better electrical performance, and higher current densities. By directly bonding the inverted LED chip to the substrate, flip chip packaging eliminates the need for wire bonding, resulting in more compact and efficient LED devices[9].

4. How does miniaturization impact LED chip SMD mounting?

Miniaturization in LED chip SMD mounting leads to higher pixel density in displays and more compact lighting solutions. This trend challenges mounting machine manufacturers to develop systems capable of handling smaller components with greater precision, often requiring advancements in vision systems and placement mechanisms[9].

5. What role does automation play in LED chip SMD mounting processes?

Automation plays a crucial role in LED chip SMD mounting processes by improving speed, accuracy, and consistency. Automated systems handle component feeding, vision-guided placement, and in-line quality control, reducing human error and increasing overall production efficiency while maintaining high product quality standards.

Citations:

[1] https://www.novastar.tech/novastar-innovation/industry-development-trends/

[2] https://www.pcbonline.com/blog/smd-led.html

[3] https://patents.google.com/patent/CN102881806A/zh

[4] https://www.doitvision.com/led-displays-4/

[5] https://www.pvtech.com.cn/index.php/Ab_index_gci_73.html

[6] https://patents.google.com/patent/CN103594603A/zh

[7] https://www.avoeleddisplay.com/news/smd-cob-gob-led-who-will-become-the-trend-of-led-technology/

[8] https://www.reddit.com/r/AskElectronics/comments/mkxpc4/how_to_hand_solder_a_smd_led_without_killing_it/

[9] https://en.kinglight.com/blog/led-packaging-structure-process-development-status-and-trends.html