Content Menu

● Introduction to AOI Machines

● Key Features of AOI Machines

● Applications of AOI in SMT Production Lines

● Benefits of Using AOI Machines

● Challenges Associated with AOI Technology

● Future Trends in AOI Technology

● Detailed Working Principle of AOI Machines

● Enhancements Through 3D Technology

● The Role of Data Analytics in AOI

● Conclusion

● Frequently Asked Questions

>> 1. What types of defects can AOI detect?

>> 2. How does an AOI machine work?

>> 3. What are the advantages of using 3D AOI systems over 2D systems?

>> 4. At what stages in SMT production are AOIs used?

>> 5. Are there any limitations associated with using AOIs?

● Citations:

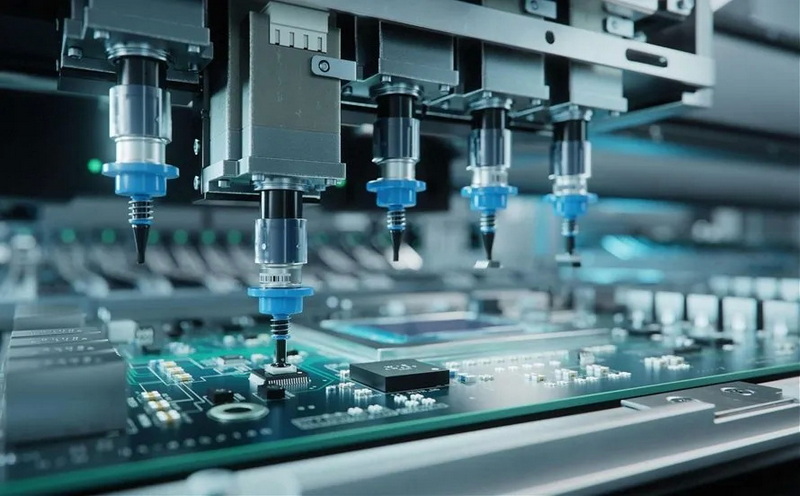

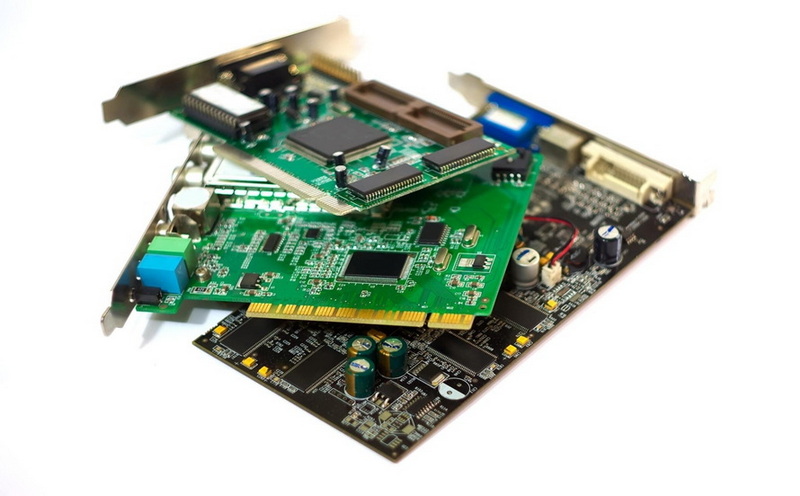

Automated Optical Inspection (AOI) machines are pivotal in the Surface Mount Technology (SMT) production lines, ensuring quality control and enhancing the efficiency of the manufacturing process. As electronic devices become more compact and complex, the need for precise inspection methods has increased significantly. This article explores the key features of AOI machines, their functionalities, and their impact on SMT production lines.

Introduction to AOI Machines

AOI machines are specialized equipment designed to inspect printed circuit boards (PCBs) during various stages of the SMT process. They utilize high-resolution cameras and sophisticated image processing algorithms to detect defects such as misaligned components, soldering issues, and other quality concerns. By automating the inspection process, AOI machines reduce reliance on manual inspections, which can be prone to human error.

Key Features of AOI Machines

The effectiveness of AOI machines in SMT production lines can be attributed to several key features:

- High-Resolution Imaging: AOI machines are equipped with high-resolution cameras that capture detailed images of PCBs. This capability allows for the detection of even minor defects that may not be visible to the naked eye.

- Advanced Image Processing Algorithms: These algorithms analyze the captured images and compare them against predefined standards or "golden" samples. They can identify discrepancies in component placement, solder quality, and other critical parameters.

- Real-Time Feedback: One of the standout features of AOI systems is their ability to provide immediate feedback during the manufacturing process. If a defect is detected, operators can quickly address the issue before it propagates further down the production line.

