Content Menu

● The Evolution of SMT Chip Mounters

>> Miniaturization and High-Density Placement

>> Increased Speed and Throughput

>> Enhanced Flexibility and Configurability

● Advanced Features in Modern SMT Chip Mounters

>> Intelligent Component Recognition

>> Real-Time Process Monitoring and Optimization

>> Integration with Industry 4.0 Technologies

>> Enhanced Component Feeding Systems

● Innovations in Placement Technology

>> Multi-Axis Placement Heads

>> Advanced Nozzle Technology

>> Laser-Guided Placement

● Advancements in Software and User Interface

>> Intuitive Programming Interfaces

>> Machine Learning and AI Integration

● Environmental Considerations and Energy Efficiency

>> Energy-Saving Features

>> Reduced Waste and Improved Material Utilization

● Future Trends in SMT Chip Mounter Technology

>> 3D Packaging and Advanced Interconnect Technologies

>> Integration with Additive Manufacturing

>> Enhanced Traceability and Quality Control

>> Autonomous Operation and Self-Optimization

● Conclusion

● FAQ

>> 1. What is the typical placement speed of modern SMT chip mounters?

>> 2. How do SMT chip mounters handle different component sizes?

>> 3. What are the key factors to consider when choosing an OEM SMT chip mounter for a PCB production line?

>> 4. How do SMT chip mounters ensure accurate component placement?

>> 5. What are the latest environmental considerations in SMT chip mounter design?

● Citations:

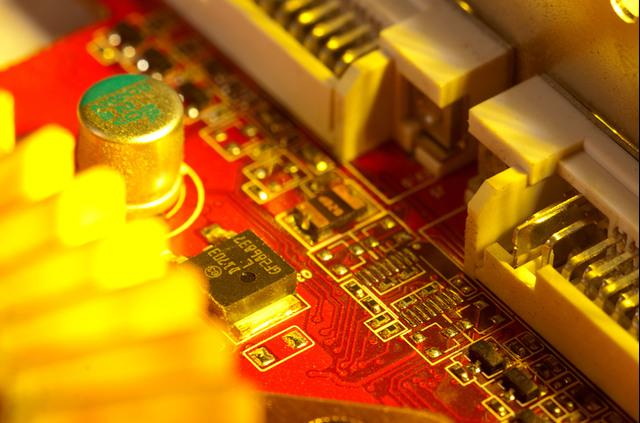

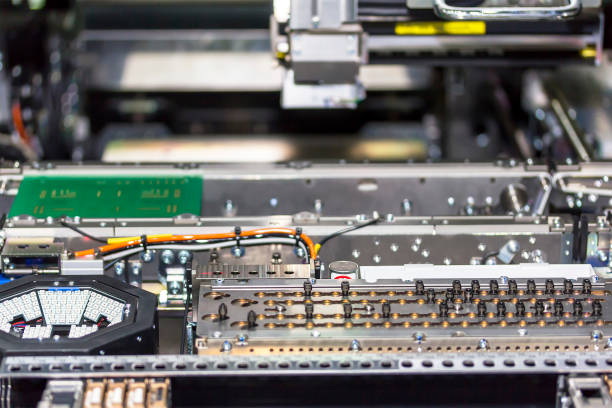

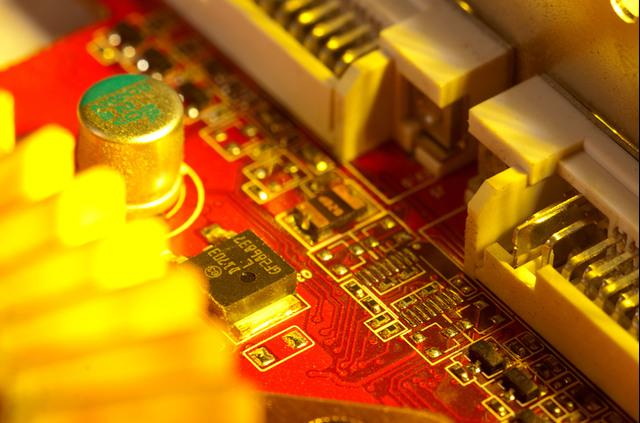

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient, and highly reliable electronic devices. At the heart of this technology lies the SMT chip mounter, a crucial piece of equipment in the PCB production line. As the demand for more advanced and compact electronic devices continues to grow, innovations in SMT chip mounter technology are constantly emerging to meet these challenges. This article explores the latest advancements in SMT chip mounter technology, with a focus on OEM SMT chip mounters for PCB production lines.

The Evolution of SMT Chip Mounters

SMT chip mounters have come a long way since their inception. These machines are essential components of the SMT production line, responsible for accurately placing surface mount components onto printed circuit boards (PCBs). The evolution of SMT chip mounters has been driven by the need for increased speed, precision, and flexibility in PCB assembly processes.

