Content Menu

● Overview of SMT Placement Machines

● Key Features of Panasonic SMT Placement Machines

>> 1. High-Speed Placement Capabilities

>> 2. Advanced Placement Accuracy

>> 3. Modular Design

>> 4. Multi-Recognition Camera Technology

>> 5. Automated Feeder Systems

>> 6. Integrated Software Solutions

>> 7. Support for Various Component Types

>> 8. User-Friendly Interface

>> 9. Robust Build Quality

>> 10. Energy Efficiency

● Advanced Features of Specific Models

>> NPM Series

>> CM602 Model

● Applications of Panasonic SMT Placement Machines

● The Role of Automation in Modern Manufacturing

● Conclusion

● FAQ

>> 1. What is the maximum speed of Panasonic SMT placement machines?

>> 2. How accurate are Panasonic placement machines?

>> 3. Can Panasonic SMT machines handle different component sizes?

>> 4. What software solutions do Panasonic offer with their SMT machines?

>> 5. Are Panasonic SMT placement machines energy-efficient?

● Citations:

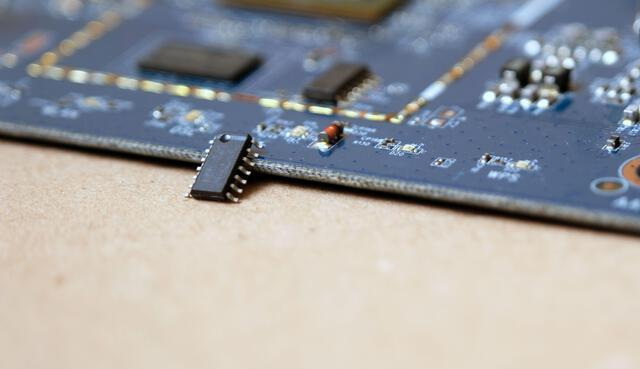

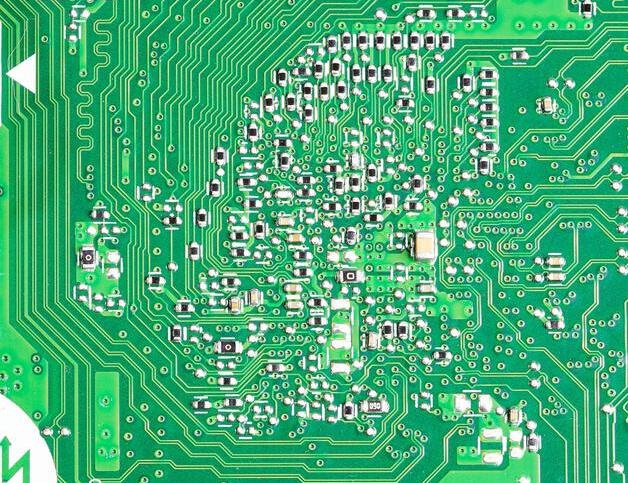

Panasonic is a leading name in the manufacturing of Surface Mount Technology (SMT) placement machines, renowned for their efficiency, precision, and technological advancements. These machines are critical in the electronics manufacturing industry, where they automate the process of placing electronic components onto printed circuit boards (PCBs). This article delves into the key features of Panasonic SMT placement machines, highlighting their capabilities, innovations, and advantages in modern manufacturing.

Overview of SMT Placement Machines

SMT placement machines are designed to enhance the speed and accuracy of component assembly on PCBs. Panasonic offers a range of models tailored for various production needs, from high-speed operations to flexible solutions for low-volume manufacturing. The core functions of these machines include:

- Component Placement: Accurately placing various types of electronic components onto PCBs.

- Speed and Efficiency: High-speed operation to maximize throughput and reduce production time.

- Flexibility: Ability to handle different component sizes and types, making them suitable for diverse manufacturing requirements.

Key Features of Panasonic SMT Placement Machines

1. High-Speed Placement Capabilities

Panasonic's SMT placement machines are designed for high-speed operations. For instance, the CM602 model can achieve a placement speed of up to 100,000 components per hour (cph), significantly enhancing productivity on the assembly line. This speed is crucial for manufacturers aiming to meet high demand while maintaining quality standards.

