Content Menu

● Overview of SMT Assembly Line Training

● Key Skills Learned in SMT Assembly Line Training

>> Technical Proficiency

>> Quality Control

>> Problem-Solving

>> Teamwork and Communication

>> Safety and Maintenance

● Additional Skills Developed Through Training

>> Design for Manufacturability (DFM)

>> Lean Manufacturing Principles

>> Emerging Technologies

● Benefits of SMT Training

● The Role of Continuous Improvement

● Conclusion

● FAQ

>> 1. What is SMT assembly line training?

>> 2. Why is SMT training important?

>> 3. What skills are taught in SMT training?

>> 4. How long does SMT training take?

>> 5. What are the career benefits of SMT training?

● Citations:

Surface Mount Technology (SMT) assembly line training is essential for individuals looking to excel in the electronics manufacturing industry. As technology advances, the need for skilled workers who can operate and manage SMT processes has become increasingly critical. This article will explore the key skills acquired through SMT assembly line training, the benefits of such training, and address common questions related to the topic.

Overview of SMT Assembly Line Training

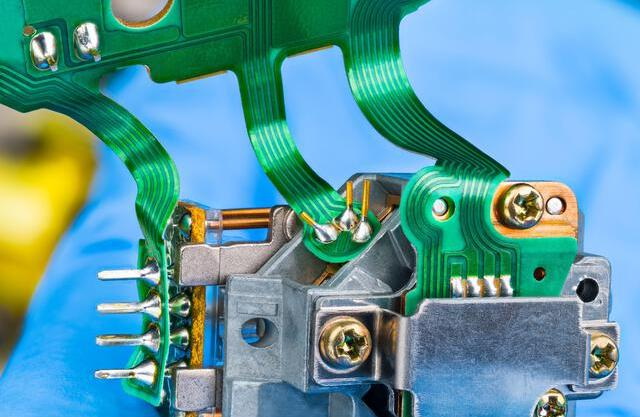

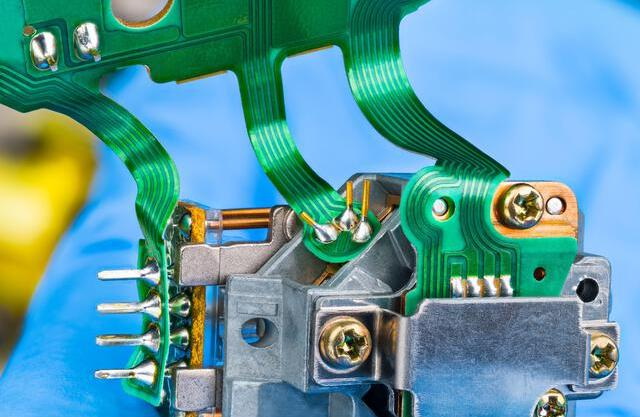

SMT assembly line training focuses on teaching participants how to operate various SMT equipment and manage the processes involved in assembling electronic components onto printed circuit boards (PCBs). This training encompasses both theoretical knowledge and practical skills, ensuring that trainees are well-equipped to handle the complexities of modern manufacturing environments.

Key Skills Learned in SMT Assembly Line Training

The following are some of the most important skills that trainees acquire during SMT assembly line training:

Technical Proficiency

- Operating SMT Equipment: Trainees learn how to effectively use various types of SMT machinery, including pick-and-place machines, solder paste printers, and reflow ovens. Understanding machine operation is crucial for ensuring smooth production processes.

- Software Usage: Familiarity with software tools used for programming machines and managing production data is also emphasized. This includes learning how to import CAD data and balance production lines.

Quality Control

- Ensuring High Standards: Quality control is a vital aspect of SMT assembly. Trainees are taught how to monitor production quality, conduct inspections, and implement corrective actions when necessary.

- Statistical Process Control (SPC): Participants learn SPC techniques to identify process variations and maintain quality standards throughout production.

Problem-Solving

- Troubleshooting Skills: The ability to diagnose and resolve issues that arise during the SMT process is essential. Trainees develop skills in error recovery and learn how to address common problems effectively.

- Critical Thinking: Participants are encouraged to think critically about production challenges and apply logical reasoning to find solutions.

Teamwork and Communication

- Collaborating Effectively: Working on an assembly line often requires collaboration with team members. Training emphasizes the importance of effective communication and teamwork in achieving production goals.

- Interpersonal Skills: Trainees develop interpersonal skills that enable them to interact positively with colleagues and supervisors, fostering a cooperative work environment.

