Content Menu

● Introduction

● Key Features of Effective SMT Line Solutions

>> Advanced Technology Integration

>> Streamlined Processes

>> Skilled Workforce

>> Quality Control Mechanisms

>> Sustainability and Cost Efficiency

>> Automation Integration

● Challenges and Solutions in SMT Line Implementation

>> Common Problems Encountered in SMT Production

● Conclusion

● FAQ

>> 1. What is an SMT line?

>> 2. Why is advanced technology important in SMT lines?

>> 3. How can workflow optimization improve SMT line efficiency?

>> 4. What role does operator training play in SMT line success?

>> 5. What are the benefits of quality control in SMT lines?

● Citations:

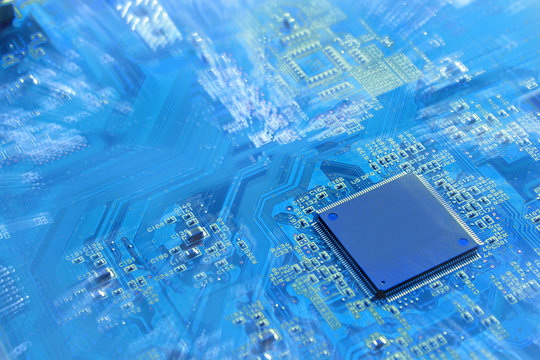

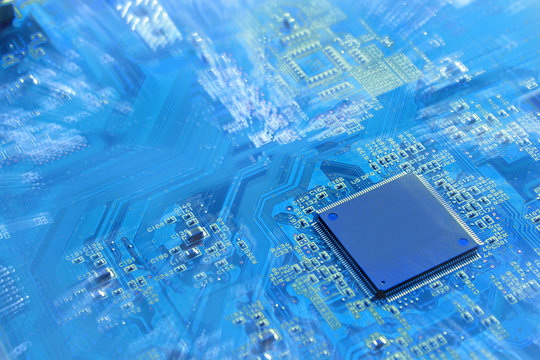

Introduction

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, particularly in the assembly of printed circuit boards (PCBs). As the demand for compact, efficient, and high-performance electronic devices grows, so does the need for effective SMT line solutions. These solutions encompass a range of technologies and processes that streamline production while ensuring high quality and reliability. In this article, we will explore the key features that define effective SMT line solutions, their importance in modern manufacturing, and how they contribute to improved productivity and product quality.

Key Features of Effective SMT Line Solutions

Advanced Technology Integration

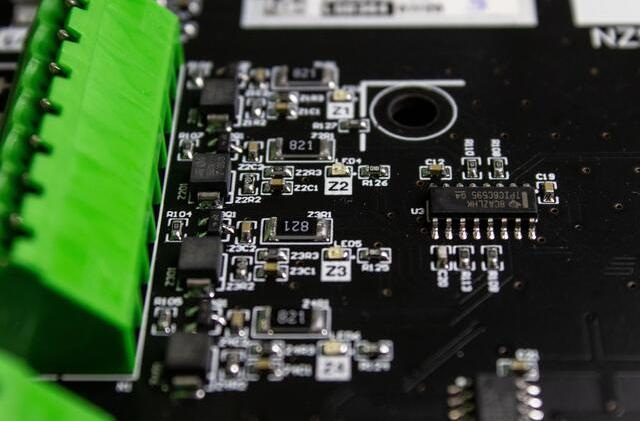

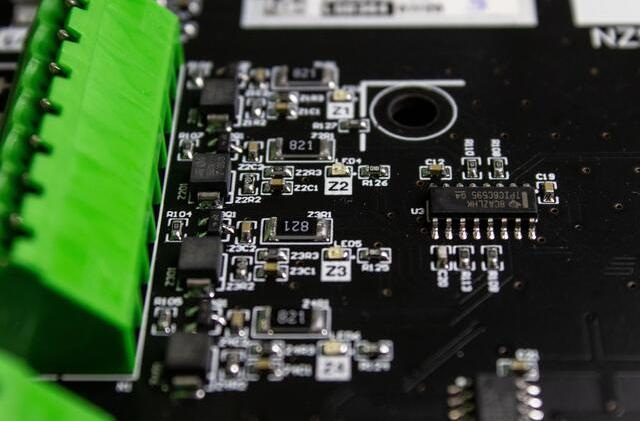

One of the most significant features of an effective SMT line is the integration of advanced technology. This includes:

- Pick-and-Place Systems: These machines are responsible for accurately placing surface mount components onto PCBs. They utilize vision systems to ensure precise placement, which is crucial for maintaining quality standards.

