Content Menu

● Understanding LED SMT PCB Board Cutting Machines

● Key Features to Consider

>> 1. Cutting Precision and Accuracy

>> 2. Cutting Speed and Efficiency

>> 3. Cutting Capacity and Versatility

>> 4. Cutting Method and Technology

>> 5. Heat Management and Dissipation

>> 6. Automation and Control Systems

>> 7. Material Compatibility

>> 8. Safety Features

>> 9. Maintenance and Durability

>> 10. Integration with Existing Systems

● Conclusion

● FAQ

>> 1. What is the typical cutting speed of an LED SMT PCB board cutting machine?

>> 2. How thick of a PCB can an LED SMT PCB board cutting machine typically handle?

>> 3. What are the advantages of using a V-Cut method in LED SMT PCB board cutting?

>> 4. How important is automation in LED SMT PCB board cutting machines?

>> 5. What maintenance is typically required for an LED SMT PCB board cutting machine?

● Citations:

LED SMT PCB board cutting machines are essential tools in the electronics manufacturing industry, particularly for producing LED lighting products. These machines are designed to precisely cut and separate PCB panels, ensuring efficient and accurate production of LED circuit boards. When selecting an LED SMT PCB board cutting machine, it's crucial to consider several key features that can significantly impact your production process and output quality.

Understanding LED SMT PCB Board Cutting Machines

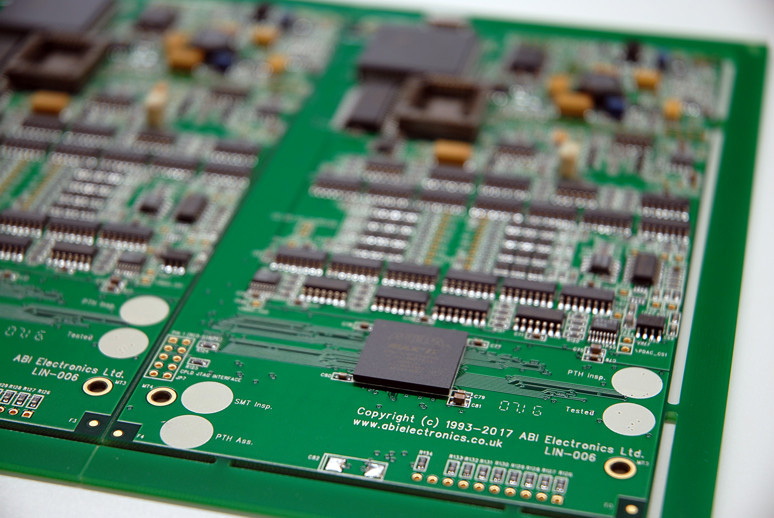

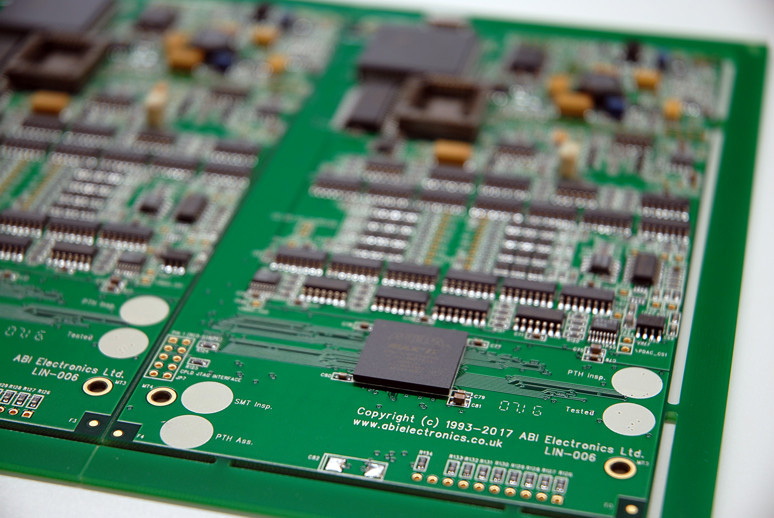

Before delving into the key features, it's important to understand what an LED SMT PCB board cutting machine is and its role in the manufacturing process. These machines are specifically designed to cut and separate PCB panels used in LED lighting applications. They are an integral part of the Surface Mount Technology (SMT) process, which is widely used in the production of LED lighting products.

