Content Menu

● Introduction to LED Chip SMD Mounting Machines

>> Key Features of Modern LED Chip SMD Mounting Machines

● Latest Innovations in LED Chip SMD Mounting Technology

>> 1. Increased Speed and Precision

>> 2. Multi-Functional Capabilities

>> 3. Intelligent Software Integration

>> 4. Improved Heat Management

>> 5. Enhanced Flexibility for Small-Batch Production

● Impact of Innovations on LED Chip SMD Mounting Machine Prices

● Market Trends and Demand

● LED Chip SMD Mounting Machine Price Ranges

● Comparison with Other Technologies

● Technological Advancements in SMD Packaging

● Role of Automation in LED Chip SMD Mounting

● Integration with Industry 4.0

● Sustainability and Energy Efficiency

● Challenges in Handling Fragile Components

● Future Directions and Challenges

● Conclusion

● FAQ

>> 1. What are the key factors affecting the price of LED chip SMD mounting machines?

>> 2. How do technological innovations impact the efficiency of LED chip SMD mounting machines?

>> 3. What are the benefits of using advanced LED chip SMD mounting machines in production?

>> 4. How does the integration of intelligent software impact the performance of LED chip SMD mounting machines?

>> 5. What trends are shaping the future of the LED chip SMD mounting machine market?

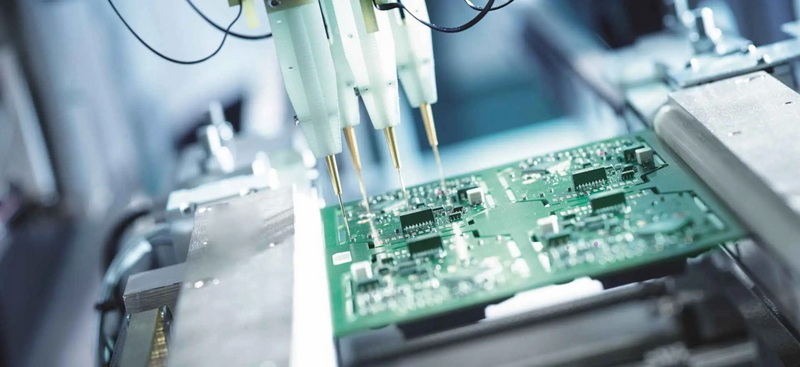

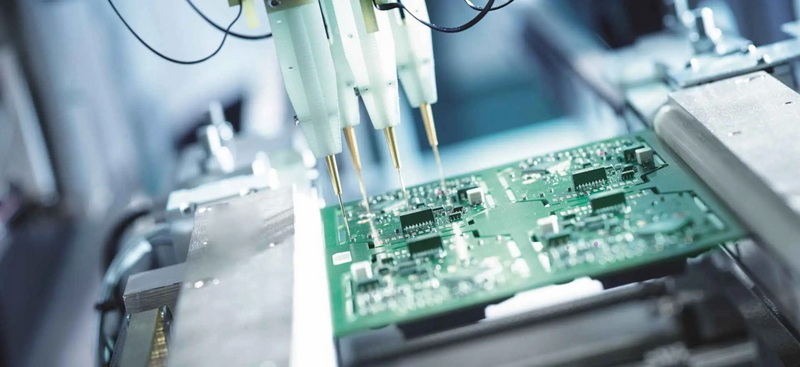

The LED chip SMD mounting machine is a crucial piece of equipment in the production of LED displays and lighting solutions. These machines utilize Surface Mount Technology (SMT) to precisely place and solder LED chips onto printed circuit boards (PCBs). The price of LED chip SMD mounting machines can vary significantly based on several factors, including technological advancements, production capacity, and market demand. This article will explore the latest innovations affecting the prices of these machines and provide insights into the current market trends.

Introduction to LED Chip SMD Mounting Machines

LED chip SMD mounting machines are designed to handle the assembly of LED components onto PCBs efficiently. They are part of the broader SMT equipment market, which has seen significant growth due to the increasing demand for electronic devices and advancements in semiconductor technology. These machines are essential for producing high-quality LED displays and lighting products, offering advantages such as high-speed placement, precision, and multi-functional capabilities.

