Content Menu

● Introduction

● Advancements in SMT Line Technology

● Automation and Robotics in SMT

● Sustainability in SMT Manufacturing

● Future Trends in SMT Line Assembling

● Enhanced Inspection Technologies

● Market Growth Drivers

● Industry 4.0 Integration

● Conclusion

● FAQ

>> 1. What is SMT line assembling?

>> 2. How does AI improve SMT line assembling?

>> 3. What are the benefits of miniaturization in SMT?

>> 4. Why is sustainability important in SMT manufacturing?

>> 5. What are flexible hybrid electronics?

● Citations:

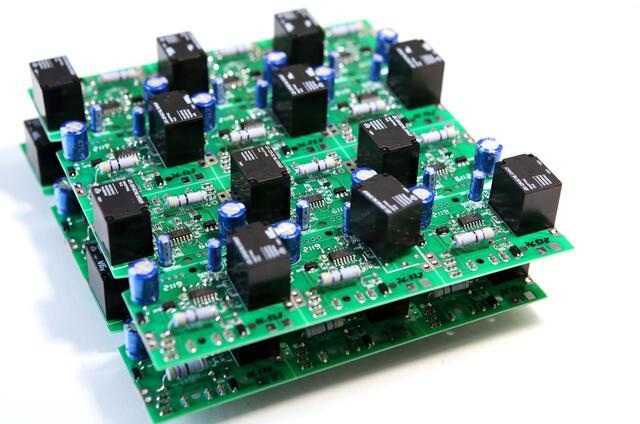

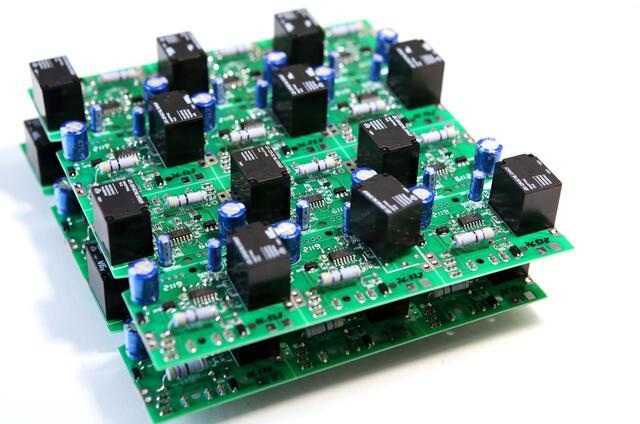

Introduction

Surface Mount Technology (SMT) line assembling has become a cornerstone of modern electronics manufacturing. By enabling the efficient and precise placement of components onto printed circuit boards (PCBs), SMT has revolutionized the production of electronic devices. This article explores the latest innovations in SMT line assembling, highlighting advancements that are shaping the future of the industry.

Advancements in SMT Line Technology

Recent years have seen significant technological advancements in SMT line assembling. Some of the most notable innovations include:

- AI-Driven Production Optimization: AI-driven software is transforming how manufacturers optimize their production processes. By providing real-time monitoring and data analysis, manufacturers can identify inefficiencies and enhance overall productivity.

- Miniaturization: The trend toward smaller components continues to push boundaries, enabling the development of compact designs that can fit into increasingly smaller electronic devices. This miniaturization allows for higher component density and improved functionality.

- 3D Packaging Techniques: Techniques such as System-in-Package (SiP) and Package-on-Package (PoP) are providing alternatives to traditional chip designs, allowing for greater functionality in limited spaces. These methods enable manufacturers to integrate multiple functions into a single package, enhancing performance while saving space.

