Content Menu

● Introduction to SMD Machines

>> Key Features of High-Speed Quick SMD Machines

● Applications of High-Speed Quick SMD Machines

>> Industries Benefiting from SMD Machines

● Benefits of Using High-Speed Quick SMD Machines

● Challenges and Future Developments

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical speed range of high-speed SMD machines?

>> 2. What are the key benefits of using high-speed SMD machines?

>> 3. How do high-speed SMD machines ensure precision?

>> 4. What types of components can high-speed SMD machines handle?

>> 5. What industries benefit most from high-speed SMD machines?

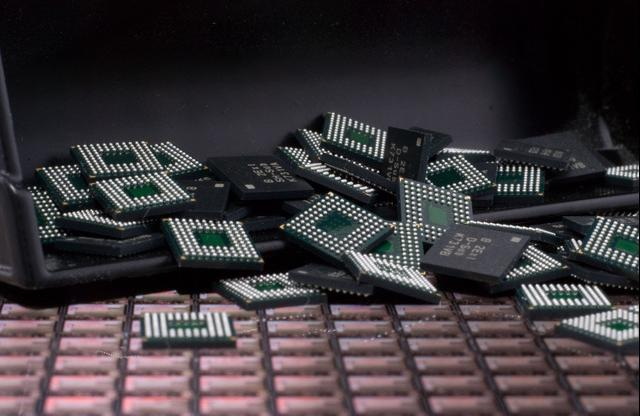

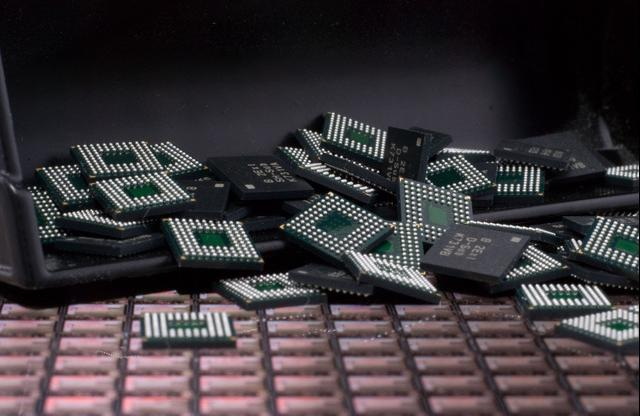

High-speed quick SMD (Surface Mount Device) machines are crucial in modern electronics manufacturing, particularly in the Surface Mount Technology (SMT) process. These machines are designed to efficiently place components onto printed circuit boards (PCBs) with high precision and speed, significantly enhancing production efficiency and reducing costs. In this article, we will delve into the key features of high-speed quick SMD machines, their applications, and the benefits they offer in the electronics industry.

Introduction to SMD Machines

SMD machines, also known as pick and place machines, are integral to the SMT process. They automate the placement of electronic components onto PCBs, ensuring accuracy and speed that manual labor cannot match. These machines are versatile, capable of handling a wide range of component sizes and types, from small resistors and capacitors to larger integrated circuits. The automation provided by SMD machines has revolutionized the electronics manufacturing sector by increasing productivity and reducing production time.

Key Features of High-Speed Quick SMD Machines

1. High Precision and Accuracy: High-speed SMD machines are equipped with advanced mechanisms that allow for precise placement of components. This precision is critical for ensuring that PCBs function correctly without defects. The machines use sophisticated vision systems to align components with their designated positions on the PCB, ensuring that even the smallest components are accurately placed.

2. Speed and Efficiency: These machines can place thousands of components per hour, significantly increasing production rates compared to manual assembly methods. High-speed SMD machines typically operate at speeds ranging from 30,000 to 60,000 components per hour, depending on the component size and type. This high throughput is essential for meeting the demands of mass production in the electronics industry.

3. Versatility: High-speed SMD machines are designed to handle various component sizes and shapes, making them suitable for assembling diverse types of PCBs. This versatility is essential in the electronics industry, where product designs frequently change. The ability to adapt to different component types allows manufacturers to produce a wide range of electronic devices efficiently.

4. Automation and Quality Control: These machines automate the placement process, reducing labor costs and minimizing human error. Built-in quality control mechanisms ensure that components are correctly placed, further enhancing the reliability of the PCBs. Automated inspection systems can detect misplacements or incorrect components, allowing for immediate correction and maintaining high-quality standards.