- Reflow Ovens: These are essential for soldering components to PCBs. Modern reflow ovens use advanced temperature profiling to ensure optimal soldering conditions, reducing defects and improving reliability.

- Automated Inspection Tools: Tools such as Automated Optical Inspection (AOI) and X-ray inspection systems are vital for detecting defects early in the production process. These technologies help maintain high-quality output by identifying issues before products move to the next stage.

- Flying Probe Testers: These versatile testers validate electrical connections and component functionality without requiring dedicated fixtures, making them ideal for low-volume production or prototypes.

Streamlined Processes

Efficiency in SMT production is heavily reliant on streamlined processes. Key aspects include:

- Workflow Optimization: Establishing clear PCB assembly instructions and standardized operating procedures helps minimize errors and delays.

- Material Handling: Efficient material handling practices reduce setup times and improve overall production flow. This includes organizing components logically to facilitate quick access during assembly.

- Production Sequencing: Optimizing the sequence of operations ensures that each step flows smoothly into the next, minimizing downtime and enhancing productivity.

- Design for Manufacturability (DFM): Implementing DFM principles early in product development can significantly enhance assembly quality by optimizing component selection and layout.

Skilled Workforce

A well-trained workforce is critical for the success of an SMT line. The importance of operator training cannot be overstated:

- Equipment Operation: Operators must be proficient in using advanced SMT machinery. Comprehensive training programs equip them with the necessary skills to handle equipment effectively.

- Troubleshooting: Skilled operators can quickly identify and resolve issues, preventing costly downtime and maintaining production schedules.

- Continuous Improvement Initiatives: Encouraging operators to participate in continuous improvement programs fosters a culture of innovation and efficiency within the manufacturing process.

Quality Control Mechanisms

Implementing robust quality control mechanisms is essential for ensuring product reliability:

- Automated Optical Inspection (AOI): This technology inspects PCBs for defects such as misaligned components or solder issues, providing real-time feedback.

- X-ray Inspection: X-ray systems are used to inspect hidden solder joints and ensure proper connections, especially in complex assemblies like Ball Grid Arrays (BGAs).

- Functional Testing: After assembly, functional tests validate that each PCB operates as intended under real-world conditions, further ensuring quality before products reach customers.

Sustainability and Cost Efficiency

In today's manufacturing landscape, sustainability and cost efficiency are paramount:

- Lean Manufacturing Principles: Implementing lean practices helps reduce waste and optimize resource utilization throughout the production process.

- Waste Reduction Strategies: By minimizing material waste through careful planning and execution, manufacturers can significantly lower costs while maintaining quality.

- Energy Efficiency: Investing in energy-efficient machinery not only reduces operational costs but also aligns with global sustainability goals.

Automation Integration

Automation has become a cornerstone of effective SMT line solutions:

- Increased Throughput: Automated machines operate at high speeds with consistent precision, allowing manufacturers to meet stringent production deadlines while maximizing output.

- Reduced Labor Costs: By automating repetitive tasks such as solder paste application and component placement, companies can decrease labor costs while enhancing overall efficiency.

- Real-Time Monitoring: Advanced automation systems can provide real-time data analytics on production processes, enabling manufacturers to make informed decisions quickly.

Challenges and Solutions in SMT Line Implementation

Despite its advantages, implementing an effective SMT line can present challenges:

- Equipment Malfunctions: Regular maintenance schedules and predictive maintenance technologies can mitigate downtime caused by equipment failures.

- Material Shortages: Robust inventory management systems ensure that necessary materials are available when needed, reducing delays in production.

- Quality Control Issues: Continuous monitoring through automated inspection systems can help identify quality issues early, allowing for timely corrections before products move further along the production line.

Common Problems Encountered in SMT Production

1. Component Placement Accuracy Issues:

- Regular maintenance and calibration of placement machines are crucial.

- Verifying CAD data against actual components ensures compatibility.

2. Adhesion Defects:

- Implement ESD prevention measures using antistatic materials.

- Train operators on proper handling techniques to reduce damage risk.

3. Inspection Challenges:

- Utilize advanced inspection techniques like AOI and X-ray inspection to detect hidden defects.

- Ensure accessibility of inspection equipment to all areas of the PCB assembly line.

4. Soldering Defects:

- Optimize reflow profiles to prevent issues like insufficient solder or bridging.