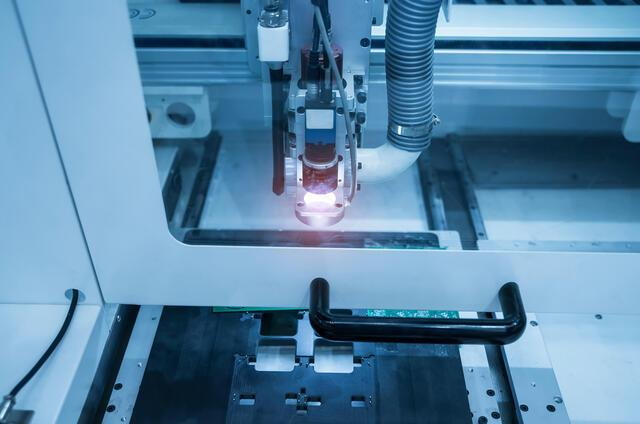

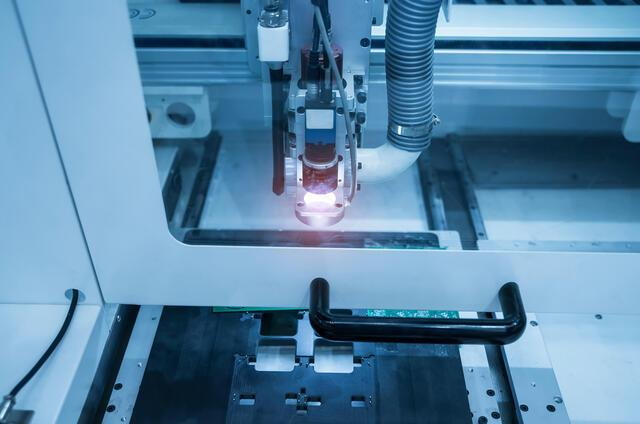

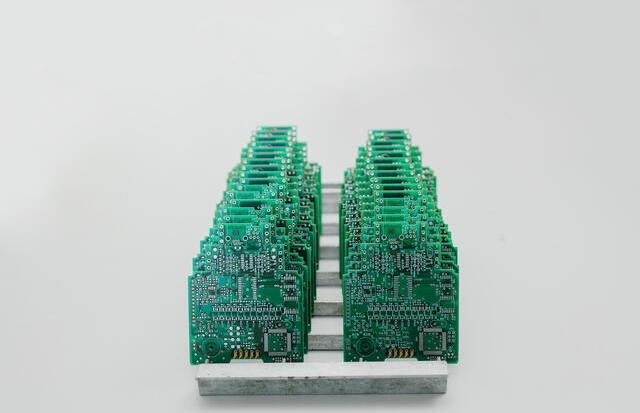

Automation and Robotics in SMT

Automation and robotics are at the forefront of SMT innovations. Key advancements include:

- Automated Pick-and-Place Machines: These machines have drastically improved the speed and accuracy of component placement. Capable of placing thousands of components per minute, they significantly reduce labor costs and production time.

- Robotic Soldering Systems: Robotic systems are being integrated into soldering processes, ensuring consistent quality and reducing human error. These advancements streamline production and enhance overall product reliability.

- Smart Automation: Intelligent automation systems are designed to optimize each step of the assembly process, ensuring rapid and precise production. They can adapt to different product configurations, enhancing flexibility in manufacturing.

Sustainability in SMT Manufacturing

As environmental concerns grow, the SMT industry is adopting more sustainable practices:

- Lead-Free Soldering: Compliance with RoHS regulations is becoming standard practice, reducing the environmental impact of electronic manufacturing by eliminating lead-based solders.

- Recyclable Materials: Manufacturers are increasingly utilizing recyclable materials in their processes, contributing to a more sustainable future for electronics production.

- Energy-Efficient Processes: The implementation of energy-efficient technologies helps reduce overall energy consumption during manufacturing, aligning with global sustainability goals.

Future Trends in SMT Line Assembling

The future of SMT line assembling is promising, with several exciting trends on the horizon:

- Flexible Hybrid Electronics: This emerging technology combines traditional electronics with printed electronics, opening new possibilities for innovative designs that can adapt to various applications.

- Smart Data Analytics: Powered by machine learning, smart data analytics enable manufacturers to optimize processes and predict maintenance needs, enhancing operational efficiency.

- Integration of 3D Printing: The integration of 3D printing techniques into PCB assembly processes is unlocking new dimensions for creating intricate and customized structures. This technology accelerates rapid prototyping and minimizes time-to-market for new products.

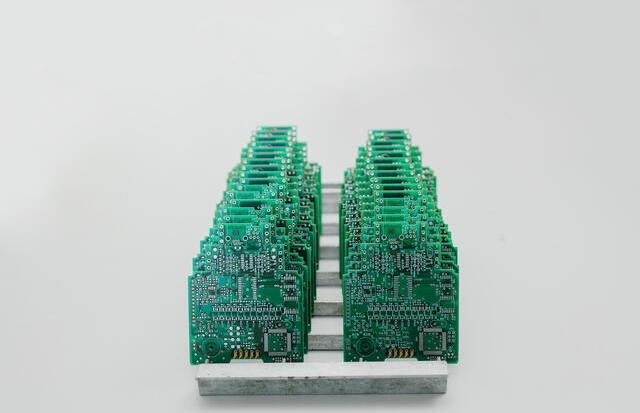

Enhanced Inspection Technologies

Another critical area of innovation within SMT line assembling is inspection technology. As quality control remains paramount in electronics manufacturing, advancements in automated inspection systems have become essential:

- Automated Optical Inspection (AOI): AOI systems utilize high-resolution cameras to detect defects on PCBs after assembly. Recent innovations have improved these systems' accuracy and speed, allowing for real-time feedback during production.

- X-ray Inspection Systems (AXI): X-ray inspection provides a non-destructive method to examine internal structures of PCBs, particularly useful for detecting solder joint issues that are not visible externally. The latest AXI technologies offer enhanced resolution and faster processing times.

