Content Menu

● Introduction

● The Role of Mini SMD Mounting Machines

>> Key Benefits of Mini SMD Mounting Machines:

● Latest Innovations in Mini SMD Mounting Technology

>> 1. Enhanced Automation and Smart Manufacturing

>> 2. High Precision Placement

>> 3. Advanced Materials and Soldering Techniques

>> 4. Compact Designs for Specialized Applications

>> 5. Scalability for Prototyping

● Emerging Trends in Mini SMD Mounting Technology

● Applications Across Industries

● Conclusion

● FAQ

>> Q1: What is the difference between mini SMD mounting machines and full-size SMT machines?

>> Q2: Can mini SMD mounting machines handle mixed components?

>> Q3: What are the trends in mini SMD mounting machine technology?

>> Q4: What industries benefit most from mini SMD mounting technology?

>> Q5: How do mini SMD mounting machines support prototyping?

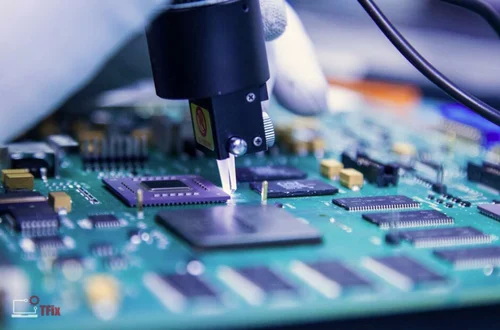

Introduction

The world of electronics manufacturing is constantly evolving, driven by the demand for smaller, faster, and more efficient devices. At the heart of this transformation lies Surface Mount Technology (SMT) and its specialized subset, mini SMD mounting machines. These compact machines are revolutionizing PCB assembly processes by enabling precise placement of surface-mount devices (SMDs) on printed circuit boards (PCBs). As industries push for miniaturization and higher performance, innovations in mini SMD mounting technology are paving the way for a new era of electronics manufacturing.

This article explores the latest advancements in mini SMD mounting machines, highlighting their role in modern manufacturing, their applications across industries, and the cutting-edge technologies that are shaping their future.

The Role of Mini SMD Mounting Machines

Mini SMD mounting machines are designed to assemble electronic components onto PCBs with remarkable accuracy and efficiency. Unlike traditional SMT machines, which are often large and geared toward high-volume production, mini SMD mounting machines cater to small-scale operations, prototyping, and specialized applications. Their compact size and versatility make them indispensable tools for manufacturers looking to optimize their production processes.

Key Benefits of Mini SMD Mounting Machines:

1. Compact Size: These machines are ideal for environments with limited space, such as small workshops or in-house production facilities.

2. Cost Efficiency: They offer a cost-effective solution for low-volume production without compromising on quality.

3. High Precision: Advanced vision systems and placement mechanisms ensure accurate alignment and positioning of components.

4. Flexibility: Mini SMD mounting machines can handle a wide range of components, from microchips to capacitors, resistors, and connectors.

5. Ease of Use: Many models are designed with user-friendly interfaces, making them accessible even to operators with minimal training.

Latest Innovations in Mini SMD Mounting Technology

The demand for smaller and more complex electronic devices has driven significant advancements in mini SMD mounting technology. Below are some of the most notable innovations:

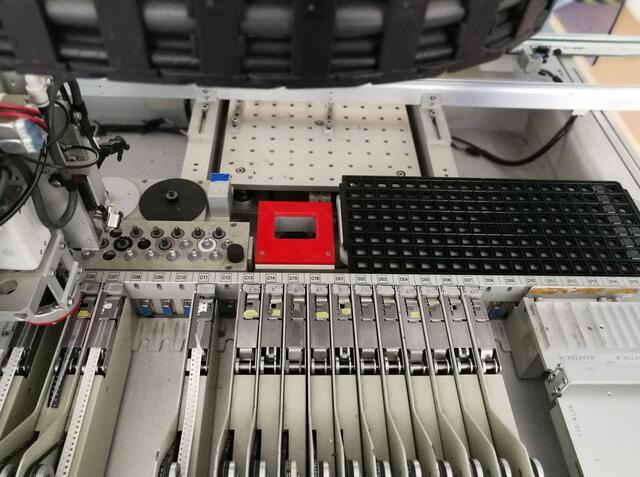

1. Enhanced Automation and Smart Manufacturing

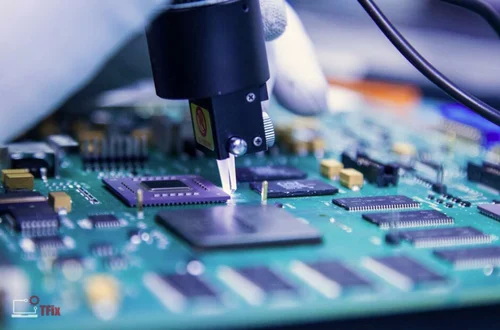

Automation has been a game-changer in the electronics manufacturing industry, and mini SMD mounting machines are no exception. Modern machines now incorporate advanced automation features that streamline operations and reduce human intervention.