Safety and Maintenance

- Adhering to Safety Protocols: Safety is paramount in manufacturing environments. Trainees learn about safety standards, proper handling of equipment, and emergency procedures to ensure a safe workplace.

- Preventive Maintenance: Understanding routine maintenance tasks helps trainees keep equipment in optimal condition, reducing downtime and enhancing productivity.

Additional Skills Developed Through Training

In addition to the core skills mentioned above, SMT assembly line training also focuses on several other important areas:

Design for Manufacturability (DFM)

Understanding DFM principles allows trainees to design products that are easier to manufacture. This includes:

- Optimizing component selection and placement

- Standardizing pad layouts

- Designing thermal reliefs for large components

- Ensuring adequate spacing for inspection and rework

Lean Manufacturing Principles

Trainees learn about lean manufacturing techniques aimed at minimizing waste while maximizing efficiency. This includes:

- Identifying bottlenecks in production

- Streamlining workflows

- Implementing continuous improvement methods such as Kaizen

Emerging Technologies

As technology evolves, so does the landscape of electronics manufacturing. Training programs often cover emerging technologies such as:

- Automation and robotics

- Artificial intelligence for defect prediction

- Advanced inspection technologies like 3D imaging

Benefits of SMT Training

Investing in SMT assembly line training provides numerous advantages for both individuals and organizations:

- Improved Productivity and Efficiency: Skilled workers can operate machinery more effectively, leading to faster production times and reduced waste.

- Enhanced Product Quality: With a focus on quality control, trained employees are better equipped to produce high-quality products that meet industry standards.

- Cost Savings: Reducing errors and downtime translates into significant cost savings for manufacturers.

- Career Advancement Opportunities: Completing SMT training can open doors for career growth within the electronics manufacturing sector, as employers value skilled technicians.

The Role of Continuous Improvement

Continuous improvement is a core principle in SMT assembly line operations. Training programs emphasize the importance of ongoing education and skill enhancement:

- Regularly updating knowledge on new technologies

- Participating in workshops or refresher courses

- Engaging in cross-training opportunities within different areas of manufacturing

Conclusion

SMT assembly line training is a vital component of modern electronics manufacturing. By acquiring key skills such as technical proficiency, quality control, problem-solving, teamwork, communication, safety awareness, maintenance knowledge, design for manufacturability principles, lean manufacturing techniques, and familiarity with emerging technologies, trainees position themselves for success in a competitive job market. As technology continues to evolve, ongoing education and training will remain essential for maintaining high standards in production processes.

FAQ

1. What is SMT assembly line training?

SMT assembly line training is a specialized program focused on teaching the skills required to operate and manage SMT equipment and processes effectively.

2. Why is SMT training important?

It ensures that workers are skilled in modern manufacturing techniques, leading to improved productivity, product quality, and overall efficiency in the industry.

3. What skills are taught in SMT training?

Skills include equipment operation, quality control techniques, troubleshooting methods, teamwork strategies, and adherence to safety protocols.

4. How long does SMT training take?

The duration varies but typically ranges from 100 to 200 hours depending on the level of expertise being targeted (technician or engineering).

5. What are the career benefits of SMT training?

Completing SMT training opens up opportunities for career advancement within the electronics manufacturing industry by equipping individuals with valuable skills that employers seek.

Citations:

[1] https://www.smtfactory.com/what-is-an-smt-line-and-how-can-it-improve-your-pcb-assembly-process.html

[2] https://www.wevolver.com/article/smt-process

[3] https://ipctraining.com.au/advanced-smt-thu-hole-rework/

[4] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[5] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[6] https://www.electronicspecifier.com/news/surface-mount-technology-best-practice-guide

[7] https://www.blackfox.com/7-benefits-of-surface-mount-technology-smt/

[8] https://www.ag5.com/smt-manufacturing/

[9] https://www.scientific-management.com/skills-training-programs/

[10] https://hawkerrichardson.com.au/blog/smt-line-efficiency-and-training/

[11] https://www.hayawin.com/resources/what-is-smt-assembly-the-advantages-and-applications-of-smt.html

[12] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[13] https://ieeexplore.ieee.org/document/6908299/1000

[14] https://www.allion.com/tech_surface_mount_tech/

[15] https://www.wnie.online/surface-mount-technology-best-practice-guide-by-a-r-t-helps-optimise-your-assembly-line/

[16] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[17] https://www.youtube.com/watch?v=8z3X99iReJM

[18] http://ieeexplore.ieee.org/document/6908299

[19] https://www.aiscorp.com/blog/the-ever-greener-grass-of-smt-manufacturing/

[20] https://itmconsulting.com/workshops/