LED SMT PCB board cutting machines are used to separate individual PCB boards from larger panels after the components have been mounted. This process, known as depaneling, requires precision and care to avoid damaging the delicate electronic components and ensure the integrity of the final product.

Key Features to Consider

1. Cutting Precision and Accuracy

One of the most critical features of an LED SMT PCB board cutting machine is its cutting precision and accuracy. High-quality machines should be able to make clean, precise cuts with minimal deviation. This is particularly important for LED PCBs, which often require intricate designs and tight tolerances.

Look for machines that offer high-precision cutting capabilities, typically measured in micrometers. Some advanced models can achieve cutting accuracies of up to 0.02mm, ensuring that your LED PCBs are cut to exact specifications[1].

2. Cutting Speed and Efficiency

In a production environment, speed and efficiency are crucial. A good LED SMT PCB board cutting machine should be able to handle high volumes of PCBs quickly without compromising on quality. Look for machines that offer high cutting speeds, typically measured in millimeters per second (mm/s).

Some advanced models can achieve cutting speeds of up to 500mm/s, significantly boosting production output[5]. However, it's important to balance speed with precision to ensure the best results for your LED PCB production.

3. Cutting Capacity and Versatility

The cutting capacity of the machine is another important consideration. This includes both the maximum cutting length and the PCB thickness that the machine can handle. For LED PCB production, you'll want a machine that can accommodate a range of board sizes and thicknesses.

Look for machines that offer a generous cutting length, typically around 350-500mm, and can handle PCB thicknesses of up to 3.5mm or more[1][5]. Some machines even offer the ability to cut PCBs up to 5mm thick, providing greater versatility for different LED PCB designs[3].

4. Cutting Method and Technology

LED SMT PCB board cutting machines use various cutting methods, each with its own advantages. The most common methods include:

- V-Cut: This method uses a V-shaped blade to score the PCB along pre-defined lines, allowing for easy separation.

- Routing: This method uses a high-speed router bit to cut through the PCB material.

- Laser Cutting: This advanced method uses a laser beam to cut the PCB with high precision.

Consider the specific requirements of your LED PCB production when choosing the cutting method. V-Cut machines are often preferred for their speed and clean cutting edge, while laser cutting offers the highest precision for complex designs[6].

5. Heat Management and Dissipation

Heat management is a crucial aspect of LED PCB production. Excessive heat can damage sensitive components and affect the overall quality of the LED board. Look for cutting machines that incorporate effective heat management systems.

Some machines feature aluminum construction, which helps in efficient heat dissipation. Others may include cooling systems or heat sinks to manage temperature during the cutting process[2].

