Content Menu

● Introduction

● Key Components of an SMT Full Line

>> 1. Solder Paste Printer

>>> Types of Solder Paste Printers

>> 2. Pick and Place Machine

>>> Features of Modern Pick and Place Machines

>> 3. Reflow Oven

>>> Types of Reflow Ovens

>> 4. Inspection Systems (AOI, SPI, X-ray)

>>> Importance of Inspection Systems

>> 5. PCB Handling Systems

>>> Types of Handling Systems

● Additional Equipment and Technologies

● The SMT Manufacturing Process

>> 1. Preparation Stage:

>> 2. Solder Paste Printing:

>> 3. Inspection After Solder Paste Application (SPI):

>> 4. Component Placement:

>> 5. Reflow Soldering:

>> 6. Post-Reflow Inspection (AOI):

>> 7. Functional Testing:

>> 8. Final Assembly Steps:

● Conclusion

● FAQ

>> 1. What is the purpose of a solder paste printer?

>> 2. How does a pick and place machine work?

>> 3. What is the function of a reflow oven?

>> 4. Why are inspection systems crucial in SMT lines?

>> 5. What are PCB handling systems?

● Citations:

Introduction

Surface Mount Technology (SMT) has transformed the electronics manufacturing landscape by allowing for the efficient assembly of electronic components onto printed circuit boards (PCBs). This technology is pivotal in creating compact, reliable, and high-performance devices that dominate the market today. Understanding the key components of an SMT full line is essential for manufacturers aiming to optimize their production processes and ensure high-quality output. This article delves into the critical elements that constitute an SMT full line, highlighting their functions and significance in modern electronics manufacturing.

Key Components of an SMT Full Line

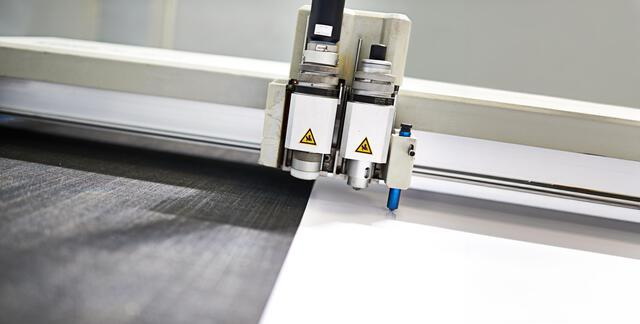

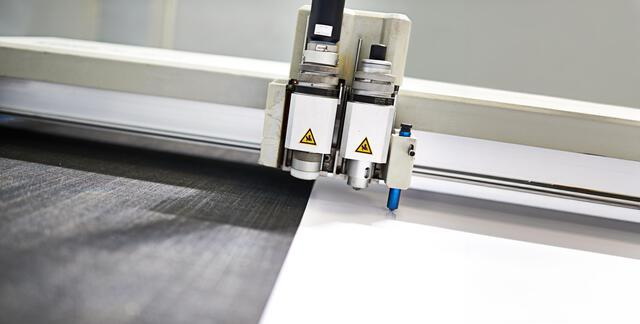

1. Solder Paste Printer

The solder paste printer is the initial step in the SMT production line. Its primary function is to apply solder paste onto the PCB pads with precision. This step is crucial as it lays the groundwork for component placement. High-quality solder paste printers enhance reliability by reducing waste and ensuring optimal adhesion of components during assembly. The printing process typically involves a stencil that aligns with the PCB pads, allowing for uniform application of solder paste.

Types of Solder Paste Printers

- Manual Printers: Suitable for low-volume production, these require operator intervention to place stencils and apply solder paste.

- Semi-Automatic Printers: These machines automate some processes, such as stencil alignment, but still require manual loading and unloading of PCBs.

- Fully Automatic Printers: Designed for high-volume production, these printers integrate seamlessly with other machines in the SMT line, offering high-speed operation and minimal manual intervention.

