Content Menu

● Introduction

● Key Components of an SMT Feeder Mechanism

>> Feed Table

>> Blowing Nozzle

>> Tape Feeding Nozzle

>> Tape Stopper and Blocking Mechanisms

>> Baffle Plates

● How These Components Work Together

● Advancements in SMT Feeder Technology

>> Technological Innovations

>> Market Dynamics

● Types of SMT Feeders

● Importance of Reliable SMT Feeders

● Challenges Facing SMT Feeders

● Conclusion

● FAQ

>> 1. What is an SMT feeder?

>> 2. What are the main types of SMT feeders?

>> 3. How does a tape feeder work?

>> 4. What are common issues with SMT feeders?

>> 5. How can I maintain an SMT feeder?

● Citations:

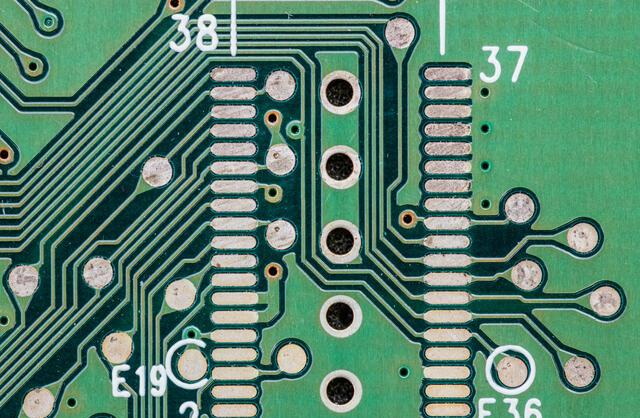

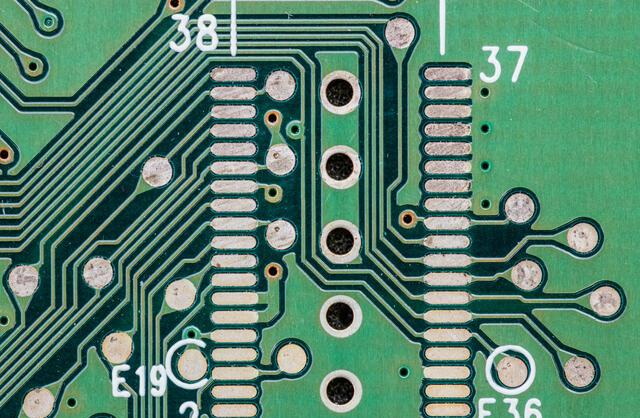

Surface Mount Technology (SMT) has transformed the electronics manufacturing landscape by enabling efficient assembly of printed circuit boards (PCBs). At the core of this process is the SMT feeder mechanism, which is pivotal in delivering electronic components to placement machines with precision and speed. This article delves into the key components of an SMT feeder mechanism, their functionalities, and the advancements in technology that enhance their performance.

Introduction

SMT feeders are essential devices that supply electronic components to pick-and-place machines used in PCB assembly. They automate the delivery process, ensuring that each part is presented in the correct orientation and at the right time. The efficiency of an SMT assembly line largely depends on the reliability and performance of its feeder mechanisms. Understanding the key components of these feeders is crucial for optimizing production processes and achieving high-quality outputs.

Key Components of an SMT Feeder Mechanism

An SMT feeder mechanism consists of several critical components that work together to facilitate the smooth feeding of components. Below are the main elements:

Feed Table

The feed table serves as a platform for stacking and processing tape. It is designed to hold multiple reels or strips of components securely, allowing for easy access as components are dispensed. The stability of the feed table is crucial for maintaining alignment during operation, ensuring that components are fed accurately to the placement machine.

Blowing Nozzle

The blowing nozzle is responsible for loosening and separating the tape holding the components. By directing a stream of air onto the tape, it helps to prevent jams and ensures that individual components can be easily accessed without damaging them. This component is vital for maintaining a continuous flow of parts to the pick-and-place machine.

