Content Menu

● Introduction

● Understanding SMT Pick and Place Equipment

>> What is SMT Pick and Place Equipment?

>> Types of SMT Pick and Place Equipment

● Key Features of SMT Pick and Place Equipment

>> 1. High-Speed Placement

>> 2. Precision Placement

>> 3. Versatile Component Handling

>> 4. Advanced Software Integration

>> 5. Flexible Feeder Systems

● Benefits of Using SMT Pick and Place Equipment

>> 1. Increased Production Efficiency

>> 2. Enhanced Product Quality

>> 3. Cost Savings

>> 4. Scalability

>> 5. Improved Flexibility

● Applications of SMT Pick and Place Equipment

● Visualizing SMT Pick and Place Equipment in Action

>> Video Demonstration: Juki High-Speed Pick-and-Place Machine

>> Image Gallery: Various SMT Pick-and-Place Machines

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In the realm of electronics manufacturing, efficiency and precision are critical. Surface Mount Technology (SMT) has significantly transformed how electronic components are assembled, enabling manufacturers to produce smaller, more complex devices. At the heart of SMT is the pick and place equipment, which plays a crucial role in accurately placing surface mount devices (SMDs) onto printed circuit boards (PCBs). This article explores the features, benefits, and applications of SMT pick and place equipment, highlighting its importance in modern electronics manufacturing.

Understanding SMT Pick and Place Equipment

What is SMT Pick and Place Equipment?

SMT pick and place equipment refers to automated machines designed to pick up electronic components from their feeders and accurately place them onto PCBs. These machines are essential in high-speed manufacturing environments where precision is paramount. The pick and place process involves several steps:

1. Component Pickup: The machine picks components from designated feeders using a suction nozzle.

2. Positioning: The machine moves to the specified location on the PCB.

3. Placement: The component is placed onto the PCB at the correct orientation.

Types of SMT Pick and Place Equipment

SMT pick and place machines can be categorized into three main types:

- Manual Pick and Place Machines: Operated by hand, these machines are suitable for low-volume production or prototyping.

- Semi-Automatic Pick and Place Machines: These machines assist operators by providing visual aids or automated features while still requiring manual input for component placement.

- Fully Automatic Pick and Place Machines: These high-speed machines operate independently, utilizing advanced software and sensors for precise placement.

Key Features of SMT Pick and Place Equipment

1. High-Speed Placement

One of the primary advantages of SMT pick and place equipment is its ability to place components at high speeds. Modern machines can achieve placement rates exceeding 100,000 components per hour (CPH), significantly increasing production efficiency.

2. Precision Placement

Accuracy is critical in electronics manufacturing. High-quality pick and place machines offer placement accuracy as fine as ±0.01 mm, ensuring that components are positioned correctly on the PCB. This precision helps reduce defects and improve overall product quality.

3. Versatile Component Handling

SMT pick and place equipment can handle a wide variety of component sizes and types, including:

- Small Components: Such as 0402, 0201, and even 01005 packages.

- Large Components: Including integrated circuits (ICs) and connectors.

This versatility allows manufacturers to use a single machine for various products, reducing the need for multiple setups.

4. Advanced Software Integration

Modern pick and place machines come equipped with sophisticated software that allows for easy programming and operation. Features often include:

- Real-Time Monitoring: Operators can track machine performance metrics during production runs.

- Error Detection: Automated systems can identify misplacements or defects in real time.

- Data Analytics: Advanced analytics tools help optimize production processes by analyzing historical data.

5. Flexible Feeder Systems

The feeder system is a critical component of pick and place equipment. High-end machines feature flexible feeder systems that can accommodate various component types, allowing for quick changeovers between different production runs.

Benefits of Using SMT Pick and Place Equipment

1. Increased Production Efficiency

By automating the component placement process, manufacturers can significantly increase their production output while minimizing labor costs. The high-speed capabilities of SMT pick and place equipment allow for faster turnaround times on orders.

