Content Menu

● Understanding SMT Production Lines

● Key Components of an SMT Production Line

● Key Benefits of SMT Production Lines

>> Increased Production Efficiency

>> Smaller and Lighter Products

>> Enhanced Performance

>> Cost Savings

>> Flexibility in Design

>> Improved Quality Control

>> Scalability

>> Environmentally Friendly Manufacturing

● Challenges Associated with SMT Production Lines

● Conclusion

● FAQ

>> 1. What is an SMT production line?

>> 2. How does an SMT production line improve efficiency?

>> 3. What are some key components of an SMT production line?

>> 4. What advantages does SMT offer over traditional methods?

>> 5. Are there any challenges associated with implementing an SMT production line?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry. As the demand for smaller, more efficient electronic devices continues to grow, SMT production lines have become essential in meeting these needs. This article will explore the key benefits of SMT production lines, their components, and how they contribute to the efficiency and effectiveness of modern electronics manufacturing.

Understanding SMT Production Lines

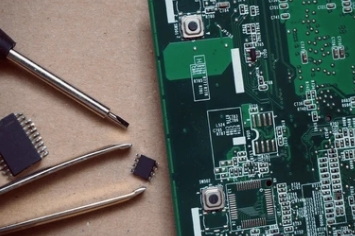

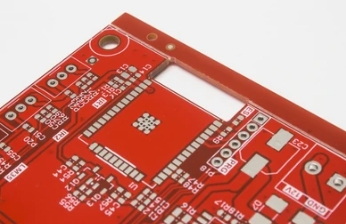

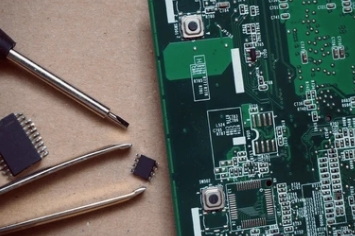

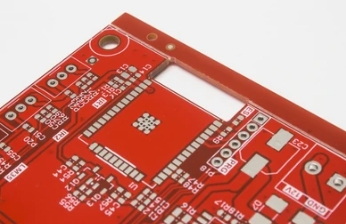

SMT production lines are specialized setups designed for assembling electronic components onto printed circuit boards (PCBs). Unlike traditional through-hole technology, SMT allows for components to be mounted directly onto the surface of PCBs. This method offers several advantages, including reduced size and weight of devices, increased manufacturing speed, and improved performance.

Key Components of an SMT Production Line

Before delving into the benefits, it is essential to understand the main components that make up an SMT production line:

- Pick and Place Machines: These machines are responsible for placing components onto the PCB with high precision. They utilize advanced vision systems to ensure accurate placement.

- Solder Paste Printers: These printers apply solder paste to the PCB before components are placed. The accuracy of solder paste application is crucial for reliable solder joints.

- Reflow Ovens: After components are placed, PCBs are passed through reflow ovens where heat is applied to melt the solder paste, creating permanent connections between the components and the board.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in component placement and solder joints. This ensures quality control throughout the manufacturing process.

- Conveyors: These systems transport PCBs between different stages of production, maintaining a smooth workflow.

Key Benefits of SMT Production Lines

Increased Production Efficiency

One of the primary benefits of an SMT production line is its ability to significantly increase production efficiency. The automation involved in SMT processes reduces human error and speeds up assembly times. With machines capable of placing thousands of components per hour, manufacturers can produce larger quantities of products in less time.

Smaller and Lighter Products

SMT allows for smaller component sizes compared to traditional methods. This reduction in size enables manufacturers to design compact devices that are lighter and more portable. As consumer electronics trend towards miniaturization, SMT production lines provide a necessary advantage in meeting these market demands.

Enhanced Performance

The use of SMT can enhance the overall performance of electronic devices. Components mounted using SMT have shorter electrical paths, which can lead to improved signal integrity and reduced electromagnetic interference (EMI). This results in devices that operate more efficiently and reliably.

Cost Savings

While the initial investment in SMT equipment may be significant, the long-term cost savings are substantial. The increased efficiency leads to lower labor costs, reduced material waste due to precise component placement, and fewer defects that require rework or scrap. Additionally, smaller products often lead to savings in shipping and storage costs.

Flexibility in Design

SMT production lines offer greater flexibility in design compared to traditional methods. Engineers can experiment with different layouts and configurations without being constrained by component size or placement limitations. This flexibility allows for innovative designs that can adapt to changing market needs.

Improved Quality Control

Quality control is a critical aspect of electronics manufacturing, and SMT production lines excel in this area. Automated inspection systems can quickly identify defects during various stages of production, ensuring that only high-quality products reach consumers. This proactive approach minimizes returns and enhances customer satisfaction.

Scalability

As demand fluctuates, manufacturers need production lines that can scale accordingly. SMT production lines can be easily adjusted to accommodate changes in product volume or design specifications. This scalability ensures that manufacturers remain competitive in a fast-paced market.

Environmentally Friendly Manufacturing

SMT processes generally produce less waste compared to traditional methods due to their precision and efficiency. Additionally, many SMT components are designed with environmental considerations in mind, such as lead-free solder options. This focus on sustainability aligns with global efforts to reduce environmental impact.

Challenges Associated with SMT Production Lines

While there are numerous benefits associated with SMT production lines, it is important to acknowledge some challenges:

- Initial Investment: The cost of acquiring advanced SMT machinery can be high, which may deter some manufacturers from transitioning from traditional methods.

- Technical Expertise: Operating an SMT production line requires skilled personnel who understand both the technology and troubleshooting techniques.

- Maintenance Requirements: Regular maintenance is essential to keep machines running efficiently and prevent downtime.

Despite these challenges, the advantages offered by SMT production lines often outweigh the drawbacks for many manufacturers.

Conclusion

In conclusion, SMT production lines represent a significant advancement in electronics manufacturing technology. Their ability to enhance efficiency, reduce product size, improve performance, and provide cost savings makes them indispensable in today's market. As technology continues to evolve, embracing SMT will be crucial for manufacturers seeking to remain competitive and meet consumer demands for smaller and more efficient electronic devices.

The benefits outlined above underscore why investing in an SMT production line is a strategic decision for any electronics manufacturer looking to thrive in a rapidly changing industry.

FAQ

1. What is an SMT production line?

An SMT production line is a specialized assembly setup used for mounting electronic components onto printed circuit boards (PCBs) using Surface Mount Technology (SMT).

2. How does an SMT production line improve efficiency?

SMT production lines utilize automated machines that can place thousands of components per hour while reducing human error and assembly time.

3. What are some key components of an SMT production line?

Key components include pick and place machines, solder paste printers, reflow ovens, inspection systems like Automated Optical Inspection (AOI), and conveyors for transporting PCBs.

4. What advantages does SMT offer over traditional methods?

SMT allows for smaller component sizes leading to lighter products, enhanced performance due to shorter electrical paths, cost savings through reduced labor and material waste, and greater design flexibility.

5. Are there any challenges associated with implementing an SMT production line?

Challenges include high initial investment costs, the need for skilled technical personnel, and regular maintenance requirements for machinery.