Content Menu

● Understanding SMD PCB Soldering Machines

>> What is an SMD PCB Soldering Machine?

>> How Does an SMD PCB Soldering Machine Work?

>> Visual Representation of the Process

● Advantages of Using an SMD PCB Soldering Machine

>> Increased Production Efficiency

>> Improved Quality and Reliability

>> Space Optimization

>> Cost-Effectiveness

>> Versatility

● Applications of SMD PCB Soldering Machines

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

● Common Questions About SMD PCB Soldering Machines

>> 1. What types of components can be used with an SMD PCB soldering machine?

>> 2. How does reflow soldering differ from wave soldering?

>> 3. What maintenance is required for these machines?

>> 4. Can I use an SMD PCB soldering machine for through-hole components?

>> 5. What are the typical costs associated with purchasing an SMD PCB soldering machine?

● Conclusion

Understanding SMD PCB Soldering Machines

What is an SMD PCB Soldering Machine?

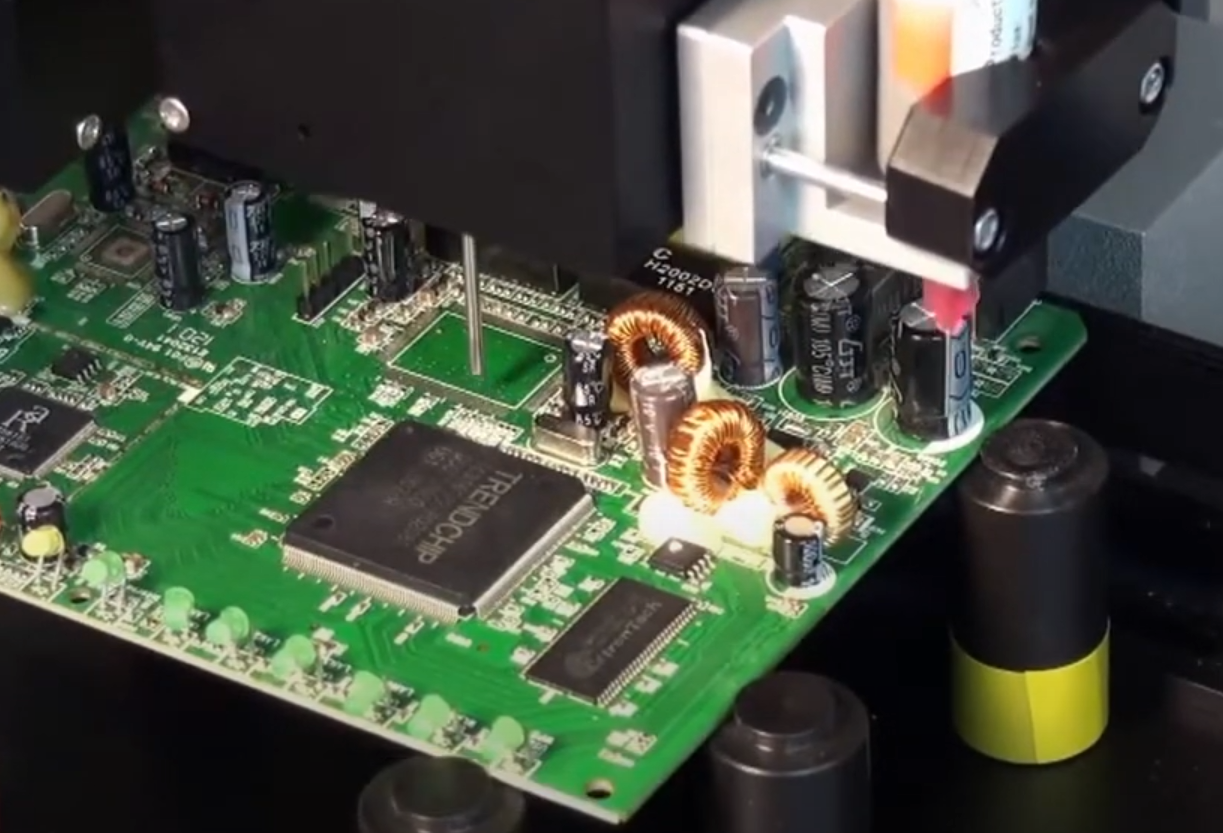

An SMD PCB soldering machine is a specialized piece of equipment designed to attach surface mount components to PCBs using solder. This process typically involves several stages, including solder paste application, component placement, and reflow soldering. These machines are essential in modern electronics manufacturing due to their ability to automate and streamline the assembly process.