2. Enhanced Product Quality

The precision offered by automated placement reduces the likelihood of human error, leading to higher quality products with fewer defects. This consistency is vital in industries where reliability is paramount, such as automotive or medical device manufacturing.

3. Cost Savings

While the initial investment in SMT pick and place equipment may be substantial, the long-term cost savings can be significant due to increased efficiency, reduced labor costs, and lower material wastage.

4. Scalability

As demand increases, manufacturers can scale their operations by adding additional pick and place machines or upgrading existing ones without significant disruptions to their workflow.

5. Improved Flexibility

With the ability to handle various component sizes and types, manufacturers can quickly adapt to changing market demands or introduce new products without extensive reconfiguration of their production lines.

Applications of SMT Pick and Place Equipment

SMT pick and place equipment is utilized across various industries, including:

- Consumer Electronics: Smartphones, tablets, laptops, and other electronic devices rely heavily on SMT technology.

- Automotive: Modern vehicles contain numerous electronic components that require precise assembly.

- Medical Devices: High-quality standards necessitate accurate placement in devices such as pacemakers or diagnostic equipment.

- Industrial Automation: Robotics and automation systems often incorporate SMT technology for efficient assembly.

Visualizing SMT Pick and Place Equipment in Action

To better understand how SMT pick and place machines operate, consider the following visual aids:

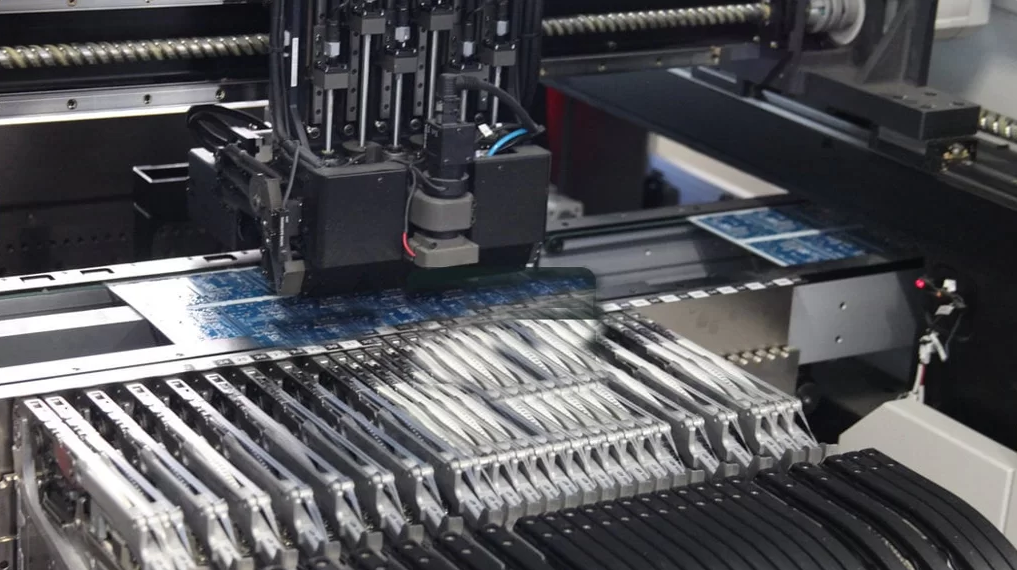

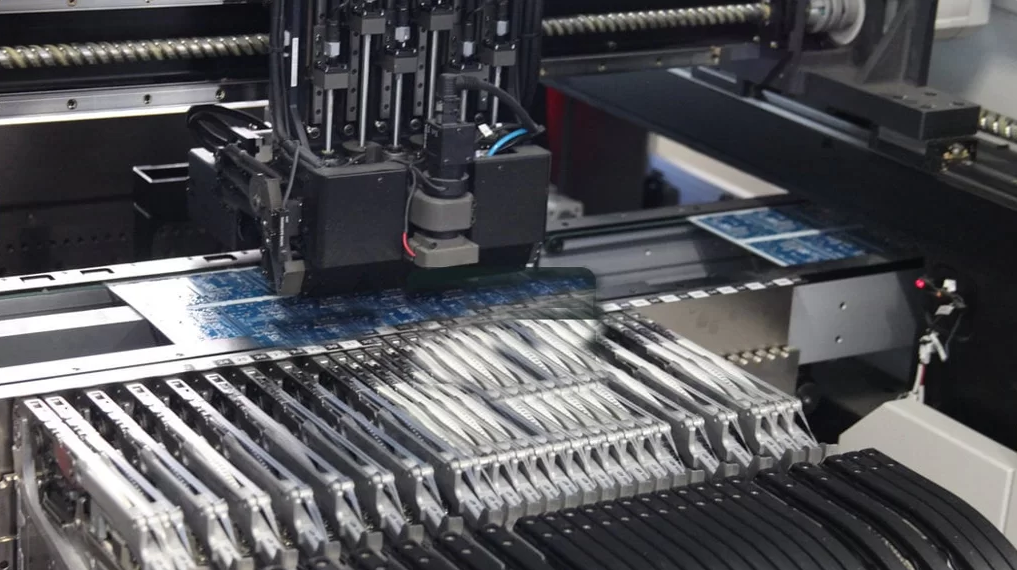

Video Demonstration: Juki High-Speed Pick-and-Place Machine

*Watch this video showcasing Juki's high-speed multifunction SMT LED pick-and-place machine in action.*