- Multi-Angle Inspection: Many modern AOI machines incorporate multiple cameras positioned at different angles to ensure comprehensive coverage of the PCB. This feature is particularly useful for detecting defects that may be hidden from a single viewpoint.

- Data Collection and Analysis: AOI systems collect vast amounts of data during inspections, which can be analyzed to identify trends and recurring issues. This information is invaluable for continuous improvement in manufacturing processes.

- Integration with Other Systems: AOI machines can be integrated with other manufacturing systems such as Statistical Process Control (SPC) tools and Manufacturing Execution Systems (MES). This integration allows for a more holistic approach to quality management.

Applications of AOI in SMT Production Lines

AOI machines are utilized at various stages of SMT production, including:

- Pre-Reflow Inspection: Before components are soldered onto the PCB, AOI can verify correct placement and orientation. This early detection helps prevent costly rework later in the process.

- Post-Reflow Inspection: After soldering, AOI systems check for solder joint integrity, bridging, and component placement issues. This stage is critical for ensuring that assembled boards meet quality standards before they proceed to final testing.

- Final Inspection: In this stage, AOI machines conduct a comprehensive review of the entire PCB assembly to catch any remaining defects before products are shipped out.

Benefits of Using AOI Machines

The implementation of AOI technology in SMT production lines offers numerous benefits:

- Increased Efficiency: Automated inspections significantly speed up the quality control process compared to manual inspections, allowing for higher throughput in manufacturing operations.

- Cost Reduction: By identifying defects early in the production process, manufacturers can minimize rework costs and reduce material waste associated with defective products.

- Improved Quality Control: The precision and consistency offered by AOI systems lead to higher product quality and reliability, which is essential in meeting customer expectations in today's competitive market.

- Enhanced Traceability: The data collected during inspections can be used for traceability purposes, allowing manufacturers to track defects back to specific processes or batches.

Challenges Associated with AOI Technology

Despite their advantages, there are challenges associated with implementing AOI systems:

- Initial Investment Costs: The upfront costs of purchasing and installing AOI equipment can be significant, especially for small manufacturers.

- Complex Programming Requirements: Setting up an AOI machine requires careful programming and calibration to ensure accurate inspections. This process can be time-consuming and may require specialized knowledge.

- Limitations in Depth Perception: Traditional 2D AOI systems may struggle with certain types of defects that require depth perception or three-dimensional analysis. However, advancements in 3D AOI technology are addressing these limitations.

Future Trends in AOI Technology

The future of AOI technology looks promising with several trends emerging:

- AI Integration: The incorporation of artificial intelligence into AOI systems is expected to enhance defect detection capabilities by allowing machines to learn from past inspections and improve over time.

- Increased Automation: As manufacturing processes become more automated, the role of AOI will expand further into real-time monitoring and control systems.

- Miniaturization of Components: As electronic components continue to shrink in size, AOI technology will need to evolve to maintain inspection accuracy at smaller scales.

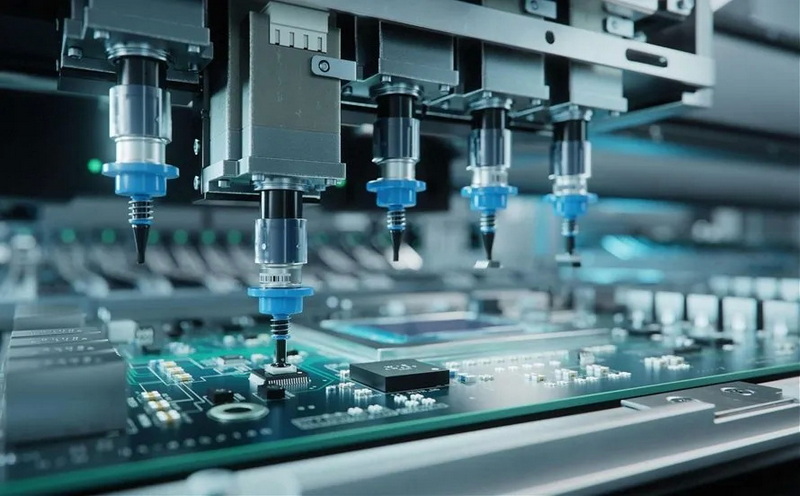

Detailed Working Principle of AOI Machines

Understanding how an AOI machine works provides insight into its capabilities:

1. Image Acquisition: High-resolution cameras capture images from various angles on the PCB. This includes checking component locations, markings, solder joints, etc., ensuring comprehensive coverage.

2. Image Processing: The captured images undergo analysis through sophisticated algorithms that evaluate component alignment, rotation angles, offsets, solder quality, etc., providing a thorough assessment of each board's integrity.

