Content Menu

● Overview of LED SMT Production Lines

● Key Components of Modern LED SMT Production Lines

>> 1. Solder Paste Printer

>> 2. Pick and Place Machines

>> 3. Reflow Ovens

>> 4. Automated Optical Inspection (AOI)

>> 5. X-ray Inspection Machines

>> 6. Conveyor Systems

● Latest Innovations in LED SMT Production

>> Integration of Industry 4.0 Technologies

>> Enhanced Automation

>> Sustainable Manufacturing Practices

● Setting Up a Wholesale LED SMT Production Line

● Benefits of Using Advanced LED SMT Production Lines

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the main components of an LED SMT production line?

>> 3. How does automation improve LED SMT production?

>> 4. What role does AI play in modern SMT production lines?

>> 5. Why is sustainability important in LED manufacturing?

● Citations:

The landscape of electronics manufacturing has undergone a significant transformation with the advent of Surface Mount Technology (SMT). This technology is particularly pivotal in the production of LED devices, which are increasingly ubiquitous in various applications, from consumer electronics to automotive lighting. As manufacturers strive to meet the growing demand for LED products, understanding the latest technologies in wholesale LED SMT production line machines becomes essential.

Overview of LED SMT Production Lines

An LED SMT production line is an automated system designed to assemble LED components onto printed circuit boards (PCBs). The process involves several key stages:

- Solder Paste Printing: Applying solder paste to PCB pads.

- Component Placement: Using pick and place machines to position components accurately.

- Reflow Soldering: Melting solder to create electrical connections.

- Inspection: Utilizing Automated Optical Inspection (AOI) and X-ray inspection for quality control.

These stages are interconnected through conveyor systems that streamline the workflow, ensuring efficiency and precision.

Key Components of Modern LED SMT Production Lines

1. Solder Paste Printer

- This machine applies solder paste onto PCBs using stencils. Precision is critical, as misalignment can lead to defective solder joints. Advanced printers incorporate vision systems for accurate alignment, enhancing reliability[1][2].

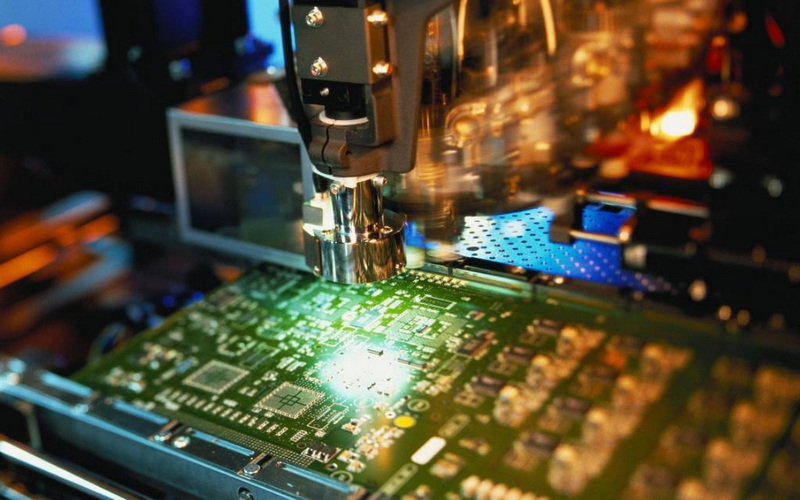

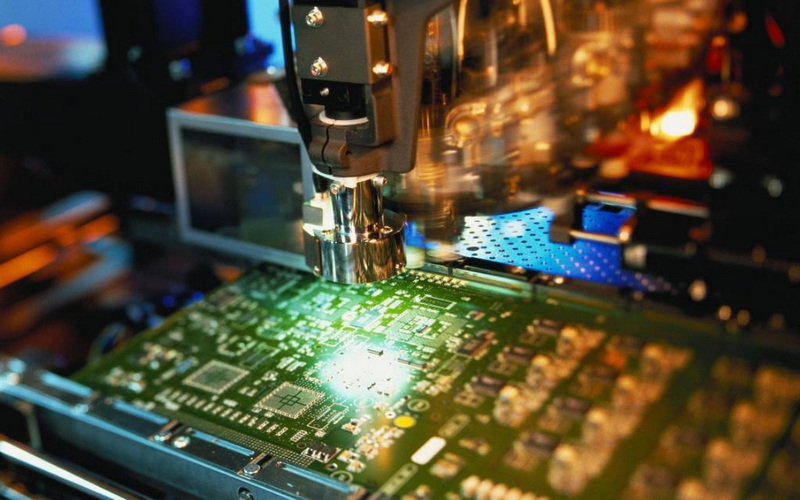

2. Pick and Place Machines

- The heart of the SMT line, these machines automate the placement of surface-mounted devices (SMDs) onto PCBs. Modern pick and place machines boast high speeds (up to 72,000 components per hour) and accuracy, with advanced vision systems ensuring correct orientation and placement[3][4].