Juki High-Speed Pick-and-Place Machine

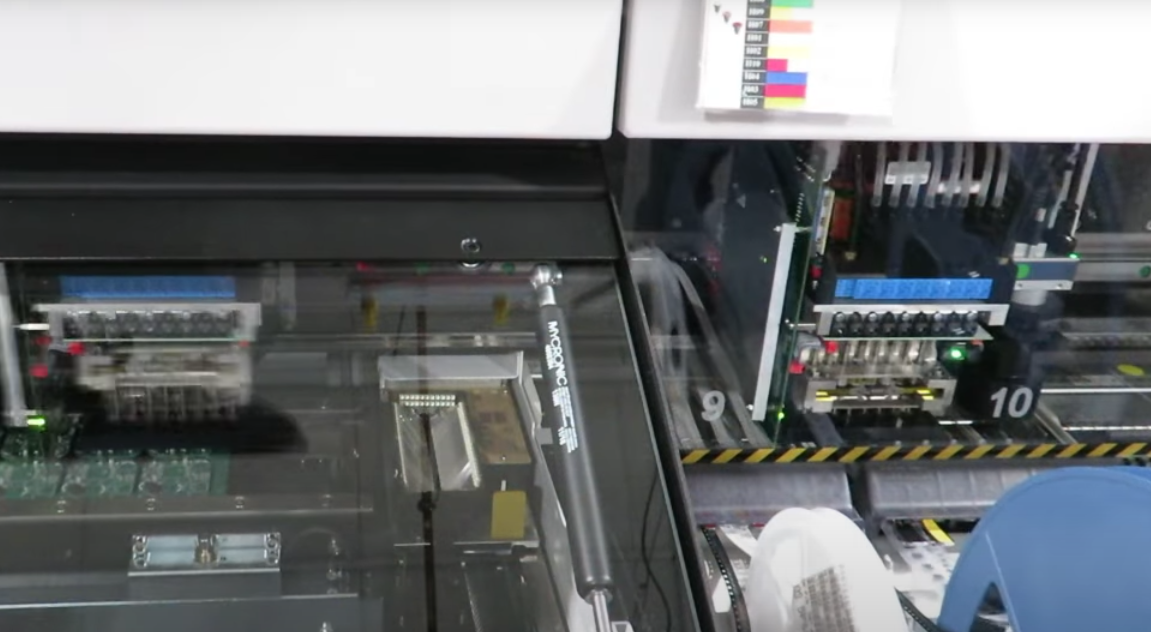

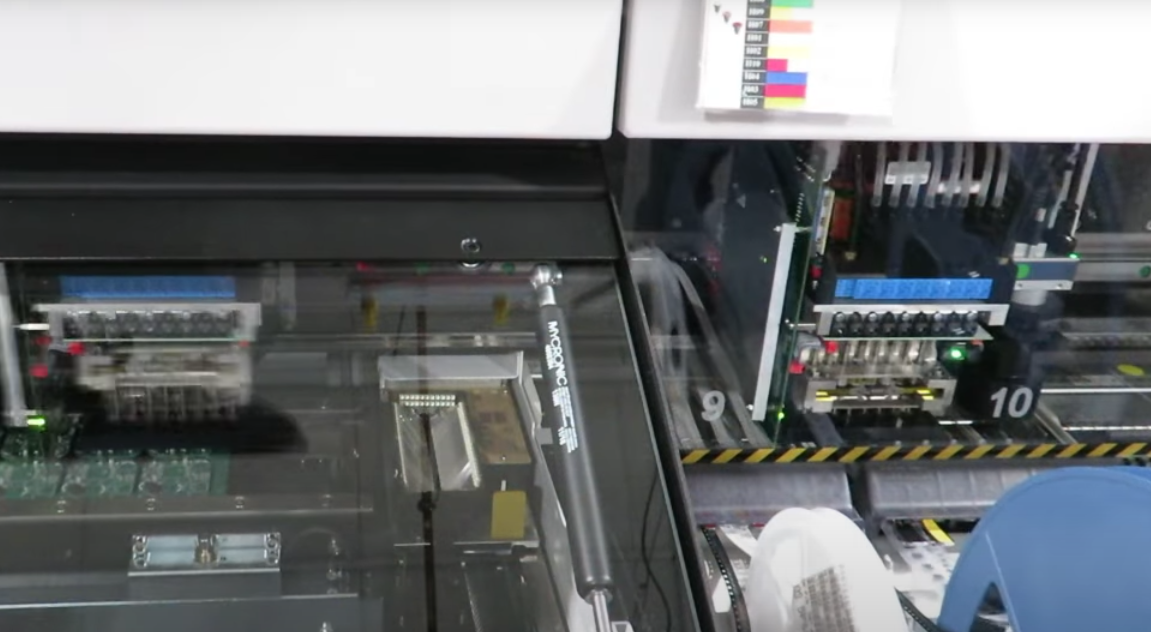

Image Gallery: Various SMT Pick-and-Place Machines

*Explore images of different models of SMT pick-and-place equipment used in various manufacturing settings.*

SMT Pick-and-Place Machine

SMT Production Line

These resources illustrate not only the technology but also its application in real-world scenarios.

Frequently Asked Questions (FAQs)

1. What is the primary function of SMT pick-and-place equipment?

- The primary function is to automate the placement of surface mount devices onto printed circuit boards with high speed and precision.

2. How does placement speed affect productivity?

- Higher placement speeds increase productivity by allowing more components to be placed per hour, reducing overall production time.

3. What types of components can be handled by these machines?

- They can handle a wide range of components including resistors, capacitors, ICs, connectors, and more.

4. Are there any maintenance requirements for SMT pick-and-place machines?

- Yes, regular maintenance is essential to ensure optimal performance; this includes cleaning nozzles, checking alignment, and software updates.

5. Can I use a single machine for different product lines?

- Yes, many modern SMT pick-and-place machines are designed for versatility, allowing them to handle multiple product lines with minimal adjustments.

Conclusion

In conclusion, SMT pick-and-place equipment plays an integral role in modern electronics manufacturing by enhancing efficiency, accuracy, and flexibility in production processes. As technology continues to advance, these machines will become even more sophisticated, further driving innovation within the industry. By investing in high-quality pick-and-place solutions like those offered by Juki Corporation or other leading manufacturers, companies can position themselves for success in an increasingly competitive market.