2. Pick and Place Machine

Following the solder paste application, the pick and place machine takes center stage. This device is responsible for accurately placing surface mount components onto the PCB. Equipped with advanced vision systems and high-speed operation, these machines ensure precise placement, minimizing errors and maximizing efficiency. The pick and place machine utilizes robotic arms to pick components from feeders and place them onto designated pads on the PCB, ensuring alignment and stability.

Features of Modern Pick and Place Machines

- Vision Systems: These allow machines to verify component placement accuracy in real-time.

- Multiple Feeder Options: Different types of feeders can handle various component sizes and shapes, enhancing flexibility.

- Speed: Advanced models can place tens of thousands of components per hour, significantly boosting production rates.

3. Reflow Oven

Once components are placed on the PCB, it moves into the reflow oven. This machine plays a critical role in melting the solder paste, which creates secure electrical connections between the components and the PCB. The reflow process involves controlled heating cycles that gradually raise and lower temperatures to avoid thermal shock to sensitive electronic parts. This step is essential for ensuring the durability and functionality of the final product.

Types of Reflow Ovens

- Convection Ovens: Use hot air to evenly distribute heat across PCBs.

- Infrared Ovens: Employ infrared radiation to heat specific areas quickly.

- Nitrogen Ovens: Utilize nitrogen environments to reduce oxidation during soldering, improving joint quality.

4. Inspection Systems (AOI, SPI, X-ray)

Quality control is paramount in SMT production, making inspection systems indispensable. Automated Optical Inspection (AOI), Solder Paste Inspection (SPI), and X-ray systems are employed to detect defects in soldering and component placement. These systems ensure that only high-quality products proceed through the production line. AOI systems use advanced cameras to scan PCBs for misaligned or missing components, while SPI systems check solder paste application quality before reflow.

Importance of Inspection Systems

- Defect Detection: Early identification of issues such as insufficient solder or misaligned components prevents defects from progressing through subsequent stages.

- Data Collection: Inspection systems generate valuable data that can be used for process optimization and quality improvement.

- Cost Efficiency: By catching errors early, manufacturers can reduce waste and avoid costly rework or product recalls.

5. PCB Handling Systems

PCB handling systems facilitate smooth movement through the production line. This includes loaders, unloaders, conveyors, and buffers that transport PCBs between different stages of assembly. Efficient handling systems minimize manual intervention, reduce handling errors, and maintain a continuous flow of production.

Types of Handling Systems

- Loaders: Automatically feed PCBs into the first machine in the SMT line.

- Conveyors: Transport PCBs between different machines while maintaining a steady flow.

- Unloaders: Receive completed PCBs after reflow soldering for further processing or packaging.

Additional Equipment and Technologies

In addition to these core components, several optional technologies can enhance an SMT line's efficiency:

- Cleaning Machines: These remove excess flux and debris from PCBs post-soldering.

- Laser Markers: Used for marking PCBs with barcodes or other identifiers for traceability.

- Software Solutions: Advanced software aids in monitoring production processes, optimizing workflows, and ensuring traceability throughout manufacturing.

These additional tools contribute to a more streamlined operation, improving overall throughput and product quality.

The SMT Manufacturing Process

Understanding how these components work together within an SMT manufacturing process is crucial for optimizing production efficiency:

1. Preparation Stage:

- Documentation creation including BOM files (Bill of Materials), XY coordinates for component placement, and operating instructions.

- Material preparation where all necessary components are gathered based on design specifications.

2. Solder Paste Printing:

- A stencil printer applies solder paste onto designated pads on the PCB using a squeegee mechanism.

- Ensuring proper thickness is vital; too much or too little can lead to poor connections or shorts.

3. Inspection After Solder Paste Application (SPI):

- Solder paste thickness is checked to ensure optimal conditions for component placement.

- Any discrepancies are corrected before moving on to component placement.

4. Component Placement:

- Pick and place machines position surface mount devices accurately onto pre-applied solder paste.