Miniaturization and High-Density Placement

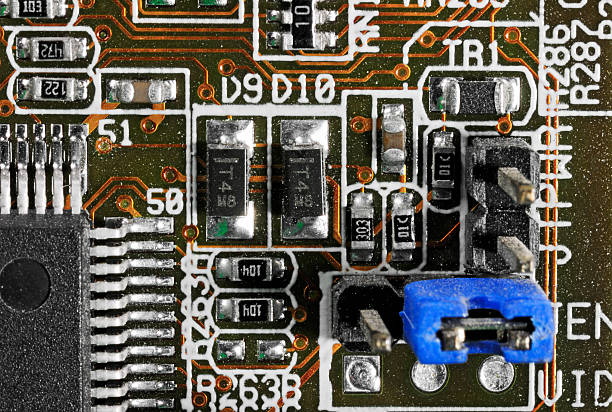

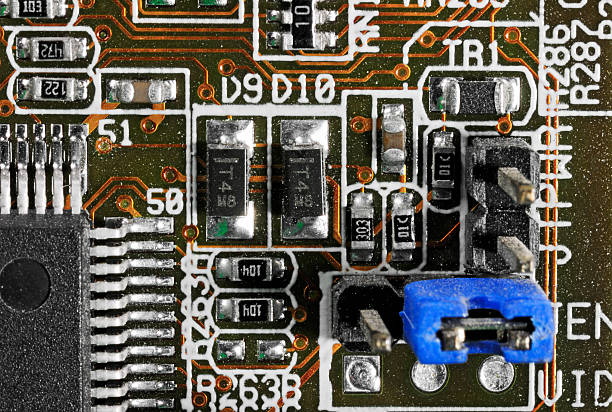

One of the most significant trends in SMT chip mounter technology is the ability to handle increasingly smaller components. As electronic devices become more compact, the components used in their construction have also shrunk in size. Modern SMT chip mounters are now capable of placing components as small as 0201 (0.6mm x 0.3mm) and even 01005 (0.4mm x 0.2mm) with high accuracy[1].

This miniaturization trend has led to the development of advanced pick-and-place mechanisms that can handle these tiny components without damaging them. OEM SMT chip mounters for PCB production lines now incorporate high-precision cameras and vision systems to ensure accurate placement of these minuscule parts.

Increased Speed and Throughput

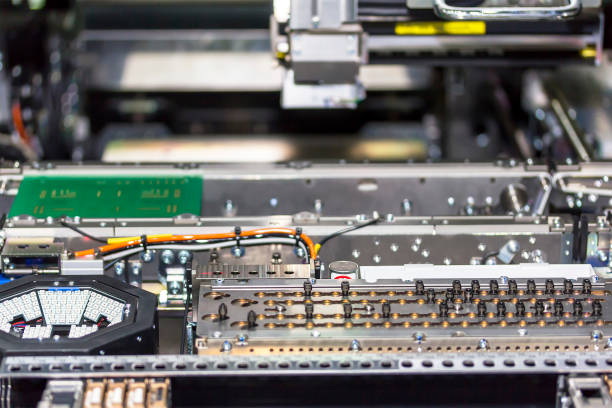

The demand for higher production volumes has driven manufacturers to develop faster SMT chip mounters. Modern machines can place tens of thousands of components per hour, with some high-end models capable of placing up to 136,000 components per hour[6]. This incredible speed is achieved through the use of multiple placement heads, advanced motion control systems, and optimized component feeding mechanisms.

OEM SMT chip mounters for PCB production lines are now designed with dual-lane capabilities, allowing for simultaneous processing of two PCBs. This feature significantly increases throughput and efficiency in high-volume production environments.

Enhanced Flexibility and Configurability

The latest SMT chip mounters offer unprecedented levels of flexibility, allowing manufacturers to adapt quickly to changing production requirements. These machines can handle a wide range of component types and sizes, from small passive components to large BGAs and QFPs.

Many OEM SMT chip mounters for PCB production lines now feature modular designs that allow for easy reconfiguration and upgrading. This modularity enables manufacturers to customize their production lines to meet specific needs and to scale up capacity as demand increases.

Advanced Features in Modern SMT Chip Mounters

Intelligent Component Recognition

Modern SMT chip mounters incorporate advanced vision systems and artificial intelligence algorithms to recognize and verify components automatically. This technology ensures that the correct components are placed in the right positions, reducing errors and improving overall quality.

The intelligent component recognition systems in OEM SMT chip mounters for PCB production lines can detect issues such as missing or misaligned components, bent leads, and other defects before placement. This proactive approach to quality control helps minimize rework and waste.

Real-Time Process Monitoring and Optimization

The latest SMT chip mounters are equipped with sophisticated sensors and data collection systems that provide real-time monitoring of the placement process. This data is used to optimize machine performance, detect anomalies, and predict potential issues before they occur.

