Content Menu

● Understanding SMT PCB Loaders

>> Key Functions of SMT PCB Loaders:

● Recent Innovations in SMT PCB Loader Technology

>> 1. Enhanced Automation Features

>> 2. Improved Speed and Efficiency

>> 3. Advanced Vision Systems

>> 4. Enhanced User Interfaces

>> 5. Energy Efficiency

● Integration with Other SMT Equipment

>> 1. Pick-and-Place Machines

>> 2. Reflow Ovens

>> 3. Inspection Systems

● Benefits of Innovations in SMT PCB Loader Technology

● Future Trends in SMT PCB Loader Technology

>> 1. Increased Use of AI and Machine Learning

>> 2. Greater Customization Options

>> 3. Enhanced Data Analytics

● Conclusion

● FAQ

>> 1. What is an SMT PCB loader?

>> 2. How do modern SMT PCB loaders improve efficiency?

>> 3. What role does AI play in SMT PCB loader technology?

>> 4. Are there eco-friendly options available for SMT PCB loaders?

>> 5. How do I choose the right SMT PCB loader for my production line?

● Citations:

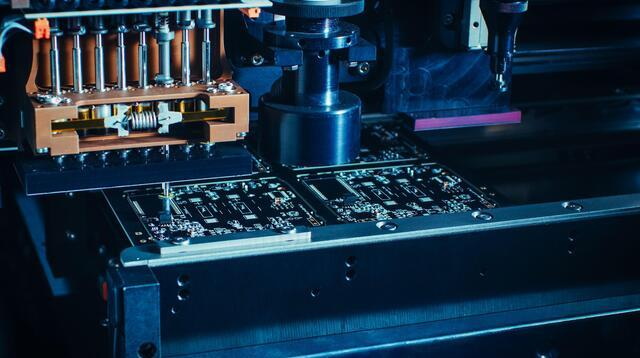

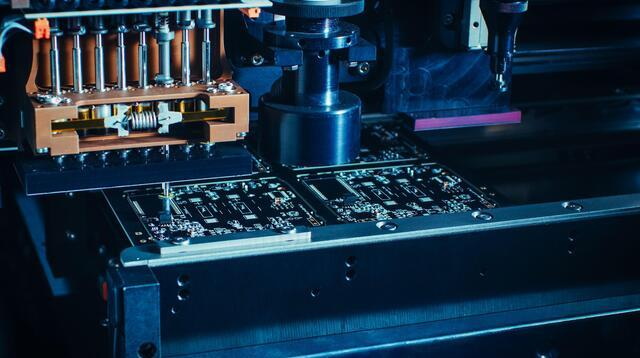

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the assembly of printed circuit boards (PCBs). As the demand for smaller, more complex electronic devices increases, the need for efficient and advanced PCB loaders has become paramount. This article explores SMT PCB loader technology, highlighting their features, benefits, and impact on the manufacturing process.

Understanding SMT PCB Loaders

SMT PCB loaders are critical components in automated manufacturing lines. They facilitate the loading of bare PCBs onto assembly lines for further processing, such as soldering and inspection. These machines are designed to minimize manual handling, reduce errors, and enhance overall efficiency.

Key Functions of SMT PCB Loaders:

- Automation: Automates the loading process, reducing labor costs and minimizing human error.

- Speed: Increases the speed of loading PCBs onto production lines, enhancing overall throughput.

- Precision: Ensures accurate placement of PCBs to prevent misalignment during subsequent assembly processes.

Recent Innovations in SMT PCB Loader Technology

The evolution of SMT PCB loaders has been driven by advancements in technology. Here are some of the latest innovations:

1. Enhanced Automation Features

Modern SMT PCB loaders now incorporate advanced automation features that streamline operations:

- Robotic Integration: Many new models feature robotic arms that can handle various sizes and types of PCBs without manual intervention. This reduces cycle times and increases production efficiency.

- Smart Sensors: Loaders equipped with smart sensors can detect PCB sizes and adjust their operations accordingly. This adaptability allows for seamless integration into existing production lines.

2. Improved Speed and Efficiency

Speed is a crucial factor in SMT production lines. Recent innovations have focused on enhancing the speed of PCB loaders:

- High-Speed Loading Mechanisms: New loading mechanisms can achieve speeds of up to 30% faster than previous models. This is particularly beneficial for high-volume production environments where time is critical.

- Dual-Lane Loading Systems: Some loaders now feature dual-lane systems that allow for simultaneous loading of multiple PCBs, significantly boosting throughput.

3. Advanced Vision Systems

Vision systems play a vital role in ensuring the accuracy of PCB placement:

- AI-Powered Vision Systems: The integration of artificial intelligence (AI) in vision systems enables real-time monitoring and adjustment during the loading process. These systems can identify defects or misalignments before they affect production quality.

- 3D Inspection Capabilities: Advanced vision systems are now capable of 3D inspections, allowing for more precise alignment and placement of PCBs based on their unique geometries.

4. Enhanced User Interfaces

User experience is crucial for efficient operation:

- Touchscreen Controls: Modern loaders come equipped with intuitive touchscreen interfaces that simplify operation and reduce training time for new operators.

- Remote Monitoring Capabilities: Many new models offer remote monitoring features that allow operators to track performance metrics and troubleshoot issues from anywhere within the facility.