3. Comparison and Analysis: The processed data is compared against predetermined standards or specifications. Any deviations trigger alerts for operators or automated corrective measures.

4. Feedback Mechanism: Upon detection of issues like misalignment or poor solder joints, immediate feedback is given either through alerts or automatic adjustments within the production line setup.

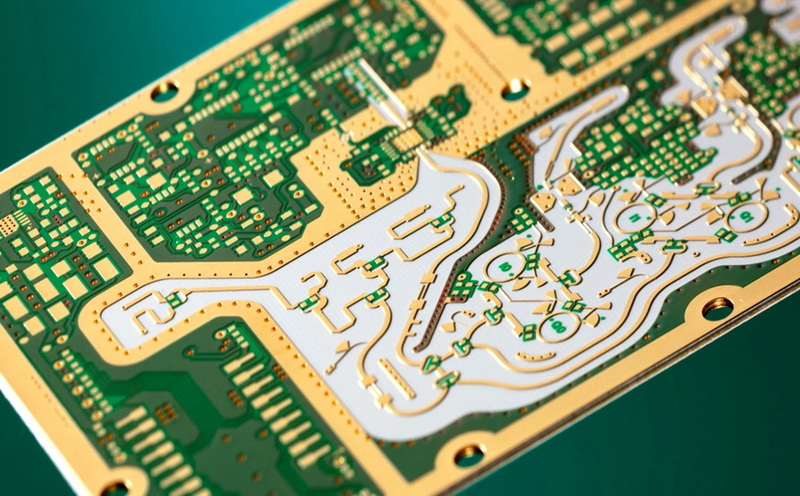

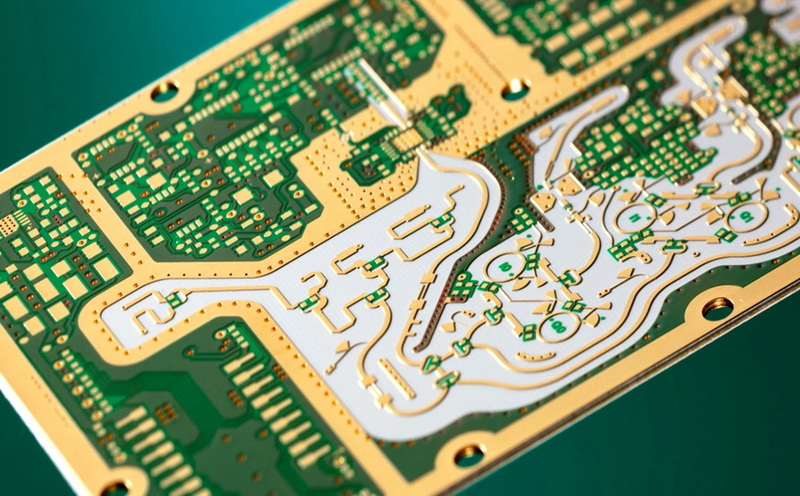

Enhancements Through 3D Technology

Recent advancements have introduced 3D Automated Optical Inspection (3D-AOI), which offers significant improvements over traditional 2D systems:

- Depth Measurement Capabilities: 3D-AOI systems measure not only length and width but also height dimensions on PCBs. This capability allows them to detect issues like lifted leads or insufficient solder heights that 2D systems might miss.

- Improved Accuracy with Multi-Angle Imaging: By capturing images from multiple angles simultaneously, 3D-AOI reduces blind spots that can occur with traditional inspection methods.

The Role of Data Analytics in AOI

The data collected by AOI machines serves multiple purposes beyond immediate defect detection:

- Trend Analysis: By analyzing historical data from inspections, manufacturers can identify recurring defects linked to specific processes or materials used.

- Process Optimization: Insights gained from data analytics help refine manufacturing processes over time by addressing root causes behind defects rather than just symptoms.

- Predictive Maintenance: Data trends can also inform maintenance schedules for machinery involved in PCB assembly, reducing downtime due to unexpected failures.

Conclusion

Automated Optical Inspection (AOI) machines are indispensable tools in modern SMT production lines. Their ability to provide rapid, accurate inspections enhances product quality while reducing costs associated with defects and rework. As technology continues to advance—particularly through AI integration and 3D imaging capabilities—AOI systems will play an increasingly critical role in ensuring high-quality manufacturing processes across various industries.

Frequently Asked Questions

1. What types of defects can AOI detect?

AOI can detect a wide range of defects including misaligned components, solder bridging, insufficient solder joints, missing components, and incorrect polarity among others.

2. How does an AOI machine work?

An AOI machine captures images of PCBs using high-resolution cameras, analyzes these images with advanced algorithms against predefined standards, and identifies any discrepancies or defects present on the board.