- Monitor environmental conditions during soldering processes to avoid thermal stress on components.

5. Testing Limitations:

- Incorporate functional testing after assembly to validate PCB performance.

- Use automated testing systems integrated into SMT lines for faster evaluations.

Conclusion

Effective SMT line solutions are integral to modern electronics manufacturing. By integrating advanced technology, streamlining processes, investing in a skilled workforce, implementing rigorous quality control measures, focusing on sustainability, and embracing automation, manufacturers can achieve higher productivity levels while maintaining exceptional product quality. As the industry continues to evolve with trends such as AI integration and increased automation capabilities, staying ahead with these key features will be essential for companies aiming to compete in a fast-paced market.

FAQ

1. What is an SMT line?

An SMT line is a series of machines and processes used to assemble PCBs using surface mount technology. It automates various stages of production for increased efficiency and accuracy.

2. Why is advanced technology important in SMT lines?

Advanced technology enhances precision, reduces errors, increases production speed, and improves overall product quality by automating critical processes.

3. How can workflow optimization improve SMT line efficiency?

Workflow optimization minimizes material handling and setup times while ensuring that production sequencing is logical and efficient, leading to faster turnaround times.

4. What role does operator training play in SMT line success?

Trained operators efficiently manage equipment, troubleshoot issues quickly, maintain quality standards, and contribute to continuous improvement initiatives within the production process.

5. What are the benefits of quality control in SMT lines?

Quality control ensures consistent product quality by reducing defects through inspections at various stages of production, ultimately leading to higher customer satisfaction.

Citations:

[1] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[2] https://www.smtfactory.com/Streamlining-Operations-How-Automation-Enhances-SMT-Line-Productivity-id47973586.html

[3] https://www.raypcb.com/smt-manufacturer/

[4] https://www.andwinmcpcb.com/smt-production-process-common-issues-and-challenges/

[5] https://www.smtfactory.com/Maximizing-Quality-Control-Importance-of-Testing-in-SMT-Production-Lines-id40973586.html

[6] https://pl.hayawin.com/resources/how-to-choose-the-full-smt-line-solution.html

[7] https://geospacemfg.com/blog/smt-assembly-technology/

[8] https://www.mycronic.com/product-areas/pcb-assembly/news-and-press-releases/news/ten-key-smt-trends-you-need-to-know/

[9] https://www.pcbasic.com/blog/smt_machines.html

[10] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[11] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[12] https://fctassembly.wordpress.com/technical-resources/technical-papers/smt-assembly-challenges-and-proven-solutions-for-improving-yields/

[13] https://www.7pcb.com/blog/smt-assembly-quality-related-standards

[14] https://global.yamaha-motor.com/business/smt/concept/oss/line/resource/

[15] https://www.greencircuits.com/automated-or-hand-pcb-assembly/

[16] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[17] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[18] https://quality-line.com/smt-quality/

[19] https://www.linkedin.com/pulse/comprehensive-overview-smt-machines-features-vickey-g--35cuc

[20] https://www.electronicdesign.com/markets/automation/article/21259057/ddm-novastar-the-pros-and-cons-of-bringing-pcb-smt-assembly-in-house

[21] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[22] https://jhdpcb.com/blog/efficient-smt-assembly/

[23] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[24] https://smt.asmpt.com/en/products/placement-solutions/siplace-smart-features/

[25] https://www.nbk1560.com/en-US/resources/mechatronics/article/SMT/

[26] https://www.pcbcart.com/article/content/smt-assembly-development-trend.html

[27] https://www.linkedin.com/pulse/optimization-challenges-smt-component-9zfsc

[28] https://www.ipcb.com/technical/3363.html

[29] https://www.smtneoden.com/news/what-are-the-advantages-of-fully-automated-smt-line/

[30] https://www.rhsmt.com/news/smt-industrys-future-trends-the-impact-of-ai-and-automation/

[31] https://www.perceptive-ic.com/news-detailed/The-First-Step-in-SMT-Assembly-Quality-Control-Is-Incoming-Inspection

[32] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[33] https://m.smt11.com/blog/SMT-Field/SMT-Process-Status-and-Future-Development-Trends-2023.html

[34] https://smt.fuji.co.jp/en/topics/2858

[35] https://blog.intraratio.com/revolutionizing-smt-manufacturing-amidst-economic-challenges

[36] https://www.someonesblog.com/post/quality-s-crucial-role-in-surface-mount-technology-smt-process