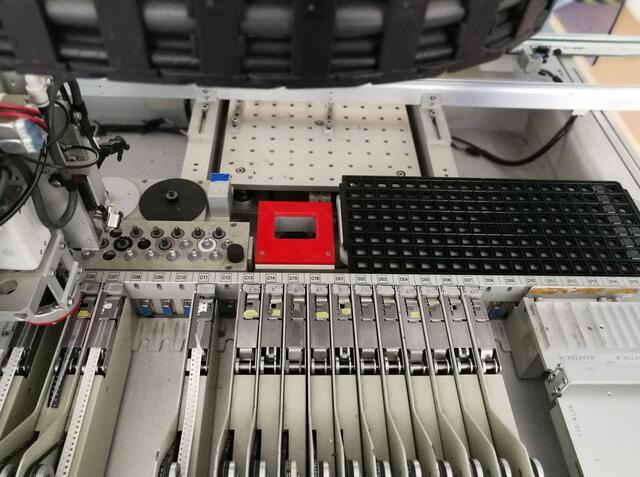

- Pick-and-Place Systems: Automated pick-and-place mechanisms have become faster and more reliable, significantly improving production efficiency.

- AI Integration: Machine learning algorithms enable real-time optimization of component placement, reducing errors and improving yield rates.

- Continuous Feeding Systems: Dual-rail systems allow uninterrupted PCB feeding during the mounting process, minimizing downtime.

These advancements not only enhance productivity but also ensure consistent quality across production runs.

2. High Precision Placement

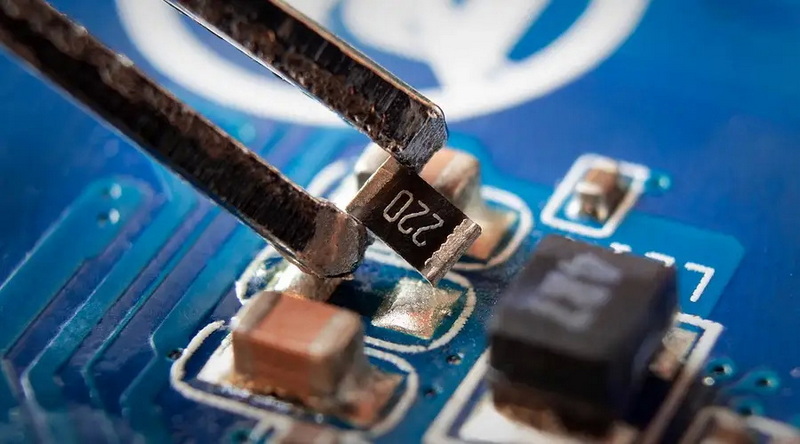

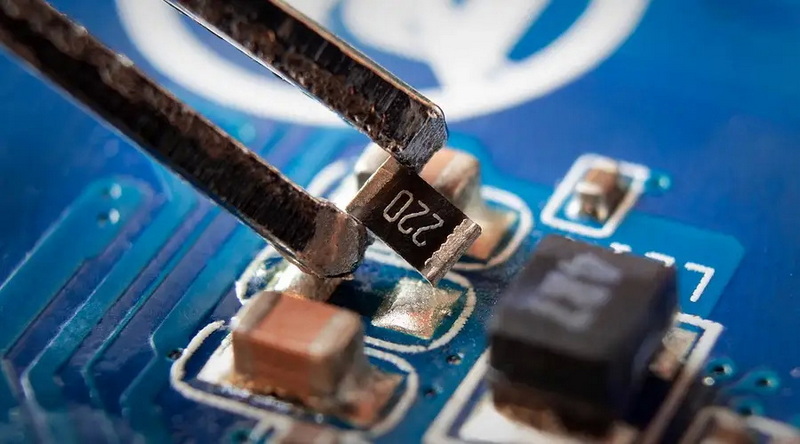

As electronic components continue to shrink in size—such as 01005 resistors and capacitors—the need for precision has become critical. Mini SMD mounting machines now feature cutting-edge technologies to meet these demands:

- Vision Systems: High-resolution cameras and image recognition software guide the accurate placement of components on PCBs.

- Micro-Assembly Techniques: These techniques enable the handling of ultra-miniature components required for compact devices like wearables and IoT gadgets.

- Laser Alignment Systems: Some machines use laser-guided alignment to achieve sub-millimeter accuracy during component placement.

Precision is especially important in industries like medical devices and aerospace, where even minor errors can have significant consequences.