3. What are the advantages of using 3D AOI systems over 2D systems?

3D AOI systems provide depth perception capabilities that allow them to detect three-dimensional defects that might be missed by 2D systems. They also improve inspection accuracy for complex geometries on PCBs.

4. At what stages in SMT production are AOIs used?

AOIs are typically used at multiple stages including pre-reflow inspection for component placement verification, post-reflow inspection for solder joint integrity checks, and final inspection before products are shipped out.

5. Are there any limitations associated with using AOIs?

While AOIs greatly enhance inspection efficiency and accuracy, they require significant initial investment costs and complex programming setups. Additionally, traditional 2D systems may struggle with depth perception issues that newer 3D technologies aim to resolve.

Citations:

[1] https://www.neodensmt.com/news/how-does-smt-aoi-machine-work-74092002.html

[2] https://instrumental.com/build-better-handbook/aoi-smart-aoi-keyence-vs-cognex-vs-instrumental

[3] https://www.manufacturingtomorrow.com/news/2024/04/30/revolutionizing-smt-tht-technology-advanced-ai-inspection-with-ict-aoi-machine/22671/

[4] https://averroes.ai/blog/aoi-semiconductor

[5] https://www.neodensmt.com/news/what-are-the-problems-of-aoi-detection-in-smt-38253467.html

[6] https://www.zjyingxing.com/info/what-is-the-role-of-aoi-machines-in-the-smt-in-91506284.html

[7] https://levisonenterprises.com/automated-optical-inspection/

[8] https://www.tm-robot.com/en/introducing-aoi-applications-in-pcb-manufacturing/

[9] https://vicoimaging.com/aoi-lens-in-ensuring-flawless-smt-and-smd-production/

[10] https://trdsf.com/blogs/news/automated-optical-inspection-aoi-in-manufacturing

[11] https://www.productronicachina.com.cn/en/building-a-new-era-in-smart-manufacturing-safety-breakthroughs-in-smt-inspection-technology

[12] https://ascinternational.com/3d-aoi/how-3d-aoi-equipment-and-machines-help-your-manufacturing-process/

[13] https://instrumental.com/resources/automate-failure-analysis/the-future-of-automated-optical-inspection-systems/

[14] https://www.wevolver.com/article/automated-optical-inspection

[15] https://www.raypcb.com/aoi-pcba/

[16] https://www.electronicsforu.com/market-verticals/industrial/automated-optical-inspection-smt-environment

[17] https://www.pcbgogo.com/Blog/What_Is_Automated_Optical_Inspection__AOI__in_A_PCB_.html

[18] http://www.ymh-teknoloji.com/images/cyberoptics/AddressingHighPrecisionAutomatedOpticalInspection.pdf

[19] https://www.pcbgogo.com/Article/AOI_in_PCB_and_SMT_Production_Line.html

[20] https://www.qualitymag.com/articles/97429-automated-inspection-101-benefits-for-industry

[21] https://www.linkedin.com/pulse/smt-aoi-inspection-equipment-market-industry-trends-forecast-nmqye

[22] https://www.ipc.org/system/files/technical_resource/E5&S08_02.pdf

[23] https://marantz-electronics.com/challenges-in-inspection/

[24] https://www.grande-pcba.com/the-purpose-of-aoi-equipment-in-smt-assembly/

[25] https://cygnuscorp.com/aoi-automated-optical-inspection-vs-manual-inspection-a-detailed-comparison/

[26] https://www.linkedin.com/pulse/smt-aoi-inspection-equipment-market-trends-report-t9lte/

[27] https://jhdpcb.com/blog/automatic-optical-inspection-guidelines/

[28] https://www.linkedin.com/pulse/aoi-pcb-smt-production-line-rigid-flex-pcb-manufactuer-7btac

[29] https://smtnet.com/library/files/upload/What-is-really-inside-your-AOI.pdf

[30] https://www.advantech.com/en/resources/case-study/automated-optical-inspection-aoi-systems-for-pcb-manufacturing

[31] https://www.linkedin.com/pulse/smt-3d-automated-optical-inspection-aoi-market-challenges-4jnuf/

[32] https://aoi-spi.com/reasons-use-automated-optical-inspection-machine/

[33] https://wevolver-project-images.s3.us-west-1.amazonaws.com/0.1jxsztuweosautomated_optical_inspection.jpg?sa=X&ved=2ahUKEwjGi4Wn4PaKAxUyADQIHf3eDgMQ_B16BAgKEAI

[34] https://www.neodensmt.com/news/joint-use-of-smt-spi-machine-and-aoi-77904564.html

[35] https://cygnuscorp.com/explore-the-common-challenges-faced-with-aoi-systems/