Content Menu

● Introduction

● Increasing Demand for Miniaturization

>> Impact on Design and Production

● Growth of Consumer Electronics

>> Market Dynamics

● Advancements in Automation

>> Enhanced Efficiency

● Technological Innovations

>> Material Development

● Regulatory Compliance and Standards

>> Importance of Certifications

● Regional Market Dynamics

>> North America

>> Asia-Pacific

● Challenges Facing Manufacturers

>> Supply Chain Disruptions

>> Competition from Alternative Technologies

● Conclusion

● Related Questions

>> 1. What types of materials are commonly used for SMT carrier tapes?

>> 2. How does automation impact the efficiency of SMT processes?

>> 3. What role do regulatory standards play in the SMT carrier tape market?

>> 4. Which regions are experiencing significant growth in the SMT carrier tape market?

>> 5. What challenges do manufacturers face in the SMT carrier tape market?

Introduction

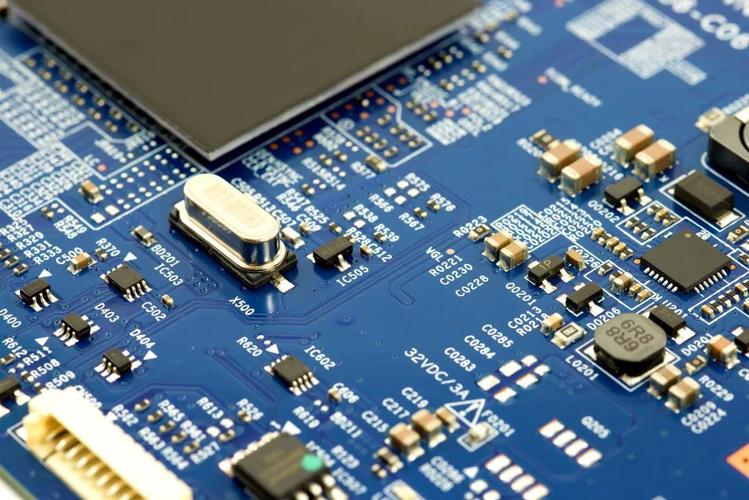

The Surface Mount Technology (SMT) Carrier Tape Market has witnessed significant growth over the past few years, driven by advancements in electronics manufacturing and increasing demand for compact and efficient electronic devices. Carrier tapes are essential components in SMT processes, as they facilitate the automated handling and placement of surface mount devices (SMDs) during assembly. This article explores the key factors driving growth in the SMT carrier tape market, including technological advancements, market dynamics, and evolving consumer preferences.

Increasing Demand for Miniaturization

One of the primary factors contributing to the growth of the Surface Mount Technology Carrier Tape Market is the increasing demand for miniaturization in electronic devices. As consumers seek smaller, more portable gadgets, manufacturers are compelled to produce compact components that can be efficiently handled and assembled. Carrier tapes play a crucial role in this process by enabling precise placement of tiny components on printed circuit boards (PCBs).

Impact on Design and Production

The trend towards miniaturization has led to innovations in carrier tape design, including the development of thinner and more flexible materials that can accommodate smaller components without compromising performance. Manufacturers are investing in research and development to create carrier tapes that enhance productivity while ensuring reliability.

Growth of Consumer Electronics

The consumer electronics sector is a significant driver of the SMT carrier tape market. With the proliferation of smartphones, tablets, wearables, and smart home devices, there is an increasing need for efficient assembly processes that can keep up with high production volumes.

Market Dynamics

As consumer preferences shift towards advanced features and functionalities, manufacturers are focusing on producing high-quality SMDs that require reliable carrier tapes for assembly. The rise of Internet of Things (IoT) devices further amplifies this demand, as these products often incorporate multiple electronic components that must be assembled quickly and accurately.