Key Features of Modern LED Chip SMD Mounting Machines

Modern LED chip SMD mounting machines are equipped with advanced features that enhance their performance and efficiency:

- High-Speed Placement: These machines can place thousands of components per hour with micron-level precision, significantly improving production efficiency.

- Multi-Functional Capabilities: They can handle various component types and sizes, reducing the need for specialized machines and increasing versatility.

- Intelligent Software Integration: Real-time monitoring, data analysis, and process optimization capabilities are integrated into these machines, allowing for adaptive production adjustments.

- Improved Heat Management: Sophisticated temperature control systems ensure optimal soldering conditions, preventing thermal damage to components.

Latest Innovations in LED Chip SMD Mounting Technology

Several innovations are impacting the prices and capabilities of LED chip SMD mounting machines:

1. Increased Speed and Precision

The latest machines are designed to operate at higher speeds while maintaining exceptional accuracy. This is achieved through advanced vision systems and precise positioning mechanisms, contributing to higher production efficiency and improved product quality. For instance, the NeoDenL460 high-speed LED SMT machine can place up to 18,000 chips per hour, making it ideal for mass production.

2. Multi-Functional Capabilities

These machines can now handle a variety of components beyond just LED chips, including resistors and capacitors. This flexibility reduces production time and costs by eliminating the need for multiple specialized machines. The NeoDen4 model, for example, can handle components like 0201, BGA, QFN, and LED strips, showcasing its versatility.

3. Intelligent Software Integration

The integration of intelligent software systems provides real-time monitoring, data analysis, and process optimization capabilities. Machine learning algorithms can adapt to changing production requirements, optimizing placement parameters for different LED chip types and board designs. This not only enhances efficiency but also reduces waste and improves product quality.

4. Improved Heat Management

Advanced temperature control systems ensure optimal soldering conditions, preventing thermal damage to components and improving the overall reliability of the final product. This is particularly important as LED chips become smaller and more powerful, requiring precise thermal management to maintain performance.

5. Enhanced Flexibility for Small-Batch Production

With the growing demand for customized LED solutions, these machines are designed to offer greater flexibility for small-batch production. Quick-change tooling and easily programmable systems allow manufacturers to switch between different product types rapidly, reducing setup times and increasing overall production efficiency.

Impact of Innovations on LED Chip SMD Mounting Machine Prices

The innovations in LED chip SMD mounting technology have both positive and negative impacts on machine prices:

- Increased Efficiency: Higher speed and precision capabilities can reduce production costs over time, potentially lowering the cost per unit of LED products. However, the initial investment in these advanced machines may be higher.

- Multi-Functional Capabilities: While these capabilities increase versatility, they also contribute to higher machine complexity and cost.

- Intelligent Software Integration: The integration of advanced software systems can increase the upfront cost of machines but offers long-term benefits through improved efficiency and reduced waste.

Market Trends and Demand

The demand for LED chip SMD mounting machines is influenced by several market trends:

- Growing Demand for LED Displays: The increasing use of LED displays in advertising, entertainment, and public information systems drives the demand for efficient SMD mounting machines. Modern SMD screens offer superior image quality and are more energy-conserving, further boosting demand.

- Advancements in SMD Technology: Innovations in SMD packaging, such as miniaturization and improved thermal management, require machines that can handle these advancements efficiently. Flip chip packaging, for example, offers superior electrical and thermal performance.

- Environmental and Energy Efficiency Regulations: The push for more energy-efficient LED products necessitates machines that can produce high-quality components while minimizing waste and energy consumption. Future machines are expected to focus on sustainability and reduced energy use.

LED Chip SMD Mounting Machine Price Ranges

The prices of LED chip SMD mounting machines vary widely based on their features and capabilities:

- Basic Models: Simple, manual or semi-automatic machines can start at around $3,000 to $5,000.

- Mid-Range Models: Machines with higher speed and precision capabilities, along with some automation features, typically range from $5,000 to $20,000.

- Advanced Models: High-speed, fully automated machines with advanced software integration and multi-functional capabilities can cost between $20,000 and $60,000 or more.

- High-End Models: Specialized machines designed for large-scale production or specific applications, such as high-density LED displays, can exceed $100,000.

Comparison with Other Technologies

In the LED display market, SMD technology competes with Chip on Board (COB) technology. While COB offers durability and finer pixel pitches, SMD technology is more versatile and cost-effective for many applications. SMD displays are ideal for outdoor environments due to their higher brightness levels and cost-effectiveness.

