Content Menu

● Introduction

● Key Components of a DIY SMT Assembly Line

>> 1. Pick and Place Machine

>> 2. Solder Paste Printing Machine

>> 3. Reflow Oven

>> 4. Inspection Tools

>> 5. Supporting Tools and Workspace Setup

● Step-by-Step Guide to Setting Up Your DIY SMT Assembly Line

● Benefits and Challenges of DIY SMT Assembly

>> Benefits

>> Challenges

● Conclusion

● FAQ

>> 1. What is the cost of setting up a DIY SMT assembly line?

>> 2. Can I use a DIY SMT line for small-scale production?

>> 3. What are the common mistakes to avoid in DIY SMT assembly?

>> 4. How do I choose the right solder paste?

>> 5. What safety precautions should I take?

Introduction

In the world of electronics, Surface Mount Technology (SMT) has revolutionized how components are assembled onto printed circuit boards (PCBs). A DIY SMT assembly line allows hobbyists, engineers, and small businesses to produce their own PCBs efficiently. Understanding the key components necessary for setting up a DIY SMT production line is crucial for achieving high-quality results. This article will explore these components in detail, provide a step-by-step guide for setup, discuss the benefits and challenges of DIY SMT assembly, and conclude with a FAQ section addressing common inquiries.

Key Components of a DIY SMT Assembly Line

A successful DIY SMT assembly line consists of several critical components, each playing a vital role in the manufacturing process.

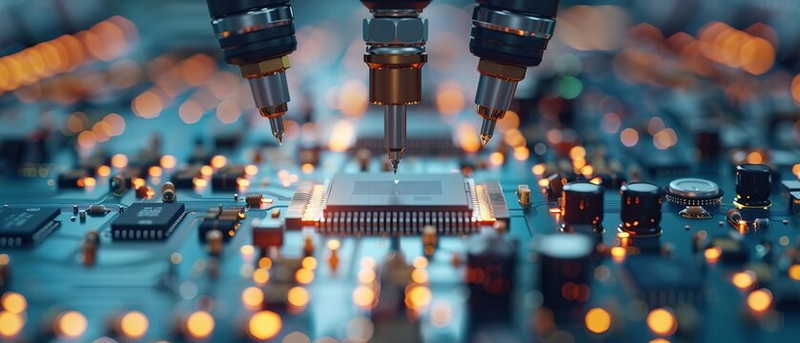

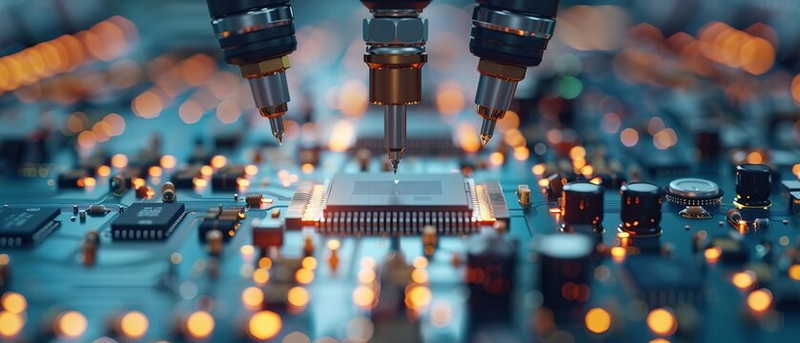

1. Pick and Place Machine

The pick and place machine is arguably the most essential piece of equipment in an SMT line. It is responsible for accurately placing surface mount components onto the PCB pads.

- Types: There are three main types of pick and place machines:

- Manual: Operated by hand, suitable for low-volume production.

- Semi-Automatic: Requires some manual input but automates the placement process.

- Automatic: Fully automated systems that can handle high-speed production.

- Considerations: When selecting a pick and place machine, consider factors such as placement speed, accuracy, and compatibility with various component sizes. For small-scale projects, a manual or semi-automatic machine may suffice, while larger operations may benefit from an automatic system.

2. Solder Paste Printing Machine

This machine applies solder paste onto the PCB where components will be placed. The solder paste acts as an adhesive that temporarily holds components in place before they are soldered during reflow.

- Importance: Proper application of solder paste is crucial as it ensures reliable electrical connections once the solder is melted and solidified.

- Techniques: Solder paste printing can be done using stencils or through more advanced methods like jet printing. Stencil printing is the most common method, where a stencil is placed over the PCB, and solder paste is spread across it to fill the openings.

3. Reflow Oven

After placing the components on the PCB with solder paste, the next step is to melt the solder to create permanent connections. The reflow oven heats the board to a specific temperature profile to ensure even melting of the solder.

- How It Works: Reflow ovens can use different heating methods such as hot air, infrared, or convection. Each method has its advantages in terms of speed and efficiency.

- Temperature Profiles: It's essential to program the reflow oven with an appropriate temperature profile that matches the solder paste specifications. A typical profile includes preheat, soak, reflow, and cooling stages.

