Content Menu

● Introduction to Surface Mount Technology

● Key Innovations in Surface Mount Technology

>> Advanced Materials

>> Automation and Robotics

>> 3D Printing Technology

>> Enhanced Inspection Techniques

>> Internet of Things (IoT) Integration

● Trends Shaping the Future of Surface Mount Technology

>> Miniaturization of Components

>> Increased Focus on Sustainability

>> Customization and Flexibility

>> Enhanced Connectivity

>> Collaboration and Knowledge Sharing

● Conclusion

● Related Questions

>> 1. What are the benefits of using Surface Mount Technology over traditional methods?

>> 2. How does automation impact the Surface Mount Technology process?

>> 3. What role does the Journal of Surface Mount Technology play in the industry?

>> 4. How can companies ensure quality control in Surface Mount Technology?

>> 5. What future trends can we expect in Surface Mount Technology?

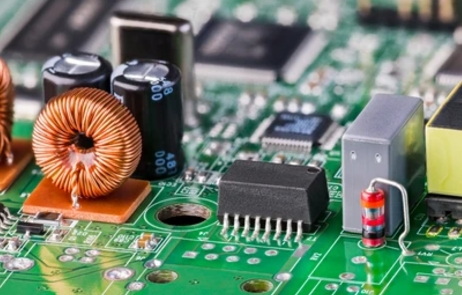

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, lighter, and more efficient electronic devices. As technology continues to advance, the innovations in SMT are crucial for meeting the demands of modern electronics. This article explores the latest innovations in Surface Mount Technology, highlighting key developments, trends, and their implications for the industry.

Introduction to Surface Mount Technology

Surface Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes in the PCB, SMT allows for a more compact design, which is essential for today's miniaturized electronic devices. The Journal of Surface Mount Technology frequently publishes research and findings that contribute to the understanding and advancement of SMT.

The evolution of SMT has been driven by the need for higher performance and greater efficiency in electronic devices. As consumer demands for smaller and more powerful gadgets increase, manufacturers are compelled to adopt SMT to stay competitive. This technology not only facilitates the miniaturization of components but also enhances the overall performance of electronic assemblies.

Key Innovations in Surface Mount Technology

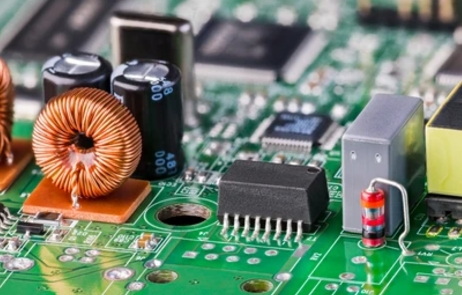

Advanced Materials

One of the most significant innovations in SMT is the development of advanced materials. New solder materials, such as lead-free solder, have been introduced to comply with environmental regulations and improve the reliability of solder joints. These materials not only enhance the performance of SMT but also reduce the risk of defects during the manufacturing process.

Additionally, the introduction of flexible substrates has opened new avenues for SMT applications. Flexible PCBs allow for the creation of bendable and lightweight devices, which are particularly useful in wearable technology and medical devices. The ability to use advanced materials in SMT processes is crucial for developing next-generation electronics that meet the demands of various industries.

Automation and Robotics

Automation has become a cornerstone of modern SMT processes. The integration of robotics in assembly lines has increased efficiency and precision. Automated pick-and-place machines can now handle a wider variety of components, including those with complex geometries. This innovation reduces human error and speeds up production, allowing manufacturers to meet the growing demand for electronic devices.

Moreover, the use of artificial intelligence (AI) in SMT processes is gaining traction. AI algorithms can optimize production schedules, predict maintenance needs, and enhance quality control by analyzing data from various stages of the manufacturing process. This level of automation not only improves productivity but also reduces operational costs, making it a vital component of modern electronics manufacturing.

3D Printing Technology

3D printing is making waves in the SMT industry by enabling rapid prototyping and the production of complex components. This technology allows engineers to create custom parts quickly, reducing the time from design to production. The ability to print circuit boards and components directly can lead to significant cost savings and increased design flexibility.

Furthermore, 3D printing facilitates the development of intricate designs that would be challenging to achieve with traditional manufacturing methods. This capability is particularly beneficial for industries that require specialized components, such as aerospace and medical devices. As 3D printing technology continues to advance, its integration with SMT will likely lead to even more innovative solutions in electronics manufacturing.

Enhanced Inspection Techniques

Quality control is critical in SMT, and recent innovations in inspection techniques have greatly improved the reliability of electronic assemblies. Automated optical inspection (AOI) systems are now equipped with advanced imaging technologies, such as 3D imaging and machine learning algorithms, to detect defects more accurately. These systems can identify issues such as misalignment, solder joint quality, and component placement errors, ensuring that only high-quality products reach the market.

In addition to AOI, X-ray inspection has become an essential tool in SMT. This non-destructive testing method allows manufacturers to inspect hidden solder joints and internal structures of components, providing a comprehensive view of the assembly quality. By implementing these advanced inspection techniques, manufacturers can significantly reduce the risk of failures in the field, enhancing the overall reliability of their products.