Technological Advancements in SMD Packaging

The trend towards miniaturization in SMD packaging continues to drive innovation. Smaller LED packages allow for higher pixel density in displays and more compact lighting solutions. Chip Scale Package (CSP) technology has emerged as a popular solution, eliminating the need for traditional packaging substrates and reducing the overall size of the LED component. This miniaturization challenges mounting machine manufacturers to develop systems capable of handling smaller components with greater precision, often requiring advancements in vision systems and placement mechanisms.

Role of Automation in LED Chip SMD Mounting

Automation plays a crucial role in modern LED chip SMD mounting processes. The integration of robotics and advanced control systems has led to significant improvements in production efficiency and product quality. Automated component feeding systems, vision-guided placement, and in-line quality control reduce human error and increase overall production speed. Advanced vision systems use high-resolution cameras and image processing algorithms to accurately identify and align components before placement, ensuring precise positioning even for ultra-fine pitch applications.

Integration with Industry 4.0

The concept of Industry 4.0, which involves the integration of smart manufacturing technologies, is set to play a significant role in the future of LED chip SMD mounting. This may include the implementation of Internet of Things (IoT) sensors for real-time monitoring, predictive maintenance systems, and seamless integration with enterprise resource planning (ERP) systems. Such integration will enhance efficiency, reduce downtime, and improve production quality by enabling real-time data-driven decisions.

Sustainability and Energy Efficiency

As the LED industry faces increasing pressure to improve its sustainability practices, future LED chip SMD mounting machines will likely focus on reducing energy consumption and minimizing waste. This may involve the development of more energy-efficient placement mechanisms and the use of eco-friendly materials in the mounting process. Innovations in this area will not only reduce environmental impact but also lower operational costs for manufacturers.

Challenges in Handling Fragile Components

As LED chips become smaller and more delicate, handling them without damage becomes increasingly challenging. Future mounting technologies may need to incorporate advanced gripping mechanisms and force-sensing capabilities to handle these fragile components safely. This will require significant advancements in machine design and component handling systems to ensure that the production process remains efficient and reliable.

Future Directions and Challenges

The future of LED chip SMD mounting technology will be shaped by several challenges and trends:

- Ultra-Fine Pitch Mounting: As display resolutions increase, machines must achieve higher levels of precision to handle ultra-fine pitch components.

- Sustainability and Energy Efficiency: There is a growing need for machines that reduce energy consumption and minimize waste, aligning with broader environmental goals.

- Integration with Industry 4.0: The integration of smart manufacturing technologies, such as IoT sensors and predictive maintenance, will enhance efficiency and production quality.

Conclusion

The latest innovations in LED chip SMD mounting machines are significantly impacting their prices and capabilities. As technology continues to evolve, these machines are becoming more efficient, versatile, and cost-effective over time. However, the initial investment in advanced models can be substantial. Understanding these trends and innovations is crucial for manufacturers looking to optimize their production processes and stay competitive in the LED industry.

FAQ

1. What are the key factors affecting the price of LED chip SMD mounting machines?

The price of LED chip SMD mounting machines is influenced by factors such as production capacity, technological advancements, market demand, and the level of automation and precision offered by the machine.

2. How do technological innovations impact the efficiency of LED chip SMD mounting machines?

Technological innovations, such as increased speed and precision, multi-functional capabilities, and intelligent software integration, significantly enhance the efficiency of these machines. They allow for faster production, reduced waste, and improved product quality.

3. What are the benefits of using advanced LED chip SMD mounting machines in production?

Advanced machines offer benefits such as higher production efficiency, improved product quality, and reduced long-term costs. They also provide flexibility for small-batch production and customization, which is increasingly important in the LED industry.

4. How does the integration of intelligent software impact the performance of LED chip SMD mounting machines?

The integration of intelligent software allows for real-time monitoring and optimization of the production process. It enables machines to adapt to different production requirements, improving efficiency and reducing errors.

5. What trends are shaping the future of the LED chip SMD mounting machine market?

Key trends include technological advancements, increased demand for energy efficiency, and the growing need for customized LED solutions. These trends drive the development of more versatile and efficient machines capable of handling a wide range of components and production volumes.