Content Menu

● Understanding SMT Production

● Key Responsibilities of an SMT Production Engineer

>> Process Development and Optimization

>> Equipment Management

>> Quality Control

>> Team Collaboration and Training

>> Project Management

>> Continuous Improvement Initiatives

● Skills Required for an SMT Production Engineer

● Conclusion

● FAQ

>> 1. What is the role of an SMT Production Engineer?

>> 2. What skills are essential for an SMT Production Engineer?

>> 3. How does an SMT Production Engineer ensure quality in production?

>> 4. What technologies do SMT Production Engineers work with?

>> 5. What are the career prospects for SMT Production Engineers?

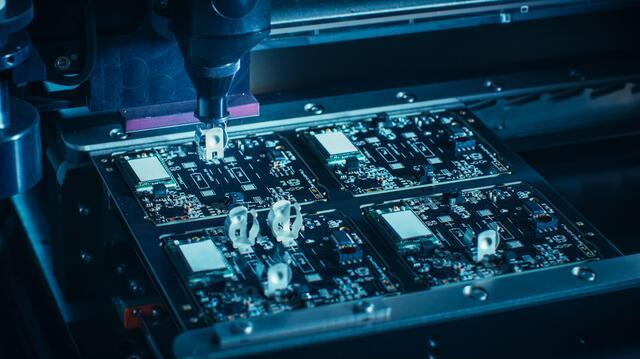

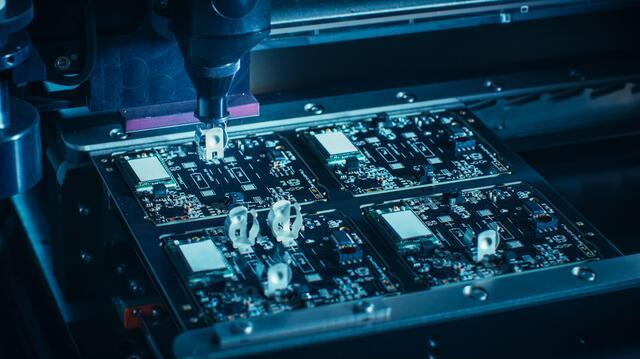

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of compact and efficient electronic devices. An SMT Production Engineer plays a crucial role in this process, ensuring that the production line operates smoothly and efficiently. This article delves into the key responsibilities of an SMT Production Engineer, highlighting their importance in the manufacturing process and the skills required to excel in this role.

Understanding SMT Production

Before exploring the responsibilities of an SMT Production Engineer, it is essential to understand what SMT entails. SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technology allows for higher component density and improved performance compared to traditional through-hole mounting techniques. The SMT process involves several stages, including:

1. Solder Paste Application: Applying solder paste to the PCB pads where components will be placed.

2. Component Placement: Using pick-and-place machines to accurately position components on the PCB.

3. Reflow Soldering: Heating the assembled PCB to melt the solder and create electrical connections.

4. Inspection and Testing: Ensuring that the assembly meets quality standards through various inspection methods.

Given the complexity of these processes, the role of an SMT Production Engineer is vital in maintaining quality and efficiency.

Key Responsibilities of an SMT Production Engineer

Process Development and Optimization

One of the primary responsibilities of an SMT Production Engineer is to develop and optimize the SMT processes. This includes:

- Analyzing Current Processes: Evaluating existing production methods to identify areas for improvement.

- Implementing New Technologies: Researching and integrating new SMT technologies and equipment to enhance production efficiency.

- Standardizing Procedures: Creating and maintaining standard operating procedures (SOPs) to ensure consistency and quality in production.

Equipment Management

SMT Production Engineers are responsible for managing the equipment used in the SMT process. This includes:

- Maintenance and Calibration: Ensuring that all SMT machines, such as pick-and-place and reflow ovens, are properly maintained and calibrated for optimal performance.