Internet of Things (IoT) Integration

The rise of the Internet of Things (IoT) has influenced SMT innovations significantly. As devices become more interconnected, the demand for smaller, more efficient components has increased. SMT plays a vital role in the production of IoT devices, enabling manufacturers to create compact designs that can accommodate the necessary sensors and communication modules. Innovations in SMT are essential for developing the next generation of smart devices.

Moreover, the integration of IoT technology into SMT processes allows for real-time monitoring and data collection during manufacturing. This capability enables manufacturers to optimize their processes, reduce waste, and improve overall efficiency. As IoT continues to expand, the role of SMT in supporting these technologies will become increasingly important.

Trends Shaping the Future of Surface Mount Technology

Miniaturization of Components

As consumer electronics continue to shrink in size, the miniaturization of components is a key trend in SMT. Manufacturers are developing smaller and more efficient components that can be easily integrated into compact designs. This trend is driven by consumer demand for portable devices, such as smartphones and wearables, which require advanced SMT techniques to achieve their small form factors.

The miniaturization trend also extends to passive components, such as capacitors and resistors, which are being designed to occupy less space while maintaining performance. This shift not only enhances the functionality of devices but also allows for more innovative designs that can incorporate additional features without increasing size.

Increased Focus on Sustainability

Sustainability is becoming increasingly important in the electronics industry. Innovations in SMT are focusing on reducing waste and energy consumption during the manufacturing process. Companies are exploring eco-friendly materials and processes, such as water-soluble solder and energy-efficient manufacturing techniques, to minimize their environmental impact.

Additionally, the push for sustainability has led to the development of recyclable and biodegradable materials for electronic components. This shift is essential for addressing the growing concerns about electronic waste and the environmental impact of discarded devices. By adopting sustainable practices, manufacturers can not only comply with regulations but also appeal to environmentally conscious consumers.

Customization and Flexibility

The demand for customized electronic solutions is on the rise. SMT innovations are enabling manufacturers to offer more flexible production options, allowing for shorter lead times and tailored designs. This trend is particularly relevant in industries such as automotive and medical devices, where specific requirements must be met.

Flexible manufacturing systems, which can quickly adapt to changes in production volume and design specifications, are becoming increasingly popular. These systems allow manufacturers to respond rapidly to market demands, reducing the time it takes to bring new products to market. As customization becomes a standard expectation, SMT will play a crucial role in enabling this flexibility.

Enhanced Connectivity

With the growing importance of connectivity in electronic devices, SMT is evolving to support advanced communication technologies. Innovations in SMT are facilitating the integration of high-frequency components and antennas, which are essential for 5G and other wireless technologies. This development is crucial for ensuring that devices can communicate effectively in an increasingly connected world.

The demand for high-speed data transmission and low-latency communication is driving the need for advanced SMT solutions. Manufacturers are focusing on developing components that can operate at higher frequencies while maintaining signal integrity. This trend is essential for supporting the next generation of wireless communication technologies.

Collaboration and Knowledge Sharing

The Journal of Surface Mount Technology plays a vital role in fostering collaboration and knowledge sharing among industry professionals. By publishing research, case studies, and best practices, the journal helps drive innovation in SMT. This collaborative approach is essential for addressing the challenges faced by manufacturers and ensuring the continued advancement of Surface Mount Technology.

Industry conferences and workshops also provide platforms for professionals to share insights and discuss emerging trends. These events facilitate networking and collaboration, allowing companies to learn from each other and adopt best practices in SMT. As the industry evolves, the importance of collaboration will only increase.

Conclusion

In conclusion, the latest innovations in Surface Mount Technology are shaping the future of electronics manufacturing. From advanced materials and automation to the integration of IoT and sustainability efforts, these developments are crucial for meeting the demands of modern consumers. As the industry continues to evolve, staying informed about these innovations is essential for manufacturers looking to remain competitive in the rapidly changing electronics landscape. The Journal of Surface Mount Technology will continue to be a valuable resource for professionals seeking to understand and implement these advancements in their operations.

Related Questions

1. What are the benefits of using Surface Mount Technology over traditional methods?

Surface Mount Technology offers several advantages, including reduced size and weight of electronic devices, improved performance, and lower manufacturing costs. SMT allows for higher component density and faster assembly times, making it ideal for modern electronics.

2. How does automation impact the Surface Mount Technology process?

Automation significantly enhances the efficiency and accuracy of the SMT process. Automated machines can place components with high precision, reducing the likelihood of errors and increasing production speed. This leads to lower costs and improved product quality.

3. What role does the Journal of Surface Mount Technology play in the industry?

The Journal of Surface Mount Technology serves as a key platform for sharing research, innovations, and best practices in the field. It helps professionals stay updated on the latest trends and technologies, fostering collaboration and knowledge sharing.

4. How can companies ensure quality control in Surface Mount Technology?

Companies can ensure quality control in SMT by implementing advanced inspection techniques, such as automated optical inspection (AOI) and X-ray inspection. These methods help identify defects early in the production process, ensuring that only high-quality products are delivered to customers.

5. What future trends can we expect in Surface Mount Technology?

Future trends in SMT may include further miniaturization of components, increased focus on sustainability, and enhanced connectivity for IoT devices. As technology continues to advance, SMT will play a crucial role in the development of innovative electronic solutions.