Content Menu

● Introduction

● Key Features of an SMT Production Line

>> 1. Automation and Efficiency

>> 2. Precision and Accuracy

>> 3. Flexibility and Scalability

>> 4. Quality Control Mechanisms

>> 5. Environmental and Energy Efficiency

● Choosing the Right SMT Equipment

● The Process of SMT Manufacturing

>> Material Preparation and Examination

>> Stencil Preparation

>> Solder Paste Printing

>> Component Placement

>> Reflow Soldering

>> Inspection Processes

● Advancements in SMT Technology

>> Integration of AI and Big Data

>> Robotics Enhancements

>> Shorter Production Cycles

>> Sustainability Initiatives

● Conclusion

● FAQs

>> 1. What is the role of automation in SMT production lines?

>> 2. How do inspection systems like AOI and SPI contribute to quality control?

>> 3. What factors should be considered when choosing SMT equipment?

>> 4. Why is energy efficiency important in SMT production lines?

>> 5. How can SMT lines be future-proofed?

● Citations:

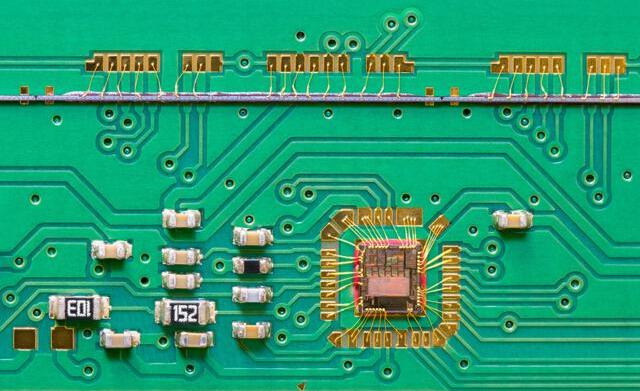

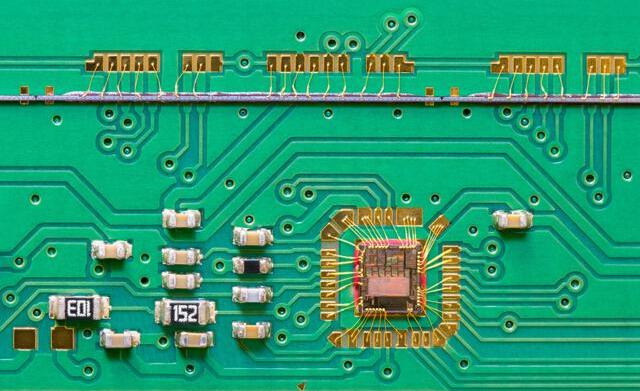

Introduction

Surface Mount Technology (SMT) production lines are critical in the modern landscape of printed circuit board (PCB) manufacturing. These lines utilize advanced machinery and processes to assemble electronic components onto PCBs with high precision and efficiency. As the demand for smaller, more complex electronics continues to rise, understanding the key features of an SMT production line becomes essential for manufacturers aiming to optimize productivity, quality, and cost-effectiveness.

Key Features of an SMT Production Line

1. Automation and Efficiency

Automation is a cornerstone of SMT production lines. Automated systems, such as pick-and-place machines and reflow ovens, significantly enhance production speed while minimizing human errors. These systems not only ensure consistent quality but also reduce labor costs, making them indispensable for high-volume manufacturing. The integration of automation allows manufacturers to achieve higher throughput rates, which is crucial in meeting the demands of today's fast-paced electronics market.

- Continuous Operation: Automated machines can operate 24/7 without fatigue, allowing for continuous production cycles that human workers cannot match.

- Reduced Labor Dependency: Automation reduces the need for manual labor, which can lead to significant cost savings and a more streamlined operation.

- Improved Cycle Times: Automated processes shorten production cycles, enabling quicker turnaround times from design to finished product.

2. Precision and Accuracy

Precision is paramount in SMT assembly. High-precision equipment is crucial for the accurate placement of components and soldering. Modern SMT machines boast placement accuracies of ±0.05mm or better, ensuring reliable connections and functionality. Advanced vision systems enhance accuracy by aligning components precisely during assembly, thus reducing the likelihood of defects that can arise from misalignment.

- Micron-Level Accuracy: Automated machines can place components with micron-level accuracy, significantly reducing the risk of human error.

- Advanced Vision Systems: These systems help in aligning components accurately during placement, ensuring that each part fits perfectly onto the PCB.

3. Flexibility and Scalability

Flexibility is vital for adapting to varying production demands. Modular SMT lines allow manufacturers to reconfigure or expand their setups as needed. This scalability is particularly beneficial for accommodating new technologies or increasing production volumes without significant downtime or investment in new equipment. Manufacturers can thus respond quickly to market changes and customer requirements.

- Modular Design: The ability to add or remove machines based on current needs allows manufacturers to scale operations efficiently.

- Adaptability to New Technologies: As technology evolves, flexible SMT lines can incorporate new processes or equipment without major overhauls.

4. Quality Control Mechanisms

Quality control is a critical aspect of SMT production lines. Inspection systems like Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) are integral to maintaining product quality. These systems detect defects in solder paste application and component placement, ensuring that only high-quality products proceed to the next stage of production. Implementing rigorous quality control measures helps reduce waste and enhances overall reliability.

- Real-Time Monitoring: Continuous monitoring during the assembly process helps identify issues before they escalate into larger problems.

- Post-Solder Inspection: AOI systems check for defects after soldering, ensuring that any faulty boards are caught before they reach customers.

5. Environmental and Energy Efficiency

As sustainability becomes increasingly important in manufacturing, eco-friendly features and energy-efficient technologies are gaining traction in SMT production lines. These systems not only reduce operational costs but also minimize environmental impact, aligning with global sustainability goals. Energy-efficient machines can significantly lower energy consumption, contributing to a more sustainable manufacturing process.