Advancements in Automation

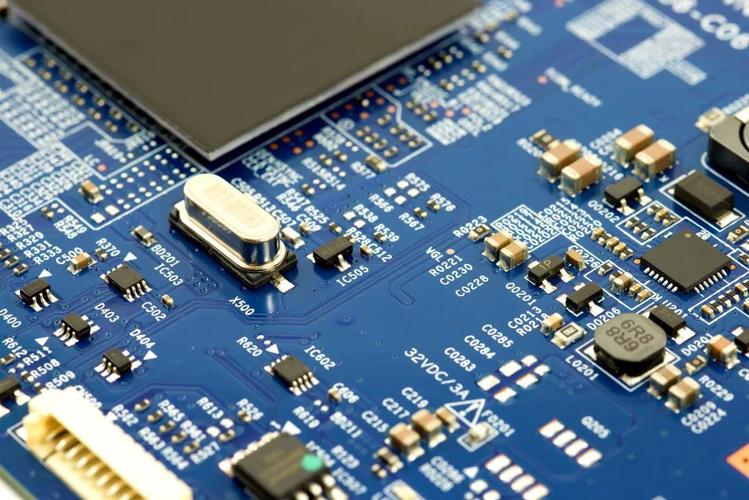

Automation is revolutionizing the electronics manufacturing industry, significantly impacting the Surface Mount Technology Carrier Tape Market. Automated assembly lines require precise handling of components, which carrier tapes facilitate through their standardized formats.

Enhanced Efficiency

The integration of robotics and automated systems in manufacturing processes has increased efficiency and reduced labor costs. Carrier tapes designed for automated systems ensure that components are fed into machines seamlessly, minimizing downtime and enhancing overall productivity.

Technological Innovations

Technological advancements in materials science have led to the development of new types of carrier tapes that offer improved performance characteristics. Innovations such as anti-static properties, moisture resistance, and enhanced durability are becoming increasingly important as manufacturers strive to meet stringent quality standards.

Material Development

Manufacturers are exploring various materials for carrier tapes, including polycarbonate, polyester, and conductive plastics. These materials not only improve the functionality of carrier tapes but also contribute to sustainability efforts by reducing waste and improving recyclability.

Regulatory Compliance and Standards

As the electronics industry becomes more regulated, compliance with international standards is essential for manufacturers operating within the SMT carrier tape market. Adhering to these regulations ensures product quality and safety while fostering consumer trust.

Importance of Certifications

Certifications such as ISO 9001 for quality management systems and IPC standards for electronics manufacturing play a crucial role in establishing credibility within the market. Manufacturers that comply with these standards are better positioned to attract clients looking for reliable suppliers.

Regional Market Dynamics

The Surface Mount Technology Carrier Tape Market exhibits varying growth patterns across different regions due to local demand dynamics, economic conditions, and technological adoption rates.

North America

North America remains a significant market due to its advanced electronics manufacturing capabilities and high consumer demand for innovative products. The presence of major technology companies fosters a competitive environment that drives growth in the SMT carrier tape sector.

Asia-Pacific

The Asia-Pacific region is witnessing rapid growth due to its robust manufacturing infrastructure and increasing investments in electronics production. Countries like China, Japan, and South Korea are key players in this market, contributing significantly to global supply chains.

Challenges Facing Manufacturers

Despite the promising growth prospects in the SMT carrier tape market, manufacturers face several challenges that could hinder progress.

Supply Chain Disruptions

Global supply chain disruptions caused by geopolitical tensions or pandemics can affect raw material availability and production timelines. Manufacturers must develop strategies to mitigate these risks while maintaining product quality.

Competition from Alternative Technologies

Emerging technologies such as chip-on-board (COB) assembly may pose competition to traditional SMT methods, potentially impacting demand for carrier tapes. Staying ahead through innovation will be crucial for manufacturers looking to maintain their market position.

Conclusion

In conclusion, the Surface Mount Technology Carrier Tape Market is poised for continued growth driven by factors such as increasing demand for miniaturization, advancements in automation, technological innovations, regulatory compliance, and regional market dynamics. While challenges remain, manufacturers that adapt to changing market conditions and invest in research and development will likely thrive in this competitive landscape.

Related Questions

1. What types of materials are commonly used for SMT carrier tapes?

Carrier tapes are typically made from materials such as polycarbonate, polyester, or conductive plastics designed to provide durability and protect components during handling.

2. How does automation impact the efficiency of SMT processes?

Automation enhances efficiency by allowing precise handling of components through standardized formats provided by carrier tapes while reducing labor costs associated with manual assembly.

3. What role do regulatory standards play in the SMT carrier tape market?

Regulatory standards ensure product quality and safety within the industry while fostering consumer trust; compliance with certifications like ISO 9001 is crucial for manufacturers.

4. Which regions are experiencing significant growth in the SMT carrier tape market?

The Asia-Pacific region is experiencing rapid growth due to its robust manufacturing infrastructure, while North America remains significant due to advanced technology companies.

5. What challenges do manufacturers face in the SMT carrier tape market?

Manufacturers face challenges such as supply chain disruptions affecting raw material availability and competition from alternative technologies like chip-on-board assembly.