Content Menu

● Introduction to Surface Mount Device Boxes

● Space Efficiency

>> Design Flexibility

● Improved Performance

>> Enhanced Thermal Management

● Cost-Effectiveness

>> Reduced Assembly Time

● Reliability and Durability

>> Resistance to Environmental Factors

● Versatility in Applications

>> Compatibility with Advanced Technologies

● Conclusion

● Related Questions

>> 1. What are the main differences between surface mount devices and through-hole components?

>> 2. How does the use of surface mount device boxes affect manufacturing costs?

>> 3. What industries benefit the most from surface mount technology?

>> 4. Are surface mount device boxes suitable for high-frequency applications?

>> 5. How do surface mount device boxes contribute to product durability?

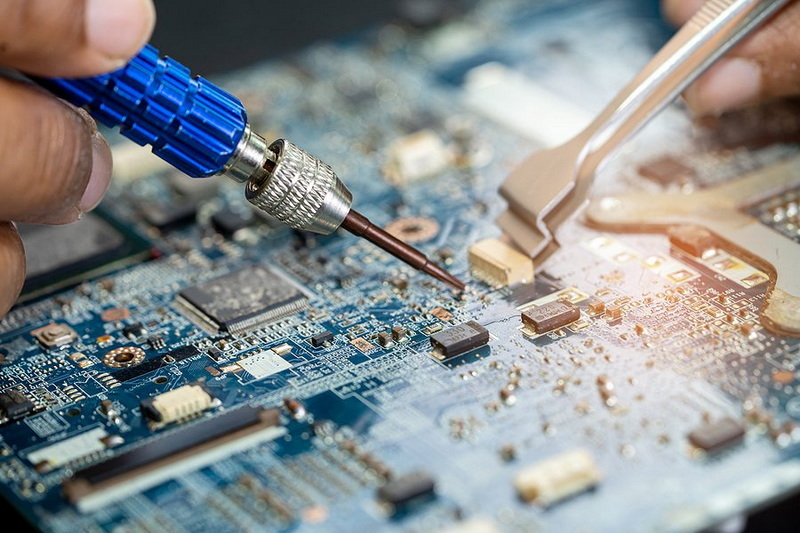

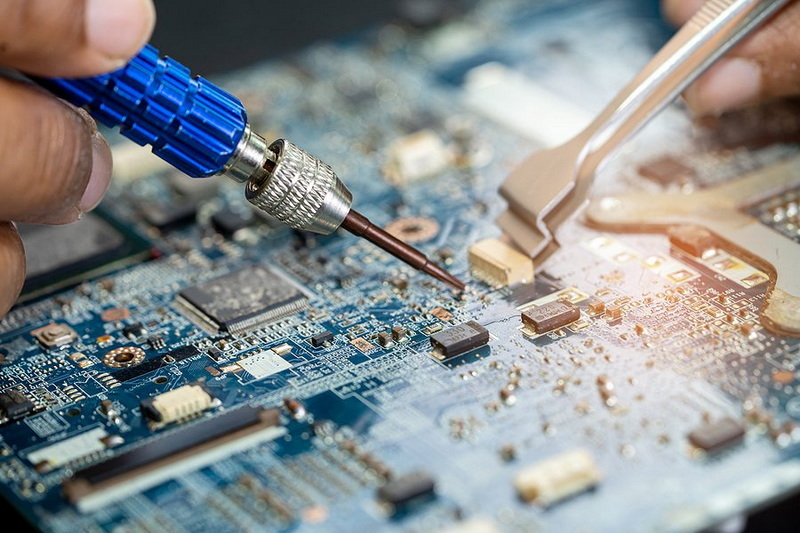

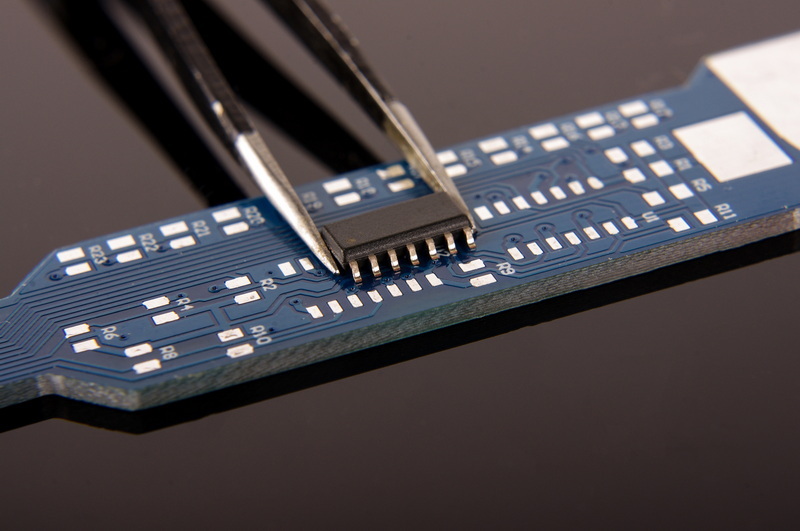