5. Design Flexibility: High-speed SMD machines support both SMT and Through-Hole Technology (THT) components, allowing for flexible design options in PCB assembly. This flexibility is beneficial for achieving high circuit speeds and electromagnetic compatibility, which are critical in modern electronic devices.

Applications of High-Speed Quick SMD Machines

High-speed quick SMD machines are widely used across various industries, including consumer electronics, automotive, aerospace, and telecommunications. Their ability to quickly assemble complex PCBs makes them indispensable for mass-producing electronic devices.

Industries Benefiting from SMD Machines

- Consumer Electronics: High-speed SMD machines are crucial for manufacturing smartphones, laptops, and other consumer electronics that require rapid assembly of complex PCBs. The demand for these devices is high, and SMD machines enable manufacturers to meet this demand efficiently.

- Automotive Industry: The automotive sector uses SMD machines for producing electronic control units and other automotive electronics, where reliability and speed are paramount. Modern vehicles rely heavily on electronic systems, making SMD machines essential for automotive manufacturing.

- Aerospace and Defense: These industries rely on high-speed SMD machines for assembling sophisticated electronic systems that require precision and reliability. The high stakes in these sectors necessitate the use of advanced manufacturing technologies to ensure the quality and performance of electronic components.

Benefits of Using High-Speed Quick SMD Machines

The use of high-speed quick SMD machines offers several benefits, including:

- Increased Production Speed: By automating the component placement process, these machines significantly reduce assembly time, enabling faster production cycles. This is particularly important in industries where time-to-market is critical.

- Improved Accuracy: High precision reduces defects, leading to higher quality PCBs and lower rework costs. The reliability of electronic devices is directly tied to the accuracy of component placement, making SMD machines invaluable.

- Cost Savings: Automation reduces labor costs and minimizes material waste, contributing to overall cost efficiency. By reducing the need for manual labor, manufacturers can allocate resources more effectively.

- Design Flexibility: The ability to handle various component types allows for more flexible PCB designs, enhancing product functionality. This flexibility supports innovation in electronic device design, enabling the creation of more complex and sophisticated products.

Challenges and Future Developments

Despite their advantages, high-speed SMD machines face challenges such as maintaining precision with increasingly smaller components and ensuring compatibility with emerging technologies like 3D printing and flexible electronics. Future developments will likely focus on enhancing precision, increasing speed, and integrating advanced technologies like AI for real-time quality control. The integration of AI can help predict and prevent errors, further improving production efficiency.

Moreover, the trend towards miniaturization in electronics poses a significant challenge for SMD machines. As components become smaller, the machines must be capable of handling these components with even greater precision. Advances in robotics and vision systems will play a crucial role in addressing these challenges.

Another area of focus for future developments is sustainability. As environmental concerns grow, manufacturers are looking for ways to reduce waste and energy consumption in their operations. High-speed SMD machines can contribute to this effort by optimizing production processes and reducing material waste.

Conclusion

High-speed quick SMD machines are vital components of modern electronics manufacturing, offering high precision, speed, and versatility. Their ability to efficiently assemble complex PCBs has revolutionized the electronics industry, enabling rapid production of high-quality electronic devices. As technology continues to evolve, these machines will play an increasingly important role in meeting the demands of emerging technologies and innovative product designs.

Frequently Asked Questions

1. What is the typical speed range of high-speed SMD machines?

High-speed SMD machines typically operate at speeds ranging from 30,000 to 60,000 components per hour, depending on the component size and type.

2. What are the key benefits of using high-speed SMD machines?

The key benefits include increased production speed, improved accuracy, cost savings, and design flexibility.

3. How do high-speed SMD machines ensure precision?

These machines use advanced vision systems and precise mechanical mechanisms to ensure accurate placement of components on PCBs.

4. What types of components can high-speed SMD machines handle?

High-speed SMD machines can handle a wide range of component sizes and types, from small resistors and capacitors to larger integrated circuits.

5. What industries benefit most from high-speed SMD machines?

Industries such as consumer electronics, automotive, aerospace, and telecommunications benefit significantly from the use of high-speed SMD machines.