Content Menu

● Introduction to SMT PCB Fixtures

>> Role of SMT PCB Fixtures in Modern Electronics

● Latest Innovations in SMT PCB Fixture Technology

>> Advanced Materials and Designs

>> Automation and Machine Learning Integration

>> Environmental Sustainability

● Impact of Innovations on PCB Assembly

● Future Prospects for SMT PCB Fixtures

>> Emerging Trends

>> Challenges and Opportunities

● Case Studies: Real-World Applications

● Conclusion

● FAQs

>> 1. What is the primary function of SMT PCB fixtures?

>> 2. How do advanced materials improve SMT PCB fixtures?

>> 3. What role does automation play in SMT PCB fixture technology?

>> 4. How do SMT PCB fixtures contribute to environmental sustainability?

>> 5. What are the future prospects for SMT PCB fixtures in electronics manufacturing?

● Citations:

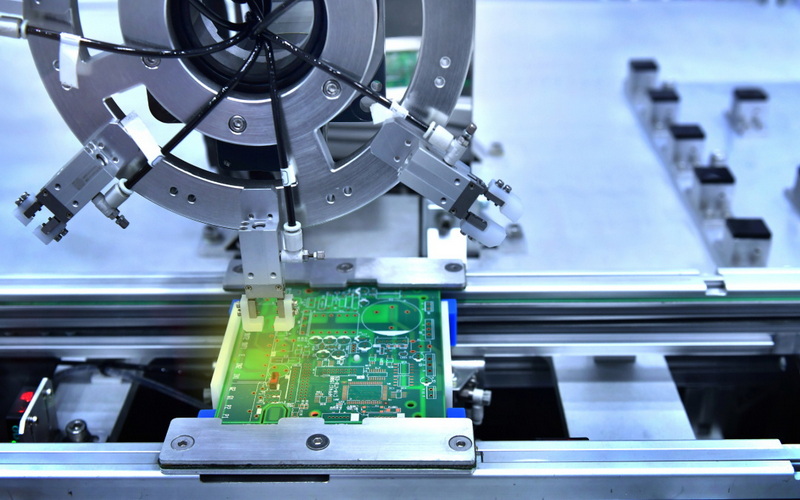

The evolution of Surface Mount Technology (SMT) has revolutionized the electronics industry, transforming the way printed circuit boards (PCBs) are designed and manufactured. Central to this transformation is the development of innovative SMT PCB fixtures, which play a crucial role in enhancing the efficiency, accuracy, and reliability of PCB assembly processes. This article delves into the latest advancements in SMT PCB fixture technology, exploring how these innovations are shaping the future of electronics production.

Introduction to SMT PCB Fixtures

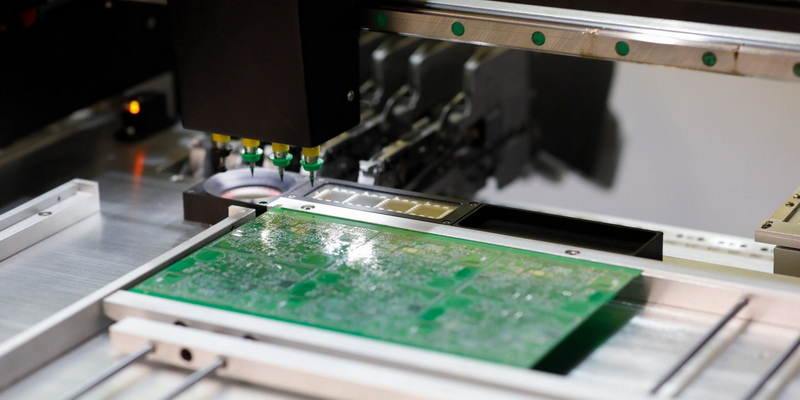

SMT PCB fixtures are specialized tools designed to support and position PCBs during the assembly process. These fixtures ensure that components are accurately placed and soldered onto the board, minimizing errors and improving overall production quality. The integration of advanced materials and automation technologies has significantly enhanced the functionality of SMT PCB fixtures, making them indispensable in modern electronics manufacturing.

Role of SMT PCB Fixtures in Modern Electronics

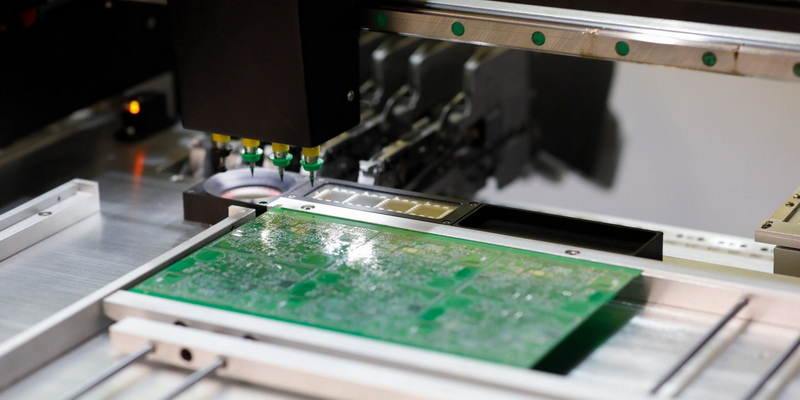

1. Enhanced Precision: SMT PCB fixtures are engineered to maintain precise alignment of components on the PCB, ensuring that each part is correctly positioned for optimal performance.