How Does an SMD PCB Soldering Machine Work?

The operation of an SMD PCB soldering machine can be broken down into several key steps:

1. Solder Paste Application: A stencil printer applies solder paste onto designated pads on the PCB. The paste consists of tiny metal particles mixed with flux, which helps in creating strong electrical connections.

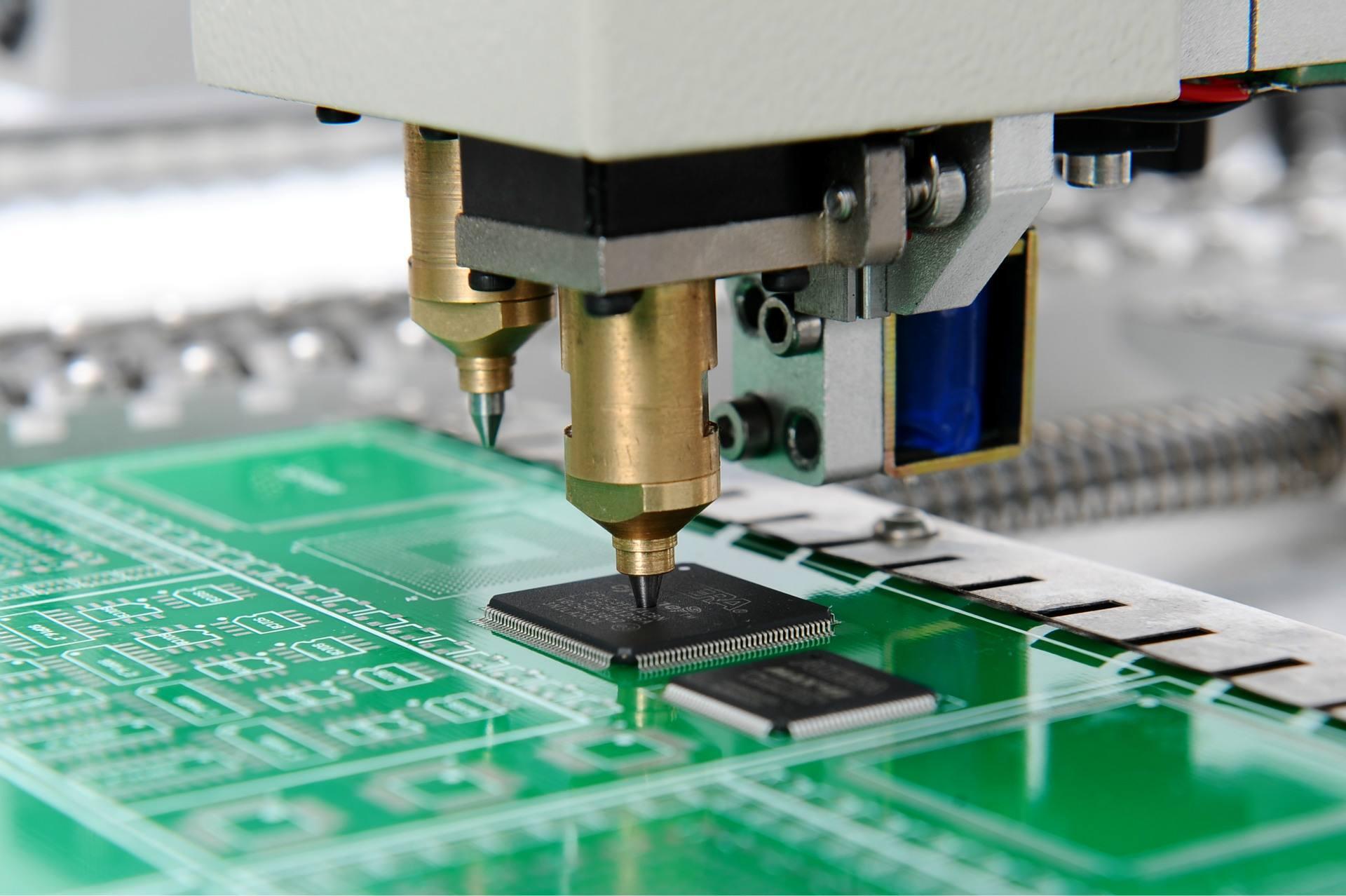

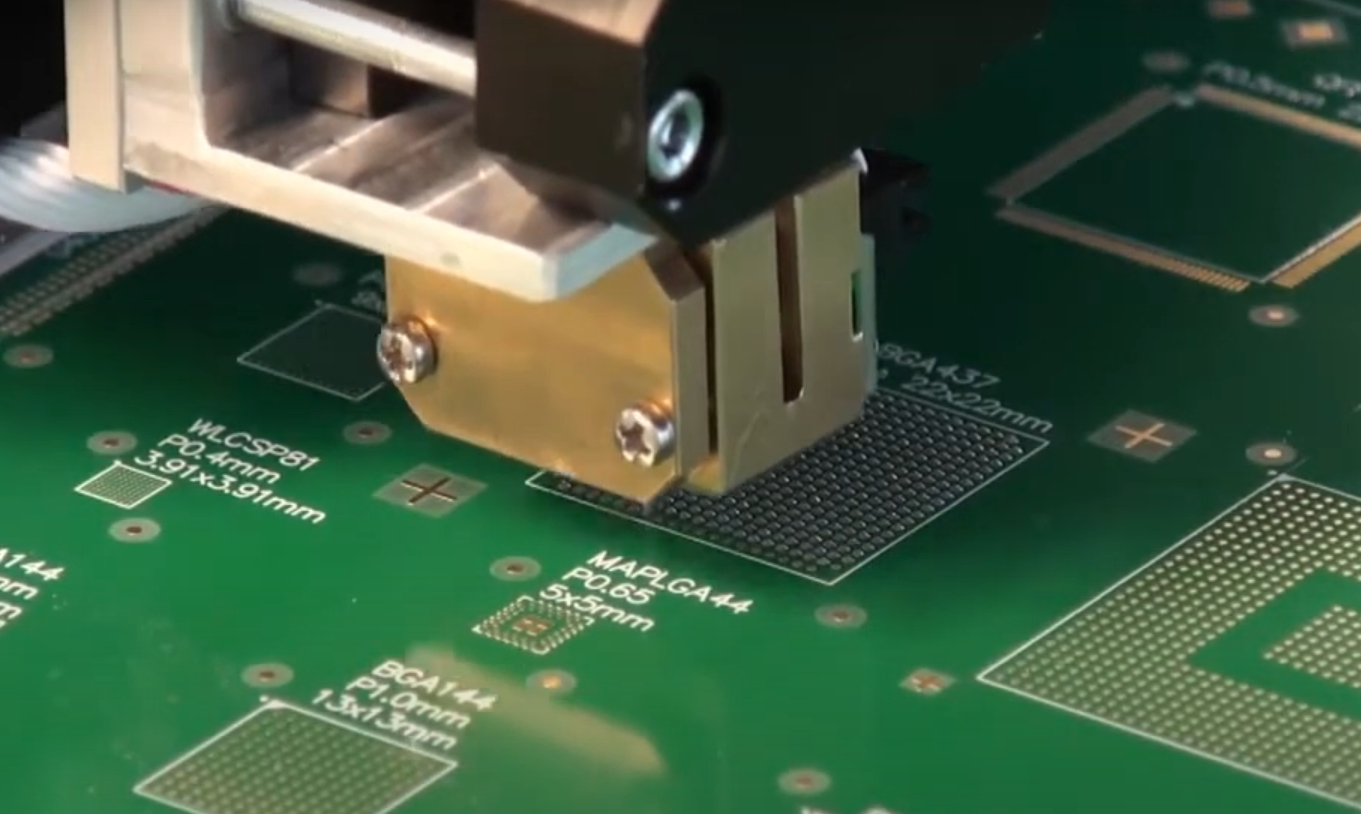

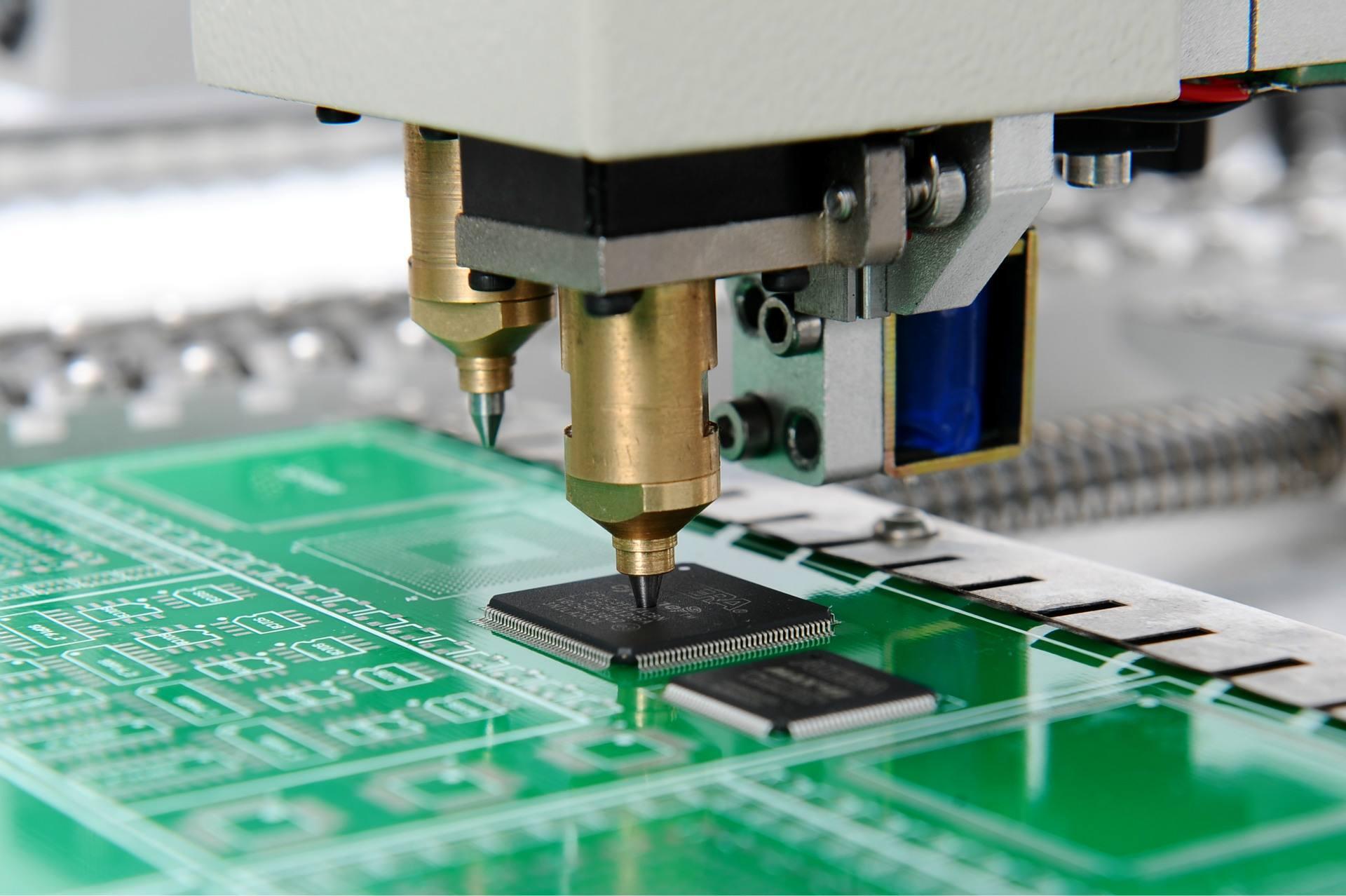

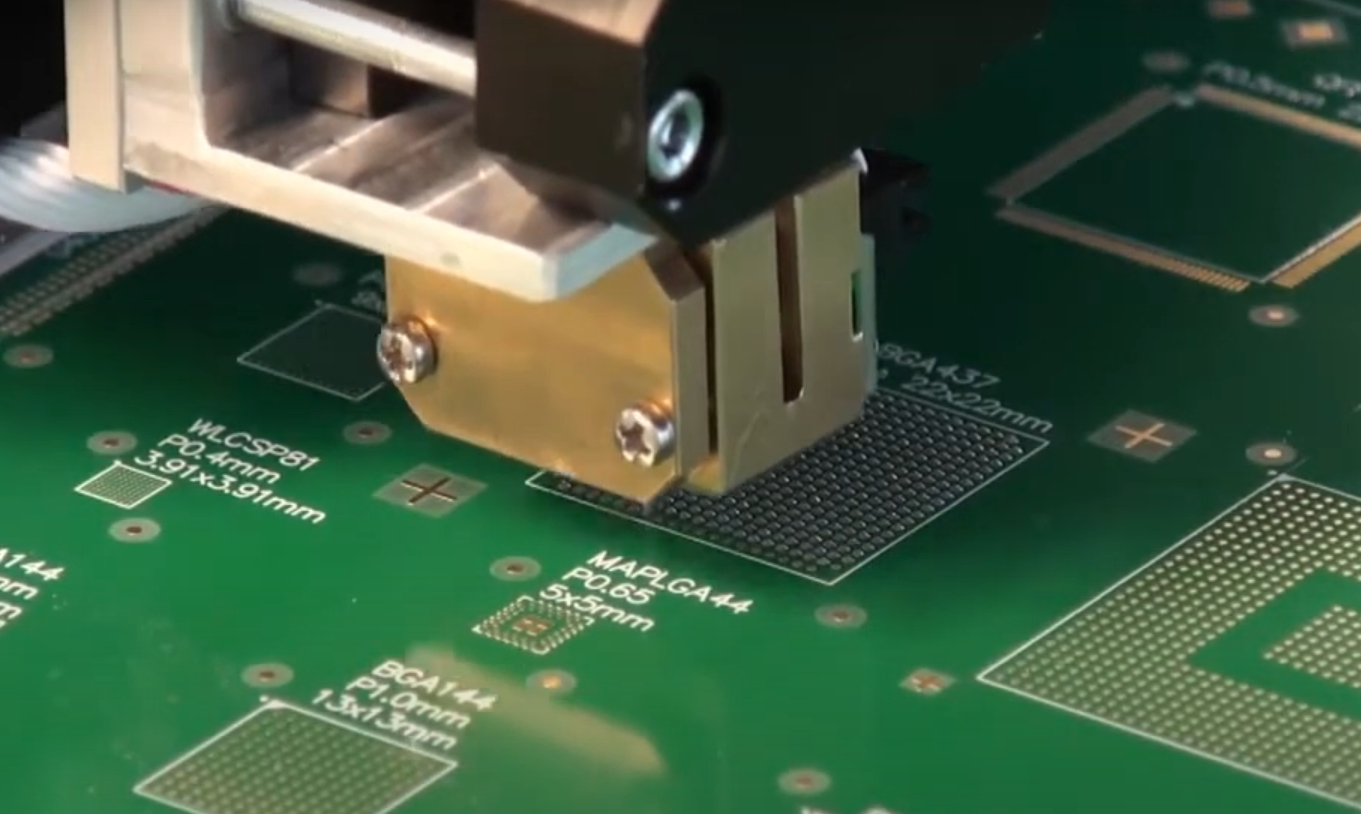

2. Component Placement: Robotic arms or pick-and-place mechanisms position the SMDs onto the solder paste deposits on the PCB.

3. Reflow Soldering: The assembled PCB is passed through a reflow oven where heat is applied to melt the solder paste, creating a solid connection between the components and the board.

4. Inspection and Testing: Automated Optical Inspection (AOI) systems check for defects in solder joints and component placement.

Advantages of Using an SMD PCB Soldering Machine

Increased Production Efficiency

One of the primary benefits of using an SMD PCB soldering machine is increased production efficiency. Automated machines can place thousands of components per hour, significantly reducing assembly time compared to manual methods.

Improved Quality and Reliability

Automated soldering processes ensure consistent application of solder paste and precise placement of components, leading to improved quality and reliability of electronic devices. The risk of human error is minimized, resulting in fewer defects.

Space Optimization

SMD technology allows for higher component density on PCBs. This means that smaller boards can accommodate more functions, which is particularly beneficial in compact electronic devices such as smartphones and wearable technology.

Cost-Effectiveness

While the initial investment in an SMD PCB soldering machine may be significant, the long-term savings from reduced labor costs and increased production rates often justify this expense. Additionally, smaller components tend to be less expensive than their through-hole counterparts.