- Solder Paste Inspection (SPI): SPI systems ensure that solder paste is applied correctly before component placement. Innovations in SPI technology have led to more sensitive detection capabilities that can identify even minor discrepancies in paste application.

Market Growth Drivers

The growth trajectory of the SMT equipment market reflects broader trends within the electronics industry:

- Rising Demand for Electronic Devices: The increasing proliferation of consumer electronics, smart home devices, automotive electronics, and medical devices drives demand for efficient SMT solutions.

- Advancements in Semiconductor Technology: Continuous improvements in semiconductor fabrication allow for smaller and more powerful components, necessitating advanced SMT equipment capable of handling these innovations.

- 5G Technology Implementation: The rollout of 5G networks requires high-performance electronic components that can manage increased data speeds and connectivity demands. SMT plays a crucial role in producing these advanced components efficiently.

Industry 4.0 Integration

The integration of Industry 4.0 principles into SMT manufacturing processes is transforming how factories operate:

- IoT Connectivity: Internet of Things (IoT) technologies enable machines within an SMT line to communicate with each other, facilitating real-time data sharing and process optimization.

- Predictive Maintenance: By utilizing data analytics from IoT devices, manufacturers can predict when machines require maintenance before failures occur. This proactive approach minimizes downtime and enhances productivity.

- Digital Twins: Creating digital replicas of physical SMT lines allows manufacturers to simulate operations, test changes without disrupting production, and optimize workflows based on real-time data insights.

Conclusion

The innovations in SMT line assembling are transforming the electronics manufacturing industry. From AI-driven optimization to sustainable practices, these advancements improve efficiency and quality while paving the way for a more sustainable and innovative future. As technology continues to evolve, the potential for further breakthroughs in SMT line assembling remains limitless.

FAQ

1. What is SMT line assembling?

SMT line assembling is the process of placing electronic components onto the surface of PCBs using automated machines. It is a faster and more efficient alternative to traditional through-hole technology.

2. How does AI improve SMT line assembling?

AI-driven production optimization software provides real-time monitoring and data analysis, helping manufacturers identify inefficiencies and improve overall production quality.

3. What are the benefits of miniaturization in SMT?

Miniaturization allows for the development of smaller, more compact electronic devices. It also enables higher component density, leading to more functionality in limited spaces.

4. Why is sustainability important in SMT manufacturing?

Sustainability is crucial for reducing the environmental impact of electronic manufacturing. Practices like lead-free soldering and using recyclable materials help create a more eco-friendly industry.

5. What are flexible hybrid electronics?

Flexible hybrid electronics combine traditional and printed electronics, allowing for innovative designs and applications in various industries, including healthcare and wearable technology.

Citations:

[1] https://smtnet.com/news/

[2] https://www.linkedin.com/pulse/exciting-developments-surface-mount-technology-snehal-kale

[3] https://blog.tbrc.info/2024/09/surface-mount-technology-smt-equipment-market-size/

[4] https://essemtec.com/en/news/news-detail-en/-/-/sf-smt-showcases-essemtecs-advanced-smt-solutions-at-elexcon-2024/

[5] https://www.openpr.com/news/3779903/surface-mount-technology-smt-global-market-trends-2024

[6] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[7] https://www.swfuliusmt.com/2024/07/17/top-10-pick-and-place-machine-manufacturers-leaders-in-smt-technology-for-2024/

[8] https://www.thebusinessresearchcompany.com/market-insights/surface-mount-technology-smt-equipment-market-2024

[9] https://www.openbom.com/blog/5-trends-of-contract-manufacturing-in-2024

[10] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[11] https://smttoday.com/2024/09/25/asys-group-technology-days-2024/

[12] https://www.raypcb.com/surface-mount-technology/

[13] https://asselems.com/en/electronics-manufacturing-industry-trends-for-2024

[14] https://smttoday.com/2024/08/27/neotech-enhances-manufacturing-edge-with-new-integrated-microelectronics-and-smt-assembly-expansion/

[15] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[16] https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook.html

[17] https://iconnect007.com/article/139444/saki-to-highlight-advanced-inspection-innovation-at-smart-smt-pcb-assembly-2024-korea/139441/smt

[18] https://www.einpresswire.com/article/754509769/global-surface-mount-technology-market-2024-to-reach-8-34-billion-by-2028-with-a-growth-rate-of-9-6

[19] https://smta.org/events/RSVPlist.aspx?id=1814998

[20] https://www.pillarhouse.co.uk/latest-news/pillarhouse-international-smart-smt-pcb-assembly-2024/

[21] https://www.linkedin.com/pulse/surface-mount-technologies-market-2024-insights-key-mh6pe/

[22] https://www.consegicbusinessintelligence.com/surface-mount-technology-equipment-market

[23] https://faroadsmt.com/the-future-of-smt/