2. Increased Efficiency: By stabilizing the PCB during assembly, these fixtures facilitate faster production cycles and reduce the likelihood of human error.

3. Improved Reliability: The use of SMT PCB fixtures contributes to the reliability of electronic devices by ensuring consistent soldering conditions and minimizing mechanical stress on components.

Latest Innovations in SMT PCB Fixture Technology

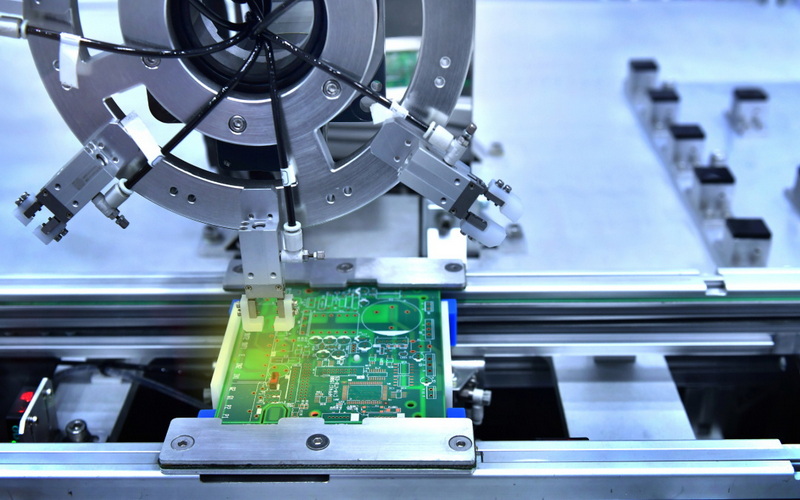

Recent years have seen significant advancements in SMT PCB fixture technology, driven by the need for more efficient, accurate, and reliable assembly processes. Some of the key innovations include:

Advanced Materials and Designs

- Thermal Management: New materials and designs are being developed to enhance thermal management during the soldering process. This includes the use of heat-insulating fixtures that protect sensitive components from excessive heat, ensuring that PCBs remain within a tolerable temperature range.

- Customizable Fixtures: Manufacturers are now offering customizable SMT PCB fixtures that can be tailored to specific PCB designs. This flexibility allows for more efficient assembly of complex boards with unique component layouts.

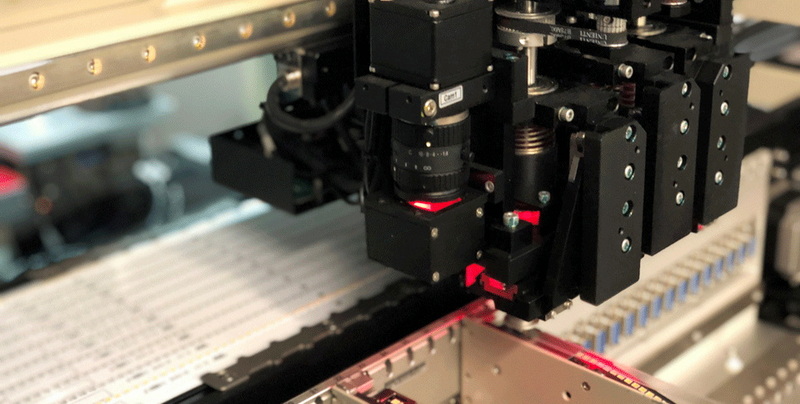

Automation and Machine Learning Integration

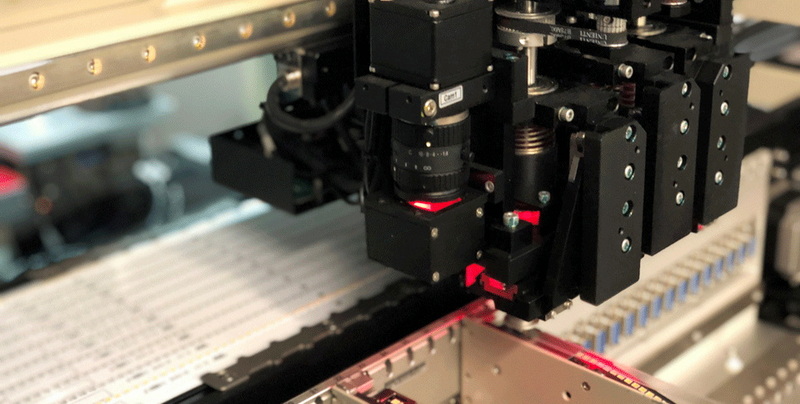

- Automated Inspection Systems: The integration of automated inspection systems with SMT PCB fixtures enables real-time monitoring of assembly processes. This technology uses machine vision to detect defects and ensure that every unit meets quality standards.