5. Energy Efficiency

As sustainability becomes a priority in manufacturing, energy-efficient designs are gaining traction:

- Low Power Consumption Designs: New loaders are designed to consume less energy without compromising performance, contributing to lower operational costs and reduced environmental impact.

- Eco-Friendly Materials: Some manufacturers are incorporating sustainable materials into their designs, further enhancing their eco-friendliness.

Integration with Other SMT Equipment

The effectiveness of SMT PCB loaders is often enhanced when integrated with other equipment within the SMT assembly line. Here are some key integrations:

1. Pick-and-Place Machines

PCB loaders work seamlessly with pick-and-place machines, which are responsible for accurately placing components onto PCBs. The loader feeds PCBs directly into these machines, ensuring a continuous workflow that minimizes downtime.

2. Reflow Ovens

After component placement, PCBs typically pass through reflow ovens to solder components securely to the board. Loaders equipped with automatic magazine systems can quickly transfer completed boards to these ovens without manual handling.

3. Inspection Systems

Automated Optical Inspection (AOI) systems verify the quality of assembled PCBs. Integrating loaders with AOI systems allows for immediate feedback on any defects detected during assembly, enabling quick adjustments to maintain quality standards.

Benefits of Innovations in SMT PCB Loader Technology

The latest innovations in SMT PCB loader technology offer numerous benefits to manufacturers:

- Increased Productivity: Enhanced speed and automation lead to higher output rates, allowing manufacturers to meet growing demand without increasing labor costs.

- Improved Quality Control: Advanced vision systems ensure that only properly aligned and defect-free PCBs proceed through the assembly line, reducing waste and rework rates.

- Cost Savings: By minimizing manual handling and improving efficiency, manufacturers can significantly reduce operational costs associated with labor and material waste.

Future Trends in SMT PCB Loader Technology

As technology continues to evolve, several trends are likely to shape the future of SMT PCB loader technology:

1. Increased Use of AI and Machine Learning

The integration of AI and machine learning will continue to enhance automation capabilities within SMT PCB loaders. Predictive maintenance algorithms will help identify potential failures before they occur, reducing downtime and maintenance costs.

2. Greater Customization Options

Manufacturers will increasingly demand customized solutions tailored to specific production needs. This trend will lead to more flexible loader designs capable of handling a wider variety of PCB sizes and configurations.

3. Enhanced Data Analytics

As manufacturers seek greater insights into their production processes, data analytics will play a crucial role in optimizing loader performance. Advanced software solutions will provide real-time data on throughput rates, error rates, and machine health metrics.

Conclusion

The innovations in SMT PCB loader technology are transforming how electronic components are assembled on printed circuit boards. With enhanced automation features, improved speed and efficiency, advanced vision systems, user-friendly interfaces, and energy-efficient designs, these loaders are paving the way for more efficient manufacturing processes. As technology continues to evolve, we can expect even more advancements that will further enhance productivity and quality in electronics manufacturing.

FAQ

1. What is an SMT PCB loader?

An SMT PCB loader is a machine used in electronics manufacturing that automatically loads bare printed circuit boards onto an assembly line for processing.

2. How do modern SMT PCB loaders improve efficiency?

Modern SMT PCB loaders improve efficiency through automation features such as robotic integration, high-speed loading mechanisms, and advanced vision systems that ensure accurate placement.

3. What role does AI play in SMT PCB loader technology?

AI enhances vision systems within SMT PCB loaders by enabling real-time monitoring, defect detection, and adaptive adjustments during the loading process.

4. Are there eco-friendly options available for SMT PCB loaders?

Yes, many manufacturers are developing energy-efficient SMT PCB loaders that use less power and incorporate sustainable materials into their designs.

5. How do I choose the right SMT PCB loader for my production line?

When choosing an SMT PCB loader, consider factors such as speed requirements, compatibility with existing equipment, automation features, and overall cost-effectiveness based on your production needs.

Citations:

[1] https://www.hayawin.com/news-smt-machine-types-and-features-of-excellent-smt-machines.html

[2] https://neodenusa.com/pcb-unloader/

[3] https://www.hayawin.com/product-250-automatic-loader.html

[4] https://faroads.com/smt-machine/

[5] https://www.hayawin.com/news-what-is-a-pcb-loader.html

[6] https://seamarksmt.com/products/pcb-loader-and-unloader/

[7] https://www.allsmt.com/Board-Handling

[8] https://smtnet.com/products/index.cfm?fuseaction=browse_products&cat_id=31

[9] https://www.tronstol.com/smt-assembly/loader-and-unloader/

[10] https://faroads.com/led-smt-line-for-pcb-assembly/

[11] https://shenzhenshengdian.en.made-in-china.com/product/COTtWMnvfjhg/China-Latest-SMT-Line-Production-PCB-Destacker-Bare-Board-Loader-PCB-Loader-Machine.html

[12] https://inlinesmt.com/pcb-handling-equipment/pcb-line-loader/

[13] https://www.hayawin.com/news-automatic-pcb-magazine-unloader-for-smt-production-line.html

[14] https://www.obsmt.com/product/automatic-pcb-loader/

[15] https://smtdevices.com/new-smt-equipment.html

[16] https://www.smtlinemachine.com/sale-10813725-smt-pcb-magazine-loader-and-unloader-professional-automatic.html

[17] https://www.chuxin-smt.com/products/zl-650/

[18] https://www.manncorp.com/blogs/learning-center/feeder-capacity

[19] https://cnsmtline.com/pcb-magazine-loader/