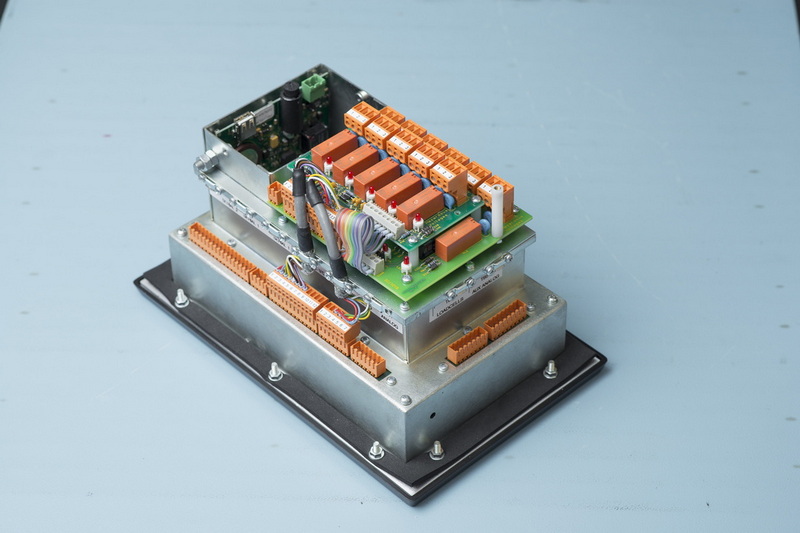

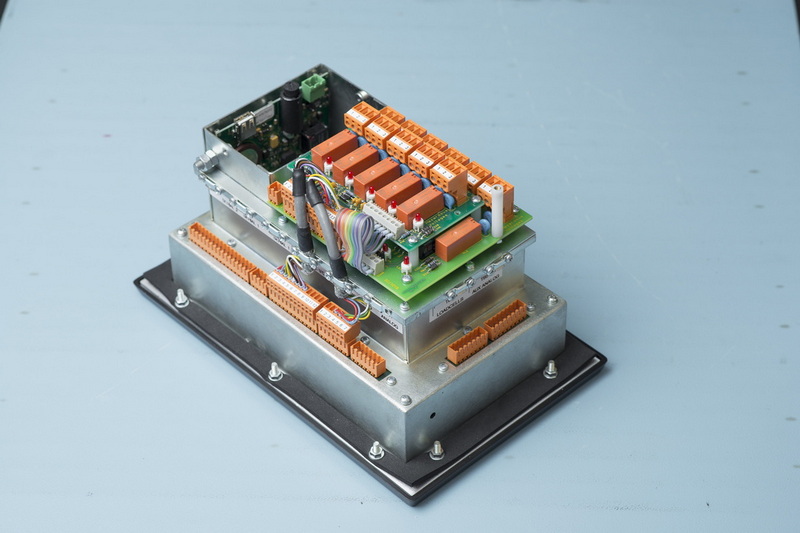

6. Automation and Control Systems

In modern manufacturing environments, automation is key to improving efficiency and consistency. Look for LED SMT PCB board cutting machines that offer advanced control systems and automation features.

Features to consider include:

- Programmable cutting paths

- Automatic tool changers

- Vision systems for alignment and quality control

- Integration with other SMT equipment

Advanced machines may offer fully automated operation, reducing the need for manual intervention and minimizing human error[4].

7. Material Compatibility

While LED PCBs are often made using aluminum due to its heat dissipation properties, your cutting machine should be able to handle a variety of PCB materials. This includes FR-4, CEM-1, and other composite materials commonly used in PCB manufacturing.

Ensure that the machine you choose is compatible with the specific materials used in your LED PCB production[2].

8. Safety Features

Safety should always be a top priority in any manufacturing process. Look for LED SMT PCB board cutting machines that incorporate robust safety features to protect operators and prevent accidents.

Common safety features include:

- Emergency stop buttons

- Safety enclosures or guards

- Dust collection systems to manage debris

- Automatic shut-off mechanisms

These features not only protect your workforce but also help maintain a clean and safe working environment[7].

9. Maintenance and Durability

Consider the long-term durability and maintenance requirements of the cutting machine. Look for machines constructed from high-quality materials like stainless steel, which offer durability and resistance to wear and tear.

Additionally, consider the availability of spare parts and the ease of maintenance. Some machines offer features like easily replaceable cutting blades or modular designs that simplify maintenance and repairs[1].

10. Integration with Existing Systems

If you're adding an LED SMT PCB board cutting machine to an existing production line, consider how well it will integrate with your current systems. Look for machines that offer compatibility with standard industry interfaces and protocols.

Some advanced machines offer features like remote monitoring and control, allowing you to integrate them into your broader manufacturing execution system (MES) or enterprise resource planning (ERP) systems[4].

Conclusion

Choosing the right LED SMT PCB board cutting machine is crucial for ensuring efficient and high-quality production of LED lighting products. By considering key features such as cutting precision, speed, capacity, and automation capabilities, you can select a machine that best meets your specific production needs.