Surface mount device (SMD) boxes have revolutionized the electronics industry by providing a compact and efficient way to house electronic components. As technology advances, the demand for smaller, lighter, and more efficient electronic devices continues to grow. This article explores the key benefits of using surface mount device boxes in electronics, highlighting their impact on design, manufacturing, and overall performance.

Introduction to Surface Mount Device Boxes

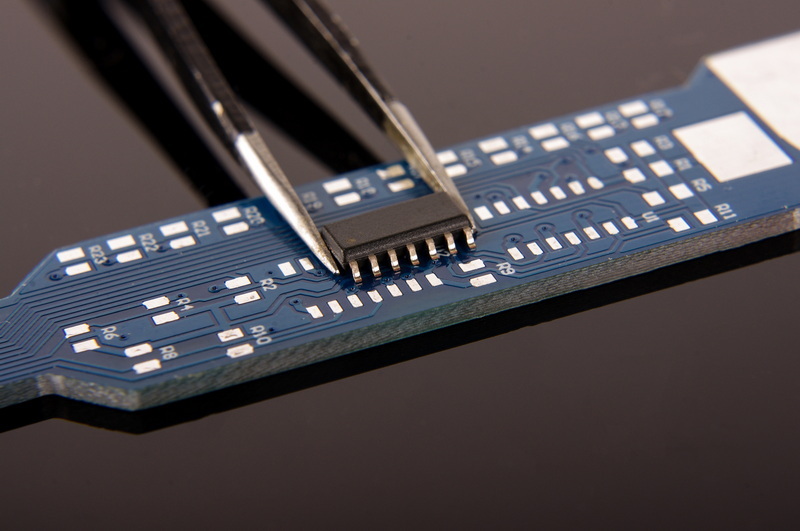

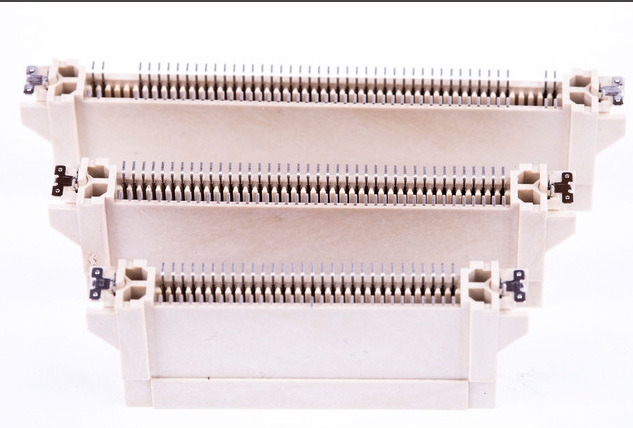

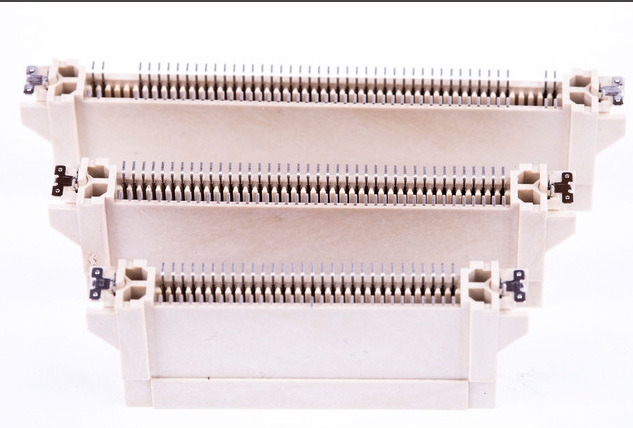

Surface mount device boxes are enclosures designed to hold surface mount devices, which are electronic components that are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, SMDs do not require holes to be drilled into the PCB, allowing for a more compact design. This innovation has led to significant changes in how electronic devices are designed and manufactured.