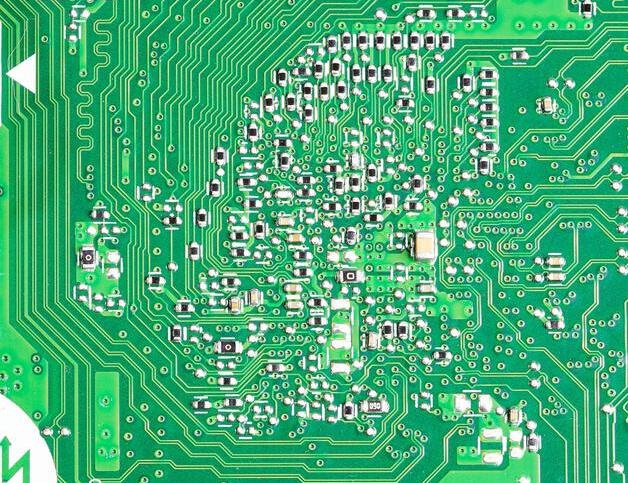

2. Advanced Placement Accuracy

Precision is paramount in electronics assembly, and Panasonic machines excel in this area. Many models boast placement accuracy within ±40 micrometers per chip. Such precision ensures that components are placed correctly on the PCB, minimizing defects and rework costs.

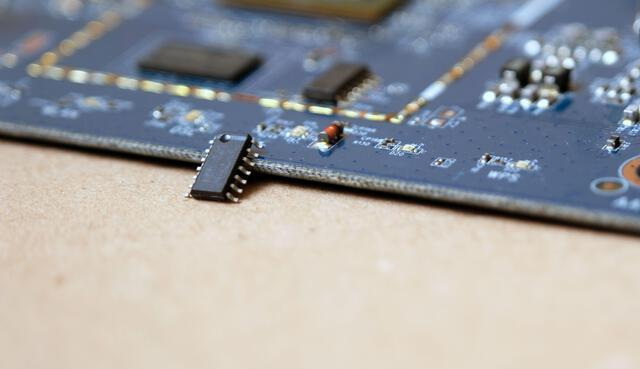

3. Modular Design

The modular design of Panasonic SMT machines allows manufacturers to customize their setup according to specific production needs. For example, models like the NPM series feature interchangeable heads that can be configured with different nozzle types for various component sizes. This flexibility enables users to adapt quickly to changing production requirements without needing extensive reconfiguration.

4. Multi-Recognition Camera Technology

To enhance accuracy and efficiency, Panasonic incorporates advanced multi-recognition camera systems in its placement machines. These cameras can identify components quickly and accurately, ensuring that each part is placed correctly on the PCB. This feature reduces errors associated with manual setup and increases overall throughput.

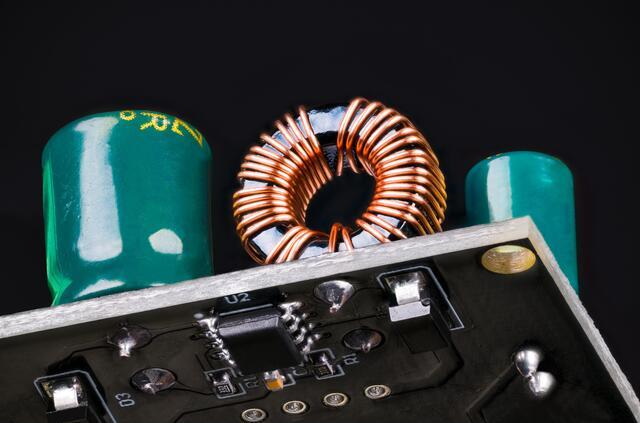

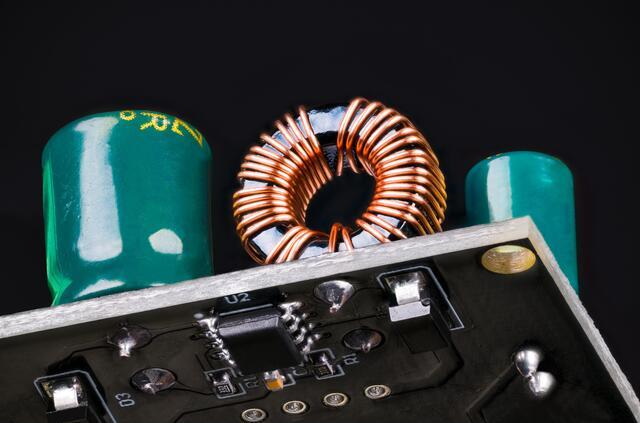

5. Automated Feeder Systems

Panasonic's automated feeder systems streamline the supply of components during the assembly process. The Auto Setting Feeder can handle a wide range of tape widths (8mm to 104mm), significantly reducing setup time and labor costs associated with manual feeding systems.

6. Integrated Software Solutions

Panasonic provides integrated software solutions that enhance machine performance and factory productivity. The Manufacturing Operations Management (MOM) system optimizes factory operations by managing workflows and monitoring equipment performance in real-time. This software integration helps manufacturers achieve higher Overall Equipment Effectiveness (OEE) by ensuring that all systems work cohesively.

7. Support for Various Component Types

Panasonic SMT placement machines are capable of handling a wide variety of components, including small chips (0402) up to larger components (5050). This versatility makes them suitable for different product lines, from consumer electronics to industrial applications.