4. Inspection Tools

Quality control is paramount in SMT assembly. Inspection tools such as Solder Paste Inspection (SPI) machines and Automated Optical Inspection (AOI) systems are used to ensure that solder paste is applied correctly and that components are placed accurately.

- SPI Machines: Check the thickness and volume distribution of solder paste to prevent issues like insufficient solder or bridging between pads.

- AOI Machines: Inspect PCBs for placement errors before and after soldering. These machines use cameras to capture images of the PCB and compare them against known good references.

5. Supporting Tools and Workspace Setup

In addition to the main machines, several supporting tools enhance efficiency and accuracy in a DIY SMT assembly line:

- Tweezers: Essential for placing small components accurately when manual intervention is needed.

- Stencils: Used for applying solder paste uniformly on PCBs; they come in various sizes based on component layout.

- Lighting: Good lighting is crucial for detailed inspection work; consider using LED lights that provide bright illumination without generating excessive heat.

- Workspace Organization: A clean and organized workspace helps streamline the assembly process. Use bins or trays to separate different components and tools to minimize confusion during assembly.

Step-by-Step Guide to Setting Up Your DIY SMT Assembly Line

Setting up a DIY SMT assembly line involves several steps:

1. Plan Your Layout: Design your workspace layout considering the flow of materials from one machine to another. Ensure there's enough space between each station for easy movement.

2. Gather Equipment: Acquire all necessary equipment including pick and place machines, solder paste printers, reflow ovens, and inspection tools. Consider purchasing second-hand equipment if budget constraints exist.

3. Set Up Workstations: Create designated areas for each stage of assembly—solder paste application, component placement, reflow, and inspection. Each workstation should be equipped with necessary tools specific to its function.

4. Test Equipment: Before starting production, test all machines to ensure they are functioning correctly. Check calibration settings on your pick and place machine and verify that your reflow oven reaches desired temperatures.

5. Create a BOM (Bill of Materials): List all components needed for your projects to streamline procurement. This document should include part numbers, quantities required, and preferred suppliers.

6. Start Production: Begin with small batches to refine your process before scaling up. Monitor each step closely during initial runs to identify any potential issues early on.

7. Document Processes: Keep detailed records of your processes including temperature profiles for reflow ovens, inspection criteria, and any modifications made along the way. This documentation will help improve future production runs.

Benefits and Challenges of DIY SMT Assembly

Benefits

- Cost Efficiency: Setting up a DIY SMT line can significantly reduce manufacturing costs compared to outsourcing.

- Flexibility: Allows for rapid prototyping and iteration on designs without long lead times.

- Skill Development: Engaging in DIY SMT assembly enhances technical skills in electronics manufacturing.

- Customization: With a DIY setup, you have complete control over your designs which allows you to customize products according to specific needs or preferences without relying on third-party manufacturers.

Challenges

- Initial Investment: The cost of purchasing equipment can be high initially; however, this investment pays off over time as you produce more PCBs in-house.

- Learning Curve: Mastering the operation of various machines requires time and practice; expect some trial-and-error as you familiarize yourself with each step.

- Quality Control: Maintaining consistent quality can be challenging without experience or automated inspection systems; implementing rigorous testing protocols can help mitigate this issue.

- Space Requirements: A fully functional SMT assembly line requires adequate space not only for machinery but also for material storage and workflow management which may be challenging in limited environments.

Conclusion

Setting up a DIY SMT assembly line is an exciting venture that opens up opportunities for creating custom electronics efficiently. By understanding the key components involved—from pick and place machines to reflow ovens—individuals can create high-quality PCBs tailored to their specific needs. Although there are challenges associated with this process, such as initial costs and learning curves, the benefits often outweigh them, making it a worthwhile investment for hobbyists and small businesses alike. With careful planning and attention to detail throughout each stage of production, anyone can successfully establish their own DIY SMT assembly line.

FAQ

1. What is the cost of setting up a DIY SMT assembly line?

The cost can vary widely depending on the equipment chosen. Basic setups may start around $1,000 for manual tools, while fully automated systems can exceed $50,000.

2. Can I use a DIY SMT line for small-scale production?

Yes! A DIY SMT assembly line is ideal for small-scale production runs or prototypes, allowing flexibility in design iterations without significant overhead costs.

3. What are the common mistakes to avoid in DIY SMT assembly?

Common mistakes include improper application of solder paste, incorrect component placement, neglecting quality inspections, and not following safety protocols during operation.

4. How do I choose the right solder paste?

Consider factors such as alloy composition (lead-free vs leaded), viscosity, melting point, and compatibility with your components when selecting solder paste.

5. What safety precautions should I take?

Always wear appropriate personal protective equipment (PPE) such as gloves and goggles when handling materials; ensure proper ventilation when using solvents or operating heating equipment.

The total word count for this article is 1,839 words.