3. Reflow Ovens

- After component placement, PCBs pass through reflow ovens where solder paste is melted to form strong electrical connections. These ovens utilize sophisticated temperature profiling to ensure optimal soldering without damaging components[2][5].

4. Automated Optical Inspection (AOI)

- AOI systems inspect PCBs for defects such as misaligned components or soldering issues. These machines provide real-time feedback, allowing for early detection of errors and reducing waste[1][6].

5. X-ray Inspection Machines

- For complex assemblies where components may obscure solder joints, X-ray inspection is employed. This non-destructive testing method ensures hidden joints are correctly formed, which is crucial for high-reliability applications[2][7].

6. Conveyor Systems

- These systems facilitate the smooth transport of PCBs between different stages of production. Customizable conveyor systems enhance workflow efficiency by reducing manual handling and increasing throughput[8][9].

Latest Innovations in LED SMT Production

The evolution of technology continues to impact LED SMT production lines significantly. Here are some notable advancements:

Integration of Industry 4.0 Technologies

- IoT and Smart Manufacturing: The integration of Internet of Things (IoT) technologies allows for real-time monitoring and data analytics throughout the production process. This capability enhances decision-making and predictive maintenance, reducing downtime[10][11].

- Artificial Intelligence (AI): AI-driven optimization software analyzes production data to identify inefficiencies and suggest improvements. This innovation leads to enhanced productivity and reduced operational costs[12][13].

Enhanced Automation

- Collaborative Robots (Cobots): Cobots work alongside human operators to improve efficiency in tasks such as component placement and inspection. Their flexibility allows manufacturers to adapt quickly to changing production needs without significant downtime[14][15].

- Advanced Robotics: New robotic technologies enable faster and more precise pick-and-place operations, accommodating smaller components and tighter tolerances essential for modern electronic devices[16][17].

Sustainable Manufacturing Practices

As environmental concerns grow, manufacturers are adopting eco-friendly practices within their SMT processes:

- Lead-Free Soldering: Many companies are transitioning to lead-free soldering techniques that comply with environmental regulations while maintaining product quality[18][19].

- Energy-Efficient Machinery: Investments in energy-efficient equipment reduce the carbon footprint of manufacturing operations while lowering operational costs over time[20][21].

Setting Up a Wholesale LED SMT Production Line

Establishing a wholesale LED SMT production line involves several critical steps:

1. Planning and Design: Assessing production requirements helps determine the layout and equipment needed for optimal workflow.

2. Equipment Selection: Choosing high-quality machinery tailored for specific LED products ensures reliability and performance.

3. Installation and Calibration: Proper installation and calibration of equipment maintain precision standards necessary for high-quality production.

4. Training and Maintenance: Continuous staff training on new technologies is essential for maximizing productivity while regular maintenance prevents operational disruptions[22][23].

Benefits of Using Advanced LED SMT Production Lines

Investing in modern LED SMT production lines offers numerous advantages:

- Increased Efficiency: Automation leads to higher throughput, enabling manufacturers to meet rising demand swiftly.

- Higher Precision: Advanced machinery reduces defect rates by ensuring accurate component placement.

- Scalability: Production lines can be easily adjusted based on changing market demands, making them suitable for various manufacturing scales.

- Cost-Effectiveness: Although initial investments may be high, long-term savings from reduced labor costs and improved quality control make these lines economically viable[24][25].

Conclusion

The latest technologies in wholesale LED SMT production line machines have revolutionized the electronics manufacturing landscape, enhancing efficiency, precision, and sustainability. As manufacturers continue to embrace automation and smart technologies, they position themselves at the forefront of innovation in the rapidly evolving LED market.