3. Advanced Materials and Soldering Techniques

The reliability of electronic assemblies depends heavily on the materials and soldering techniques used during manufacturing. Recent innovations in this area include:

- Lead-Free Soldering: As environmental regulations become stricter, lead-free soldering has emerged as a standard practice. Modern mini SMD mounting machines are equipped to handle these materials without compromising performance.

- Improved Flux Application: Advanced flux dispensing systems ensure uniform application, enhancing solder joint reliability.

- Thermal Management Solutions: Innovations in heat dissipation techniques help prevent overheating during soldering, extending the lifespan of electronic components.

These advancements contribute to the overall durability and performance of electronic products.

4. Compact Designs for Specialized Applications

Mini SMD mounting machines have evolved to meet the unique requirements of various industries. Their compact size makes them particularly suitable for specialized applications:

- Medical Devices: Cleanroom-compatible designs allow these machines to be used in assembling diagnostic tools and portable medical devices.

- Robotics and Drones: Lightweight designs enable precise assembly of sensors, control boards, and other critical components for robotics and drones.

- Wearable Technology: The ability to handle ultra-miniature components is essential for assembling compact wearables like fitness trackers and smartwatches.

By catering to niche markets, mini SMD mounting machines have expanded their utility beyond traditional electronics manufacturing.

5. Scalability for Prototyping

Prototyping is a crucial phase in product development, allowing manufacturers to test designs before committing to full-scale production. Mini SMD mounting machines excel in this area due to their flexibility and adaptability:

- Rapid Prototyping Capabilities: These machines enable quick turnaround times for prototype assemblies, accelerating the product development cycle.

- Mixed Component Handling: Many models can accommodate both surface-mount and through-hole components, making them ideal for hybrid designs.

- Customizable Settings: Operators can easily adjust machine parameters to suit specific project requirements.

This scalability makes mini SMD mounting machines an invaluable tool for startups, research labs, and educational institutions.

Emerging Trends in Mini SMD Mounting Technology

As technology continues to advance, several trends are shaping the future of mini SMD mounting machines:

1. Integration with IoT: Machines equipped with IoT capabilities can provide real-time data on performance metrics, enabling predictive maintenance and process optimization.

2. Energy Efficiency: Newer models are designed to consume less power without sacrificing performance, aligning with sustainability goals.

3. Modular Designs: Modular configurations allow manufacturers to upgrade or customize their machines based on evolving needs.

4. Cloud-Based Software Updates: Remote software updates ensure that machines stay up-to-date with the latest features and improvements.

These trends underscore the ongoing evolution of mini SMD mounting technology as it adapts to meet changing industry demands.

Applications Across Industries

Mini SMD mounting machines have found applications across a wide range of industries due to their versatility and precision:

1. Consumer Electronics: Smartphones, tablets, wearables, and other consumer gadgets benefit from compact designs enabled by miniaturized components.

2. Home Automation: Devices like smart thermostats, security cameras, and smart locks rely on efficient assembly processes facilitated by these machines.

3. Medical Technology: Portable medical devices such as glucose monitors and handheld diagnostic tools require precise component placement.

4. Robotics: The assembly of advanced robotic systems often involves space constraints that mini SMD mounting machines can easily address.

5. Education & Research: Makerspaces and educational institutions use these machines to teach PCB assembly techniques and foster innovation among students.

Conclusion

The innovations in mini SMD mounting technology are reshaping electronics manufacturing by enabling compact designs, improving efficiency, and supporting diverse applications across industries. From AI-driven automation to enhanced precision systems, these advancements cater to the growing demand for smaller yet powerful electronic devices. As industries continue to embrace these technologies, mini SMD mounting machines will play a critical role in driving innovation forward.

Whether you're a startup prototyping your next big idea or an established manufacturer looking to optimize your production line, investing in a modern mini SMD mounting machine could be the key to staying competitive in today's fast-paced market.

FAQ

Q1: What is the difference between mini SMD mounting machines and full-size SMT machines?

Mini SMD mounting machines are designed for low-volume production or prototyping. They occupy less space and cost less compared to full-size SMT machines, which are optimized for high-speed, high-volume production lines.

Q2: Can mini SMD mounting machines handle mixed components?

Yes, many models can accommodate both surface-mount and through-hole components using adapters or removable inserts.

Q3: What are the trends in mini SMD mounting machine technology?

Current trends include increased automation, higher precision placement capabilities, reduced machine size, improved flexibility, energy efficiency, IoT integration, modular designs, and cloud-based software updates.

Q4: What industries benefit most from mini SMD mounting technology?

Industries such as consumer electronics, medical devices, robotics, home automation, wearable technology development, education research labs benefit significantly due to their need for compact designs & precise component placements

Q5: How do mini SMD mounting machines support prototyping?

These Machines enable rapid prototyping by allowing manufacturers iterative design processes before scaling up production flexibly handling hybrid assemblies .