Tape Feeding Nozzle

This nozzle plays a pivotal role in transferring individual components from the feed table to the feeding roller. It picks up a component after it has been separated by the blowing nozzle and positions it accurately for placement. The efficiency of this nozzle directly impacts the speed at which components can be delivered to the assembly line.

Tape Stopper and Blocking Mechanisms

Tape stoppers are essential for maintaining proper alignment and preventing errors during feeding. They ensure that only one component is released at a time, minimizing misfeeds that can disrupt production. Additionally, blocking mechanisms such as brushes help keep the tape stack neat and organized, further reducing potential issues.

Baffle Plates

Baffle plates are used to ensure that the tape stack remains neat and orderly during operation. These plates prevent components from shifting or becoming misaligned, which could lead to feeding errors. Properly designed baffle plates contribute significantly to the overall reliability of the SMT feeder mechanism.

How These Components Work Together

The integration and synchronization of these components are crucial for optimal performance in an SMT feeder mechanism. Each part must operate seamlessly with others to ensure that electronic components are fed accurately and efficiently:

- The feed table holds multiple reels or strips securely.

- The blowing nozzle creates airflow to separate individual components from their tape.

- Once separated, the tape feeding nozzle picks up these components and transfers them to the placement machine.

- Tape stoppers maintain alignment while baffle plates ensure orderliness throughout this process.

This harmonious interaction minimizes downtime and enhances throughput, making SMT feeders vital in high-volume electronics manufacturing.

Advancements in SMT Feeder Technology

Recent advancements in SMT feeder technology have led to significant improvements in their functionality:

- High-Precision Electric Feeders: Modern feeders utilize electric mechanisms that offer greater transmission accuracy and faster feeding speeds compared to traditional mechanical systems.

- Automatic Component Loading: Some advanced feeders now feature automatic loading systems that reduce manual intervention, further streamlining operations.

- Real-Time Monitoring: Innovations include real-time monitoring capabilities that allow manufacturers to track performance metrics and quickly address any issues that arise during production.

Technological Innovations

The evolution of SMT feeders has been marked by several technological innovations aimed at enhancing precision, efficiency, and automation:

- Advanced Sensors and Cameras: New feeder models incorporate advanced sensor and camera technologies that enable more accurate identification of component types, sizes, and pin orientations. This improvement enhances both accuracy and efficiency during component placement processes[1].

- Modular Designs: To meet diverse placement needs across various electronic components, there is an increasing variety of feeders available. Customized modular feeder solutions can be flexibly combined to adapt quickly to different production requirements[1].

- Intelligent Automation: With advancements in smart manufacturing technologies, many new feeder models are equipped with intelligent control systems capable of automatically adjusting feeding speeds, positions, and orientations based on real-time data. This reduces manual intervention while improving overall production stability[1][2].

Market Dynamics

The demand for SMT technology continues to grow across various sectors including consumer electronics, automotive electronics, healthcare devices, and telecommunications infrastructure:

- Consumer Electronics: The push for miniaturization in consumer electronics drives demand for efficient SMT processes capable of handling smaller components with high precision[9].

- Automotive Electronics: As vehicles become more technologically advanced with features like autonomous driving systems, reliable SMT assembly lines are essential for producing compact yet complex electronic assemblies[9].

- Healthcare Devices: The rise in wearable technology requires precise placement capabilities offered by modern SMT feeders[9].

Types of SMT Feeders

Understanding different types of SMT feeders is essential for selecting appropriate equipment based on specific production needs:

- Tape Feeders: These are commonly used standard feeders designed for handling components mounted on reels of adhesive tape. They unwind tape precisely while presenting each component accurately to pick-and-place machines.

- Tray Feeders: Suitable for larger or irregularly shaped components housed in trays or magazines. Robotic arms within these feeders select and present each component for pick-up.