8. User-Friendly Interface

Many Panasonic models feature intuitive user interfaces that simplify operation and reduce training time for new operators. Touchscreen controls allow users to easily navigate settings and monitor machine performance in real-time.

9. Robust Build Quality

Built with high-quality materials, Panasonic SMT machines are designed for durability and long-term use in demanding production environments. Their robust construction minimizes downtime due to mechanical failures.

10. Energy Efficiency

In today's manufacturing landscape, energy efficiency is crucial not only for cost savings but also for environmental sustainability. Panasonic's SMT placement machines are designed with energy-saving features that reduce power consumption without compromising performance.

Advanced Features of Specific Models

NPM Series

The NPM series represents a significant advancement in SMT technology, focusing on flexibility and productivity:

- NPM-DX: This model provides greater line throughput with an autonomous line control feature that guarantees stable operation based on automatic functionality. It can process PCB sizes up to 510 x 590 mm and place large connectors up to 150 x 25 mm.

- NPM-WX: Designed for smart manufacturing, this model integrates automated systems that improve quality while reducing costs through enhanced utilization and lower labor requirements.

CM602 Model

The CM602 model stands out due to its combination of speed and versatility:

- It features a high-speed head capable of placing up to 100,000 components per hour.

- The machine is equipped with multifunctional heads that allow it to cater to various PCB configurations seamlessly.

Applications of Panasonic SMT Placement Machines

Panasonic's SMT placement machines are utilized across various industries due to their versatility and reliability:

- Consumer Electronics: Used in assembling smartphones, tablets, and other electronic devices where precision is vital.

- Automotive: Essential for producing complex automotive electronics that require high reliability.

- Industrial Equipment: Employed in manufacturing control systems and automation devices.

- Medical Devices: Critical in producing medical equipment where precision and compliance with safety standards are paramount.

The Role of Automation in Modern Manufacturing

Automation is transforming manufacturing processes by enhancing efficiency and reducing human error. Panasonic's commitment to integrating automation into its SMT placement machines ensures that manufacturers can achieve higher levels of productivity while maintaining quality standards.

- Real-Time Monitoring: With integrated software solutions like MOM, manufacturers can monitor production lines in real time, allowing for immediate adjustments based on performance data.

- Predictive Maintenance: Advanced diagnostics enable predictive maintenance schedules that minimize downtime by addressing potential issues before they lead to machine failure.

Conclusion

Panasonic SMT placement machines stand out in the competitive landscape of electronics manufacturing due to their high-speed capabilities, advanced accuracy, modular design, integrated software solutions, and commitment to automation. These features not only enhance production efficiency but also ensure that manufacturers can adapt quickly to changing market demands while maintaining quality standards.

As technology continues to evolve, Panasonic remains at the forefront by continuously innovating its product offerings to meet the needs of modern manufacturing environments. Investing in Panasonic SMT placement machines allows manufacturers to optimize their production processes, reduce costs, improve overall product quality, and stay competitive in an increasingly automated industry.

FAQ

1. What is the maximum speed of Panasonic SMT placement machines?

Panasonic SMT placement machines can achieve speeds up to 100,000 components per hour depending on the model.

2. How accurate are Panasonic placement machines?

Most models offer a placement accuracy within ±40 micrometers per chip.

3. Can Panasonic SMT machines handle different component sizes?

Yes, they support a wide range of component sizes from small chips (0402) up to larger components (5050).

4. What software solutions do Panasonic offer with their SMT machines?

Panasonic provides integrated software solutions like Manufacturing Operations Management (MOM) that optimize factory operations.

5. Are Panasonic SMT placement machines energy-efficient?

Yes, they are designed with energy-saving features that reduce power consumption while maintaining performance levels.

Citations:

[1] https://ap.connect.panasonic.com/th/en/smart-factory-smt-tht-fatp-and-beyond

[2] https://cnsmtline.com/products/panasonic-cm602-smd-machine/

[3] https://connect.na.panasonic.com/smart-factory/electronics-assembly/smt/am100-flexible-all-in-one-placement-system

[4] https://www.rhsmt.com/panasonic-npm-w2-placement-product/

[5] https://bwmarketingworld.com/article/panasonic-smart-factory-solutions-india-introduces-advanced-npm-g-series-smt-machines--491718

[6] https://connect.panasonic.com/en/products-services_fa/products/mounting-related

[7] https://www.smt11.com/product/SMT-Pick-Place-Machines/Panasonic-NPM-W2-Modular-SMT-Chip-Mounter-Machine-165753.html

[8] https://www.youtube.com/watch?v=911uyOoG2O8

[9] https://timestech.in/panasonic-unveils-npm-g-series-smt-machines-for-fully-automated/

[10] http://www.smtengineer.com/te_news_media/2019-12-17/25361.chtml