Content Menu

>> Understanding Pick and Place Machine Nozzles

>> Types of Pick and Place Machine Nozzles

>> Key Features to Consider

>> Benefits of Using High-Quality Nozzles

>> Selecting a Reliable Supplier

>> Advanced Technologies in Nozzle Design

>>> Smart Nozzle Technology

>>> Modular Nozzle Systems

>>> Enhanced Vacuum Systems

>> Case Studies: Successful Implementations

>>> Case Study 1: Consumer Electronics Manufacturer

>>> Case Study 2: Automotive Industry Supplier

>> Conclusion

>> Frequently Asked Questions (FAQs)

Understanding Pick and Place Machine Nozzles

What is a Pick and Place Machine Nozzle?

A pick and place machine nozzle is a critical component of SMT equipment. It is designed to handle different sizes and shapes of components during the assembly process. The effectiveness of a nozzle can significantly impact the accuracy and efficiency of PCB assembly.

Types of Pick and Place Machine Nozzles

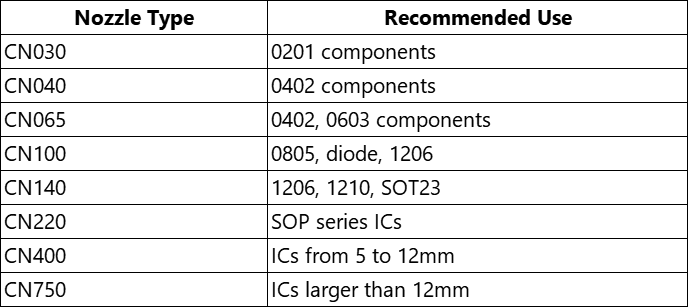

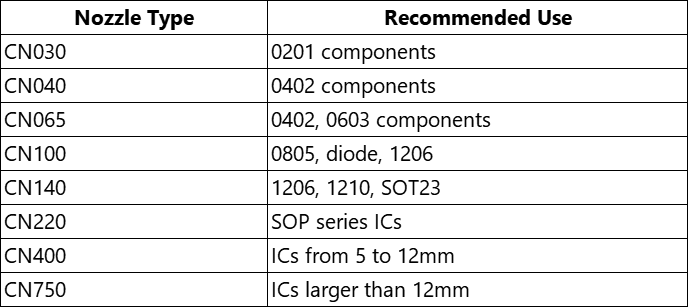

There are several types of nozzles available, each suited for specific applications. Below are some common types:

These nozzles are designed for compatibility with various pick and place machines, ensuring flexibility in component handling.

Key Features to Consider

When selecting a pick and place machine nozzle, consider the following features:

- Material Quality: High-quality materials ensure durability and resistance to wear. Common materials include aluminum alloys, stainless steel, and specialized plastics.

- Compatibility: Ensure that the nozzle is compatible with your specific pick and place machine model. Different machines may require different mounting styles or sizes.

- Precision: Look for nozzles that offer high precision in placement to reduce errors during assembly. Precision is crucial for handling small components like 0201s or fine-pitch ICs.

- Variety: A good supplier should offer a range of nozzles to accommodate different component sizes and shapes. This variety allows manufacturers to adapt quickly to changing production needs.

- Vacuum Performance: The ability of a nozzle to maintain a strong vacuum grip on components is essential for successful placement. Look for specifications that indicate the vacuum performance of the nozzle.

Benefits of Using High-Quality Nozzles

Using high-quality pick and place machine nozzles provides several advantages:

- Increased Efficiency: Quality nozzles enhance the speed of component placement, leading to faster production cycles. This efficiency can significantly improve throughput in high-volume manufacturing environments.

- Reduced Downtime: Durable nozzles minimize the need for frequent replacements, reducing operational downtime. This reliability allows manufacturers to maintain consistent production schedules.

- Improved Accuracy: Precision in component placement reduces defects in finished products. High-quality nozzles help ensure that components are placed correctly every time, which is critical for maintaining product quality.

Selecting a Reliable Supplier

Choosing a reputable pick and place machine nozzle supplier is critical for maintaining production quality. Here are some tips for selecting the right supplier:

- Industry Experience: Look for suppliers with extensive experience in SMT equipment. Experienced suppliers are more likely to understand industry challenges and provide effective solutions.

- Customer Reviews: Check reviews or testimonials from other customers to gauge reliability. Positive feedback can provide insights into product performance and customer service quality.

- Product Range: A supplier that offers a wide range of nozzles can better meet diverse needs. This variety ensures that you can find exactly what you need without switching suppliers frequently.

- Technical Support: Ensure that the supplier provides adequate technical support for their products. Good technical support can help resolve issues quickly, minimizing downtime.

Advanced Technologies in Nozzle Design

With advancements in technology, pick and place machine nozzles have evolved significantly over recent years. Here are some innovations that are shaping the future of nozzle design:

Smart Nozzle Technology

Smart nozzles equipped with sensors can provide real-time feedback on component handling. These sensors can detect if a component has been picked up correctly or if there's an error during placement. This technology enhances accuracy and reduces waste by allowing operators to correct mistakes immediately.

Modular Nozzle Systems

Modular systems allow manufacturers to easily swap out different nozzle types based on production requirements without needing extensive downtime for changes. This flexibility is particularly beneficial in environments where production runs vary frequently.

Enhanced Vacuum Systems

Modern nozzles often incorporate advanced vacuum systems that enhance grip strength while using less energy. These systems can handle delicate components without damaging them, which is especially important in high-density PCB assemblies.

Case Studies: Successful Implementations

To illustrate the importance of selecting the right pick and place machine nozzle supplier, let's look at two case studies from different industries:

Case Study 1: Consumer Electronics Manufacturer

A leading consumer electronics manufacturer faced challenges with component misplacement during high-speed assembly lines. After consulting with an experienced pick and place machine nozzle supplier, they upgraded their nozzles to models designed specifically for small components like 0201s. The result was a significant reduction in defects—by over 30%—and an increase in overall production efficiency by 20%.

Case Study 2: Automotive Industry Supplier

An automotive parts supplier needed to adapt quickly to new designs requiring larger ICs while maintaining high throughput rates. By partnering with a modular nozzle supplier, they were able to efficiently switch between different nozzle types as needed without lengthy downtime between production runs. This adaptability allowed them to meet tight deadlines while maintaining quality standards.

Conclusion

The choice of pick and place machine nozzle can significantly influence the efficiency and quality of SMT processes. By understanding the types, features, benefits of these nozzles, as well as how to select a reliable supplier, manufacturers can enhance their production capabilities. Investing in high-quality nozzles not only improves operational efficiency but also contributes to better product quality—an essential factor in today's competitive electronics market.

Frequently Asked Questions (FAQs)

1. What factors should I consider when choosing a pick and place machine nozzle?

- Consider material quality, compatibility with your machine, precision, variety offered by the supplier, and vacuum performance.

2. How often should I replace my pick and place machine nozzles?

- Replacement frequency depends on usage; however, regular checks for wear can help determine when to replace them.

3. Can I customize nozzles for specific components?

- Yes, many suppliers offer customization options based on specific requirements.

4. What are common materials used in manufacturing pick and place nozzles?

- Common materials include aluminum alloys, stainless steel, and various plastics designed for durability.

5. How does nozzle quality affect production efficiency?

- Higher quality nozzles lead to faster placement speeds and fewer errors, improving overall production efficiency.