- Reduced Energy Consumption: Modern SMT equipment is designed to use less power while maintaining high performance levels.

- Sustainable Practices: Many manufacturers are adopting environmentally friendly materials and processes to reduce their carbon footprint.

Choosing the Right SMT Equipment

Selecting the right SMT equipment involves careful consideration of several factors:

- Production Volume: Assess current and projected production volumes to determine the necessary throughput rates.

- PCB Complexity: Evaluate the complexity of your PCBs and the variety of components used, ensuring that the selected equipment can handle your specific requirements.

- Vendor Reputation: Choose equipment from reputable vendors with a proven track record in the SMT industry.

- Technical Support: Ensure that adequate technical support is available for maintenance and troubleshooting.

- Energy Efficiency: Consider the energy consumption of equipment as part of your long-term operational costs.

By taking these factors into account, manufacturers can make informed decisions that will optimize their production capabilities.

The Process of SMT Manufacturing

Understanding the entire process involved in SMT manufacturing is essential for optimizing efficiency:

Material Preparation and Examination

This step involves preparing the SMT components and PCBs while examining them for any flaws. At this stage, the PCB should be flat with solder pads (silver, tin-lead, or gold-plated copper pads with no holes).

Stencil Preparation

Stencils give fixed positions for solder paste printing. They should be in perfect alignment with solder pads on the PCB.

Solder Paste Printing

Solder paste is the material used to connect the SMT components to the solder pads. A solder paste printer applies it to the stencil above the PCB using a squeegee at a 45°-60° angle.

Component Placement

The solder-printed PCB then heads to the pick & place machine, where surface mount devices get placed on board. Some placement machines can position as many as 136,000 components per hour.

Reflow Soldering

After component placement, PCBs move into reflow ovens where heat melts solder paste to create permanent connections between components and pads on the PCB.

Inspection Processes

Following reflow soldering, inspection processes such as SPI and AOI are employed to ensure quality control by checking for defects in solder joints and component placements.

Advancements in SMT Technology

The future of SMT production lines is being shaped by several key trends:

Integration of AI and Big Data

Artificial Intelligence (AI) is increasingly being integrated into SMT processes for real-time monitoring and predictive maintenance. This technology enhances decision-making capabilities by analyzing vast amounts of data generated during production.

Robotics Enhancements

Robotic technologies are evolving rapidly within SMT environments. New robots are being designed not just for component placement but also for handling materials throughout various stages of production.

Shorter Production Cycles

The demand for faster turnaround times has led manufacturers to streamline their processes further. This includes optimizing workflows between different stages of assembly and reducing bottlenecks caused by manual handling or inefficiencies in machine operations.

Sustainability Initiatives

Manufacturers are focusing on eco-friendly practices by utilizing lead-free solders and recyclable materials in their production processes. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Conclusion

In conclusion, the success of a PCB SMT production line hinges on its automation, precision, flexibility, quality control mechanisms, and environmental efficiency. By carefully selecting the right equipment and optimizing production processes, manufacturers can achieve higher productivity, superior product quality, and a competitive edge in the electronics industry. The investment in advanced SMT technology not only enhances operational efficiency but also positions manufacturers favorably in an increasingly competitive market.

FAQs

1. What is the role of automation in SMT production lines?

Automation reduces manual errors, increases production speed, and ensures consistency, making it a cornerstone of modern SMT production lines.

2. How do inspection systems like AOI and SPI contribute to quality control?

Inspection systems detect defects in solder paste application and component placement, ensuring high-quality output and reducing the risk of product failures.

3. What factors should be considered when choosing SMT equipment?

Key factors include production volume, component complexity, accuracy, vendor support, and compatibility with emerging technologies.

4. Why is energy efficiency important in SMT production lines?

Energy-efficient systems lower operational costs and reduce environmental impact, contributing to sustainable manufacturing practices.

5. How can SMT lines be future-proofed?

Future-proofing involves selecting modular systems, ensuring compatibility with new technologies, and investing in equipment that supports Industry 4.0 initiatives.

Citations:

[1] https://www.ourpcb.com/smt-line.html

[2] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[3] https://www.altestcorp.com/automation-is-revolutionizing-pcb-board-assembly/

[4] https://www.jt-int.com/pcb-smt-a-revolution-in-electronics-manufacturing/

[5] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[6] https://www.clarydon.com/benefits-pcb-assembly-automation

[7] https://www.pcbasic.com/blog/smt_machines.html

[8] https://riversideintegratedsolutions.com/n/value-automation-pcb-assembly/

[9] https://finestpcb.com/smt-assembly/

[10] https://www.globalwellpcba.com/industrial-automation-pcb-assembly/

[11] https://www.andwinpcb.com/advancements-in-smt-assembly-equipment-for-enhanced-efficiency/

[12] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[13] https://develop-llc.com/insights/guide-to-pcb-assembly-automation/

[14] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[15] https://blog.isa.org/the-opportunities-and-obstacles-in-using-automation-for-pcb-assembly

[16] https://www.globenewswire.com/news-release/2024/10/14/2962707/28124/en/Surface-Mount-Technology-Equipment-SMT-Market-to-Surge-to-8-32-Billion-by-2028-Global-Long-term-Forecast-to-2033.html

[17] https://profabelectronics.com/posts/how-automated-pcb-assembly-improves-efficiency/

[18] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[19] https://www.linkedin.com/pulse/advantages-automated-pcb-assembly-m-tek-assembly-ltd

[20] https://smt.fuji.co.jp/en/topics/2858

[21] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[22] https://www.pcbpower.us/blog/trends_in_surface_mount_technology_and_its_relevance_with_pcb_surface_finish