- Adaptive Placement Strategies: Advanced software systems are being developed to optimize component placement strategies in real-time. These systems analyze production data to identify the most efficient placement patterns, further enhancing assembly speed and accuracy.

Environmental Sustainability

- Lead-Free Soldering: Innovations in lead-free soldering processes have become increasingly important for environmental sustainability. Specialized fixtures are designed to support these processes, ensuring that PCBs can be assembled using eco-friendly materials without compromising performance.

Impact of Innovations on PCB Assembly

The latest innovations in SMT PCB fixture technology have a profound impact on PCB assembly processes:

1. Increased Efficiency: Automated systems and advanced materials reduce production time and enhance assembly speed.

2. Improved Accuracy: Precision alignment and real-time inspection ensure that components are correctly placed and soldered.

3. Enhanced Reliability: Better thermal management and reduced mechanical stress contribute to more reliable electronic devices.

Future Prospects for SMT PCB Fixtures

As technology continues to evolve, SMT PCB fixtures will play an increasingly critical role in shaping the future of electronics manufacturing. The integration of advanced automation and machine learning technologies will further enhance efficiency and accuracy, enabling the production of more complex and sophisticated electronic devices.

Emerging Trends

- Integration with IoT: The future of SMT PCB fixtures involves their integration into IoT-enabled production lines, allowing for real-time monitoring and optimization of assembly processes.

- Advanced Materials Science: Research into new materials and substrates will continue to improve the durability and performance of electronic components, further expanding the capabilities of SMT PCB fixtures.

Challenges and Opportunities

Despite the advancements, there are challenges that need to be addressed. One of the primary challenges is the cost associated with implementing advanced automation and machine learning technologies. However, these investments can lead to significant long-term benefits, including reduced labor costs and improved product quality.

Moreover, the integration of SMT PCB fixtures with emerging technologies like 3D printing and flexible electronics presents new opportunities. These technologies enable the creation of complex geometries and flexible PCBs, which can be used in a wide range of innovative applications, from wearable devices to advanced medical equipment.

Case Studies: Real-World Applications

Several companies have successfully implemented advanced SMT PCB fixture technologies to improve their manufacturing processes. For instance, a leading automotive electronics manufacturer used customized fixtures to enhance the assembly of complex PCBs for vehicle control systems. This resulted in a significant reduction in production time and an increase in product reliability.

Another example is a consumer electronics company that integrated automated inspection systems with their SMT PCB fixtures. This allowed them to detect defects early in the production process, reducing waste and improving overall product quality.

Conclusion

In conclusion, the latest innovations in SMT PCB fixture technology are transforming the landscape of electronics manufacturing. By enhancing precision, efficiency, and reliability, these advancements are driving the production of more compact, efficient, and high-performance electronic devices. As the industry continues to evolve, the role of SMT PCB fixtures will become even more pivotal in meeting the demands of modern electronics production.

FAQs

1. What is the primary function of SMT PCB fixtures?

SMT PCB fixtures are designed to support and position PCBs during the assembly process, ensuring accurate placement and soldering of components to enhance production quality.

2. How do advanced materials improve SMT PCB fixtures?

Advanced materials improve SMT PCB fixtures by enhancing thermal management, allowing for customizable designs, and supporting eco-friendly soldering processes, which contribute to more efficient and reliable assembly processes.

3. What role does automation play in SMT PCB fixture technology?

Automation plays a crucial role in SMT PCB fixture technology by integrating automated inspection systems and machine learning to optimize component placement, reduce errors, and enhance production speed.

4. How do SMT PCB fixtures contribute to environmental sustainability?

SMT PCB fixtures contribute to environmental sustainability by supporting lead-free soldering processes and reducing waste through more efficient assembly processes.

5. What are the future prospects for SMT PCB fixtures in electronics manufacturing?

The future prospects for SMT PCB fixtures involve further integration with automation and IoT technologies, enabling real-time monitoring and optimization of assembly processes, and the development of advanced materials to enhance component durability and performance.

Citations:

[1] https://www.andwinpcb.com/innovations-in-surface-mount-technology-for-enhanced-electronics/

[2] https://arkcircuits.com/blog/impact-of-smt-on-modern-pcb-design/

[3] https://www.andwinpcb.com/advancements-in-smt-assembly-for-modern-electronics-production/

[4] https://patents.google.com/patent/CN102922070B/en

[5] https://novaenginc.com/future-of-circuit-board-assembly/

[6] https://www.anypcba.com/blogs/pcb-assembly-knowledge/the-ultimate-guide-to-pcb-smt-technology-process-applications.html

[7] https://www.hayawin.com/news-pcb-printed-circuit-board-assembly-technologies-smt-vs-through-hole.html

[8] https://smtnet.com/library/index.cfm?fuseaction=browse_articles&start_at=296