OEM SMT chip mounters for PCB production lines now offer advanced software interfaces that allow operators to monitor and control multiple machines from a single workstation. These interfaces provide detailed analytics and performance metrics, enabling manufacturers to continuously improve their production processes.

Integration with Industry 4.0 Technologies

As the manufacturing industry moves towards greater automation and connectivity, SMT chip mounters are being designed to integrate seamlessly with Industry 4.0 technologies. These machines can now communicate with other equipment in the production line, sharing data and coordinating operations for optimal efficiency.

OEM SMT chip mounters for PCB production lines are increasingly incorporating features such as:

- Cloud connectivity for remote monitoring and diagnostics

- Machine learning algorithms for predictive maintenance

- Integration with Manufacturing Execution Systems (MES) for streamlined production planning

Enhanced Component Feeding Systems

The efficiency of an SMT chip mounter is heavily dependent on its component feeding system. Recent innovations in this area include:

- Intelligent feeders that can detect and report low component levels

- High-speed tray exchangers for quick changeovers between different component types

- Vibration-free feeders that ensure stable component presentation, even at high speeds

These advanced feeding systems contribute to the overall performance and reliability of OEM SMT chip mounters for PCB production lines, reducing downtime and improving productivity.

Innovations in Placement Technology

Multi-Axis Placement Heads

Traditional SMT chip mounters used simple up-and-down motion for component placement. However, the latest machines feature multi-axis placement heads that can rotate and tilt components during placement. This capability allows for more precise positioning and enables the placement of odd-shaped components that were previously challenging to handle.

OEM SMT chip mounters for PCB production lines now offer placement heads with up to six degrees of freedom, providing unparalleled flexibility in component placement.

Advanced Nozzle Technology

The nozzles used in SMT chip mounters play a crucial role in component handling and placement. Recent innovations in nozzle technology include:

- Self-cleaning nozzles that reduce maintenance requirements

- Adaptive nozzles that can adjust their shape to handle different component sizes

- Nozzles with integrated sensors for real-time force feedback during placement

These advanced nozzles contribute to the overall accuracy and reliability of OEM SMT chip mounters for PCB production lines, ensuring consistent performance even with challenging components.

Laser-Guided Placement

Some cutting-edge SMT chip mounters now incorporate laser guidance systems for ultra-precise component placement. These systems use laser triangulation to measure the exact position of components and the PCB, allowing for placement accuracies of up to ±0.025mm.

This level of precision is particularly important for OEM SMT chip mounters for PCB production lines that handle high-density boards with fine-pitch components.

Advancements in Software and User Interface

Intuitive Programming Interfaces

Modern SMT chip mounters feature user-friendly programming interfaces that simplify the setup and operation of the machines. These interfaces often include:

- Graphical programming tools for easy creation and editing of placement programs

- Drag-and-drop functionality for component and feeder assignments

- 3D visualization of the PCB and component placement for easy verification

OEM SMT chip mounters for PCB production lines now offer software that can automatically optimize placement sequences for maximum efficiency, reducing programming time and improving overall productivity.

Machine Learning and AI Integration

Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being integrated into SMT chip mounter software. These technologies enable:

- Automatic component recognition and classification

- Predictive maintenance based on historical performance data

- Self-optimization of placement parameters for improved accuracy and speed

By leveraging AI and ML, OEM SMT chip mounters for PCB production lines can continuously improve their performance over time, adapting to changing production requirements and environmental conditions.

Environmental Considerations and Energy Efficiency

As sustainability becomes a growing concern in manufacturing, SMT chip mounter manufacturers are focusing on developing more environmentally friendly and energy-efficient machines.

Energy-Saving Features

Modern SMT chip mounters incorporate various energy-saving features, such as:

- Low-power standby modes

- Energy-efficient motors and drives

- Optimized motion control to reduce energy consumption during operation

OEM SMT chip mounters for PCB production lines are now designed with these energy-saving features as standard, helping manufacturers reduce their carbon footprint and operating costs.

Reduced Waste and Improved Material Utilization

Innovations in component feeding and placement technology have led to significant reductions in material waste. Advanced SMT chip mounters now offer:

- Precise component pick-up mechanisms that minimize component loss

- Intelligent feeder systems that reduce component spillage

- Optimized placement algorithms that minimize solder paste waste

These features not only improve the environmental performance of OEM SMT chip mounters for PCB production lines but also contribute to cost savings in high-volume production environments.

Future Trends in SMT Chip Mounter Technology

As we look to the future, several emerging trends are likely to shape the development of SMT chip mounter technology:

3D Packaging and Advanced Interconnect Technologies

The increasing adoption of 3D packaging technologies, such as System-in-Package (SiP) and Package-on-Package (PoP), will require SMT chip mounters to handle more complex assembly processes. Future machines will need to be capable of placing components with even finer pitches and in three-dimensional configurations.