By investing in advanced SMT solutions, businesses can not only meet current demands but also prepare for future challenges in the competitive electronics industry.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs), allowing for higher component density and reduced manufacturing costs compared to traditional through-hole technology.

2. What are the main components of an LED SMT production line?

Key components include solder paste printers, pick and place machines, reflow ovens, automated optical inspection systems, X-ray inspection machines, and conveyor systems.

3. How does automation improve LED SMT production?

Automation enhances speed and precision in component placement while minimizing human error, leading to higher throughput and lower defect rates.

4. What role does AI play in modern SMT production lines?

AI optimizes manufacturing processes by analyzing data in real-time to identify inefficiencies, predict maintenance needs, and enhance overall productivity.

5. Why is sustainability important in LED manufacturing?

Sustainability practices help reduce environmental impact through energy-efficient processes and lead-free materials while also aligning with regulatory standards that promote eco-friendly manufacturing practices.

Citations:

[1] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[2] https://www.hct-smt.com/blog/comprehensive-guide-to-led-smt-production-line

[3] https://www.tronstol.com/smt-equipment-led.html

[4] https://levisonenterprises.com/your-surface-mount-technology-questions-answered/

[5] https://ko.hct-smt.com/blog/comprehensive-guide-to-led-smt-production-line

[6] https://en.rangdong.com.vn/news/overview-of-a-smt-production-line

[7] https://www.grandviewresearch.com/industry-analysis/surface-mount-technology-market-report

[8] https://de.hct-smt.com/blog/wholesale-led-smt-production-line--revolutionizing-the-led-manufacturing-industry

[9] https://www.lumitronix.com/en/smt-fertigung

[10] https://versae.com/smt-assembly-faq/

[11] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[12] https://www.neodensmt.com/other-products/smt-pick-and-place-machine-for-led-assembly.html

[13] https://www.smtfactory.com/Cutting-edge-Full-auto-SMT-Line-Equipment-id49217676.html

[14] https://www.smtfactory.com/JUKI-Multi-functional-SMD-LED-Production-Line-pd49129564.html

[15] https://www.made-in-china.com/products-search/hot-china-products/Smt_Assembly_Line.html

[16] https://www.smtmachine.eu/role-of-smt-production-line-in-the-led-industry/

[17] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=53641&news_id=27434

[18] https://www.thebusinessresearchcompany.com/report/surface-mount-technology-smt-equipment-global-market-report

[19] https://www.smtfactory.com/Future-Trends-in-SMT-Lines-Innovations-Shaping-The-Electronics-Manufacturing-Industry-id44863586.html

[20] https://eastson-smt.en.made-in-china.com/product/RwutgUJoIhaY/China-SMT-Machine-LED-Production-Line-PCBA-Placement-Machine-High-Speed-Automatic-Placement.html

[21] https://www.linkedin.com/pulse/revolutionize-led-production-discover-how-smt-lines-shaping-wang-mqdkc

[22] https://www.neodensmt.com

[23] https://smt.asmpt.com/en/news-center/news/bridging-the-gap-ipc-2591-cfx-clears-the-way-to-the-integrated-smart-factory-4/

[24] https://www.globalwellpcba.com/surface-mount-technology/

[25] https://www.smtmachine.eu/top-5-smt-line-of-2024-advanced-smt-solutions/

[26] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[27] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[28] https://www.diodedynamics.com/h3-cob12-leds-pair.html

[29] https://www.venture-mfg.com/smt-manufacturing/

[30] https://www.pcbcart.com/article/content/qa-about-smt-assembly.html

[31] https://www.youtube.com/watch?v=y0Qk8nNxyXY

[32] https://www.allsmt.com/Total-Line-Solutions-Guide-and-Concepts-for-SMT-and-THT-Automisation

[33] https://www.viasion.com/blog/smt-assembly-introduction-applications-steps-common-errors/

[34] https://www.raypcb.com/led-pcb-strip/

[35] https://www.smtfactory.com/What-is-the-LED-Display-SMT-Production-Process-id41946657.html

[36] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[37] https://global.yamaha-motor.com/business/smt/faq/

[38] https://www.alibaba.com/product-detail/Meraif-smt-machine-Yamaha-YV180-SMD_1600902908469.html

[39] https://electronics.stackexchange.com/questions/141438/smd-led-polarity-marking-is-the-cathode-marking-standardized