Remember to balance these features with your budget and production volume requirements. While high-end machines may offer advanced features and capabilities, they may not be necessary for all production environments. Carefully assess your needs and choose a machine that offers the best value for your specific LED PCB manufacturing process.

As technology continues to advance, LED SMT PCB board cutting machines are likely to become even more sophisticated, offering greater precision, speed, and automation capabilities. Staying informed about the latest developments in this field can help you make informed decisions and keep your LED PCB production at the cutting edge of technology.

FAQ

1. What is the typical cutting speed of an LED SMT PCB board cutting machine?

The cutting speed of LED SMT PCB board cutting machines can vary widely depending on the model and technology used. However, many high-quality machines offer cutting speeds ranging from 300 to 500 mm/s. Some advanced models may even achieve higher speeds while maintaining precision. It's important to note that the actual cutting speed may be affected by factors such as the PCB material, thickness, and complexity of the cutting path.

2. How thick of a PCB can an LED SMT PCB board cutting machine typically handle?

Most LED SMT PCB board cutting machines are designed to handle PCB thicknesses ranging from 0.6mm to 3.5mm. However, some more robust models can cut PCBs up to 5mm thick. When selecting a machine, it's crucial to consider the typical thickness of the LED PCBs you'll be producing and choose a machine that can comfortably handle that range.

3. What are the advantages of using a V-Cut method in LED SMT PCB board cutting?

The V-Cut method offers several advantages for LED SMT PCB board cutting:

1. Clean cutting edge: V-Cut produces a smooth, clean edge that requires minimal post-processing.

2. Speed: V-Cut is generally faster than routing methods, especially for straight-line cuts.

3. Reduced stress on components: The scoring method used in V-Cut applies less stress to the PCB and mounted components compared to some other cutting methods.

4. Flexibility: V-Cut allows for easy separation of multiple PCBs from a single panel, which is common in LED PCB production.

4. How important is automation in LED SMT PCB board cutting machines?

Automation is increasingly important in LED SMT PCB board cutting machines for several reasons:

1. Increased efficiency: Automated systems can operate continuously with minimal human intervention, increasing overall production output.

2. Improved consistency: Automation helps ensure that each cut is made with the same precision, reducing variations in quality.

3. Reduced human error: By minimizing manual handling, automation reduces the risk of errors and damage to PCBs.

4. Integration with other systems: Automated cutting machines can be more easily integrated into broader SMT production lines, improving overall workflow.

5. What maintenance is typically required for an LED SMT PCB board cutting machine?

Regular maintenance is crucial for ensuring the longevity and performance of an LED SMT PCB board cutting machine. Typical maintenance tasks include:

1. Regular cleaning: Removing dust and debris from the cutting area and moving parts.

2. Blade replacement: Cutting blades will wear over time and need to be replaced to maintain cutting quality.

3. Lubrication: Moving parts may require regular lubrication to ensure smooth operation.

4. Calibration: Periodic calibration of the cutting system ensures continued accuracy.

5. Software updates: For machines with advanced control systems, regular software updates may be necessary to maintain optimal performance and security.

Always refer to the manufacturer's maintenance guidelines for specific requirements for your machine.

Citations:

[1] https://www.lnwrench.in/automatic-pcb-cutting-machine.html

[2] https://www.pcbasic.com/blog/led_pcb.html

[3] https://m.smt11.com/product/SMT-PCB-Cutting-Machine/PCB-cutter-LED-cutting-machine-185113.html

[4] https://www.cgtrader.com/free-3d-models/industrial/industrial-machine/smt-solutions-for-led-pcb-assembly-pick-and-place-machine

[5] https://www.morequip.com/product/Fully-Automatic-2-Axis-PCB-Cutting-Machine-HML-850.html

[6] https://smtmachineline.com/pcb-depaneling-machine/

[7] https://www.all-smt.com/smt-machine/pcb-cutting-machine/

[8] https://smtnet.com/products/index.cfm?fuseaction=browse_products&cat_id=22

[9] https://emsginc.com/resources/10-common-pcb-applications/

[10] https://patents.google.com/patent/CN112318566A/zh