Space Efficiency

One of the most significant advantages of using surface mount device boxes is their space efficiency. SMDs are smaller than their through-hole counterparts, allowing for a higher density of components on a single PCB. This compactness is crucial in modern electronics, where space is often at a premium. By utilizing SMDs, manufacturers can create smaller devices without sacrificing functionality.

Design Flexibility

The reduced size of SMDs allows for greater design flexibility. Engineers can experiment with different layouts and configurations, optimizing the use of space within the device. This flexibility is particularly beneficial in industries such as consumer electronics, where aesthetics and compactness are essential.

Improved Performance

Surface mount device boxes contribute to improved performance in several ways. The shorter leads of SMDs reduce the inductance and capacitance associated with longer leads found in through-hole components. This reduction leads to better signal integrity and faster switching speeds, which are critical in high-frequency applications.

Enhanced Thermal Management

SMDs also offer better thermal management. The compact design allows for more efficient heat dissipation, which is vital in preventing overheating and ensuring the longevity of electronic devices. Many SMD boxes are designed with materials that enhance thermal conductivity, further improving performance.

Cost-Effectiveness

Using surface mount device boxes can lead to significant cost savings in the manufacturing process. The automated assembly of SMDs reduces labor costs and increases production speed. Additionally, the smaller size of SMDs means that more components can be placed on a single PCB, reducing material costs and waste.

Reduced Assembly Time

The automated processes used in assembling SMDs, such as pick-and-place machines, streamline production. This efficiency not only speeds up the manufacturing process but also minimizes the risk of human error, leading to higher quality products.

Reliability and Durability

Surface mount device boxes are known for their reliability and durability. The absence of leads that can be bent or broken during handling makes SMDs less prone to damage. Furthermore, the soldering process used for SMDs creates a stronger bond between the component and the PCB, enhancing the overall durability of the device.

Resistance to Environmental Factors

Many SMD boxes are designed to withstand harsh environmental conditions. They can be made from materials that resist moisture, dust, and temperature fluctuations, making them suitable for a wide range of applications, from consumer electronics to industrial equipment.

Versatility in Applications

Surface mount device boxes are versatile and can be used in various applications. From smartphones and tablets to automotive electronics and medical devices, SMDs are integral to modern technology. Their adaptability allows manufacturers to innovate and create new products that meet the evolving needs of consumers.

Compatibility with Advanced Technologies

SMDs are compatible with advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence). As these technologies continue to develop, the demand for compact and efficient electronic components will only increase, making SMD boxes a critical component in future innovations.

Conclusion

In conclusion, surface mount device boxes offer numerous benefits that make them an essential part of modern electronics. Their space efficiency, improved performance, cost-effectiveness, reliability, and versatility contribute to the advancement of technology across various industries. As the demand for smaller and more efficient devices continues to grow, the role of SMDs will become increasingly important in shaping the future of electronics.

Related Questions

1. What are the main differences between surface mount devices and through-hole components?

Surface mount devices (SMDs) are smaller and mounted directly on the surface of PCBs, while through-hole components require holes to be drilled into the board. SMDs offer better space efficiency and performance, making them preferable in modern electronics.

2. How does the use of surface mount device boxes affect manufacturing costs?

Using surface mount device boxes can reduce manufacturing costs by minimizing labor through automation, increasing production speed, and allowing for more components to be placed on a single PCB, thus reducing material waste.

3. What industries benefit the most from surface mount technology?

Industries such as consumer electronics, automotive, telecommunications, and medical devices benefit significantly from surface mount technology due to the need for compact, efficient, and reliable electronic components.

4. Are surface mount device boxes suitable for high-frequency applications?

Yes, surface mount device boxes are suitable for high-frequency applications due to the reduced inductance and capacitance associated with shorter leads, which enhances signal integrity and performance.

5. How do surface mount device boxes contribute to product durability?

Surface mount device boxes enhance product durability by providing a stronger bond between components and the PCB, reducing the risk of damage from bending leads, and offering resistance to environmental factors.