- Troubleshooting: Diagnosing and resolving equipment malfunctions to minimize downtime and maintain production schedules.

- Upgrading Equipment: Evaluating the need for new equipment and overseeing its installation and integration into the production line.

Quality Control

Quality assurance is a critical aspect of SMT production. Engineers must implement and monitor quality control measures, which involve:

- Conducting Inspections: Performing regular inspections of the production process and finished products to ensure they meet quality standards.

- Implementing Testing Protocols: Establishing testing protocols to identify defects and ensure the reliability of the assembled PCBs.

- Analyzing Quality Data: Collecting and analyzing data related to defects and production efficiency to drive continuous improvement.

Team Collaboration and Training

An SMT Production Engineer often works closely with various teams, including design, manufacturing, and quality assurance. Their responsibilities include:

- Cross-Functional Collaboration: Collaborating with design engineers to ensure that PCB designs are optimized for SMT manufacturing.

- Training Staff: Providing training and guidance to production staff on SMT processes, equipment operation, and quality standards.

- Leading Teams: Leading teams of technicians and operators to ensure that production goals are met efficiently and effectively.

Project Management

SMT Production Engineers often oversee specific projects related to the introduction of new products or processes. This involves:

- Planning and Scheduling: Developing project plans, timelines, and resource allocations to ensure successful project execution.

- Budget Management: Managing project budgets and ensuring that expenditures align with financial goals.

- Reporting: Providing regular updates to management on project status, challenges, and outcomes.

Continuous Improvement Initiatives

To remain competitive, SMT Production Engineers must engage in continuous improvement initiatives. This includes:

- Lean Manufacturing Practices: Implementing lean manufacturing principles to reduce waste and improve efficiency.

- Six Sigma Methodologies: Utilizing Six Sigma tools to analyze processes and reduce variability in production.

- Feedback Loops: Establishing feedback mechanisms to gather input from production staff and incorporate their insights into process improvements.

Skills Required for an SMT Production Engineer

To effectively fulfill their responsibilities, SMT Production Engineers must possess a diverse skill set, including:

- Technical Knowledge: A strong understanding of SMT processes, equipment, and materials is essential.

- Problem-Solving Skills: The ability to diagnose issues and develop effective solutions is crucial in a fast-paced production environment.

- Project Management Skills: Strong organizational and project management skills are necessary to oversee multiple projects simultaneously.

- Communication Skills: Effective communication is vital for collaborating with cross-functional teams and training staff.

- Attention to Detail: A keen eye for detail is essential for quality control and process optimization.

Conclusion

In conclusion, the role of an SMT Production Engineer is multifaceted and critical to the success of electronics manufacturing. From process development and equipment management to quality control and team collaboration, these engineers ensure that SMT production runs smoothly and efficiently. As technology continues to evolve, the responsibilities of SMT Production Engineers will likely expand, requiring them to stay abreast of industry trends and advancements. Their expertise not only contributes to the quality of electronic products but also drives innovation in the manufacturing process.

FAQ

1. What is the role of an SMT Production Engineer?

An SMT Production Engineer is responsible for overseeing the manufacturing process of electronic components using surface mount technology. Their duties include process development, equipment management, quality control, and team collaboration.

2. What skills are essential for an SMT Production Engineer?

Essential skills include technical knowledge of SMT processes, problem-solving abilities, project management skills, effective communication, and attention to detail.

3. How does an SMT Production Engineer ensure quality in production?

They implement quality control measures, conduct inspections, establish testing protocols, and analyze quality data to identify defects and drive continuous improvement.

4. What technologies do SMT Production Engineers work with?

They work with various SMT equipment, including pick-and-place machines, reflow ovens, and inspection systems, as well as software for process management and quality control.

5. What are the career prospects for SMT Production Engineers?

Career prospects are strong, with opportunities for advancement into management roles or specialized positions in process engineering, quality assurance, or project management within the electronics manufacturing industry.