Versatility

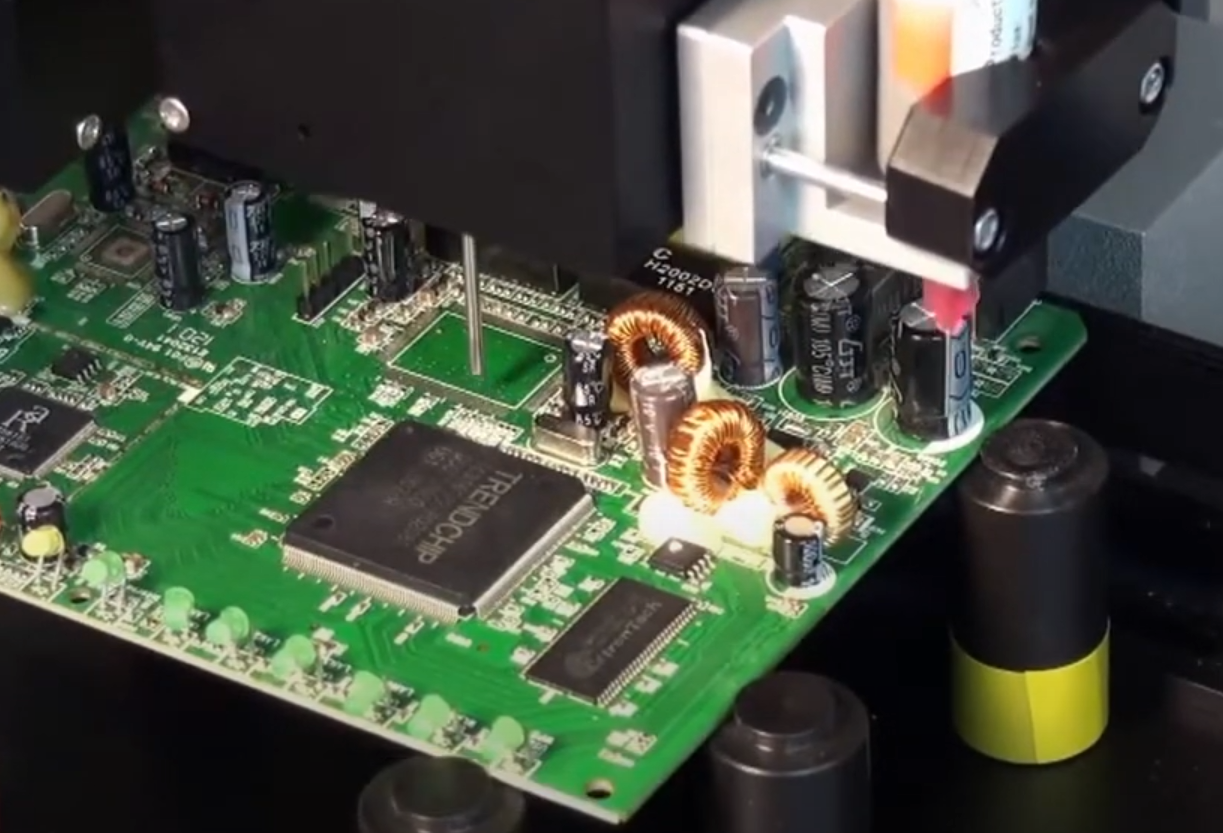

Modern soldering machines are versatile and can handle a wide range of component sizes and types. This flexibility makes them suitable for various industries, including consumer electronics, automotive, medical devices, and telecommunications.

Applications of SMD PCB Soldering Machines

Consumer Electronics

In consumer electronics, where miniaturization is key, SMD PCB soldering machines enable manufacturers to produce compact devices with high functionality. Products such as smartphones, tablets, and laptops rely heavily on SMT for their assembly.

Automotive Industry

The automotive industry benefits from SMT technology by integrating more electronic features into vehicles while maintaining compact designs. Applications include control systems, infotainment units, and safety features.

Medical Devices

In medical technology, reliability is paramount. SMT allows for precise assembly of critical components in devices such as pacemakers and diagnostic equipment.

Common Questions About SMD PCB Soldering Machines

1. What types of components can be used with an SMD PCB soldering machine?

An SMD PCB soldering machine can handle a variety of components including resistors, capacitors, integrated circuits (ICs), and connectors.

2. How does reflow soldering differ from wave soldering?

Reflow soldering involves melting solder paste on a PCB to attach components, while wave soldering immerses entire PCBs into molten solder. Reflow is more suited for SMT due to its precision.

3. What maintenance is required for these machines?

Regular maintenance includes cleaning nozzles and stencils, calibrating placement accuracy, and inspecting mechanical parts for wear.

4. Can I use an SMD PCB soldering machine for through-hole components?

While primarily designed for surface mount technology, some machines can accommodate mixed technology PCBs that include both SMT and through-hole components.

5. What are the typical costs associated with purchasing an SMD PCB soldering machine?

Costs vary widely based on features and capabilities but can range from several thousand to hundreds of thousands of dollars depending on automation levels and production capacity.

Conclusion

The adoption of SMD PCB soldering machines has revolutionized electronics manufacturing by enhancing efficiency, quality, and versatility in assembling complex electronic devices. As technology continues to advance, these machines will play an even more critical role in meeting the demands of modern electronics production.