- Stick Feeders: Ideal for non-standard or oddly shaped components; they utilize vibrating mechanisms to advance components along a linear track.

- Tube Feeders: Designed for long or delicate components like LEDs or resistors; tube feeders gently guide these parts from a refillable tube to their designated pick-up point[4][5][7].

Importance of Reliable SMT Feeders

A dependable SMT feeder is paramount for achieving optimal results in PCB assembly:

- Efficiency and Speed: Well-functioning feeders ensure a steady flow of components, minimizing downtime while maximizing production speed.

- Placement Accuracy: Precise operation is crucial for accurate component placement on PCBs, minimizing errors while ensuring proper circuit functionality.

- Reduced Waste: Reliable feeders minimize component damage or misfeeds, leading to less wasted materials and improved production costs[8].

Challenges Facing SMT Feeders

Despite advancements in technology, several challenges persist within SMT feeder operations:

- Heat Dissipation Management: As electronic assemblies become denser with more integrated circuits packed closely together, managing heat dissipation effectively becomes increasingly challenging[9].

- Integration with Advanced Technologies: Incorporating AI-driven inspection systems into existing feeder technologies requires significant investment but promises enhanced production efficiency[9].

- Environmental Compliance: Adhering to stringent environmental regulations while maintaining high production standards poses ongoing challenges for manufacturers[9].

Conclusion

In conclusion, SMT feeder mechanisms are integral to modern electronics manufacturing. Understanding their key components—such as feed tables, blowing nozzles, tape feeding nozzles, tape stoppers, blocking mechanisms, and baffle plates—provides insights into how these systems function effectively. With ongoing technological advancements such as intelligent automation and real-time monitoring capabilities, SMT feeders continue evolving to meet industry demands.

As manufacturers strive for higher efficiency rates in PCB assembly processes amidst growing market demands across various sectors—consumer electronics, automotive applications, healthcare devices—the importance of reliable SMT feeder mechanisms cannot be overstated. They not only enhance assembly efficiency but also contribute significantly to improving product quality through precise component placement.

FAQ

1. What is an SMT feeder?

An SMT feeder is a device responsible for holding and supplying electronic components for placement on printed circuit boards (PCBs). It ensures accurate positioning and rapid delivery during manufacturing processes.

2. What are the main types of SMT feeders?

The main types include:

- Tape Feeders

- Tray Feeders

- Vibratory/Stick Feeders

- Tube Feeders

Each type caters to different component sizes and shapes.

3. How does a tape feeder work?

A tape feeder unwinds a reel containing electronic components mounted on adhesive tape, presenting each part individually to a pick-and-place machine's nozzle for precise placement onto PCBs.

4. What are common issues with SMT feeders?

Common issues include misalignment, component jams, and incorrect feeding sequences. Regular maintenance along with proper setup can help mitigate these problems effectively.

5. How can I maintain an SMT feeder?

To maintain an SMT feeder:

- Regularly clean all parts.

- Check for wear on moving components.

- Ensure proper calibration.

- Monitor performance metrics frequently.

Citations:

[1] https://www.smtglobe.com/product/innovations-and-upgrades-in-smt-feeders.html

[2] https://www.zjyingxing.com/info/what-is-the-function-of-the-feeder-in-the-smt-83821364.html

[3] https://www.smtglobe.com/product/smt-feeders-lead-trends.html

[4] https://www.hayawin.com/news-what-is-a-smt-feeder-3-main-types.html

[5] https://madpcb.com/glossary/smt-feeder/

[6] https://www.raypcb.com/surface-mount-technology/

[7] https://www.smtmanufacturing.net/smt-feeder-all-you-need-to-know/

[8] https://www.hayawin.com/resources/ndash-how-does-smt-electronics-assembly-work.html

[9] https://itbrief.asia/story/smt-market-to-reach-usd-16-8-billion-by-2034-fmi

[10] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/