- Real-time verification ensures alignment with PCB design specifications.

5. Reflow Soldering:

- The assembled board enters a reflow oven where heat melts the solder paste to form solid connections between components and pads on the PCB.

- Temperature profiles are carefully controlled to prevent damage to sensitive components.

6. Post-Reflow Inspection (AOI):

- Automated Optical Inspection checks for defects such as misaligned components or insufficient solder joints.

- Any identified issues are addressed immediately before proceeding further.

7. Functional Testing:

- After inspection, boards may undergo electrical testing to verify functionality.

- Tests include In-Circuit Testing (ICT) which checks each connection on the board electrically.

8. Final Assembly Steps:

- Boards may be depanelized if produced in panels.

- Final visual inspections are conducted before packaging or shipping products out.

Conclusion

The key components of an SMT full line work synergistically to produce high-quality electronic devices efficiently. From solder paste application to final inspection, each component plays a vital role in ensuring reliability and performance in electronic manufacturing. By understanding these elements along with their interconnections within the manufacturing process—ranging from preparation through functional testing—manufacturers can optimize their production lines for maximum efficiency and quality output.

FAQ

1. What is the purpose of a solder paste printer?

The solder paste printer applies solder paste to PCB pads, providing a foundation for component placement while ensuring strong solder joints.

2. How does a pick and place machine work?

A pick and place machine uses robotic arms equipped with vision systems to accurately place components onto PCBs, ensuring precision during assembly.

3. What is the function of a reflow oven?

A reflow oven melts solder paste to create secure electrical connections between components and PCBs through controlled heating cycles.

4. Why are inspection systems crucial in SMT lines?

Inspection systems detect defects in soldering and component placement, ensuring that only high-quality products proceed through the production line.

5. What are PCB handling systems?

PCB handling systems facilitate efficient movement of PCBs through various stages of assembly, minimizing manual handling errors and maintaining workflow continuity.

Citations:

[1] https://www.smtpark.com/what-are-the-key-components-of-a-smt-line.html

[2] https://www.viasion.com/blog/smt-manufacturing-process-step-by-step-guide/

[3] https://www.seamarkzm.com/function-and-components-of-smt-inspection-machines.html

[4] https://yellowtommy.com/blogs/an-exhaustive-guide-to-smt-machines

[5] https://www.fs-pcba.com/smt-process-flow/

[6] https://www.raypcb.com/pcb-inspection-in-smt-assembly-process-ict-aoi-and-axi/

[7] https://www.quick-pcba.com/the-main-equipment-in-an-smt-line/

[8] https://www.pcbonline.com/blog/smt-manufacturing-process.html

[9] https://iconnect007.com/article/138062/the-knowledge-base-the-role-of-automated-inspection-systems/138059/smt

[10] https://www.ablcircuits.co.uk/blog/what-is-the-smt-process-and-why-should-oems-care/

[11] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[12] https://www.custom-mfg-eng.com/blog/what-is-an-smt-process-assembly-line

[13] https://wellmanxray.com/blog/demystifying-aoi-and-axi-in-the-smt-industry/

[14] https://minearc.com/what-is-an-smt-line/

[15] https://www.viasion.com/blog/smt-pcb-assembly-process-8-basic-steps/

[16] https://www.myemssolutions.com/smt-assembly-inspection-processes-and-test-technologies/

[17] https://www.smtfactory.com/The-Key-Components-of-An-Efficient-SMT-Production-Line-for-PCB-Assembly-id48363586.html

[18] https://www.pcbcart.com/article/content/smt-assembly-inspection.html

[19] https://www.linkedin.com/pulse/importance-types-smt-inspection-electronics-manufacturing-rzfac

[20] https://www.wevolver.com/article/smt-process

[21] https://www.smtfactory.com/The-Role-of-Vision-Inspection-Equipment-in-SMT-Inspection-Processes-id44363586.html