Integration with Additive Manufacturing

As additive manufacturing techniques become more prevalent in electronics production, SMT chip mounters may need to integrate with 3D printing technologies. This could lead to hybrid machines that combine traditional pick-and-place functionality with additive manufacturing capabilities for creating custom interconnects or embedded components.

Enhanced Traceability and Quality Control

Future OEM SMT chip mounters for PCB production lines are likely to incorporate even more advanced traceability features, such as:

- Individual component tracking using RFID or similar technologies

- Real-time quality monitoring using advanced sensors and imaging systems

- Integration with blockchain technologies for secure and transparent supply chain management

Autonomous Operation and Self-Optimization

The ultimate goal for many manufacturers is to achieve fully autonomous production lines. Future SMT chip mounters may incorporate advanced AI systems that can:

- Automatically adjust placement parameters based on real-time quality data

- Predict and prevent potential failures before they occur

- Optimize production schedules and component inventory management

These autonomous capabilities will enable OEM SMT chip mounters for PCB production lines to operate with minimal human intervention, further improving efficiency and reliability.

Conclusion

The field of SMT chip mounter technology is rapidly evolving, driven by the ever-increasing demands of the electronics industry. From miniaturization and increased speed to advanced software integration and environmental considerations, the latest innovations in SMT chip mounters are reshaping PCB production lines.

OEM SMT chip mounters for PCB production lines are at the forefront of these advancements, offering manufacturers unprecedented levels of precision, flexibility, and efficiency. As we look to the future, it's clear that SMT chip mounter technology will continue to play a crucial role in enabling the production of increasingly complex and sophisticated electronic devices.

The ongoing development of SMT chip mounter technology promises to bring even more exciting innovations in the years to come, further revolutionizing the electronics manufacturing industry and pushing the boundaries of what's possible in PCB assembly.

FAQ

1. What is the typical placement speed of modern SMT chip mounters?

Modern SMT chip mounters can achieve placement speeds of up to 136,000 components per hour for high-end models. However, the actual speed can vary depending on the complexity of the PCB and the types of components being placed. OEM SMT chip mounters for PCB production lines often offer customizable speed options to balance throughput with placement accuracy.

2. How do SMT chip mounters handle different component sizes?

SMT chip mounters use a combination of advanced vision systems, multiple nozzle types, and flexible feeding mechanisms to handle a wide range of component sizes. Modern machines can place components as small as 01005 (0.4mm x 0.2mm) and as large as 50mm x 50mm or more. OEM SMT chip mounters for PCB production lines often feature modular designs that allow for easy reconfiguration to accommodate different component sizes and types.

3. What are the key factors to consider when choosing an OEM SMT chip mounter for a PCB production line?

When selecting an OEM SMT chip mounter for a PCB production line, consider the following factors:

- Placement speed and accuracy

- Component size range and feeder capacity

- Machine footprint and line integration capabilities

- Software features and ease of programming

- Maintenance requirements and support availability

- Future scalability and upgrade options

4. How do SMT chip mounters ensure accurate component placement?

SMT chip mounters use several technologies to ensure accurate component placement:

- High-resolution cameras and vision systems for component recognition and alignment

- Precision motion control systems for accurate positioning

- Force feedback sensors to control placement pressure

- Laser guidance systems for ultra-precise placement

- Real-time calibration and self-correction mechanisms

OEM SMT chip mounters for PCB production lines often incorporate multiple layers of quality control to maintain placement accuracy throughout long production runs.

5. What are the latest environmental considerations in SMT chip mounter design?

The latest environmental considerations in SMT chip mounter design include:

- Energy-efficient motors and drive systems

- Low-power standby modes and intelligent power management

- Optimized motion control to reduce energy consumption

- Improved material utilization to minimize waste

- Use of recyclable materials in machine construction

- Integration with energy monitoring and management systems

OEM SMT chip mounters for PCB production lines are increasingly designed with these environmental features to help manufacturers reduce their carbon footprint and operating costs.

Citations:

[1] https://www.andwinpcb.com/innovations-in-surface-mount-technology-for-enhanced-electronics/

[2] https://www.hct-smt.com/blog/oem-smt-chip-mounter-for-pcb-production-line--a-comprehensive-guide

[3] https://www.pcbasic.com/blog/smt_production_line.html

[4] https://patents.google.com/patent/CN103140046A/en

[5] https://www.raypcb.com/surface-mount-technology/

[6] https://www.ourpcb.com/smt-line.html

[7] https://id.hct-smt.com/blog/oem-smt-chip-mounter-for-pcb-production-line

[8] https://www.electronicsforu.com/news/high-speed-chip-mounter-reforms-smt-and-tht-production